334:

reflow technology using either standard air or nitrogen gas. Each method has its advantages and disadvantages. With infrared reflow, the board designer must lay the board out so that short components do not fall into the shadows of tall components. Component location is less restricted if the designer knows that vapor phase reflow or convection soldering will be used in production. Following reflow soldering, certain irregular or heat-sensitive components may be installed and soldered by hand, or in large-scale automation, by focused infrared beam (FIB) or localized convection equipment.

772:

478:

Whereas through-hole components will stay in place (under gravitational force) once inserted and can be mechanically secured prior to soldering by bending out two leads on the solder side of the board, SMDs are easily moved out of place by a touch of a soldering iron. Without developed skill, when manually soldering or desoldering a component, it is easy to accidentally reflow the solder of an adjacent SMT component and unintentionally displace it, something that is almost impossible to do with through-hole components.

821:

colours and these can give an approximate idea of the capacitance of the component. Generally physical size is proportional to capacitance and (squared) voltage for the same dielectric. For example, a 100 nF, 50 V capacitor may come in the same package as a 10 nF, 150 V device. SMD (non-electrolytic) capacitors, which are usually monolithic ceramic capacitors, exhibit the same body color on all four faces not covered by the end caps. SMD electrolytic capacitors, usually tantalum capacitors, and

167:

temperature-controlled manual soldering iron, but unfortunately, those that are very small or have too fine a lead pitch are impossible to manually solder without expensive hot-air solder reflow equipment. SMDs can be one-quarter to one-tenth the size and weight, and one-half to one-quarter the cost of equivalent through-hole parts, but on the other hand, the costs of a certain SMT part and of an equivalent through-hole part may be quite similar, though rarely is the SMT part more expensive.

244:

381:

according to IPC, are acceptable "provided that these residues have been qualified and documented as benign". However, while shops conforming to IPC standard are expected to adhere to the

Association's rules on board condition, not all manufacturing facilities apply IPC standard, nor are they required to do so. Additionally, in some applications, such as low-end electronics, such stringent manufacturing methods are excessive both in expense and time required.

47:

887:

522:

407:

255:

31:

58:

836:(nH) range and are often used as power supply rail decouplers or in high frequency parts of a circuit. Larger inductors and transformers may of course be through-hole mounted on the same board. SMT inductors with larger inductance values often have turns of wire or flat strap around the body or embedded in clear epoxy, allowing the wire or strap to be seen. Sometimes a

854:

Discrete semiconductors, such as diodes and transistors are often marked with a two- or three-symbol code. The same code marked on different packages or on devices from different manufacturers can translate to different devices. Many of these codes, used because the devices are too small to be marked

511:

SMDs, usually being smaller than equivalent through-hole components, have less surface area for marking, requiring marked part ID codes or component values to be more cryptic and smaller, often requiring magnification to be read, whereas a larger through-hole component could be read and identified by

507:

Solder joint dimensions in SMT quickly become much smaller as advances are made toward ultra-fine pitch technology. The reliability of solder joints becomes more of a concern, as less and less solder is allowed for each joint. Voiding is a fault commonly associated with solder joints, especially when

309:

oven. They first enter a pre-heat zone, where the temperature of the board and all the components is gradually, uniformly raised to prevent thermal shock. The boards then enter a zone where the temperature is high enough to melt the solder particles in the solder paste, bonding the component leads to

430:

Small errors in component placement are corrected automatically as the surface tension of molten solder pulls components into alignment with solder pads. (On the other hand, through-hole components cannot be slightly misaligned, because once the leads are through the holes, the components are fully

123:

Surface-mount technology was developed in the 1960s. By 1986 surface mounted components accounted for 10% of the market at most, but was rapidly gaining popularity. By the late 1990s, the great majority of high-tech electronic printed circuit assemblies were dominated by surface mount devices. Much

831:

Smaller inductance with moderately high current ratings are usually of the ferrite bead type. They are simply a metal conductor looped through a ferrite bead and almost the same as their through-hole versions but possess SMD end caps rather than leads. They appear dark grey and are magnetic, unlike

809:

For 5% precision SMD resistors usually are marked with their resistance values using three digits: two significant digits and a multiplier digit. These are quite often white lettering on a black background, but other colored backgrounds and lettering can be used. For 1% precision SMD resistors, the

367:

and detergent, followed by an air blast to quickly remove residual water. However, most electronic assemblies are made using a "No-Clean" process where the flux residues are designed to be left on the circuit board, since they are considered harmless. This saves the cost of cleaning, speeds up the

144:

vehicles. Components were mechanically redesigned to have small metal tabs or end caps that could be directly soldered to the surface of the PCB. Components became much smaller and component placement on both sides of a board became far more common with surface mounting than through-hole mounting,

682:

Today, nozzles can often no longer be deposited on the PCB by neighboring components, which means that there is no longer a closed process chamber and adjacent components can be blown on strongly from the side. This can lead to the blowing of adjacent components and even to thermal damage. In this

99:

construction method of fitting components, in large part because SMT allows for increased manufacturing automation which reduces cost and improves quality. It also allows for more components to fit on a given area of substrate. Both technologies can be used on the same board, with the through-hole

820:

Non-electrolytic capacitors are usually unmarked and the only reliable method of determining their value is removal from the circuit and subsequent measurement with a capacitance meter or impedance bridge. The materials used to fabricate the capacitors, such as nickel tantalate, possess different

372:

and underfill materials. Regardless of cleaning or not those PCBs, current industry trend suggests to carefully review a PCB assembly process where "No-Clean" is applied, since flux residues trapped under components and RF shields may affect surface insulation resistance (SIR), especially on high

333:

liquids with high boiling points which use a method called vapor phase reflow. Due to environmental concerns, this method was falling out of favor until lead-free legislation was introduced which requires tighter controls on soldering. At the end of 2008, convection soldering was the most popular

840:

is present also. These higher inductance types are often limited to small current ratings, although some of the flat strap types can handle a few amps. As with capacitors, component values and identifiers for smaller inductors are not usually marked on the component itself; if not documented or

741:

Closed loop temperature control directly on the component possible by applied thermocouple or pyrometric measurement. This allows compensation of varying environmental influences and temperature losses. Enables use of the same temperature profile on slightly different assemblies, as the heating

599:

Closed loop temperature control directly on the component possible by applied thermocouple or pyrometric measurement. This allows compensation of varying environmental influences and temperature losses. Enables use of the same temperature profile on slightly different assemblies, as the heating

477:

Manual prototype assembly or component-level repair is more difficult and requires skilled operators and more expensive tools, due to the small sizes and lead spacings of many SMDs. Handling of small SMT components can be difficult, requiring tweezers, unlike nearly all through-hole components.

380:

require cleaning regardless of the solder flux type used to ensure a thoroughly clean board. Proper cleaning removes all traces of solder flux, as well as dirt and other contaminants that may be invisible to the naked eye. No-Clean or other soldering processes may leave "white residues" that,

562:

Sometimes hundreds or thousands of the same part need to be repaired. Such errors, if due to assembly, are often caught during the process. However, a whole new level of rework arises when component failure is discovered too late, and perhaps unnoticed until the end user of the device being

368:

manufacturing process, and reduces waste. However, it is generally suggested to wash the assembly, even when a "No-Clean" process is used, when the application uses very high frequency clock signals (in excess of 1 GHz). Another reason to remove no-clean residues is to improve adhesion of

166:

Conversely, SMT does not lend itself well to manual or low-automation fabrication, which is more economical and faster for one-off prototyping and small-scale production, and this is one reason why many through-hole components are still manufactured. Some SMDs can be soldered with a

841:

printed on the PCB, measurement, usually removed from the circuit, is the only way of determining them. Larger inductors, especially wire-wound types in larger footprints, usually have the value printed on the top. For example, "330", which equates to a value of 33

563:

manufactured experiences it. Rework can also be used if products of sufficient value to justify it require revision or re-engineering, perhaps to change a single firmware-based component. Reworking in large volume requires an operation designed for that purpose.

298:, where they are placed on a conveyor belt. The components to be placed on the boards are usually delivered to the production line in either paper/plastic tapes wound on reels or plastic tubes. Some large integrated circuits are delivered in static-free trays.

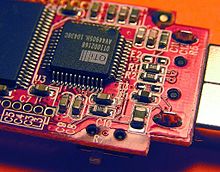

38:'s circuit board. The small rectangular chips with numbers are resistors, while the unmarked small rectangular chips are capacitors. The capacitors and resistors pictured are 0603 (1608 metric) package sizes, along with a very slightly larger 0805 (2012 metric)

162:

mask is used to prevent the solder holding those parts in place from reflowing and the parts floating away during wave soldering. Surface mounting lends itself well to a high degree of automation, reducing labor cost and greatly increasing production rates.

157:

process is used to solder both SMT and through-hole components simultaneously. Alternatively, SMT and through-hole components can be soldered on the same side of a board without adhesive if the SMT parts are first reflow-soldered, then a

869:

Generally, integrated circuit packages are large enough to be imprinted with the complete part number which includes the manufacturer's specific prefix, or a significant segment of the part number and the manufacturer's name or

148:

Often the surface tension of the solder is enough to hold the parts to the board; in rare cases parts on the bottom or "second" side of the board may be secured with a dot of adhesive to keep components from dropping off inside

466:

SMT may be unsuitable as the sole attachment method for components that are subject to frequent mechanical stress, such as connectors that are used to interface with external devices that are frequently attached and

492:(a quick snap-and-play prototyping tool), requiring either a custom PCB for every prototype or the mounting of the SMD upon a pin-leaded carrier. For prototyping around a specific SMD component, a less-expensive

542:(for some connections), or using a non-contact rework system. In most cases a rework system is the better choice because SMD work with a soldering iron requires considerable skill and is not always feasible.

855:

with more traditional numbers used on larger packages, correlate to more familiar traditional part numbers when a correlation list is consulted. GM4PMK in the United

Kingdom has prepared a

698:

A direct temperature control of the component is not possible, because the measurement of the actual component temperature is difficult due to the high gas velocity (measurement failure!)

485:, which provide for easy installation or exchange of components to modify a circuit and easy replacement of failed components. (Virtually all through-hole components can be socketed.)

686:

Local turbulence of the hot gas can create hot and cold spots on the heated surfaces, resulting in uneven heating. Perfectly designed, high-quality nozzles are therefore a must!

689:

Swirls at component edges, especially at bases and connectors, can heat these edges significantly more than other surfaces. Overheating can occur (burns, melting of plastics)

337:

If the circuit board is double-sided then this printing, placement, reflow process may be repeated using either solder paste or glue to hold the components in place. If a

810:

code is used, as three digits would otherwise not convey enough information. This code consists of two digits and a letter: the digits denote the value's position in the

759:

Temperature sensitive nearby components must be shielded from heat to prevent damage, which requires additional time for every board. Shield must cover also from gas flow

427:

Higher density of connections because holes do not block routing space on inner layers, nor on back-side layers if components are mounted on only one side of the PCB.

310:

the pads on the circuit board. The surface tension of the molten solder helps keep the components in place, and if the solder pad geometries are correctly designed,

776:

437:

Lower resistance and inductance at the connection; consequently, fewer unwanted RF signal effects and better and more predictable high-frequency performance.

745:

Direct setting of target profile temperatures and gradients possible through direct control of component temperature in each individual soldering process.

679:

Precise, sometimes very complex, component-specific hot gas nozzles are needed to direct the hot gas to the target component. These can be very expensive.

603:

Direct setting of target profile temperatures and gradients possible through direct control of component temperature in each individual soldering process.

153:

if the part is above the limit of 30g per square inch of pad area. Adhesive is sometimes used to hold SMT components on the bottom side of a board if a

789:

Surface-mount components are usually smaller than their counterparts with leads, and are designed to be handled by machines rather than by humans. The

1523:

DerMarderosian, Aaron; Gionet, Vincent (1983). "The

Effects of Entrapped Bubbles in Solder Used for the Attachment of Leadless Ceramic Chip Carriers".

574:

With infrared soldering, the energy for heating up the solder joint is transmitted by long-, medium- or short-wave infrared electromagnetic radiation.

1562:

398:(AOI) systems are commonly used in PCB manufacturing. This technology has proven highly efficient for process improvements and quality achievements.

1628:

348:

After soldering, the boards may be washed to remove flux residues and any stray solder balls that could short out closely spaced component leads.

2082:

103:

An SMT component is usually smaller than its through-hole counterpart because it has either smaller leads or no leads at all. It may have short

508:

reflowing a solder paste in the SMT application. The presence of voids can deteriorate the joint strength and eventually lead to joint failure.

1358:

1116:

994:

692:

Losses due to environmental influences are not compensated for, since the component temperature is not measured in the production process

100:

technology often used for components not suitable for surface mounting such as large transformers and heat-sinked power semiconductors.

2023:

1454:

925:

175:

Different terms describe the components, technique, and machines used in manufacturing. These terms are listed in the following table:

2956:

617:

Temperature sensitive nearby components must be shielded from heat to prevent damage, which requires additional time for every board

1804:

1798:

1792:

1780:

1768:

1762:

1750:

1654:

1333:

434:

Better mechanical performance under shock and vibration conditions (partly due to lower mass, and partly due to less cantilevering)

384:

Finally, the boards are visually inspected for missing or misaligned components and solder bridging. If needed, they are sent to a

676:

Thermal capacity of the heat generator results in slow reaction whereby thermal profiles can be distorted (depends on system used)

512:

the unaided eye. This is a disadvantage for prototyping, repair, rework, reverse engineering, and possibly for production set-up.

444:(lower radiated emissions) due to the smaller radiation loop area (because of the smaller package) and the lesser lead inductance.

2597:

145:

allowing much higher circuit densities and smaller circuit boards and, in turn, machines or subassemblies containing the boards.

639:

During hot gas soldering, the energy for heating up the solder joint is transmitted by a hot gas. This can be air or inert gas (

920:

129:

1590:

17:

453:

Simpler and faster automated assembly. Some placement machines are capable of placing more than 136,000 components per hour.

2514:

1935:

1621:

345:

to the board prior to processing to prevent them from floating off when the solder paste holding them in place is melted.

2295:

2075:

3130:

1862:

1424:

1395:

915:

748:

No increased oxidation due to strong blowing of the solder joints with hot air, reduces flux wear or flux blowing away

723:

No requirement for different nozzles for many component shapes and sizes, reducing cost and the need to change nozzles

720:

Heat transfer does not depend entirely on the flow velocity of hot gas at the component/assembly surface (see hot gas)

606:

No increased oxidation due to strong blowing of the solder joints with hot air, reduces flux wear or flux blowing away

587:

No requirement for different nozzles for many component shapes and sizes, reducing cost and the need to change nozzles

2278:

2174:

2049:

It is relatively common to find packages that contain other components than their designated ones, such as diodes or

1992:

1872:

545:

Reworking usually corrects some type of error, either human- or machine-generated, and includes the following steps:

566:

There are essentially two non-contact soldering/desoldering methods: infrared soldering and soldering with hot gas.

286:

and tiny solder particles, is first applied to all the solder pads with a stainless steel or nickel stencil using a

2418:

2145:

1857:

695:

Creation of a suitable reflow profile requires an adjustment and test phase, in some cases involving several stages

825:

are marked like resistors, with two significant figures and a multiplier in units of picofarads or pF, (10 farad.)

2466:

2265:

1614:

1499:

1265:

717:

The low flow velocity hot air supporting the IR radiation improves heat transfer, but cannot blow away components

363:(derived from orange peels) which require extra rinsing or drying cycles. Water-soluble fluxes are removed with

2068:

500:

style protoboards can be used, some of which include pads for standard sized SMD components. For prototyping, "

1666:

729:

Heating even very large / long and exotically shaped components possible, depending on the type of top heater

441:

1011:

2497:

2249:

2018:

832:

capacitors with a similar dark grey appearance. These ferrite bead type are limited to small values in the

395:

128:. The design approach first demonstrated by IBM in 1960 in a small-scale computer was later applied in the

2301:

2238:

1901:

935:

930:

683:

case, adjacent components must be protected from the air flow, e.g. by covering them with polyimide tape.

1112:

Artifact: Digital

Computer Memory and Circuit Boards, LVDC, Saturn IB/V Guidance, Navigation and Control

3125:

2961:

2508:

1906:

1867:

1852:

1837:

1231:

388:

station where a human operator repairs any errors. They are then usually sent to the testing stations (

1064:

501:

2715:

2429:

2272:

2157:

751:

Documentation of the temperature elapsed on the component for each individual rework process possible

609:

Documentation of the temperature elapsed on the component for each individual rework process possible

1484:

1143:

2724:

2582:

2434:

2290:

1697:

1110:

900:

302:

pick-and-place machines remove the parts from the tapes, tubes or trays and place them on the PCB.

133:

526:

2735:

2455:

2254:

2038:

1877:

1157:

955:

950:

421:

Much higher component density (components per unit area) and many more connections per component.

295:

96:

738:

No compressed air required for the heating process (some systems use compressed air for cooling)

584:

No compressed air required for the heating process (some systems use compressed air for cooling)

3120:

2904:

2471:

2336:

2312:

1847:

1821:

1207:

985:

248:

742:

process adapts itself automatically. Enables (re)entry into the profile even on hot assemblies

600:

process adapts itself automatically. Enables (re)entry into the profile even on hot assemblies

2973:

2925:

2746:

2562:

2477:

2408:

2244:

2028:

1997:

1637:

1039:

940:

860:

668:

Rapid cooling after reflow, resulting in small-grained solder joints (depends on system used)

471:

263:

84:

1441:

83:, is a method in which the electrical components are mounted directly onto the surface of a

3047:

2791:

2686:

2460:

2353:

2207:

2168:

2099:

2091:

2013:

1896:

1842:

1689:

1387:

790:

533:

8:

2767:

2675:

2567:

2403:

2380:

1955:

1678:

771:

450:

Lower initial cost and time of setting up for mass production, using automated equipment.

410:

SMD resistors in original packaging - this packaging allows for use in a mounting machine

159:

3072:

2932:

2640:

2607:

2423:

2307:

2285:

1982:

1972:

1544:

1472:

1131:

892:

104:

1080:

735:

Gentle reflow process with low surface temperatures, assuming correct profile settings

593:

Gentle reflow process with low surface temperatures, assuming correct profile settings

3067:

2988:

2879:

2831:

2660:

2587:

2549:

2050:

1911:

1536:

1450:

1420:

1391:

1084:

377:

369:

299:

283:

1548:

653:

Standard and component-specific nozzles allow high reliability and faster processing

2783:

2730:

2557:

2196:

1528:

1076:

306:

2592:

1586:

726:

Adjustment of the heating surface possible through various attachments if required

3060:

2993:

2846:

2577:

2487:

2331:

1987:

1940:

1930:

662:

Even heating of the affected board area (depends on system / nozzle quality used)

447:

Fewer holes need to be drilled. (Drilling PCBs is time-consuming and expensive.)

389:

364:

311:

287:

112:

35:

2218:

3035:

2816:

2806:

2572:

2375:

1945:

1443:

High Speed

Amplifier Techniques - A Designer's Companion for Wideband Circuitry

856:

822:

793:

has standardized package shapes and sizes (the leading standardisation body is

539:

493:

338:

291:

154:

3114:

3097:

2920:

2836:

2655:

2482:

2450:

1540:

1532:

1088:

620:

On short wavelength IR only: Surface temperature depends on the component's

2978:

2966:

2854:

2821:

2650:

2635:

2202:

905:

837:

784:

732:

Very uniform heating possible, assuming high quality hybrid heating systems

665:

Temperature of the component will never exceed the adjusted gas temperature

330:

290:

process. It can also be applied by a jet-printing mechanism, similar to an

279:

258:

PCB assembly line: pick-and-place machine followed by an SMT soldering oven

39:

707:

Hybrid rework systems combine medium-wave infrared radiation with hot air

243:

87:(PCB). An electrical component mounted in this manner is referred to as a

3020:

2762:

2711:

2617:

2602:

2385:

2347:

1606:

1384:

EMC and the

Printed Circuit Board: Design, Theory, and Layout Made Simple

910:

356:

353:

192:

Surface-mount devices (active, passive and electromechanical components)

150:

108:

2060:

1359:"Surface Mount Technology Advantages and Disadvantages for PCB Assembly"

3092:

3082:

3015:

2889:

2859:

2826:

2801:

2796:

2773:

2645:

2625:

2503:

2365:

2342:

2228:

2130:

2125:

2120:

845:

811:

590:

Very uniform heating possible, assuming high quality IR heating systems

497:

489:

482:

326:

65:

1290:"PCB Manufacturer with HDI Circuit Board fabrication for PCB and PCBA"

1182:

414:

The main advantages of SMT over the older through-hole technique are:

46:

3055:

2899:

2894:

2884:

2811:

2691:

2525:

2520:

2445:

2370:

1977:

960:

833:

137:

51:

1314:

3077:

3025:

3005:

2983:

2869:

2864:

2752:

2741:

2670:

2440:

1416:

1040:"(SMT) Surface-Mount Technology: Meaning, Definition, and Examples"

965:

886:

640:

521:

360:

325:

lamps; this is called infrared reflow. Another is to use a hot gas

322:

141:

406:

392:

and/or functional testing) to verify that they operate correctly.

254:

2937:

2874:

2696:

2681:

2535:

2492:

2140:

552:

Remove residual solder (may be not required for some components)

329:. Another technology which is becoming popular again is special

3010:

2701:

2665:

2630:

2190:

2162:

2135:

2110:

1786:

1774:

1756:

1744:

1672:

1660:

1289:

1012:"Surface Mount Technology - an overview | ScienceDirect Topics"

621:

555:

Print solder paste on PCB, directly or by dispensing or dipping

271:

62:

57:

1411:

Judd, Mike; Brindley, Keith (1999). "CS soldering processes".

656:

Allow reproducible soldering profiles (depends on system used)

376:

Certain manufacturing standards, such as those written by the

200:

Surface-mount technology (assembling and mounting technology)

30:

3087:

2998:

2757:

2530:

2323:

2185:

2180:

1738:

1732:

1726:

1720:

1646:

794:

349:

1338:

Electronics

Tutorial | The Best Electronics Tutorial Website

987:

Status of the

Technology Industry Activities and Action Plan

538:

Defective surface-mount components can be repaired by using

481:

Many types of SMT component packages cannot be installed in

456:

Many SMT parts cost less than equivalent through-hole parts.

424:

Components can be placed on both sides of the circuit board.

3030:

2413:

2359:

2260:

2213:

2151:

1714:

1708:

1702:

945:

871:

659:

Efficient heating, large amounts of heat can be transferred

342:

1563:"Two Prevalent Rework Heating Methods--Which One is Best?"

1315:"3D Solder Joint Reconstruction on SMD based on 2D Images"

775:

Example of component sizes, metric and imperial codes for

68:, placed upon a British postage stamp for size comparison.

863:

is also available, although these lists are not complete.

650:

Some systems allow switching between hot air and nitrogen

624:: dark surfaces will be heated more than lighter surfaces

596:

Fast reaction of infrared source (depends on system used)

267:

125:

1334:"Surface Mount Technology Advantages and Disadvantages"

107:

or leads of various styles, flat contacts, a matrix of

95:). In industry, this approach has largely replaced the

124:

of the pioneering work in this technology was done by

814:

of values, while the letter indicates the multiplier.

630:

No reflow atmosphere possible (but also not required)

1522:

882:

431:

aligned and cannot move laterally out of alignment.)

1102:

993:. Surface Mount Technology. Surface Mount Council.

762:

Convective loss of energy at the component possible

627:

Convective loss of energy at the component possible

378:

IPC - Association

Connecting Electronics Industries

314:automatically aligns the components on their pads.

208:Surface-mount assembly (module assembled with SMT)

232:Surface-mount equipment (SMT assembling machines)

352:flux is removed with fluorocarbon solvents, high

115:), or terminations on the body of the component.

3112:

1579:

1382:Montrose, Mark I. (1999). "Components and EMC".

1266:"SMT Manufacturing: Everything You Need to Know"

216:Surface-mount components (components for SMT)

2076:

1622:

1498:Dr. Lee, Ning-Cheng; Hance, Wanda B. (1993).

294:. After pasting, the boards proceed to the

1497:

1410:

1404:

1062:

1375:

470:SMDs' solder connections may be damaged by

2083:

2069:

2024:List of integrated circuit packaging types

1636:

1629:

1615:

1491:

1433:

926:List of integrated circuit packaging types

488:SMDs cannot be used directly with plug-in

2090:

1312:

1439:

1381:

983:

770:

520:

474:compounds going through thermal cycling.

405:

341:process is used, then the parts must be

253:

242:

224:Surface-mount packages (SMD case forms)

56:

45:

29:

27:Method for producing electronic circuits

1681:(SOD-123 / SOD-323 / SOD-523 / SOD-923)

1516:

262:Where components are to be placed, the

170:

14:

3113:

1357:Team, VSE | Engineering (2020-05-07).

1232:"No-clean is a process, not a product"

1108:

1038:Staff, History Computer (2022-05-19).

977:

921:List of electronics package dimensions

525:Removal of surface-mount device using

305:The boards are then conveyed into the

238:

2064:

1610:

1063:Garner, R.; Taylor, D. (1 May 1986).

1037:

359:solvents, or low flash solvents e.g.

2515:Three-dimensional integrated circuit

1356:

1180:

1033:

1031:

702:

321:for reflowing solder. One is to use

2296:Programmable unijunction transistor

1331:

1263:

549:Melt solder and remove component(s)

24:

2197:Multi-gate field-effect transistor

916:Electronics manufacturing services

25:

3142:

2175:Insulated-gate bipolar transistor

1413:Soldering in Electronics Assembly

1158:"Reflow of double sided assembly"

1028:

800:

2419:Heterostructure barrier varactor

2146:Chemical field-effect transistor

1181:Jena, Hanings (4 January 2016).

1000:from the original on 2015-12-28.

885:

460:

2467:Mixed-signal integrated circuit

1593:from the original on 2015-12-28

1555:

1460:from the original on 2015-12-28

1350:

1325:

1306:

1282:

1257:

1248:

1119:from the original on 2015-12-28

558:Place new component and reflow.

130:Launch Vehicle Digital Computer

1663:(DO-7 / DO-26 / DO-35 / DO-41)

1313:Vitoriano, Pedro (June 2016).

1224:

1200:

1174:

1150:

1056:

1004:

270:-lead, silver, or gold plated

34:Surface-mount components on a

13:

1:

1525:Reliability Physics Symposium

1504:Indium Corporation Tech Paper

1254:IPC-A-610E, paragraph 10.6.3.

1081:10.1016/S0026-2692(86)80170-7

971:

401:

2498:Silicon controlled rectifier

2360:Organic light-emitting diode

2250:Diffused junction transistor

2053:in transistor packages, etc.

2019:Integrated circuit packaging

1183:"PCB Assembly - Description"

984:Williams, Paul, ed. (1999).

504:" breadboarding can be used.

396:Automated optical inspection

7:

2302:Static induction transistor

2239:Bipolar junction transistor

2191:MOS field-effect transistor

2163:Fin field-effect transistor

1500:"Voiding Mechanisms in SMT"

1332:Das, Santosh (2019-10-01).

936:Point-to-point construction

931:Plastic leaded chip carrier

878:

766:

569:

496:may be used. Additionally,

385:

274:pads without holes, called

266:normally has flat, usually

10:

3147:

2509:Static induction thyristor

1453:. pp. 26–29, 98–121.

782:

634:

531:

373:component density boards.

118:

3131:Electronics manufacturing

3046:

2946:

2913:

2845:

2782:

2710:

2678:(Hexode, Heptode, Octode)

2616:

2548:

2430:Hybrid integrated circuit

2394:

2322:

2273:Light-emitting transistor

2227:

2109:

2098:

2047:

2006:

1954:

1923:

1886:

1830:

1814:

1688:

1644:

1065:"Surface mount packaging"

901:Board-to-board connectors

516:

2725:Backward-wave oscillator

2435:Light emitting capacitor

2291:Point-contact transistor

2261:Junction Gate FET (JFET)

2034:Surface-mount technology

1533:10.1109/IRPS.1983.361989

1069:Microelectronics Journal

73:Surface-mount technology

2736:Crossed-field amplifier

2255:Field-effect transistor

2039:Through-hole technology

956:Through-hole technology

951:SMT placement equipment

851:Discrete semiconductors

779:and comparison included

296:pick-and-place machines

249:pick-and-place machines

97:through-hole technology

2905:Voltage-regulator tube

2472:MOS integrated circuit

2337:Constant-current diode

2313:Unijunction transistor

1669:(MELF / SOD-80 / LL34)

1638:Semiconductor packages

1440:Williams, Jim (1991).

780:

529:

411:

317:There are a number of

282:, a sticky mixture of

259:

251:

69:

54:

43:

2974:Electrolytic detector

2747:Inductive output tube

2563:Low-dropout regulator

2478:Organic semiconductor

2409:Printed circuit board

2245:Darlington transistor

2092:Electronic components

2029:Printed circuit board

1208:"Why Clean No-Clean?"

1162:SURFACE MOUNT PROCESS

1016:www.sciencedirect.com

941:Printed circuit board

777:two-terminal packages

774:

524:

409:

264:printed circuit board

257:

246:

85:printed circuit board

79:), originally called

60:

49:

33:

18:Surface Mount Devices

2792:Beam deflection tube

2461:Metal-oxide varistor

2354:Light-emitting diode

2208:Thin-film transistor

2169:Floating-gate MOSFET

2014:Electronic packaging

791:electronics industry

534:Rework (electronics)

171:Common abbreviations

89:surface-mount device

2768:Traveling-wave tube

2568:Switching regulator

2404:Printed electronics

2381:Step recovery diode

2158:Depletion-load NMOS

1587:"Resistor SMD code"

1567:smt.iconnect007.com

1294:www.hemeixinpcb.com

1109:Schneeweis, Scott.

866:Integrated circuits

418:Smaller components.

247:Assembly line with

239:Assembly techniques

3073:Crystal oscillator

2933:Variable capacitor

2608:Switched capacitor

2550:Voltage regulators

2424:Integrated circuit

2308:Tetrode transistor

2286:Pentode transistor

2279:Organic LET (OLET)

2266:Organic FET (OFET)

2051:voltage regulators

1589:. Resistor Guide.

1388:Wiley-Interscience

893:Electronics portal

781:

530:

527:soldering tweezers

412:

390:in-circuit testing

370:conformal coatings

260:

252:

70:

55:

44:

3126:Electronic design

3108:

3107:

3068:Ceramic resonator

2880:Mercury-arc valve

2832:Video camera tube

2784:Cathode-ray tubes

2544:

2543:

2152:Complementary MOS

2058:

2057:

1807:(Super-247) (SMT)

1801:(Super-220) (SMT)

1675:(SMA / SMB / SMC)

1451:Linear Technology

1321:. pp. 82–93.

1264:Ayodele, Abiola.

1212:Assembly Magazine

861:similar .pdf list

703:Hybrid technology

300:Numerical control

236:

235:

16:(Redirected from

3138:

2962:electrical power

2847:Gas-filled tubes

2731:Cavity magnetron

2558:Linear regulator

2107:

2106:

2085:

2078:

2071:

2062:

2061:

1631:

1624:

1617:

1608:

1607:

1602:

1601:

1599:

1598:

1583:

1577:

1576:

1574:

1573:

1559:

1553:

1552:

1520:

1514:

1513:

1511:

1510:

1495:

1489:

1488:

1482:

1478:

1476:

1468:

1466:

1465:

1459:

1448:

1437:

1431:

1430:

1408:

1402:

1401:

1379:

1373:

1372:

1370:

1369:

1354:

1348:

1347:

1345:

1344:

1329:

1323:

1322:

1310:

1304:

1303:

1301:

1300:

1286:

1280:

1279:

1277:

1276:

1261:

1255:

1252:

1246:

1245:

1243:

1242:

1228:

1222:

1221:

1219:

1218:

1204:

1198:

1197:

1195:

1193:

1178:

1172:

1171:

1169:

1168:

1154:

1148:

1147:

1141:

1137:

1135:

1127:

1125:

1124:

1106:

1100:

1099:

1097:

1095:

1060:

1054:

1053:

1051:

1050:

1044:History-Computer

1035:

1026:

1025:

1023:

1022:

1008:

1002:

1001:

999:

992:

981:

895:

890:

889:

857:correlation list

844:

307:reflow soldering

178:

177:

160:selective solder

136:that guided all

21:

3146:

3145:

3141:

3140:

3139:

3137:

3136:

3135:

3111:

3110:

3109:

3104:

3042:

2957:audio and video

2942:

2909:

2841:

2778:

2706:

2687:Photomultiplier

2612:

2540:

2488:Quantum circuit

2396:

2390:

2332:Avalanche diode

2318:

2230:

2223:

2112:

2101:

2094:

2089:

2059:

2054:

2043:

2002:

1950:

1919:

1882:

1826:

1810:

1684:

1640:

1635:

1605:

1596:

1594:

1585:

1584:

1580:

1571:

1569:

1561:

1560:

1556:

1521:

1517:

1508:

1506:

1496:

1492:

1480:

1479:

1470:

1469:

1463:

1461:

1457:

1446:

1438:

1434:

1427:

1419:. p. 128.

1409:

1405:

1398:

1380:

1376:

1367:

1365:

1355:

1351:

1342:

1340:

1330:

1326:

1311:

1307:

1298:

1296:

1288:

1287:

1283:

1274:

1272:

1262:

1258:

1253:

1249:

1240:

1238:

1230:

1229:

1225:

1216:

1214:

1206:

1205:

1201:

1191:

1189:

1179:

1175:

1166:

1164:

1156:

1155:

1151:

1139:

1138:

1129:

1128:

1122:

1120:

1115:. Spaceaholic.

1107:

1103:

1093:

1091:

1061:

1057:

1048:

1046:

1036:

1029:

1020:

1018:

1010:

1009:

1005:

997:

990:

982:

978:

974:

891:

884:

881:

842:

823:film capacitors

803:

787:

769:

705:

672:Disadvantages:

637:

613:Disadvantages:

572:

540:soldering irons

536:

519:

463:

442:EMC performance

404:

365:deionized water

312:surface tension

288:screen printing

241:

173:

134:Instrument Unit

121:

81:planar mounting

36:USB flash drive

28:

23:

22:

15:

12:

11:

5:

3144:

3134:

3133:

3128:

3123:

3106:

3105:

3103:

3102:

3101:

3100:

3095:

3085:

3080:

3075:

3070:

3065:

3064:

3063:

3052:

3050:

3044:

3043:

3041:

3040:

3039:

3038:

3036:Wollaston wire

3028:

3023:

3018:

3013:

3008:

3003:

3002:

3001:

2996:

2986:

2981:

2976:

2971:

2970:

2969:

2964:

2959:

2950:

2948:

2944:

2943:

2941:

2940:

2935:

2930:

2929:

2928:

2917:

2915:

2911:

2910:

2908:

2907:

2902:

2897:

2892:

2887:

2882:

2877:

2872:

2867:

2862:

2857:

2851:

2849:

2843:

2842:

2840:

2839:

2834:

2829:

2824:

2819:

2817:Selectron tube

2814:

2809:

2807:Magic eye tube

2804:

2799:

2794:

2788:

2786:

2780:

2779:

2777:

2776:

2771:

2765:

2760:

2755:

2750:

2744:

2739:

2733:

2728:

2721:

2719:

2708:

2707:

2705:

2704:

2699:

2694:

2689:

2684:

2679:

2673:

2668:

2663:

2658:

2653:

2648:

2643:

2638:

2633:

2628:

2622:

2620:

2614:

2613:

2611:

2610:

2605:

2600:

2595:

2590:

2585:

2580:

2575:

2570:

2565:

2560:

2554:

2552:

2546:

2545:

2542:

2541:

2539:

2538:

2533:

2528:

2523:

2518:

2512:

2506:

2501:

2495:

2490:

2485:

2480:

2475:

2469:

2464:

2458:

2453:

2448:

2443:

2438:

2432:

2427:

2421:

2416:

2411:

2406:

2400:

2398:

2392:

2391:

2389:

2388:

2383:

2378:

2376:Schottky diode

2373:

2368:

2363:

2357:

2351:

2345:

2340:

2334:

2328:

2326:

2320:

2319:

2317:

2316:

2310:

2305:

2299:

2293:

2288:

2283:

2282:

2281:

2270:

2269:

2268:

2263:

2252:

2247:

2242:

2235:

2233:

2225:

2224:

2222:

2221:

2216:

2211:

2205:

2200:

2194:

2188:

2183:

2178:

2172:

2166:

2160:

2155:

2149:

2143:

2138:

2133:

2128:

2123:

2117:

2115:

2104:

2096:

2095:

2088:

2087:

2080:

2073:

2065:

2056:

2055:

2048:

2045:

2044:

2042:

2041:

2036:

2031:

2026:

2021:

2016:

2010:

2008:

2007:Related topics

2004:

2003:

2001:

2000:

1995:

1990:

1985:

1980:

1975:

1970:

1967:

1964:

1960:

1958:

1952:

1951:

1949:

1948:

1943:

1938:

1933:

1927:

1925:

1921:

1920:

1918:

1917:

1914:

1909:

1904:

1899:

1894:

1890:

1888:

1884:

1883:

1881:

1880:

1875:

1873:TSSOP / HTSSOP

1870:

1865:

1860:

1855:

1850:

1845:

1840:

1834:

1832:

1828:

1827:

1825:

1824:

1818:

1816:

1812:

1811:

1809:

1808:

1802:

1796:

1790:

1784:

1778:

1772:

1766:

1760:

1754:

1748:

1742:

1736:

1730:

1724:

1718:

1712:

1706:

1700:

1694:

1692:

1686:

1685:

1683:

1682:

1676:

1670:

1664:

1658:

1651:

1649:

1642:

1641:

1634:

1633:

1626:

1619:

1611:

1604:

1603:

1578:

1554:

1515:

1490:

1432:

1426:978-0750635455

1425:

1415:(2 ed.).

1403:

1397:978-0780347038

1396:

1390:. p. 64.

1374:

1349:

1324:

1305:

1281:

1256:

1247:

1223:

1199:

1187:www.ourpcb.com

1173:

1149:

1101:

1055:

1027:

1003:

975:

973:

970:

969:

968:

963:

958:

953:

948:

943:

938:

933:

928:

923:

918:

913:

908:

903:

897:

896:

880:

877:

876:

875:

867:

864:

852:

849:

829:

826:

818:

815:

807:

802:

801:Identification

799:

783:Main article:

768:

765:

764:

763:

760:

755:Disadvantages

753:

752:

749:

746:

743:

739:

736:

733:

730:

727:

724:

721:

718:

715:

704:

701:

700:

699:

696:

693:

690:

687:

684:

680:

677:

670:

669:

666:

663:

660:

657:

654:

651:

636:

633:

632:

631:

628:

625:

618:

611:

610:

607:

604:

601:

597:

594:

591:

588:

585:

582:

571:

568:

560:

559:

556:

553:

550:

532:Main article:

518:

515:

514:

513:

509:

505:

494:breakout board

486:

479:

475:

468:

462:

459:

458:

457:

454:

451:

448:

445:

438:

435:

432:

428:

425:

422:

419:

403:

400:

339:wave soldering

292:inkjet printer

240:

237:

234:

233:

230:

226:

225:

222:

218:

217:

214:

210:

209:

206:

202:

201:

198:

194:

193:

190:

186:

185:

184:Expanded form

182:

172:

169:

155:wave soldering

120:

117:

50:Surface-mount

26:

9:

6:

4:

3:

2:

3143:

3132:

3129:

3127:

3124:

3122:

3121:Chip carriers

3119:

3118:

3116:

3099:

3098:mercury relay

3096:

3094:

3091:

3090:

3089:

3086:

3084:

3081:

3079:

3076:

3074:

3071:

3069:

3066:

3062:

3059:

3058:

3057:

3054:

3053:

3051:

3049:

3045:

3037:

3034:

3033:

3032:

3029:

3027:

3024:

3022:

3019:

3017:

3014:

3012:

3009:

3007:

3004:

3000:

2997:

2995:

2992:

2991:

2990:

2987:

2985:

2982:

2980:

2977:

2975:

2972:

2968:

2965:

2963:

2960:

2958:

2955:

2954:

2952:

2951:

2949:

2945:

2939:

2936:

2934:

2931:

2927:

2924:

2923:

2922:

2921:Potentiometer

2919:

2918:

2916:

2912:

2906:

2903:

2901:

2898:

2896:

2893:

2891:

2888:

2886:

2883:

2881:

2878:

2876:

2873:

2871:

2868:

2866:

2863:

2861:

2858:

2856:

2853:

2852:

2850:

2848:

2844:

2838:

2837:Williams tube

2835:

2833:

2830:

2828:

2825:

2823:

2820:

2818:

2815:

2813:

2810:

2808:

2805:

2803:

2800:

2798:

2795:

2793:

2790:

2789:

2787:

2785:

2781:

2775:

2772:

2769:

2766:

2764:

2761:

2759:

2756:

2754:

2751:

2748:

2745:

2743:

2740:

2737:

2734:

2732:

2729:

2726:

2723:

2722:

2720:

2717:

2713:

2709:

2703:

2700:

2698:

2695:

2693:

2690:

2688:

2685:

2683:

2680:

2677:

2674:

2672:

2669:

2667:

2664:

2662:

2659:

2657:

2656:Fleming valve

2654:

2652:

2649:

2647:

2644:

2642:

2639:

2637:

2634:

2632:

2629:

2627:

2624:

2623:

2621:

2619:

2615:

2609:

2606:

2604:

2601:

2599:

2596:

2594:

2591:

2589:

2586:

2584:

2581:

2579:

2576:

2574:

2571:

2569:

2566:

2564:

2561:

2559:

2556:

2555:

2553:

2551:

2547:

2537:

2534:

2532:

2529:

2527:

2524:

2522:

2519:

2516:

2513:

2510:

2507:

2505:

2502:

2499:

2496:

2494:

2491:

2489:

2486:

2484:

2483:Photodetector

2481:

2479:

2476:

2473:

2470:

2468:

2465:

2462:

2459:

2457:

2454:

2452:

2451:Memtransistor

2449:

2447:

2444:

2442:

2439:

2436:

2433:

2431:

2428:

2425:

2422:

2420:

2417:

2415:

2412:

2410:

2407:

2405:

2402:

2401:

2399:

2393:

2387:

2384:

2382:

2379:

2377:

2374:

2372:

2369:

2367:

2364:

2361:

2358:

2355:

2352:

2349:

2346:

2344:

2341:

2338:

2335:

2333:

2330:

2329:

2327:

2325:

2321:

2314:

2311:

2309:

2306:

2303:

2300:

2297:

2294:

2292:

2289:

2287:

2284:

2280:

2277:

2276:

2274:

2271:

2267:

2264:

2262:

2259:

2258:

2256:

2253:

2251:

2248:

2246:

2243:

2240:

2237:

2236:

2234:

2232:

2226:

2220:

2217:

2215:

2212:

2209:

2206:

2204:

2201:

2198:

2195:

2192:

2189:

2187:

2184:

2182:

2179:

2176:

2173:

2170:

2167:

2164:

2161:

2159:

2156:

2153:

2150:

2147:

2144:

2142:

2139:

2137:

2134:

2132:

2129:

2127:

2124:

2122:

2119:

2118:

2116:

2114:

2108:

2105:

2103:

2100:Semiconductor

2097:

2093:

2086:

2081:

2079:

2074:

2072:

2067:

2066:

2063:

2052:

2046:

2040:

2037:

2035:

2032:

2030:

2027:

2025:

2022:

2020:

2017:

2015:

2012:

2011:

2009:

2005:

1999:

1996:

1994:

1991:

1989:

1986:

1984:

1981:

1979:

1976:

1974:

1971:

1968:

1965:

1962:

1961:

1959:

1957:

1953:

1947:

1944:

1942:

1939:

1937:

1934:

1932:

1929:

1928:

1926:

1922:

1915:

1913:

1910:

1908:

1905:

1903:

1900:

1898:

1895:

1892:

1891:

1889:

1885:

1879:

1876:

1874:

1871:

1869:

1866:

1864:

1861:

1859:

1856:

1854:

1851:

1849:

1846:

1844:

1841:

1839:

1836:

1835:

1833:

1829:

1823:

1820:

1819:

1817:

1813:

1806:

1803:

1800:

1797:

1795:(D3PAK) (SMT)

1794:

1791:

1789:(D2PAK) (SMT)

1788:

1785:

1783:(I2PAK) (SMT)

1782:

1779:

1776:

1773:

1770:

1767:

1764:

1761:

1758:

1755:

1752:

1749:

1746:

1743:

1740:

1737:

1734:

1731:

1728:

1725:

1722:

1719:

1716:

1713:

1710:

1707:

1704:

1701:

1699:

1696:

1695:

1693:

1691:

1687:

1680:

1677:

1674:

1671:

1668:

1665:

1662:

1659:

1656:

1653:

1652:

1650:

1648:

1643:

1639:

1632:

1627:

1625:

1620:

1618:

1613:

1612:

1609:

1592:

1588:

1582:

1568:

1564:

1558:

1550:

1546:

1542:

1538:

1534:

1530:

1526:

1519:

1505:

1501:

1494:

1486:

1474:

1456:

1452:

1445:

1444:

1436:

1428:

1422:

1418:

1414:

1407:

1399:

1393:

1389:

1385:

1378:

1364:

1360:

1353:

1339:

1335:

1328:

1320:

1316:

1309:

1295:

1291:

1285:

1271:

1267:

1260:

1251:

1237:

1233:

1227:

1213:

1209:

1203:

1188:

1184:

1177:

1163:

1159:

1153:

1145:

1133:

1118:

1114:

1113:

1105:

1090:

1086:

1082:

1078:

1074:

1070:

1066:

1059:

1045:

1041:

1034:

1032:

1017:

1013:

1007:

996:

989:

988:

980:

976:

967:

964:

962:

959:

957:

954:

952:

949:

947:

944:

942:

939:

937:

934:

932:

929:

927:

924:

922:

919:

917:

914:

912:

909:

907:

904:

902:

899:

898:

894:

888:

883:

873:

868:

865:

862:

858:

853:

850:

847:

839:

835:

830:

827:

824:

819:

816:

813:

808:

805:

804:

798:

796:

792:

786:

778:

773:

761:

758:

757:

756:

750:

747:

744:

740:

737:

734:

731:

728:

725:

722:

719:

716:

713:

712:

711:

708:

697:

694:

691:

688:

685:

681:

678:

675:

674:

673:

667:

664:

661:

658:

655:

652:

649:

648:

647:

644:

642:

629:

626:

623:

619:

616:

615:

614:

608:

605:

602:

598:

595:

592:

589:

586:

583:

580:

579:

578:

575:

567:

564:

557:

554:

551:

548:

547:

546:

543:

541:

535:

528:

523:

510:

506:

503:

499:

495:

491:

487:

484:

480:

476:

473:

469:

465:

464:

461:Disadvantages

455:

452:

449:

446:

443:

439:

436:

433:

429:

426:

423:

420:

417:

416:

415:

408:

399:

397:

393:

391:

387:

382:

379:

374:

371:

366:

362:

358:

355:

351:

346:

344:

340:

335:

332:

328:

324:

320:

315:

313:

308:

303:

301:

297:

293:

289:

285:

281:

277:

273:

269:

265:

256:

250:

245:

231:

228:

227:

223:

220:

219:

215:

212:

211:

207:

204:

203:

199:

196:

195:

191:

188:

187:

183:

180:

179:

176:

168:

164:

161:

156:

152:

146:

143:

139:

135:

131:

127:

116:

114:

110:

106:

101:

98:

94:

90:

86:

82:

78:

74:

67:

64:

59:

53:

48:

41:

37:

32:

19:

2855:Cold cathode

2822:Storage tube

2712:Vacuum tubes

2661:Neutron tube

2636:Beam tetrode

2618:Vacuum tubes

2203:Power MOSFET

2033:

1998:WL-CSP / WLP

1868:TSOP / HTSOP

1777:(DPAK) (SMT)

1771:(IPAK) (SMT)

1765:(TH / Panel)

1759:(TH / Panel)

1753:(TH / Panel)

1747:(TH / Panel)

1735:(TH / Panel)

1705:(TH / Panel)

1595:. Retrieved

1581:

1570:. Retrieved

1566:

1557:

1524:

1518:

1507:. Retrieved

1503:

1493:

1462:. Retrieved

1442:

1435:

1412:

1406:

1383:

1377:

1366:. Retrieved

1362:

1352:

1341:. Retrieved

1337:

1327:

1319:SMT Magazine

1318:

1308:

1297:. Retrieved

1293:

1284:

1273:. Retrieved

1269:

1259:

1250:

1239:. Retrieved

1235:

1226:

1215:. Retrieved

1211:

1202:

1190:. Retrieved

1186:

1176:

1165:. Retrieved

1161:

1152:

1121:. Retrieved

1111:

1104:

1092:. Retrieved

1072:

1068:

1058:

1047:. Retrieved

1043:

1019:. Retrieved

1015:

1006:

986:

979:

906:Chip carrier

838:ferrite core

788:

785:Chip carrier

754:

710:Advantages:

709:

706:

671:

646:Advantages:

645:

638:

612:

577:Advantages:

576:

573:

565:

561:

544:

537:

413:

394:

383:

375:

347:

336:

331:fluorocarbon

318:

316:

304:

280:Solder paste

275:

261:

174:

165:

151:reflow ovens

147:

132:used in the

122:

109:solder balls

102:

92:

88:

80:

76:

72:

71:

40:ferrite bead

3021:Transformer

2763:Sutton tube

2603:Charge pump

2456:Memory cell

2386:Zener diode

2348:Laser diode

2231:transistors

2113:transistors

1916:QUIP / QUIL

1527:: 235–241.

1481:|work=

1236:www.ipc.org

1140:|work=

1075:(3): 5–13.

911:Electronics

490:breadboards

357:hydrocarbon

354:flash point

276:solder pads

3115:Categories

3093:reed relay

3083:Parametron

3016:Thermistor

2994:resettable

2953:Connector

2914:Adjustable

2890:Nixie tube

2860:Crossatron

2827:Trochotron

2802:Iconoscope

2797:Charactron

2774:X-ray tube

2646:Compactron

2626:Acorn tube

2583:Buck–boost

2504:Solaristor

2366:Photodiode

2343:Gunn diode

2339:(CLD, CRD)

2121:Transistor

1924:Grid array

1863:SOP / SSOP

1815:Single row

1698:SOT / TSOT

1597:2015-12-28

1572:2018-07-27

1509:2015-12-28

1464:2015-12-28

1368:2022-09-30

1343:2022-09-30

1299:2022-09-30

1275:2022-09-30

1241:2017-10-03

1217:2017-10-03

1192:7 February

1167:2020-09-16

1123:2015-12-28

1094:19 January

1049:2022-09-30

1021:2022-09-30

972:References

817:Capacitors

812:E96 Series

714:Easy setup

581:Easy setup

498:stripboard

402:Advantages

327:convection

319:techniques

66:transistor

3056:Capacitor

2900:Trigatron

2895:Thyratron

2885:Neon lamp

2812:Monoscope

2692:Phototube

2676:Pentagrid

2641:Barretter

2526:Trancitor

2521:Thyristor

2446:Memristor

2371:PIN diode

2148:(ChemFET)

1978:Flip Chip

1897:QIP / QIL

1858:SO / SOIC

1848:Flat Pack

1843:DIP / DIL

1822:SIP / SIL

1690:3...5-pin

1541:0735-0791

1483:ignored (

1473:cite book

1142:ignored (

1132:cite book

1089:0026-2692

961:Wire wrap

834:nanohenry

828:Inductors

806:Resistors

467:detached.

138:Saturn IB

52:capacitor

3078:Inductor

3048:Reactive

3026:Varistor

3006:Resistor

2984:Antifuse

2870:Ignitron

2865:Dekatron

2753:Klystron

2742:Gyrotron

2671:Nuvistor

2588:Split-pi

2474:(MOS IC)

2441:Memistor

2199:(MuGFET)

2193:(MOSFET)

2165:(FinFET)

1887:Quad row

1831:Dual row

1591:Archived

1549:11459596

1455:Archived

1270:Wevolver

1117:Archived

995:Archived

966:RKM code

879:See also

859:, and a

767:Packages

641:nitrogen

570:Infrared

502:dead bug

361:limonene

323:infrared

181:SMp term

142:Saturn V

2979:Ferrite

2947:Passive

2938:Varicap

2926:digital

2875:Krytron

2697:Tetrode

2682:Pentode

2536:Varicap

2517:(3D IC)

2493:RF CMOS

2397:devices

2171:(FGMOS)

2102:devices

1657:(DO-27)

1645:Single

635:Hot gas

483:sockets

472:potting

440:Better

119:History

3011:Switch

2702:Triode

2666:Nonode

2631:Audion

2511:(SITh)

2395:Other

2362:(OLED)

2324:Diodes

2275:(LET)

2257:(FET)

2229:Other

2177:(IGBT)

2154:(CMOS)

2141:BioFET

2136:BiCMOS

1805:TO-274

1799:TO-273

1793:TO-268

1787:TO-263

1781:TO-262

1775:TO-252

1769:TO-251

1763:TO-247

1757:TO-220

1751:TO-202

1745:TO-126

1673:DO-214

1667:DO-213

1661:DO-204

1655:DO-201

1547:

1539:

1423:

1417:Newnes

1394:

1087:

843:

622:albedo

517:Rework

386:rework

272:copper

63:MOSFET

3088:Relay

3061:types

2999:eFUSE

2770:(TWT)

2758:Maser

2749:(IOT)

2738:(CFA)

2727:(BWO)

2651:Diode

2598:SEPIC

2578:Boost

2531:TRIAC

2500:(SCR)

2463:(MOV)

2437:(LEC)

2356:(LED)

2315:(UJT)

2304:(SIT)

2298:(PUT)

2241:(BJT)

2210:(TFT)

2186:LDMOS

2181:ISFET

1956:Wafer

1739:TO-92

1733:TO-66

1727:TO-39

1721:TO-18

1647:diode

1545:S2CID

1458:(PDF)

1447:(PDF)

998:(PDF)

991:(PDF)

795:JEDEC

350:Rosin

343:glued

3031:Wire

2989:Fuse

2573:Buck

2426:(IC)

2414:DIAC

2350:(LD)

2219:UMOS

2214:VMOS

2131:PMOS

2126:NMOS

2111:MOS

1993:UICC

1936:eWLB

1902:PLCC

1853:MSOP

1741:(TH)

1729:(TH)

1723:(TH)

1717:(TH)

1715:TO-8

1711:(TH)

1709:TO-5

1703:TO-3

1537:ISSN

1485:help

1421:ISBN

1392:ISBN

1194:2018

1144:help

1096:2021

1085:ISSN

946:RoHS

872:logo

284:flux

229:SME

221:SMP

213:SMC

205:SMA

197:SMT

189:SMD

140:and

113:BGAs

105:pins

2593:Ćuk

1983:PoP

1973:CSP

1969:COG

1966:COF

1963:COB

1946:PGA

1941:LGA

1931:BGA

1912:QFP

1907:QFN

1893:LCC

1878:ZIP

1838:DFN

1679:SOD

1529:doi

1363:VSE

1077:doi

797:).

643:).

278:.

268:tin

126:IBM

93:SMD

77:SMT

3117::

2967:RF

2716:RF

1988:QP

1565:.

1543:.

1535:.

1502:.

1477::

1475:}}

1471:{{

1449:.

1386:.

1361:.

1336:.

1317:.

1292:.

1268:.

1234:.

1210:.

1185:.

1160:.

1136::

1134:}}

1130:{{

1083:.

1073:17

1071:.

1067:.

1042:.

1030:^

1014:.

846:μH

61:A

2718:)

2714:(

2084:e

2077:t

2070:v

1630:e

1623:t

1616:v

1600:.

1575:.

1551:.

1531::

1512:.

1487:)

1467:.

1429:.

1400:.

1371:.

1346:.

1302:.

1278:.

1244:.

1220:.

1196:.

1170:.

1146:)

1126:.

1098:.

1079::

1052:.

1024:.

874:.

848:.

111:(

91:(

75:(

42:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.