380:

Furthermore, the precision placement machines are capable of handling larger or more irregularly shaped parts such as large package integrated circuits or packaged inductor coils and trimpots. Unlike the rapid placers, precision placers generally do not use turret mounted nozzles and instead rely on a gantry-supported moving head. These precision placers rely upon placement heads with relatively few pickup nozzles. The head sometimes has a laser identifier that scans a reflective marker on the PC board to orient the head to the board. Parts are picked up from tape feeders or trays, scanned by a camera (on some machines), and then placed in the proper position on the board. Some machines also center the parts on the head with two arms that close to center the part; the head then rotates 90 degrees and the arms close again to center the part once more. The margin of error for some components is less than half a millimeter (less than 0.02 inches).

373:, place mainly low-precision, simple package components such as resistors and capacitors. These high-speed P&P machines were built around a single turret design capable of mounting up to two dozen stations. As the turret spins, the stations passing the back of the machine pick up parts from tape feeders mounted on a moving carriage. As the station proceeds around the turret, it passes an optical station that calculates the angle at which the part was picked up, allowing the machine to compensate for drift. Then, as the station reaches the front of the turret, the board is moved into the proper position, the nozzle is spun to put the part in the proper angular orientation, and the part is placed on the board. Typical chip shooters can, under optimal conditions, place up to 53,000 parts per hour, or almost 15 parts per second.

464:

there was a new concept wherein the user could borrow performance during peak periods. There is a big change in the industry approach these days with more focus on software applications for the process. With new applications like POP and wafer placement on substrate the industry is moving beyond conventional component placement. There is a big difference in the needs of SMT users. For many, the high speed machines are not suitable due to cost and speed. With recent changes in the economic climate the requirement for SMT placement becomes focused on the machine's versatility to deal with short runs and fast changeover. This means that lower cost machines with vision systems provide an affordable option for SMT users. There are more users of low end and mid-range machines than the ultra fast placement systems.

278:

539:

to a database for future use. In addition to this, advanced software is available for monitoring the production and interconnect database — of the production floor to that of supply chain — in real-time. ASM provides an optional feature for increasing accuracy while placing LED components on a high end product where in the optical center of the LED is critical rather than the calculated mechanical center based on the component's lead structure. The special camera system measures both physical and optical center and makes the necessary adjustments before placement. It also can acquire the

295:

226:

124:

403:

25:

66:

389:

multi-headed, and multi-gantry machines that could have heads quickly swapped on different modules depending on the product being built to machines with multiple mini turrets capable of placing the whole spectrum of components with theoretical speeds of 136,000 components an hour. The fastest machines can have speeds of up to 200,000 CPH (components per hour).

303:

574:, applied by a glue-dispensing machine that can be incorporated on to the pick and place machine. The glue is added before component placement. It is dispensed by nozzles or by using jet dispensing. Jet dispensing dispenses material by shooting it towards the target, which in this case, is the circuit board.

562:

To minimize the distance the pickup gantry must travel, it is common to have multiple nozzles with separate vertical motion on a single gantry. This can pick up multiple parts with one trip to the feeders. Also, advanced software in the newer generation machines allows different robotic heads to work

463:

Swapping heads onboard placement machines required more inventory of heads and related spare parts for different heads to minimize the downtime. Placement machines have an all-in-one head that can place components ranging from 0.4 mm × 0.2 mm to 50 mm × 40 mm. In addition to this

538:

Some machines have these optical systems on the robot arm and can carry out the optical calculations without losing time, thereby achieving a lower derating factor. The high-end optical systems mounted on the heads can also be used to capture details of the non-standard type components and save them

521:

in the center of the machine. The PCB is clamped, and the nozzles pick up individual components from the feeders/trays, rotate them to the correct orientation and then place them on the appropriate pads on the PCB with high precision. High-end machines can have multiple conveyors to produce multiple

534:

to see if it is damaged or missing (was not picked up), and the inevitable registration errors in pickup are measured and compensated for when the part is placed. For example, if the part was shifted 0.25 mm and rotated 10° when picked up, the pickup head will adjust the placement position to

379:

From the high speed machine, the board transits to a precision placement machine. These pick-and-place machines often use high resolution verification cameras and fine adjustment systems via high precision linear encoders on each axis to place parts more accurately than the high-speed machines.

505:(ICs) are sometimes supplied and arranged in trays which are stacked in a compartment. More commonly used ICs will be provided in tapes rather than trays or sticks. Improvements in feeder technology mean that tape format is becoming the preferred method of presenting parts on an SMT machine.

388:

Due to the huge cost of having two separate machines to place parts, the speed limitations of the chip shooters, and the inflexibility of the machines, the electronic component machine manufacturers abandoned the technique. To overcome these limitations they moved to all-in-one modular,

508:

Early feeder heads were much bulkier, and as a result, it was not designed to be the mobile part of the system. Rather, the PCB itself was mounted on a moving platform that aligned the areas of the board to be populated with the feeder head above.

289:

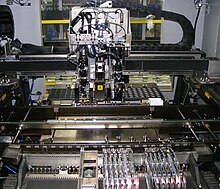

feeders, then the (currently empty) conveyor belt for printed circuit boards, and in back are large parts in a tray. The gantry carries two pickup nozzles, flanking a camera (marked "do not touch" to avoid fingerprints on the

500:

Surface mount components are placed along the front (and often back) faces of the machine. Most components are supplied on paper or plastic tape, in tape reels that are loaded onto feeders mounted to the machine. Larger

530:

The part being carried from the part feeders on either side of the conveyor belt to the PCB, it is photographed from below by using high resolution camera and a lighting system. Its silhouette is

550:

on the PCB to measure its position on the conveyor belt accurately. Two fiducial marks, measured in two dimensions each, usually placed diagonally, let the PCB's orientation and

413:

76:

376:

Because the PCB is moved rather than the turret, only lightweight parts that will not be shaken loose by the violent motion of the PCB can be placed this way.

286:

87:

554:

be measured and compensated for as well. Some machines are also able to measure the PCB shear by measuring a third fiducial mark on the PCB.

734:

492:-like device to allow the cup to be accurately manipulated in three dimensions. Additionally, each nozzle can be rotated independently.

428:

608:

630:

366:

During this time, a typical SMT assembly line employed two different types of pick-and-place (P&P) machines arranged in sequence.

345:, consumer electronics, and industrial, medical, automotive, military and telecommunications equipment. Similar equipment exists for

188:

160:

141:

38:

167:

174:

450:

264:

207:

105:

52:

472:

The placement equipment is part of a larger overall machine that carries out specific programmed steps to create a

156:

432:

329:(PCB). They are used for high speed, high precision placing of a broad range of electronic components (such as

145:

531:

678:

44:

235:

517:

Through the middle of the machine there is a conveyor belt, along which blank PCBs travel, and a PCB

277:

181:

80:

that states a

Knowledge editor's personal feelings or presents an original argument about a topic.

702:

588:

346:

134:

420:

83:

659:

369:

The unpopulated board was fed into a rapid placement machine. These machines, sometimes called

638:

616:

326:

322:

8:

583:

679:"Circuit Assembly Online Magazine - A History of Placement Programming and Optimization"

242:

Please help update this article to reflect recent events or newly available information.

547:

502:

338:

551:

349:

components. This type of equipment is sometimes used to package microchips using the

298:

Tape-and-reel feed mechanism used to load components into a pick-and-place machine

294:

424:

728:

567:

518:

473:

485:

350:

330:

123:

571:

566:

The components may be temporarily adhered to the PCB using the wet

342:

334:

484:

the components onto the PCB. These systems normally use pneumatic

489:

318:

563:

independently of each other to further increase the throughput.

543:

in either single field of view or multiple field of view modes.

540:

281:

Internal details of a two head, gantry style pick-and-place

282:

77:

personal reflection, personal essay, or argumentative essay

311:

Surface-mount technology (SMT) component placement systems

302:

546:

A separate camera on the pick-and-place head photographs

306:

SMD pick-and-place machine (with simulated motion blurs)

522:

same or different kinds of products simultaneously.

431:, and by adding encyclopedic content written from a

148:. Unsourced material may be challenged and removed.

631:"SMT-JUKI, pioneer of "Multi Task Platform JM-20""

238:may be compromised due to out-of-date information

726:

525:

570:itself, or by using small blobs of a separate

704:PICK & PLACE MACHINES: Europlacer 1702 h

53:Learn how and when to remove these messages

341:) onto the PCBs which are in turn used in

451:Learn how and when to remove this message

265:Learn how and when to remove this message

208:Learn how and when to remove this message

106:Learn how and when to remove this message

535:place the part in the correct location.

301:

293:

276:

476:. Several sub-systems work together to

727:

412:contains content that is written like

396:

285:SMT machine. In the foreground are

219:

146:adding citations to reliable sources

117:

59:

18:

735:Printed circuit board manufacturing

13:

495:

361:

14:

746:

321:machines which are used to place

34:This article has multiple issues.

710:, InterElectronic, February 2017

676:

512:

401:

224:

122:

64:

23:

392:

133:needs additional citations for

42:or discuss these issues on the

695:

670:

652:

623:

601:

1:

594:

557:

526:Inspection and visual system

467:

7:

577:

10:

751:

356:

383:

157:"Pick-and-place machine"

589:Insertion mount machine

315:pick-and-place machines

609:"PCB Assembly Example"

307:

299:

291:

86:by rewriting it in an

664:Yamaha Motor Co., Ltd

433:neutral point of view

327:printed circuit board

323:surface-mount devices

305:

297:

280:

683:circuitsassembly.com

142:improve this article

584:Component placement

503:integrated circuits

425:promotional content

339:integrated circuits

427:and inappropriate

313:, commonly called

308:

300:

292:

88:encyclopedic style

75:is written like a

619:on April 1, 2018.

552:thermal expansion

461:

460:

453:

317:or P&Ps, are

275:

274:

267:

257:

256:

218:

217:

210:

192:

116:

115:

108:

57:

742:

719:

718:

717:

715:

709:

699:

693:

692:

690:

689:

674:

668:

667:

656:

650:

649:

647:

646:

637:. Archived from

627:

621:

620:

615:. Archived from

605:

488:, attached to a

456:

449:

445:

442:

436:

414:an advertisement

405:

404:

397:

270:

263:

252:

249:

243:

236:factual accuracy

228:

227:

220:

213:

206:

202:

199:

193:

191:

150:

126:

118:

111:

104:

100:

97:

91:

68:

67:

60:

49:

27:

26:

19:

750:

749:

745:

744:

743:

741:

740:

739:

725:

724:

723:

722:

713:

711:

707:

701:

700:

696:

687:

685:

677:Ford, Michael.

675:

671:

658:

657:

653:

644:

642:

629:

628:

624:

607:

606:

602:

597:

580:

560:

528:

515:

498:

496:Component feeds

470:

457:

446:

440:

437:

418:

406:

402:

395:

386:

364:

362:1980s and 1990s

359:

271:

260:

259:

258:

253:

247:

244:

241:

233:This article's

229:

225:

214:

203:

197:

194:

151:

149:

139:

127:

112:

101:

95:

92:

84:help improve it

81:

69:

65:

28:

24:

17:

16:Robotic machine

12:

11:

5:

748:

738:

737:

721:

720:

694:

669:

651:

635:www.juki.co.jp

622:

599:

598:

596:

593:

592:

591:

586:

579:

576:

559:

556:

548:fiducial marks

527:

524:

514:

511:

497:

494:

480:and correctly

469:

466:

459:

458:

429:external links

409:

407:

400:

394:

391:

385:

382:

363:

360:

358:

355:

325:(SMDs) onto a

273:

272:

255:

254:

232:

230:

223:

216:

215:

130:

128:

121:

114:

113:

72:

70:

63:

58:

32:

31:

29:

22:

15:

9:

6:

4:

3:

2:

747:

736:

733:

732:

730:

706:

705:

698:

684:

680:

673:

665:

661:

655:

641:on 2019-12-08

640:

636:

632:

626:

618:

614:

610:

604:

600:

590:

587:

585:

582:

581:

575:

573:

569:

564:

555:

553:

549:

544:

542:

536:

533:

523:

520:

513:Conveyor belt

510:

506:

504:

493:

491:

487:

483:

479:

475:

465:

455:

452:

444:

434:

430:

426:

422:

416:

415:

410:This section

408:

399:

398:

390:

381:

377:

374:

372:

371:chip shooters

367:

354:

352:

348:

344:

340:

336:

332:

328:

324:

320:

316:

312:

304:

296:

288:

287:tape and reel

284:

279:

269:

266:

251:

248:February 2010

239:

237:

231:

222:

221:

212:

209:

201:

190:

187:

183:

180:

176:

173:

169:

166:

162:

159: –

158:

154:

153:Find sources:

147:

143:

137:

136:

131:This article

129:

125:

120:

119:

110:

107:

99:

96:December 2011

89:

85:

79:

78:

73:This article

71:

62:

61:

56:

54:

47:

46:

41:

40:

35:

30:

21:

20:

712:, retrieved

703:

697:

686:. Retrieved

682:

672:

663:

654:

643:. Retrieved

639:the original

634:

625:

617:the original

612:

603:

568:solder paste

565:

561:

545:

537:

529:

516:

507:

499:

486:suction cups

481:

477:

474:PCB assembly

471:

462:

447:

438:

423:by removing

419:Please help

411:

393:2010 onwards

387:

378:

375:

370:

368:

365:

347:through-hole

314:

310:

309:

261:

245:

234:

204:

195:

185:

178:

171:

164:

152:

140:Please help

135:verification

132:

102:

93:

74:

50:

43:

37:

36:Please help

33:

714:January 27,

688:2016-05-10

645:2019-06-01

595:References

558:Variations

421:improve it

331:capacitors

198:March 2015

168:newspapers

39:improve it

532:inspected

468:Operation

441:June 2016

351:flip chip

343:computers

335:resistors

45:talk page

729:Category

660:"Z:TA-R"

578:See also

572:adhesive

353:method.

490:plotter

478:pick up

357:History

319:robotic

182:scholar

82:Please

541:images

337:, and

290:lens).

184:

177:

170:

163:

155:

708:(PDF)

519:clamp

482:place

384:2000s

189:JSTOR

175:books

716:2023

613:Fuji

283:JUKI

161:news

144:by

731::

681:.

662:.

633:.

611:.

333:,

48:.

691:.

666:.

648:.

454:)

448:(

443:)

439:(

435:.

417:.

268:)

262:(

250:)

246:(

240:.

211:)

205:(

200:)

196:(

186:·

179:·

172:·

165:·

138:.

109:)

103:(

98:)

94:(

90:.

55:)

51:(

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.