166:

287:

214:(after a time window where the impinging atoms will hop around the surface) or reflected. Atoms on the surface may also desorb. Controlling the temperature of the source will control the rate of material impinging on the substrate surface and the temperature of the substrate will affect the rate of hopping or desorption. The term "beam" means that evaporated atoms do not interact with each other or vacuum-chamber gases until they reach the wafer, due to the long

31:

268:). Cold surfaces act as a sink for impurities in the vacuum, so vacuum levels need to be several orders of magnitude better to deposit films under these conditions. In other systems, the wafers on which the crystals are grown may be mounted on a rotating platter, which can be heated to several hundred degrees Celsius during operation.

363:

The Asaro–Tiller–Grinfeld (ATG) instability, also known as the

Grinfeld instability, is an elastic instability often encountered during molecular-beam epitaxy. If there is a mismatch between the lattice sizes of the growing film and the supporting crystal, elastic energy will be accumulated in the

169:

One-atom-thick islands of silver deposited on the (111) surface of palladium by thermal evaporation. The substrate, even though it received a mirror polish and vacuum annealing, appears as a series of terraces. Calibration of the coverage was achieved by tracking the time needed to complete a full

338:

MBE systems can also be modified according to need. Oxygen sources, for example, can be incorporated for depositing oxide materials for advanced electronic, magnetic and optical applications. Here, a molecular beam of an oxidant is used to achieve the desired oxidation state of a multicomponent

229:, allowing precise control of the thickness of each layer, down to a single layer of atoms. Intricate structures of layers of different materials may be fabricated this way. Such control has allowed the development of structures where the electrons can be confined in space, giving

105:

The original ideas of the MBE process were first established by K. G. Günther. Films that he deposited were not epitaxial, but were deposited on glass substrates. With the development of vacuum technology, the MBE process was demonstrated by John Davey and

775:

Mayer, B.; Janker, L.; Loitsch, B.; Treu, J.; Kostenbader, T.; Lichtmannecker, S.; Reichert, T.; Morkötter, S.; Kaniber, M.; Abstreiter, G.; Gies, C.; Koblmüller, G.; Finley, J. J. (2016). "Monolithically

Integrated High-β Nanowire Lasers on Silicon".

696:

Trontl, V. Mikšić; Pletikosić, I.; Milun, M.; Pervan, P.; Lazić, P.; Šokčević, D.; Brako, R. (2005-12-16). "Experimental and ab initio study of the structural and electronic properties of subnanometer thick Ag films on Pd(111)".

364:

growing film. At some critical height, the free energy of the film can be lowered if the film breaks into isolated islands, where the tension can be relaxed laterally. The critical height depends on the

351:

and quantum structures built within them can allow for information processing and the possible integration with on-chip applications for quantum communication and computing. These heterostructure

347:

One of the achievements of molecular-beam epitaxy is the nano-structures that permit the formation of atomically flat and abrupt hetero-interfaces. Most recently, the construction of

165:

162:

levels as other deposition techniques. The absence of carrier gases, as well as the ultra-high vacuum environment, result in the highest achievable purity of the grown films.

978:

Frigeri, P.; Seravalli, L.; Trevisi, G.; Franchi, S. (2011). "3.12: Molecular Beam

Epitaxy: An Overview". In Pallab Bhattacharya; Roberto Fornari; Hiroshi Kamimura (eds.).

295:

1011:

1021:

1041:

252:

In systems where the substrate needs to be cooled, the ultra-high vacuum environment within the growth chamber is maintained by a system of

355:

are only possible to build using advanced MBE techniques, allowing monolithical integration on silicon and picosecond signal processing.

222:

127:

179:

17:

995:

845:

680:

158:(in layers on top of the existing crystal). These deposition rates require proportionally better vacuum to achieve the same

210:

is formed. When evaporation sources such as copper or gold are used, the gaseous elements impinging on the surface may be

298:. The system is designed for growth of monocrystalline semiconductors, semiconducting heterostructures, materials for

225:(RHEED) is often used for monitoring the growth of the crystal layers. A computer controls shutters in front of each

414:

408:

393:

275:. In this case, molecules, rather than atoms, are evaporated and deposited onto the wafer. Other variations include

522:

1051:

1046:

376:

171:

902:

Shchukin, Vitaliy A.; Dieter

Bimberg (1999). "Spontaneous ordering of nanostructures on crystal surfaces".

206:

on the wafer, where they may react with each other. In the example of gallium and arsenic, single-crystal

732:

Mata, Maria de la; Zhou, Xiang; Furtmayr, Florian; Teubert, Jörg; Gradečak, Silvija; Eickhoff, Martin;

934:

820:"Long-term mutual phase locking of picosecond pulse pairs generated by a semiconductor nanowire laser"

942:

904:

733:

280:

74:

388:

199:

114:

GaAs substrates using Günther's method. Major subsequent development of MBE films was enabled by

203:

601:

Davey, John E.; Pankey, Titus (1968). "Epitaxial GaAs films deposited by vacuum evaporation".

857:

466:

444:

424:

276:

272:

195:

58:

951:

913:

866:

785:

749:

706:

610:

557:

475:

246:

50:

8:

242:

34:

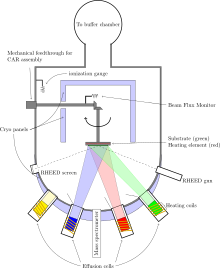

A simple sketch showing the layout of the main chamber in a molecular-beam epitaxy system

955:

917:

870:

789:

753:

710:

614:

561:

479:

987:

890:

583:

499:

365:

226:

115:

737:

991:

894:

882:

841:

801:

676:

649:

575:

503:

491:

151:

143:

587:

983:

959:

921:

874:

793:

757:

714:

668:

645:

618:

565:

483:

434:

207:

797:

419:

352:

257:

517:

925:

718:

403:

398:

215:

111:

54:

963:

819:

672:

286:

271:

Molecular-beam epitaxy (MBE) is also used for the deposition of some types of

1035:

579:

439:

372:

238:

119:

86:

886:

878:

805:

495:

487:

230:

175:

154:(typically less than 3,000 nm per hour) that allows the films to grow

107:

570:

545:

371:

Some applications for this instability have been researched, such as the

299:

234:

155:

147:

761:

429:

211:

139:

62:

935:"Structural properties of self-organized semiconductor nanostructures"

738:"A review of MBE grown 0D, 1D and 2D quantum structures in a nanowire"

622:

1016:

348:

319:

303:

78:

855:

McCray, W. P. (2007). "MBE Deserves a Place in the

History Books".

315:

253:

159:

464:

McCray, W.P. (2007). "MBE Deserves a Place in the

History Books".

327:

311:

307:

191:

187:

123:

46:

636:

Cho, A. Y.; Arthur, J. R. Jr. (1975). "Molecular beam epitaxy".

331:

323:

261:

82:

70:

977:

291:

66:

265:

118:

investigations of kinetic behavior of growth mechanisms and

1026:

1022:

Physics of Thin Films: Molecular Beam

Epitaxy (class notes)

695:

296:

FZU – Institute of

Physics of the Czech Academy of Sciences

94:

1012:

Silicon and germanium nanowires by molecular beam epitaxy

662:

90:

546:"Aufdampfschidhten aus halbleitenden III-V-Verbindungen"

198:

or electron-beam evaporators until they begin to slowly

731:

260:

or cold nitrogen gas to a temperature close to 77

982:. Vol. 3. Amsterdam: Elsevier. pp. 480–522.

901:

774:

150:). The most important aspect of an MBE process is the

30:

932:

237:. Such layers are now a critical part of many modern

1017:

University of Texas MBE group (Primer on MBE growth)

358:

840:(2nd ed.). Upper Saddle River: Prentice Hall.

194:, in ultra-pure form, are heated in separate quasi-

980:Comprehensive Semiconductor Science and Technology

375:of quantum dots. Some communities use the name of

110:who succeeded in growing GaAs epitaxial films on

1033:

302:and other compound material systems containing

178:characteristic of the silver film thickness in

836:Jaeger, Richard C. (2002). "Film Deposition".

1027:CrystalXE: A specialized software in epitaxy

838:Introduction to Microelectronic Fabrication

600:

223:reflection high-energy electron diffraction

128:reflection high-energy electron diffraction

57:. MBE is widely used in the manufacture of

635:

569:

342:

822:. Nature Communications 8 (2017): 15521.

665:RHEED Transmission Mode and Pole Figures

285:

182:(ARPES). Image size is 250 nm by 250 nm.

164:

29:

543:

14:

1034:

933:Stangl, J.; V. Holý; G. Bauer (2004).

854:

835:

463:

368:, mismatch size, and surface tension.

186:In solid source MBE, elements such as

138:Molecular-beam epitaxy takes place in

1042:Physical vapor deposition techniques

663:Gwo-Ching Wang; Toh-Ming Lu (2013).

81:frequencies, and to manufacture the

24:

988:10.1016/B978-0-44-453153-7.00099-7

971:

25:

1063:

1005:

415:Heterojunction bipolar transistor

409:High-electron-mobility transistor

394:Metalorganic vapour phase epitaxy

359:Asaro–Tiller–Grinfeld instability

126:observation of MBE process using

742:Journal of Materials Chemistry C

550:Zeitschrift für Naturforschung A

174:(STM) and from the emergence of

812:

523:National Inventors Hall of Fame

768:

725:

689:

656:

629:

594:

537:

510:

457:

290:Molecular beam epitaxy system

256:and cryopanels, chilled using

13:

1:

829:

544:Günther, K. G. (1958-12-01).

202:. The gaseous elements then

798:10.1021/acs.nanolett.5b03404

650:10.1016/0079-6786(75)90005-9

7:

382:

130:(RHEED) in the late 1960s.

10:

1068:

926:10.1103/RevModPhys.71.1125

734:Fontcuberta i Morral, Anna

719:10.1103/PhysRevB.72.235418

180:photoemission spectroscopy

100:

964:10.1103/RevModPhys.76.725

943:Reviews of Modern Physics

905:Reviews of Modern Physics

673:10.1007/978-1-4614-9287-0

377:Stranski–Krastanov growth

281:chemical vapor deposition

133:

736:; Arbiol, Jordi (2013).

450:

75:field-effect transistors

389:Pulsed laser deposition

27:Crystal growth process

879:10.1038/nnano.2007.121

638:Prog. Solid State Chem

488:10.1038/nnano.2007.121

343:Quantum nanostructures

335:

273:organic semiconductors

196:Knudsen effusion cells

183:

65:. MBE is used to make

39:Molecular-beam epitaxy

35:

18:Molecular beam epitaxy

858:Nature Nanotechnology

571:10.1515/zna-1958-1210

467:Nature Nanotechnology

445:Thermal Laser Epitaxy

425:Quantum cascade laser

289:

247:light-emitting diodes

168:

59:semiconductor devices

33:

1052:Thin film deposition

1047:Semiconductor growth

243:semiconductor lasers

172:tunneling microscopy

51:thin-film deposition

956:2004RvMP...76..725S

918:1999RvMP...71.1125S

871:2007NatNa...2..259M

790:2016NanoL..16..152M

754:2013JMCC....1.4300D

711:2005PhRvB..72w5418T

615:1968JAP....39.1941D

562:1958ZNatA..13.1081G

480:2007NatNa...2..259M

241:devices, including

176:quantum-well states

818:Mayer, B., et al.

762:10.1039/C3TC30556B

336:

279:, which resembles

221:During operation,

184:

36:

997:978-0-444-53153-7

847:978-0-201-44494-0

699:Physical Review B

682:978-1-4614-9286-3

623:10.1063/1.1656467

556:(12): 1081–1089.

144:ultra-high vacuum

16:(Redirected from

1059:

1001:

967:

939:

929:

912:(4): 1125–1171.

898:

851:

823:

816:

810:

809:

772:

766:

765:

729:

723:

722:

693:

687:

686:

660:

654:

653:

633:

627:

626:

609:(4): 1941–1948.

598:

592:

591:

573:

541:

535:

534:

532:

530:

514:

508:

507:

461:

435:Ben G. Streetman

208:gallium arsenide

170:monolayer using

21:

1067:

1066:

1062:

1061:

1060:

1058:

1057:

1056:

1032:

1031:

1008:

998:

974:

972:Further reading

937:

848:

832:

827:

826:

817:

813:

773:

769:

730:

726:

694:

690:

683:

661:

657:

634:

630:

599:

595:

542:

538:

528:

526:

518:"Alfred Y. Cho"

516:

515:

511:

462:

458:

453:

420:Herbert Kroemer

385:

366:Young's modulus

361:

353:nanowire lasers

345:

258:liquid nitrogen

216:mean free paths

152:deposition rate

136:

103:

55:single crystals

28:

23:

22:

15:

12:

11:

5:

1065:

1055:

1054:

1049:

1044:

1030:

1029:

1024:

1019:

1014:

1007:

1006:External links

1004:

1003:

1002:

996:

973:

970:

969:

968:

950:(3): 725–783.

930:

899:

865:(5): 259–261.

852:

846:

831:

828:

825:

824:

811:

784:(1): 152–156.

767:

724:

705:(23): 235418.

688:

681:

655:

628:

593:

536:

509:

474:(5): 259–261.

455:

454:

452:

449:

448:

447:

442:

437:

432:

427:

422:

417:

412:

406:

404:Arthur Gossard

401:

399:Colin P. Flynn

396:

391:

384:

381:

360:

357:

344:

341:

294:Gen II at the

277:gas-source MBE

266:degree Celsius

218:of the atoms.

135:

132:

112:single crystal

102:

99:

26:

9:

6:

4:

3:

2:

1064:

1053:

1050:

1048:

1045:

1043:

1040:

1039:

1037:

1028:

1025:

1023:

1020:

1018:

1015:

1013:

1010:

1009:

999:

993:

989:

985:

981:

976:

975:

965:

961:

957:

953:

949:

945:

944:

936:

931:

927:

923:

919:

915:

911:

907:

906:

900:

896:

892:

888:

884:

880:

876:

872:

868:

864:

860:

859:

853:

849:

843:

839:

834:

833:

821:

815:

807:

803:

799:

795:

791:

787:

783:

779:

771:

763:

759:

755:

751:

747:

743:

739:

735:

728:

720:

716:

712:

708:

704:

700:

692:

684:

678:

674:

670:

666:

659:

651:

647:

643:

639:

632:

624:

620:

616:

612:

608:

604:

603:J. Appl. Phys

597:

589:

585:

581:

577:

572:

567:

563:

559:

555:

551:

547:

540:

525:

524:

519:

513:

505:

501:

497:

493:

489:

485:

481:

477:

473:

469:

468:

460:

456:

446:

443:

441:

440:Wetting layer

438:

436:

433:

431:

428:

426:

423:

421:

418:

416:

413:

410:

407:

405:

402:

400:

397:

395:

392:

390:

387:

386:

380:

378:

374:

373:self-assembly

369:

367:

356:

354:

350:

340:

333:

329:

325:

321:

317:

313:

309:

305:

301:

297:

293:

288:

284:

282:

278:

274:

269:

267:

263:

259:

255:

250:

248:

244:

240:

239:semiconductor

236:

232:

231:quantum wells

228:

224:

219:

217:

213:

209:

205:

201:

197:

193:

189:

181:

177:

173:

167:

163:

161:

157:

153:

149:

145:

141:

131:

129:

125:

121:

120:Alfred Y. Cho

117:

116:J.R. Arthur's

113:

109:

98:

96:

92:

88:

87:optical discs

85:used to read

84:

80:

76:

72:

68:

64:

60:

56:

52:

48:

44:

40:

32:

19:

979:

947:

941:

909:

903:

862:

856:

837:

814:

781:

778:Nano Letters

777:

770:

748:(28): 4300.

745:

741:

727:

702:

698:

691:

664:

658:

641:

637:

631:

606:

602:

596:

553:

549:

539:

527:. Retrieved

521:

512:

471:

465:

459:

370:

362:

346:

337:

270:

251:

235:quantum dots

220:

185:

146:(10–10

137:

108:Titus Pankey

104:

61:, including

42:

38:

37:

644:: 157–192.

300:spintronics

264:(−196

156:epitaxially

140:high vacuum

63:transistors

49:method for

1036:Categories

830:References

430:Solar cell

895:205442147

580:1865-7109

529:17 August

504:205442147

379:for ATG.

349:nanowires

254:cryopumps

89:(such as

79:microwave

887:18654274

806:26618638

588:97543040

496:18654274

383:See also

233:or even

212:adsorbed

204:condense

160:impurity

45:) is an

952:Bibcode

914:Bibcode

867:Bibcode

786:Bibcode

750:Bibcode

707:Bibcode

611:Bibcode

558:Bibcode

476:Bibcode

339:oxide.

262:kelvins

227:furnace

200:sublime

192:arsenic

188:gallium

124:in situ

101:History

71:MOSFETs

47:epitaxy

994:

893:

885:

844:

804:

679:

586:

578:

502:

494:

411:(HEMT)

134:Method

83:lasers

67:diodes

938:(PDF)

891:S2CID

584:S2CID

500:S2CID

451:Notes

292:Veeco

77:) at

73:(MOS

992:ISBN

883:PMID

842:ISBN

802:PMID

677:ISBN

576:ISSN

531:2019

492:PMID

330:and

245:and

190:and

148:Torr

95:DVDs

93:and

69:and

984:doi

960:doi

922:doi

875:doi

794:doi

758:doi

715:doi

669:doi

646:doi

619:doi

566:doi

484:doi

142:or

122:'s

97:).

91:CDs

53:of

43:MBE

1038::

990:.

958:.

948:76

946:.

940:.

920:.

910:71

908:.

889:.

881:.

873:.

861:.

800:.

792:.

782:16

780:.

756:.

744:.

740:.

713:.

703:72

701:.

675:.

667:.

642:10

640:.

617:.

607:39

605:.

582:.

574:.

564:.

554:13

552:.

548:.

520:.

498:.

490:.

482:.

470:.

328:Si

326:,

324:Cu

322:,

320:Mn

318:,

314:,

312:As

310:,

308:Ga

306:,

304:Al

283:.

249:.

1000:.

986::

966:.

962::

954::

928:.

924::

916::

897:.

877::

869::

863:2

850:.

808:.

796::

788::

764:.

760::

752::

746:1

721:.

717::

709::

685:.

671::

652:.

648::

625:.

621::

613::

590:.

568::

560::

533:.

506:.

486::

478::

472:2

334:.

332:C

316:P

41:(

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.