54:

247:

20:

392:

242:

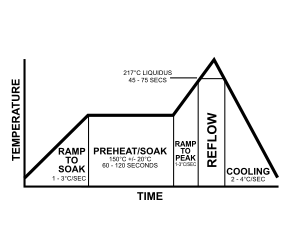

Thermal profiling is the act of measuring several points on a circuit board to determine the thermal excursion it takes through the soldering process. In the electronics manufacturing industry, SPC (statistical process control) helps determine if the process is in control, measured against the reflow

194:

In a pressure cure process, air is pressurized in a rigid vessel or chamber while heating or cooling with forced convection. Heaters, heat exchangers, and blowers are mounted internal to the pressure vessel, continuously circulating air across the pressure chamber providing consistent heat

65:

Commercial conveyorised reflow ovens contain multiple individually heated zones, which can be individually controlled for temperature. PCBs being processed travel through the oven and through each zone at a controlled rate. Technicians adjust the conveyor speed and zone temperatures to achieve a

190:

Pressure curing ovens, or

Autoclave, is widely utilized to minimize voiding and improve adhesion strength in bonding processes. Pressure cure ovens are typically employed in die attach and underfill applications. Increasing pressure during the curing process removes voids.

226:

Formic acid reflow ovens operate similarly to a traditionally reflow oven, with the addition of formic acid vapor injection into the key soak zones for flux-free reflow and vapor soldering. Upon injection, the formic acid removes any oxides present on the metal prior to reflow.

233:

Formic acid reflow ovens employ sets of double doors at the oven’s entrance and exit to dramatically reduce process gas consumption. During production, only one door opens at a time, thus isolating the process chamber and lowering nitrogen and formic acid consumption.

213:

Employing heat inside the vacuum chamber allows peak temperatures to be achieved during vacuum, assuring shorter time above liquidous and greater process flexibility. High vacuum chamber temperatures also prevent flux buildup inside the chamber.

128:

of the surfaces to be soldered. The nitrogen reflow oven takes a few minutes to reduce Oxygen concentration to acceptable levels within the chamber. Thus nitrogen ovens typically have nitrogen injection in at all times which decreases defect rates.

206:

Traditional reflow can be augmented by the addition of a late-stage vacuum chamber. Introducing a vacuum chamber to the reflow process allows voids and bubbles to escape, significantly reducing voiding in solder joints and interfaces.

106:. They may be fan assisted to control the airflow within the oven. This indirect heating using air allows more accurate temperature control than directly heating PCBs by infrared radiation, as PCBs and components vary in infrared

217:

Advanced vacuum reflow ovens employ multiple conveyor systems allowing higher throughput by optimizing transfer time into the vacuum chamber, dual rail processing, and closed-loop vacuum pumps to prevent solder and flux spatter.

230:

Formic acid concentration is maintained by a bubbler system that is monitored in real time to provide stable and consistent formic concentrations to within 0.5% in the process chamber.

210:

During the vacuum process, the circuit board is stationary, assuring no shifting parts. Smooth travel into and out of the vacuum chamber, minimizing vibration, is critical.

452:

113:

Ovens may use a combination of infrared radiative heating and convection heating, and would then be known as 'infrared convection' ovens.

366:

433:

335:

91:

source is normally ceramic infrared heaters above and below the conveyor, which transfer heat to the PCBs by means of

195:

transfer to the product. Upon completion of the curing process, pressure is relieved and the product cools.

426:

50:

along which PCBs travel. For prototyping or hobbyist use PCBs can be placed in a small oven with a door.

70:. The profile in use may vary depending on the requirements of the PCBs being processed at the time.

457:

419:

98:

Convection ovens heat air in chambers, using that air to transfer heat to the PCBs by means of

370:

174:

No overheating of assemblies. The maximum temperature assemblies can reach is limited by the

40:

161:

8:

399:

46:

In commercial high-volume use, reflow ovens take the form of a long tunnel containing a

313:"Guidelines for Temperature Profiling for Mass Soldering Processes (Reflow & Wave)"

103:

407:

265:

260:

138:

32:

67:

58:

403:

53:

286:

243:

parameters defined by the soldering technologies and component requirements.

446:

175:

150:

142:

47:

36:

198:

Pressure cure ovens can utilize air or nitrogen as the pressurizing agent.

246:

107:

19:

167:

Soldering is oxygen-free. There is no need for any protective gas (e.g.

99:

312:

125:

116:

Some ovens are designed to reflow PCBs in an oxygen-free atmosphere.

92:

137:

The heating of the PCBs is sourced by thermal energy emitted by the

168:

149:) condensing on the PCBs. The liquid used is chosen with a desired

117:

84:

164:

due to the high heat transfer coefficient of vapour phase media

146:

88:

391:

124:) is a common gas used for this purpose. This minimizes

271:

153:in mind to suit the solder alloy to be reflowed.

444:

78:

156:Some advantages of vapour phase soldering are:

182:This is also known as condensation soldering.

427:

221:

434:

420:

245:

185:

73:

52:

18:

16:Machine used in circuit board production

445:

201:

358:

386:

284:

250:Example of a modern thermal profiler

237:

132:

453:Printed circuit board manufacturing

13:

14:

469:

336:"Modern thermal profiling device"

390:

31:is a machine used primarily for

328:

305:

278:

272:References and further reading

1:

367:"T.Bazouni: Reflow Soldering"

79:Infrared and convection ovens

406:. You can help Knowledge by

57:Example of reflow soldering

7:

254:

66:known time and temperature

10:

474:

385:

291:Heller Industries Website

39:electronic components to

23:A convection reflow oven.

222:Formic Acid Reflow Ovens

293:. Heller Industries Inc

402:-related article is a

251:

62:

41:printed circuit boards

24:

249:

186:Pressure Curing Ovens

74:Types of reflow ovens

56:

22:

287:"Mark5 Reflow Oven"

202:Vacuum Reflow Ovens

359:General references

340:Solderstar Website

285:Girouard, Roland.

252:

87:reflow ovens, the

63:

25:

415:

414:

266:Thermal profiling

238:Thermal profiling

162:energy efficiency

133:Vapour phase oven

465:

436:

429:

422:

394:

387:

381:

379:

378:

369:. Archived from

352:

351:

349:

347:

332:

326:

325:

323:

322:

317:

309:

303:

302:

300:

298:

282:

261:Reflow soldering

139:phase transition

33:reflow soldering

473:

472:

468:

467:

466:

464:

463:

462:

443:

442:

441:

440:

384:

376:

374:

365:

361:

356:

355:

345:

343:

334:

333:

329:

320:

318:

315:

311:

310:

306:

296:

294:

283:

279:

274:

257:

240:

224:

204:

188:

135:

123:

81:

76:

59:thermal profile

17:

12:

11:

5:

471:

461:

460:

458:Industry stubs

455:

439:

438:

431:

424:

416:

413:

412:

395:

383:

382:

362:

360:

357:

354:

353:

327:

304:

276:

275:

273:

270:

269:

268:

263:

256:

253:

239:

236:

223:

220:

203:

200:

187:

184:

180:

179:

178:of the medium.

172:

165:

145:liquid (e. g.

134:

131:

121:

80:

77:

75:

72:

15:

9:

6:

4:

3:

2:

470:

459:

456:

454:

451:

450:

448:

437:

432:

430:

425:

423:

418:

417:

411:

409:

405:

401:

396:

393:

389:

388:

373:on 2008-06-18

372:

368:

364:

363:

341:

337:

331:

314:

308:

292:

288:

281:

277:

267:

264:

262:

259:

258:

248:

244:

235:

231:

228:

219:

215:

211:

208:

199:

196:

192:

183:

177:

176:boiling point

173:

170:

166:

163:

159:

158:

157:

154:

152:

151:boiling point

148:

144:

143:heat transfer

140:

130:

127:

119:

114:

111:

109:

105:

101:

96:

94:

90:

86:

71:

69:

60:

55:

51:

49:

48:conveyor belt

44:

42:

38:

37:surface mount

34:

30:

21:

408:expanding it

397:

375:. Retrieved

371:the original

346:28 September

344:. Retrieved

342:. Solderstar

339:

330:

319:. Retrieved

307:

297:28 September

295:. Retrieved

290:

280:

241:

232:

229:

225:

216:

212:

209:

205:

197:

193:

189:

181:

155:

136:

115:

112:

97:

82:

64:

45:

28:

26:

108:absorptance

29:reflow oven

447:Categories

377:2008-04-11

321:2019-07-01

104:conduction

100:convection

126:oxidation

93:radiation

43:(PCBs).

400:industry

255:See also

169:nitrogen

118:Nitrogen

85:infrared

68:profile

398:This

316:(PDF)

160:High

141:of a

404:stub

348:2018

299:2012

147:PFPE

102:and

89:heat

95:.

83:In

35:of

449::

338:.

289:.

120:(N

110:.

27:A

435:e

428:t

421:v

410:.

380:.

350:.

324:.

301:.

171:)

122:2

61:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.