1394:

different oxidizing solutions are aimed at removing the active layer of the polyamide membrane, intended for reuse in applications such as MF or UF. This causes an extended life of approximately two years. A very limited number of reports have mentioned the potential of direct RO reuse. Studies shows that hydraulic permeability, salt rejection, morphological and topographical characteristics, and field emission scanning electron and atomic force microscopy were used in an autopsy investigation conducted. The old RO element's performance resembled that of nanofiltration (NF) membranes, thus it was not surprising to see the permeability increase from 1.0 to 2.1 L m-2 h-1 bar-1 and the drop in NaCl rejection from >90% to 35-50%.

1075:

1068:

1371:

also increased significantly, with some reaching a production capacity exceeding 600,000 m3 of water per day. This means a generation of 14,000 tonnes of membrane waste that is landfilled every year. To increment the lifespan of a membrane, different prevention methods are developed: combining the RO process with the pre-treatment process to improve efficiency; developing anti-fouling techniques; and developing suitable procedures for cleaning the membranes. Pre-treatment processes lower the operating costs because of lesser amounts of chemical additives in the saltwater feed and the lower operational maintenance required for the RO system.

1398:

high rejection, low productivity membranes in the upstream segment of the filtration train, followed by high productivity, low energy membranes in the downstream section. There are two ways in which this design can help: either by decreasing energy use due to decreased pressure needs or by increasing output. Since this concept would reduce the number of modules and pressure vessels needed for a given application, it has the potential to significantly reduce initial investment costs. It is proposed to adapt this original concept, by internally reusing older RO membranes within the same pressure vessel.

866:

1336:. Recent efforts have focused on eliminating membrane fouling by altering the surface chemistry of the membrane material to reduce the likelihood that foulants will adhere to the membrane surface. The exact chemical strategy used is dependent on the chemistry of the solution that is being filtered. For example, membranes used in desalination might be made hydrophobic to resist fouling via accumulation of minerals, while membranes used for biologics might be made hydrophilic to reduce protein/organic accumulation. Modification of surface chemistry via

27:

1060:

179:

1364:

221:

widely used desalination technology because of its simplicity of use and relatively low energy costs compared with distillation, which uses technology based on thermal processes. Note that RO membranes remove water constituents at the ionic level. To do so, most current RO systems use a thin-film composite (TFC), mainly consisting of three layers: a polyamide layer, a polysulphone layer and a polyester layer.

1092:

defined as the consequence of irreversible attachment and growth of bacterial cells on the membrane, is also a common reason for discarding old membranes. A variety of oxidative solutions, cleaning and anti-fouling agents is widely used in desalination plants, and their repetitive and incidental exposure can adversely affect the membranes, generally through the decrease of their rejection efficiencies.

1360:

the past decades to avoid this, such as waste prevention, direct reapplication, and ways of recycling. In this regard, membranes also follows the waste management hierarchy. This means that the most preferable action is to upgrade the design of the membrane which leads to a reduction in use at same application and the least preferred action is a disposal and landfilling

1583:

By recycling RO membranes, we reduce the need for new materials, thereby lessening the environmental footprint. Producing new membranes from petroleum-derived polymers increases GHG emissions. Recycling existing membranes helps mitigate this impact by reusing materials that would otherwise contribute

354:

and modules. Flat sheet membranes are typically built-into submerged vacuum-driven filtration systems which consist of stacks of modules each with several sheets. Filtration mode is outside-in where the water passes through the membrane and is collected in permeate channels. Cleaning can be performed

2438:

Jafarzadeh, E., Kabiri-Samani, A., Mansourzadeh, S., & Bohluly, A. (2021). Experimental modeling of the interaction between waves and submerged flexible mound breakwaters. Proceedings of the

Institution of Mechanical Engineers, Part M: Journal of Engineering for the Maritime Environment, 235(1),

1397:

On the other hand, In order to maximize the overall efficiency of the process, it has lately been common practice to combine RO elements of varying performances within the same pressure vessel, which is called Multi-membrane vessel design. In principle, this innovative hybrid system recommends using

1163:

Since fouling is an important consideration in the design and operation of membrane systems, as it affects pre-treatment needs, cleaning requirements, operating conditions, cost and performance, it should prevent, and if necessary, removed. Optimizing the operation conditions is important to prevent

854:

The operation modes will be affected when the rejected materials and particles in the retentate tend to accumulate in the membrane. At a given TMP, the flux of water through the membrane will decrease and at a given flux, the TMP will increase, reducing the permeability (k). This phenomenon is known

1552:

Separation techniques are employed to recover valuable materials from reverse osmosis membranes, such as polyamide or polysulfone, which can be recycled and reused in the production of new membranes or other products. During the material recovery stage, physical or chemical separation processes are

174:

Ultrafiltration removes particles higher than 0.005-2 μm and operates within a range of 70-700kPa. Ultrafiltration is used for many of the same applications as microfiltration. Some ultrafiltration membranes have also been used to remove dissolved compounds with high molecular weight, such as

1580:

environmental impact associated with producing new membranes from raw materials. RO membranes contain polymers derived from petroleum, a major source of greenhouse gases (GHGs) that contribute to climate change. Additionally, these polymers are not biodegradable, making them challenging to recycle.

1393:

Reuse of RO membranes include the direct reapplication of modules in other separation processes with less stringent specifications. The conversion from the RO TFC membrane to a porous membrane is possible by degrading the dense layer of polyamide. Converting RO membranes by chemical treatment with

1359:

Once the membrane reaches a significant performance decline it is discarded. Discarded RO membrane modules are currently classified worldwide as inert solid waste and are often disposed of in landfills; although they can also be energetically recovered. However, various efforts have been made over

1091:

Fouling can be defined as the potential deposition and accumulation of constituents in the feed stream on the membrane. The loss of RO performance can result from irreversible organic and/or inorganic fouling and chemical degradation of the active membrane layer. Microbiological fouling, generally

892:

where the feed water is pumped with a cross-flow tangential to the membrane and concentrate and permeate streams are obtained. This model implies that for a flow of feed-water across the membrane, only a fraction is converted to permeate product. This parameter is termed "conversion" or "recovery"

81:

This concept of a membrane has been known since the eighteenth century but was used little outside of the laboratory until the end of World War II. Drinking water supplies in Europe had been compromised by the war and membrane filters were used to test for water safety. However, due to the lack of

1370:

RO membranes have some environmental challenges that must be resolved in order to comply with the circular economy principles. Mainly they have a short service life of 5–10 years. Over the past two decades, the number of RO desalination plants has increased by 70%. The size of these RO plants has

1322:

is used to reduce the suspended solids and bacterial content of the feed-water. Flocculants and coagulants are also used, like ferric chloride and aluminium sulphate that, once dissolved in the water, adsorbs materials such as suspended solids, colloids and soluble organic. Metaphysical numerical

1191:

consists of pumping the permeate in the reverse direction through the membrane. Back-washing removes successfully most of the reversible fouling caused by pore blocking. Backwashing can also be enhanced by flushing air through the membrane. Backwashing increase the operating costs since energy is

322:

Spiral wound, where a flexible permeate spacer is placed between two flat membranes sheet. A flexible feed spacer is added and the flat sheets are rolled into a circular configuration. In recent developments, surface patterning techniques have allowed for the integration of permeable feed spacers

220:

Reverse osmosis is commonly used for desalination. As well, RO is commonly used for the removal of dissolved constituents from wastewater remaining after advanced treatment with microfiltration. RO excludes ions but requires high pressures to produce deionized water (850–7000 kPa). RO is the most

1374:

Four types of fouling are found on RO membranes: (i) Inorganic (salt precipitation), (ii) Organic, (iii) Colloidal (particle deposition in the suspension) (iv) Microbiological (bacteria and fungi). Thereby, an appropriate combination of pre-treatment procedures and chemical dosing, as well as an

205:

Likewise, nanofiltration can be used as a pre-treatment before directed reverse osmosis. The main objectives of NF pre-treatment are: (1). minimize particulate and microbial fouling of the RO membranes by removal of turbidity and bacteria, (2) prevent scaling by removal of the hardness ions, (3)

1066:

Filtration leads to an increase in the resistance against the flow. In the case of the dead-end filtration process, the resistance increases according to the thickness of the cake formed on the membrane. As a consequence, the permeability (k) and the flux rapidly decrease, proportionally to the

201:

Nanofiltration is also known as "loose" RO and can reject particles smaller than 0,002 μm. Nanofiltration is used for the removal of selected dissolved constituents from wastewater. NF is primarily developed as a membrane softening process which offers an alternative to chemical softening.

152:

Microfiltration removes particles higher than 0.08-2 μm and operates within a range of 7-100 kPa. Microfiltration is used to remove residual suspended solids (SS), to remove bacteria in order to condition the water for effective disinfection and as a pre-treatment step for reverse osmosis.

1412:

Recycling of materials is a general term that involves physically transforming the material or its components so that they can be regenerated into other useful products. The membrane modules are complex structures, consisting of a number of different polymeric components and, potentially, the

1579:

Implementing a recycling process for RO membranes can incur additional costs, which many companies or organizations may be hesitant to accept. Moreover, recycled membranes often exhibit lower performance and efficiency. However, one significant advantage of recycling is the reduction of the

1556:

Following waste removal, the membrane is tested in a pilot system. During this phase, its performance is carefully analyzed to determine if the output meets the defined parameters and limits. This step is crucial to verify that the membrane operates efficiently and effectively after

1309:. The flux always reduces fouling but it impacts on capital cost since it demands more membrane area. It consists of working at sustainable flux which can be defined as the flux for which the TMP increases gradually at an acceptable rate, such that chemical cleaning is not necessary.

1649:

as a membrane assisted extraction process relies on the gradient in chemical potential. A submerged flexible mound breakwater as a type of using membrane can be employed for wave control in shallow water as an advanced alternative to the conventional rigid submerged designs.

269:

In the membrane field, the term module is used to describe a complete unit composed of the membranes, the pressure support structure, the feed inlet, the outlet permeate and retentate streams, and an overall support structure. The principal types of membrane modules are:

336:

Plate and frame consist of a series of flat membrane sheets and support plates. The water to be treated passes between the membranes of two adjacent membrane assemblies. The plate supports the membranes and provides a channel for the permeate to flow out of the unit

1491:

Polyester materials (such as in the permeate spacer and components of the membrane sheet) are suitable for chemical recycling processes, and hydrolysis is used to reverse the poly-condensation reaction used to make the polymer, with the addition of water to cause

1591:

The increasing demand for RO membranes has led to higher prices. In contrast, the recycling process is generally more cost-effective than purchasing new membranes. This cost advantage can help offset the initial investment required for setting up recycling

883:

where all the feed applied to the membrane passes through it, obtaining a permeate. Since there is no concentrate stream, all the particles are retained in the membrane. Raw feed-water is sometimes used to flush the accumulated material from the membrane

1283:, where the main cleaning agents are sodium hypochlorite (for organic fouling) and citric acid (for inorganic fouling). Every membrane supplier proposes their chemical cleaning recipes, which differ mainly in terms of concentration and methods.

2329:

Rattanakul S (2012) Concentrate and solid waste management in reverse osmosis plants. Master’s Thesis, Engineering in

Environmental Engineering and Management, Asian Institute of Technology School of Environment, Resources and Development,

2224:

De Napoli, Ilaria E.; Zanetti, Elisabetta M.; Fragomeni, Gionata; Giuzio, Ermenegildo; Audenino, Alberto L.; Catapano, Gerardo (2014). "Transport modeling of convection-enhanced hollow fiber membrane bioreactors for therapeutic applications".

1264:. Relaxation and backwashing effectiveness will decrease with operation time as more irreversible fouling accumulates on the membrane surface. Therefore, besides the physical cleaning, chemical cleaning may also be recommended. It includes:

1073:

For cross-flow processes, the deposition of material will continue until the forces of the binding cake to the membrane will be balanced by the forces of the fluid. At this point, cross-flow filtration will reach a steady-state condition

1095:

Fouling can take place through several physicochemical and biological mechanisms which are related to the increased deposition of solid material onto the membrane surface. The main mechanisms by which fouling can occur, are:

1048:

1587:

The demand for RO membranes has surged due to stricter regulations on wastewater discharge. This demand could potentially surpass supply, making the recycling of current RO membranes a viable solution to address this

1212:

consists of pausing the filtration during a period, and thus, there is no need for permeate flow reversion. Relaxation allows filtration to be maintained for a longer period before the chemical cleaning of the

846:

1864:

Alfonsín C, Lebrero R, Estrada JM, et al. (2015) Selection of odour removal technologies in wastewater treatment plants: A guideline based on life cycle assessment. Journal of

Environmental Management 149:

1517:

Waste incinerators can generally operate from 760 °C to 1100 °C and would therefore be capable of removing all combustible material, with the exception of the residual inorganic filler in the fiberglass

1378:

Most plants clean their membranes every week (CEB – Chemically

Enhanced Backwash). In addition to this maintenance cleaning, an intensive cleaning (CIP) is recommended, from two to four times annually.

1340:

deposition can thereby largely reduce fouling. One drawback to using modification techniques is that, in some cases, the flux rate and selectivity of the membrane process can be negatively impacted.

692:

593:

2017:

Mata GK, Bagchi S, Zhang K, Oerther DB, Saikaly PE (October 2017). "Membrane biofilm communities in full-scale membrane bioreactors are not randomly assembled and consist of a core microbiome".

1413:

individual components can be recovered for other purposes. Plastic solid waste treatment and recycling can be separated into mechanical recycling, chemical recycling and energy recovery.

1316:

instead of dead-end. In cross-flow filtration, only a thin layer is deposited on the membrane since not all the particles are retained on the membrane, but the concentrate removes them.

2429:

Coutinho de Paula, E. and Amaral, M.C.S. (already referenced) and Lawler, W., Bradford-Hartke, Z., Cran, M.J., Duke, M., Leslie, G.,Ladewig, B.P and Le-Chen, P. (already referenced).

1797:

Chadha, Utkarsh; Selvaraj, Senthil

Kumaran; Vishak Thanu, S.; Cholapadath, Vishnu; Abraham, Ashesh Mathew; Zaiyan, Mohammed; Manikandan, M; Paramasivam, Velmurugan (6 January 2022).

500:

281:, where membranes are placed inside a support porous tubes, and these tubes are placed together in a cylindrical shell to form the unit module. Tubular devices are primarily used in

1673:

434:

1549:

The first step in post-treatment involves removing all residual waste from the equipment. This ensures that no contaminants remain that could affect the membrane's performance.

751:

1521:

Heat energy can be recovered and used for electricity generation or other heat related processes, and can also offset the greenhouse gas emissions from traditional energy.

1992:

851:

To control the operation of a membrane process, two modes, concerning the flux and the TMP, can be used. These modes are (1) constant TMP, and (2) constant flux.

2339:

Coutinho de Paula, E. and Amaral, M.C.S. (2017). Extending the life-cycle of membranes: A review. Waste

Management & Research, 35(5), 456-470. doi: 10.1177/

249:(MOFs). These membranes can be used for size selective separations such as nanofiltration and reverse osmosis, but also adsorption selective separations such as

1749:

289:

applications because of their ability to handle process streams with high solids and high viscosity properties, as well as for their relative ease of cleaning.

82:

reliability, slow operation, reduced selectivity and elevated costs, membranes were not widely exploited. The first use of membranes on a large scale was with

2085:

Vallero, M. V. G.; Lettinga, G.; Lens, P. N. L. (2005). "High rate sulfate reduction in a submerged anaerobic membrane bioreactor (sambar) at high salinity".

1454:

Main advantage: it displaces virgin plastic production. • Main disadvantages: need to separate all components, large-enough amount of components to be viable.

1451:

Membrane sheets: constructed from a number of different polymers and additives and therefore inherently difficult to accurately and efficiently separate.

1237:

351:

904:

1546:

After applying the chosen technique, it is necessary to carry out a post-treatment process to ensure that the membrane can function normally again.

2112:

I.-J. Kang; C.-H. Lee; K.-J. Kim (2003). "Characteristics of microfiltration membranes in a membrane coupled sequencing batch reactor system".

1877:"Enhancing ultrafiltration membrane permeability and antifouling performance through surface patterning with features resembling feed spacers"

2528:

2291:

Lawler, Will; Bradford-Hartke, Zenah; Cran, Marlene J.; Duke, Mikel; Leslie, Greg; Ladewig, Bradley P.; Le-Clech, Pierre (1 August 2012).

2070:

Sun, Y; Huang, X.; Chen, E; Wen, X. (2004). "dual functional filtration/aeration membrane bioreactor for domestic wastewater treatment".

1553:

conducted to isolate and purify these materials, ensuring their quality and facilitating their reintroduction into the production chain.

759:

1059:

893:(S). The recovery will be reduced if the permeate is further used for maintaining processes operation, usually for membrane cleaning.

278:

865:

1375:

efficient cleaning plan that tackle these types of fouling, should enable the development of an effective anti-fouling technique.

97:

The degree of selectivity of a membrane depends on the membrane pore size. Depending on the pore size, they can be classified as

1296:. Several mechanisms can be carried out to optimize the operating conditions of the membrane to prevent fouling, for instance:

368:

The key elements of any membrane process relate to the influence of the following parameters on the overall permeate flux are:

1653:

However, their overwhelming success in biological systems is not matched by their application. The main reasons for this are:

1715:

623:

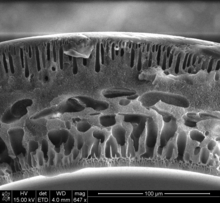

2658:

511:

242:

1981:

Metcalf and Eddy (2004) Wastewater

Engineering, Treatment and Reuse, McGraw-Hill Book Company, New York. Fourth Edition.

2458:

1799:"A review of the function of using carbon nanomaterials in membrane filtration for contaminant removal from wastewater"

1759:

1077:, and thus, the flux will remain constant with time. Therefore, this configuration will demand less periodic cleaning.

1103:

of the feedwater on the membrane which causes a resistance to flow. This build-up can be divided into different types:

206:

lower the operating pressure of the RO process by reducing the feed-water total dissolved solids (TDS) concentration.

2501:

The

Membrane Bioreactor Book: Principles and Applications of Membrane Bioreactors for Water and Wastewater Treatment

309:. The feed can be applied to the inside of the fiber (inside-out flow) or the outside of the fiber (outside-in flow).

1765:

2521:

1951:"Integration of Porous and Permeable Poly(ether sulfone) Feed Spacer onto Membrane Surfaces via Direct 3D Printing"

1164:

fouling. However, if fouling has already taken place, it should be removed by using physical or chemical cleaning.

1233:

high frequency back pulsing resulting in efficient removal of dirt layer. This method is most commonly used for

2678:

1171:

452:

114:

2737:

2389:

2350:

2292:

2252:

Musthafa O.Mavukkandy; Samantha McBride; David

Warsinger; Nadir Dizge; Shadi Hasan; Hassan Arafat (2020).

1993:"Understanding The Critical Relationship Between Reverse Osmosis Recovery Rates And Concentration Factors"

2514:

617:

The rejection (r) could be defined as the number of particles that have been removed from the feedwater.

305:, consists of a bundle of hundreds to thousands of hollow fibers. The entire assembly is inserted into a

246:

2166:

Le-Clech, P.; Fane, A.; Leslie, G.; Childress, A. (June 2005). "MBR focus: the operator's perspective".

1918:"A Critical Assessment of Surface-Patterned Membranes and Their Role in Advancing Membrane Technologies"

393:

2626:

2390:"Current trends and future prospects in the design of seawater reverse osmosis desalination technology"

703:

2727:

1846:

Adam S, Cheng RC, Vuong DX, Wattier KL (2003). "Long Beach's dual-stage NF beats single-stage SWRO".

20:

2134:

1621:

Equipment simplicity and modularity, which facilitates the incorporation of more efficient membranes

2732:

2621:

38:

is a selective barrier; it allows some things to pass through but stops others. Such things may be

1476:

Break down the polymers into smaller molecules, using depolymerisation and degradation techniques.

1117:, which consists of solid material that it has been attached to the interior surface of the pores.

1277:, that is, a low concentration of chemical cleaning agent is added during the backwashing period.

2293:"Towards new opportunities for reuse, recycling and disposal of used reverse osmosis membranes"

2251:

2129:

117:

or heterogeneous structure. Membranes can be neutral or charged, and particle transport can be

2588:

2573:

1129:

takes places when the solid matter in the feed is larger than the pore sizes of the membrane.

888:

302:

183:

2349:

Ould

Mohamedou, E.; Penate Suarez, D. B.; Vince, F.; Jaouen, P.; Pontie, M. (1 April 2010).

1607:

Distinct features of membranes are responsible for the interest in using them as additional

2401:

2362:

2304:

2121:

2026:

1888:

1810:

1634:

229:

An emerging class of membranes rely on nanostructure channels to separate materials at the

94:, are employed in large plants and, today, several experienced companies serve the market.

2197:; Fane, Tony A.G. (2006). "Fouling in membrane bioreactors used in wastewater treatment".

1485:

Advantage: that heterogeneous polymers with limited use of pre-treatment can be processed.

8:

2547:

2485:

1626:

306:

157:

51:

2405:

2366:

2308:

2125:

2030:

1892:

1814:

1524:

If not properly controlled, can emit greenhouse gases as well as other harmful products.

1253:

Recent studies have assessed to combine relaxation and backwashing for optimum results,.

257:

and alcohols from water that traditionally have required expensive and energy intensive

2567:

2537:

2273:

1828:

1642:

47:

2179:

2143:

1123:

occurs when the particles of the feed-water become stuck in the pores of the membrane.

2555:

2454:

2277:

2147:

2052:

1832:

1755:

1711:

234:

122:

58:(outer coverings of cells or organelles that allow passage of certain constituents);

1439:

Grinding of the polymeric materials into suitable size (loss of 5% of the material).

2722:

2598:

2563:

2484:

Paula van den Brink, Frank Vergeldt, Henk Van As, Arie Zwijnenburg, Hardy Temmink,

2409:

2370:

2312:

2265:

2234:

2206:

2175:

2139:

2094:

2042:

2034:

1962:

1929:

1896:

1818:

1618:

Do not demand adsorbents or solvents, which may be expensive or difficult to handle

1354:

1234:

1086:

857:

375:

The operational driving force per unit membrane area (Trans Membrane Pressure, TMP)

323:

directly into the membrane, giving rise to the concept of an integrated membrane

118:

59:

26:

1043:{\displaystyle S={Q_{permeate} \over Q_{feed}}=1-{Q_{concentrate} \over Q_{feed}}}

2269:

2238:

2210:

2098:

2038:

1630:

286:

282:

215:

169:

147:

110:

102:

98:

91:

87:

83:

67:

63:

2413:

2374:

2316:

1934:

1917:

1901:

1876:

1823:

1798:

1608:

387:

The total permeate flow from a membrane system is given by following equation:

196:

175:

proteins and carbohydrates. Also, they can remove viruses and some endotoxins.

160:(MBR) which combine microfiltration and a bioreactor for biological treatment.

106:

75:

2488:. "Potential of mechanical cleaning of membranes from a membrane bioreactor".

1448:

Membrane components than can be recycled (thermoplastics): PP, polyester, etc.

16:

Thin, film-like structure separating two fluids, acting as a selective barrier

2716:

2699:

2653:

1686:

1638:

178:

130:

55:

1967:

1950:

1751:

Membranes on Polyolefins Plants Vent Recovery, Improvement Economics Program

1611:

for separation processes in fluid processes. Some advantages noted include:

2683:

2663:

2151:

2056:

1646:

258:

2673:

2668:

2645:

2583:

2253:

2047:

505:

The trans-membrane pressure (TMP) is given by the following expression:

2693:

2616:

2194:

1150:

71:

46:, or other small particles. Membranes can be generally classified into

19:

This article is about selective barrier membranes. For other uses, see

2348:

90:

technologies. Since the 1980s, these separation processes, along with

2611:

2606:

2506:

2453:(2nd ed.). München: Elsevier, Spektrum Akad. Verl. p. 279.

1796:

1407:

1337:

1323:

models have been introduced in order to optimize transport phenomena

186:, with characteristic outer (top) and inner (bottom) layers of pores.

1615:

Less energy-intensive, since they do not require major phase changes

1436:

Previous washing to avoid property deterioration during the process.

1192:

required to achieve a pressure suitable for permeate flow reversion.

2254:"Thin film deposition techniques for polymeric membranes– A review"

1488:

Disadvantage: more expensive and complex than mechanical recycling.

446:

The permeability (k) of a membrane is given by the next equation:

238:

230:

126:

39:

1363:

841:{\displaystyle Q_{f}\cdot C_{f}=Q_{p}\cdot C_{p}+Q_{c}\cdot C_{c}}

2636:

2578:

1657:

1482:

Chemical recycling processes are tailored for specific materials.

1170:

techniques for membrane include membrane relaxation and membrane

113:(RO) membranes. Membranes can also be of various thickness, with

1777:

1775:

876:

Two operation modes for membranes can be used. These modes are:

2451:

Bioprozesstechnik : Einführung in die Bioverfahrenstechnik

2223:

1744:

1742:

861:, and it is the main limitation to membrane process operation.

254:

250:

2388:

Peñate, Baltasar; García-Rodríguez, Lourdes (4 January 2012).

1445:

Melting and extrusion process (loss of 10 % of material).

2290:

2069:

1772:

1625:

Membranes are used with pressure as the driving processes in

1388:

1154:

takes place when microorganisms grow on the membrane surface.

2111:

1739:

1514:

Volume reduction by 90–99%, reducing the strain on landfill.

378:

The fouling and subsequent cleaning of the membrane surface.

133:, chemical or electrical gradients of the membrane process.

62:, which cover a cell nucleus; and tissue membranes, such as

2481:. McGraw-Hill Book Company, New York. Fourth Edition, 2004.

2165:

1664:

1433:

A first separation of the components of interest is needed.

1645:

along a concentration gradient is the driving force. Also

871:

1781:

43:

1567:

2387:

2016:

687:{\displaystyle r={(C_{f}-C_{p}) \over C_{f}}\cdot 100}

2072:

Proceedings of Water Environment- Membrane Technology

1990:

1845:

1784:

Small and Decentralized Wastewater Management Systems

907:

762:

706:

626:

588:{\displaystyle P_{TMP}={(P_{f}+P_{c}) \over 2}-P_{p}}

514:

455:

396:

136:

70:. Synthetic membranes are made by humans for use in

443:is the water flux rate and A is the membrane area

2084:

2351:"New lives for old reverse osmosis (RO) membranes"

1042:

840:

745:

686:

587:

494:

428:

1158:

2714:

2192:

1735:. Lancaster, PA.: echonomic Publishing Co., Inc.

1997:American Membrane Technology Association (AMTA)

382:

1705:

697:The corresponding mass balance equations are:

2522:

2425:

2423:

363:

1948:

1915:

1874:

1733:Ultrafiltration and Microfiltration Handbook

1343:

1140:Formation of chemical precipitates known as

439:Where Qp is the permeate stream flowrate , F

2479:Wastewater Engineering, Treatment and Reuse

1479:Cannot be used with contaminated materials.

224:

2546:Mechanisms for chemical transport through

2529:

2515:

2442:

2420:

1730:

1058:

864:

264:

30:Schematic of size-based membrane exclusion

2133:

2046:

1966:

1933:

1900:

1822:

1710:(2 ed.). Kluwer Academic: Springer.

1362:

1070:and, thus, requiring periodic cleaning.

177:

25:

1991:Harold G. Fravel, Jr. (28 April 2014).

1708:Basic principles of membrane technology

1416:

872:Dead-end and cross-flow operation modes

495:{\displaystyle k={F_{w} \over P_{TMP}}}

209:

163:

141:

2715:

2536:

2448:

610:the pressure of concentrate stream ; P

190:

2510:

1949:Ibrahim, Yazan; Hilal, Nidal (2024).

1916:Ibrahim, Yazan; Hilal, Nidal (2023).

1875:Ibrahim, Yazan; Hilal, Nidal (2023).

1786:. New York: McGraw-Hill Book Company.

1422:Mechanical recycling characteristics:

606:the inlet pressure of feed stream ; P

2659:Non-specific, adsorptive pinocytosis

1568:Advantages of RO membranes recycling

245:(PIMS), and membranes incorporating

1670:Lack of solvent resistant materials

1660:– the decrease of function with use

1503:Energetic recovery characteristics:

1465:Chemical recycling characteristics:

1348:

243:polymers of intrinsic microporosity

156:Relatively recent developments are

125:. The latter can be facilitated by

13:

1782:Crites and Tchobangiglous (1998).

1294:Optimizing the operation condition

614:the pressure if permeate stream .

602:is the trans-membrane pressure , P

429:{\displaystyle Q_{p}=F_{w}\cdot A}

137:Membrane processes classifications

14:

2749:

1955:ACS Applied Engineering Materials

746:{\displaystyle Q_{f}=Q_{p}+Q_{c}}

1148:Colonization of the membrane or

2471:

2432:

2381:

2342:

2333:

2323:

2284:

2245:

2217:

2186:

2159:

2105:

2078:

2063:

2010:

1984:

1975:

1942:

1602:

1320:Pre-treatment of the feed water

241:membranes, membranes made from

182:The wall of an ultrafiltration

54:. Biological membranes include

1909:

1868:

1858:

1839:

1790:

1724:

1699:

1159:Fouling control and mitigation

662:

636:

563:

537:

355:by aeration, backwash and CIP.

1:

2679:Receptor-mediated endocytosis

2180:10.1016/S0015-1882(05)70556-5

2144:10.1016/s0043-1354(02)00534-1

1692:

1584:to environmental degradation.

372:The membrane permeability (k)

2270:10.1016/j.memsci.2020.118258

2239:10.1016/j.memsci.2014.08.026

2211:10.1016/j.memsci.2006.08.019

2099:10.1016/j.memsci.2004.12.032

2039:10.1016/j.watres.2017.06.052

383:Flux, pressure, permeability

7:

2490:Journal of membrane science

2414:10.1016/j.desal.2011.09.010

2375:10.1016/j.desal.2009.11.032

2317:10.1016/j.desal.2012.05.030

2258:Journal of Membrane Science

2227:Journal of Membrane Science

2199:Journal of Membrane Science

2168:Filtration & Separation

2087:Journal of Membrane Science

1935:10.1021/acsestwater.3c00564

1680:

1442:Possible posterior washing.

10:

2754:

2627:Secondary active transport

1902:10.1038/s41545-023-00277-3

1803:Materials Research Express

1405:

1401:

1386:

1352:

1275:Chemical enhanced backwash

1084:

1080:

364:Membrane process operation

213:

194:

167:

145:

18:

2692:

2644:

2635:

2597:

2554:

2544:

1344:Recycling of RO membranes

235:carbon nanotube membranes

21:Membrane (disambiguation)

2622:Primary active transport

1848:Desalination Water Reuse

1824:10.1088/2053-1591/ac48b8

1382:

1127:Gel/cake layer formation

1101:Build-up of constituents

247:metal–organic frameworks

225:Nanostructured membranes

2486:Mark C.M.van Loosdrecht

1968:10.1021/acsaenm.4c00086

1706:Mulder, Marcel (1996).

265:Membrane configurations

2449:Chmiel, Horst (2006).

1367:

1044:

842:

747:

688:

589:

496:

430:

350:Ceramic and polymeric

187:

74:and industry (such as

31:

2574:Facilitated diffusion

1366:

1314:cross-flow filtration

1067:solids concentration

1045:

889:Cross-flow filtration

843:

748:

689:

590:

497:

431:

303:Hollow fiber membrane

233:scale. These include

184:hollow fiber membrane

181:

29:

2548:biological membranes

1417:Techniques recycling

905:

760:

704:

624:

512:

453:

394:

352:flat sheet membranes

210:Reverse osmosis (RO)

164:Ultrafiltration (UF)

158:membrane bioreactors

142:Microfiltration (MF)

52:biological membranes

2738:Membrane technology

2406:2012Desal.284....1P

2367:2010Desal.253...62O

2309:2012Desal.299..103L

2126:2003WatRe..37.1192K

2031:2017WatRe.123..124M

1893:2023npjCW...6...60I

1815:2022MRE.....9a2003C

1731:Cheryan, M (1998).

1627:membrane filtration

1334:Membrane alteration

1210:Membrane relaxation

881:Dead-end filtration

191:Nanofiltration (NF)

48:synthetic membranes

2568:mediated transport

2538:Membrane transport

2477:Metcalf and Eddy.

2193:Le-Clech, Pierre;

1922:ACS ES&T Water

1754:. Intratec. 2012.

1643:chemical potential

1629:of solutes and in

1368:

1040:

838:

743:

684:

585:

492:

426:

188:

32:

2710:

2709:

2706:

2705:

2556:Passive transport

2503:. Elsevier, 2010.

1928:(12): 3807–3834.

1717:978-0-7923-4248-9

1667:per membrane area

1281:Chemical cleaning

1262:Chemical cleaning

1235:ceramic membranes

1168:Physical cleaning

1038:

966:

676:

570:

490:

60:nuclear membranes

2745:

2728:Water technology

2642:

2641:

2599:Active transport

2564:Simple diffusion

2531:

2524:

2517:

2508:

2507:

2496:, 2013. 259-267.

2465:

2464:

2446:

2440:

2436:

2430:

2427:

2418:

2417:

2385:

2379:

2378:

2346:

2340:

2337:

2331:

2327:

2321:

2320:

2288:

2282:

2281:

2249:

2243:

2242:

2221:

2215:

2214:

2190:

2184:

2183:

2163:

2157:

2155:

2137:

2120:(5): 1192–1197.

2109:

2103:

2102:

2093:(1–2): 217–232.

2082:

2076:

2075:

2067:

2061:

2060:

2050:

2014:

2008:

2007:

2005:

2003:

1988:

1982:

1979:

1973:

1972:

1970:

1961:(4): 1094–1109.

1946:

1940:

1939:

1937:

1913:

1907:

1906:

1904:

1872:

1866:

1862:

1856:

1855:

1843:

1837:

1836:

1826:

1794:

1788:

1787:

1779:

1770:

1769:

1764:. Archived from

1746:

1737:

1736:

1728:

1722:

1721:

1703:

1355:Waste prevention

1349:Waste prevention

1087:Membrane fouling

1062:

1049:

1047:

1046:

1041:

1039:

1037:

1036:

1018:

1017:

978:

967:

965:

964:

946:

945:

915:

868:

847:

845:

844:

839:

837:

836:

824:

823:

811:

810:

798:

797:

785:

784:

772:

771:

752:

750:

749:

744:

742:

741:

729:

728:

716:

715:

693:

691:

690:

685:

677:

675:

674:

665:

661:

660:

648:

647:

634:

594:

592:

591:

586:

584:

583:

571:

566:

562:

561:

549:

548:

535:

530:

529:

501:

499:

498:

493:

491:

489:

488:

473:

472:

463:

435:

433:

432:

427:

419:

418:

406:

405:

2753:

2752:

2748:

2747:

2746:

2744:

2743:

2742:

2733:Water treatment

2713:

2712:

2711:

2702:

2688:

2631:

2593:

2550:

2540:

2535:

2474:

2469:

2468:

2461:

2447:

2443:

2437:

2433:

2428:

2421:

2386:

2382:

2347:

2343:

2338:

2334:

2328:

2324:

2289:

2285:

2264:(1–2): 118258.

2250:

2246:

2222:

2218:

2191:

2187:

2164:

2160:

2135:10.1.1.464.9473

2110:

2106:

2083:

2079:

2068:

2064:

2015:

2011:

2001:

1999:

1989:

1985:

1980:

1976:

1947:

1943:

1914:

1910:

1881:npj Clean Water

1873:

1869:

1863:

1859:

1844:

1840:

1795:

1791:

1780:

1773:

1762:

1748:

1747:

1740:

1729:

1725:

1718:

1704:

1700:

1695:

1683:

1631:reverse osmosis

1605:

1570:

1419:

1410:

1404:

1391:

1385:

1357:

1351:

1346:

1161:

1089:

1083:

1023:

1019:

983:

979:

977:

951:

947:

920:

916:

914:

906:

903:

902:

874:

832:

828:

819:

815:

806:

802:

793:

789:

780:

776:

767:

763:

761:

758:

757:

737:

733:

724:

720:

711:

707:

705:

702:

701:

670:

666:

656:

652:

643:

639:

635:

633:

625:

622:

621:

613:

609:

605:

601:

579:

575:

557:

553:

544:

540:

536:

534:

519:

515:

513:

510:

509:

478:

474:

468:

464:

462:

454:

451:

450:

442:

414:

410:

401:

397:

395:

392:

391:

385:

366:

307:pressure vessel

287:ultrafiltration

267:

227:

218:

216:Reverse osmosis

212:

199:

193:

172:

170:Ultrafiltration

166:

150:

148:Microfiltration

144:

139:

111:reverse osmosis

103:ultrafiltration

99:microfiltration

92:electrodialysis

88:ultrafiltration

84:microfiltration

76:chemical plants

24:

17:

12:

11:

5:

2751:

2741:

2740:

2735:

2730:

2725:

2708:

2707:

2704:

2703:

2698:

2696:

2690:

2689:

2687:

2686:

2681:

2676:

2671:

2666:

2661:

2656:

2650:

2648:

2639:

2633:

2632:

2630:

2629:

2624:

2619:

2614:

2609:

2603:

2601:

2595:

2594:

2592:

2591:

2586:

2581:

2576:

2571:

2560:

2558:

2552:

2551:

2545:

2542:

2541:

2534:

2533:

2526:

2519:

2511:

2505:

2504:

2497:

2482:

2473:

2470:

2467:

2466:

2460:978-3827416070

2459:

2441:

2431:

2419:

2380:

2361:(1–3): 62–70.

2341:

2332:

2322:

2283:

2244:

2216:

2205:(1–2): 17–53.

2185:

2158:

2104:

2077:

2062:

2025:(1): 124–133.

2019:Water Research

2009:

1983:

1974:

1941:

1908:

1867:

1857:

1838:

1789:

1771:

1768:on 2013-05-13.

1761:978-0615678917

1760:

1738:

1723:

1716:

1697:

1696:

1694:

1691:

1690:

1689:

1682:

1679:

1678:

1677:

1671:

1668:

1661:

1623:

1622:

1619:

1616:

1609:unit operation

1604:

1601:

1600:

1599:

1598:

1597:

1596:

1595:

1594:

1593:

1589:

1585:

1581:

1569:

1566:

1565:

1564:

1563:

1562:

1561:

1560:

1559:

1558:

1554:

1550:

1547:

1535:Post-treatment

1532:

1531:

1530:

1529:

1528:

1527:

1526:

1525:

1522:

1519:

1515:

1500:

1499:

1498:

1497:

1496:

1495:

1494:

1493:

1492:decomposition.

1489:

1486:

1483:

1480:

1477:

1462:

1461:

1460:

1459:

1458:

1457:

1456:

1455:

1452:

1449:

1446:

1443:

1440:

1437:

1434:

1418:

1415:

1406:Main article:

1403:

1400:

1387:Main article:

1384:

1381:

1353:Main article:

1350:

1347:

1345:

1342:

1331:

1330:

1329:

1328:

1327:

1326:

1325:

1324:

1317:

1310:

1291:

1290:

1289:

1288:

1287:

1286:

1285:

1284:

1278:

1259:

1258:

1257:

1256:

1255:

1254:

1246:

1245:

1244:

1243:

1242:

1241:

1240:

1239:

1221:

1220:

1219:

1218:

1217:

1216:

1215:

1214:

1200:

1199:

1198:

1197:

1196:

1195:

1194:

1193:

1160:

1157:

1156:

1155:

1146:

1137:

1136:

1135:

1134:

1133:

1132:

1131:

1130:

1124:

1118:

1115:Pore narrowing

1105:

1104:

1085:Main article:

1082:

1079:

1064:

1063:

1055:

1054:

1053:

1052:

1051:

1050:

1035:

1032:

1029:

1026:

1022:

1016:

1013:

1010:

1007:

1004:

1001:

998:

995:

992:

989:

986:

982:

976:

973:

970:

963:

960:

957:

954:

950:

944:

941:

938:

935:

932:

929:

926:

923:

919:

913:

910:

895:

894:

885:

873:

870:

849:

848:

835:

831:

827:

822:

818:

814:

809:

805:

801:

796:

792:

788:

783:

779:

775:

770:

766:

754:

753:

740:

736:

732:

727:

723:

719:

714:

710:

695:

694:

683:

680:

673:

669:

664:

659:

655:

651:

646:

642:

638:

632:

629:

611:

607:

603:

599:

596:

595:

582:

578:

574:

569:

565:

560:

556:

552:

547:

543:

539:

533:

528:

525:

522:

518:

503:

502:

487:

484:

481:

477:

471:

467:

461:

458:

440:

437:

436:

425:

422:

417:

413:

409:

404:

400:

384:

381:

380:

379:

376:

373:

365:

362:

361:

360:

359:

358:

357:

356:

343:

342:

341:

340:

339:

338:

329:

328:

327:

326:

325:

324:

315:

314:

313:

312:

311:

310:

295:

294:

293:

292:

291:

290:

266:

263:

226:

223:

214:Main article:

211:

208:

197:Nanofiltration

195:Main article:

192:

189:

168:Main article:

165:

162:

146:Main article:

143:

140:

138:

135:

107:nanofiltration

56:cell membranes

15:

9:

6:

4:

3:

2:

2750:

2739:

2736:

2734:

2731:

2729:

2726:

2724:

2721:

2720:

2718:

2701:

2700:Degranulation

2697:

2695:

2691:

2685:

2682:

2680:

2677:

2675:

2672:

2670:

2667:

2665:

2662:

2660:

2657:

2655:

2654:Efferocytosis

2652:

2651:

2649:

2647:

2643:

2640:

2638:

2634:

2628:

2625:

2623:

2620:

2618:

2615:

2613:

2610:

2608:

2605:

2604:

2602:

2600:

2596:

2590:

2587:

2585:

2582:

2580:

2577:

2575:

2572:

2569:

2565:

2562:

2561:

2559:

2557:

2553:

2549:

2543:

2539:

2532:

2527:

2525:

2520:

2518:

2513:

2512:

2509:

2502:

2498:

2495:

2491:

2487:

2483:

2480:

2476:

2475:

2462:

2456:

2452:

2445:

2435:

2426:

2424:

2415:

2411:

2407:

2403:

2399:

2395:

2391:

2384:

2376:

2372:

2368:

2364:

2360:

2356:

2352:

2345:

2336:

2326:

2318:

2314:

2310:

2306:

2302:

2298:

2294:

2287:

2279:

2275:

2271:

2267:

2263:

2259:

2255:

2248:

2240:

2236:

2232:

2228:

2220:

2212:

2208:

2204:

2200:

2196:

2189:

2181:

2177:

2173:

2169:

2162:

2153:

2149:

2145:

2141:

2136:

2131:

2127:

2123:

2119:

2115:

2108:

2100:

2096:

2092:

2088:

2081:

2073:

2066:

2058:

2054:

2049:

2044:

2040:

2036:

2032:

2028:

2024:

2020:

2013:

1998:

1994:

1987:

1978:

1969:

1964:

1960:

1956:

1952:

1945:

1936:

1931:

1927:

1923:

1919:

1912:

1903:

1898:

1894:

1890:

1886:

1882:

1878:

1871:

1861:

1853:

1849:

1842:

1834:

1830:

1825:

1820:

1816:

1812:

1809:(1): 012003.

1808:

1804:

1800:

1793:

1785:

1778:

1776:

1767:

1763:

1757:

1753:

1752:

1745:

1743:

1734:

1727:

1719:

1713:

1709:

1702:

1698:

1688:

1687:Collodion bag

1685:

1684:

1675:

1672:

1669:

1666:

1662:

1659:

1656:

1655:

1654:

1651:

1648:

1644:

1640:

1639:pervaporation

1636:

1632:

1628:

1620:

1617:

1614:

1613:

1612:

1610:

1590:

1586:

1582:

1578:

1577:

1576:

1575:

1574:

1573:

1572:

1571:

1555:

1551:

1548:

1545:

1544:

1543:

1542:

1541:

1540:

1539:

1538:

1537:

1536:

1523:

1520:

1516:

1513:

1512:

1511:

1510:

1509:

1508:

1507:

1506:

1505:

1504:

1490:

1487:

1484:

1481:

1478:

1475:

1474:

1473:

1472:

1471:

1470:

1469:

1468:

1467:

1466:

1453:

1450:

1447:

1444:

1441:

1438:

1435:

1432:

1431:

1430:

1429:

1428:

1427:

1426:

1425:

1424:

1423:

1414:

1409:

1399:

1395:

1390:

1380:

1376:

1372:

1365:

1361:

1356:

1341:

1339:

1335:

1321:

1318:

1315:

1311:

1308:

1307:Reducing flux

1305:

1304:

1303:

1302:

1301:

1300:

1299:

1298:

1297:

1295:

1282:

1279:

1276:

1273:

1272:

1271:

1270:

1269:

1268:

1267:

1266:

1265:

1263:

1252:

1251:

1250:

1249:

1248:

1247:

1238:

1236:

1232:

1229:

1228:

1227:

1226:

1225:

1224:

1223:

1222:

1211:

1208:

1207:

1206:

1205:

1204:

1203:

1202:

1201:

1190:

1189:back-flushing

1186:

1183:

1182:

1181:

1180:

1179:

1178:

1177:

1176:

1175:

1173:

1169:

1165:

1153:

1152:

1147:

1145:

1144:

1139:

1138:

1128:

1125:

1122:

1121:Pore blocking

1119:

1116:

1113:

1112:

1111:

1110:

1109:

1108:

1107:

1106:

1102:

1099:

1098:

1097:

1093:

1088:

1078:

1076:

1071:

1069:

1061:

1057:

1056:

1033:

1030:

1027:

1024:

1020:

1014:

1011:

1008:

1005:

1002:

999:

996:

993:

990:

987:

984:

980:

974:

971:

968:

961:

958:

955:

952:

948:

942:

939:

936:

933:

930:

927:

924:

921:

917:

911:

908:

901:

900:

899:

898:

897:

896:

891:

890:

886:

882:

879:

878:

877:

869:

867:

862:

860:

859:

852:

833:

829:

825:

820:

816:

812:

807:

803:

799:

794:

790:

786:

781:

777:

773:

768:

764:

756:

755:

738:

734:

730:

725:

721:

717:

712:

708:

700:

699:

698:

681:

678:

671:

667:

657:

653:

649:

644:

640:

630:

627:

620:

619:

618:

615:

580:

576:

572:

567:

558:

554:

550:

545:

541:

531:

526:

523:

520:

516:

508:

507:

506:

485:

482:

479:

475:

469:

465:

459:

456:

449:

448:

447:

444:

423:

420:

415:

411:

407:

402:

398:

390:

389:

388:

377:

374:

371:

370:

369:

353:

349:

348:

347:

346:

345:

344:

335:

334:

333:

332:

331:

330:

321:

320:

319:

318:

317:

316:

308:

304:

301:

300:

299:

298:

297:

296:

288:

284:

280:

277:

276:

275:

274:

273:

272:

271:

262:

260:

256:

252:

248:

244:

240:

236:

232:

222:

217:

207:

203:

198:

185:

180:

176:

171:

161:

159:

154:

149:

134:

132:

131:concentration

128:

124:

120:

116:

112:

108:

104:

100:

95:

93:

89:

85:

79:

77:

73:

69:

65:

61:

57:

53:

49:

45:

41:

37:

28:

22:

2684:Transcytosis

2664:Phagocytosis

2500:

2499:Simon Judd.

2493:

2489:

2478:

2472:Bibliography

2450:

2444:

2434:

2397:

2394:Desalination

2393:

2383:

2358:

2355:Desalination

2354:

2344:

2335:

2325:

2300:

2297:Desalination

2296:

2286:

2261:

2257:

2247:

2230:

2226:

2219:

2202:

2198:

2188:

2174:(5): 20–23.

2171:

2167:

2161:

2117:

2113:

2107:

2090:

2086:

2080:

2071:

2065:

2048:10754/625148

2022:

2018:

2012:

2000:. Retrieved

1996:

1986:

1977:

1958:

1954:

1944:

1925:

1921:

1911:

1884:

1880:

1870:

1860:

1851:

1847:

1841:

1806:

1802:

1792:

1783:

1766:the original

1750:

1732:

1726:

1707:

1701:

1663:Prohibitive

1652:

1647:perstraction

1624:

1606:

1603:Applications

1534:

1533:

1502:

1501:

1464:

1463:

1421:

1420:

1411:

1396:

1392:

1377:

1373:

1369:

1358:

1333:

1332:

1319:

1313:

1306:

1293:

1292:

1280:

1274:

1261:

1260:

1231:Back pulsing

1230:

1209:

1188:

1185:Back-washing

1184:

1167:

1166:

1162:

1149:

1142:

1141:

1126:

1120:

1114:

1100:

1094:

1090:

1072:

1065:

887:

880:

875:

863:

856:

853:

850:

696:

616:

597:

504:

445:

438:

386:

367:

268:

259:distillation

228:

219:

204:

200:

173:

155:

151:

96:

80:

72:laboratories

35:

33:

2674:Potocytosis

2669:Pinocytosis

2646:Endocytosis

2303:: 103–112.

2233:: 347–361.

2195:Chen, Vicki

1592:operations.

1172:backwashing

115:homogeneous

2717:Categories

2694:Exocytosis

2617:Antiporter

1693:References

1588:challenge.

1557:treatment.

1151:biofouling

2612:Symporter

2607:Uniporter

2330:Thailand.

2278:219428325

2130:CiteSeerX

2114:Water Res

1887:(1): 60.

1833:245810763

1408:Recycling

1338:thin film

1213:membrane.

975:−

826:⋅

800:⋅

774:⋅

679:⋅

650:−

573:−

421:⋅

255:paraffins

231:molecular

109:(NF) and

40:molecules

2589:Carriers

2584:Channels

2566:(or non-

2439:127-141.

2152:12553996

2057:28658633

1854:: 18–21.

1681:See also

1674:Scale-up

1635:dialysis

884:surface.

239:graphene

127:pressure

36:membrane

2723:Fouling

2637:Cytosis

2579:Osmosis

2402:Bibcode

2400:: 1–8.

2363:Bibcode

2305:Bibcode

2122:Bibcode

2027:Bibcode

1889:Bibcode

1811:Bibcode

1658:Fouling

1518:casing.

1402:Recycle

1143:scaling

1081:Fouling

858:fouling

598:where P

337:module.

279:Tubular

251:olefins

123:passive

68:serosae

64:mucosae

2457:

2276:

2150:

2132:

2055:

2002:15 May

1865:77–84.

1831:

1758:

1714:

1312:Using

283:micro-

119:active

105:(UF),

101:(MF),

2274:S2CID

1829:S2CID

1676:risks

1633:. In

1389:Reuse

1383:Reuse

253:from

2455:ISBN

2148:PMID

2053:PMID

2004:2015

1756:ISBN

1712:ISBN

1665:cost

1641:the

1637:and

285:and

86:and

66:and

50:and

44:ions

2494:429

2410:doi

2398:284

2371:doi

2359:253

2313:doi

2301:299

2266:doi

2262:610

2235:doi

2231:471

2207:doi

2203:284

2176:doi

2140:doi

2095:doi

2091:253

2043:hdl

2035:doi

2023:123

1963:doi

1930:doi

1897:doi

1819:doi

1187:or

855:as

682:100

600:TMP

121:or

78:).

2719::

2492:.

2422:^

2408:.

2396:.

2392:.

2369:.

2357:.

2353:.

2311:.

2299:.

2295:.

2272:.

2260:.

2256:.

2229:.

2201:.

2172:42

2170:.

2146:.

2138:.

2128:.

2118:37

2116:.

2089:.

2051:.

2041:.

2033:.

2021:.

1995:.

1957:.

1953:.

1924:.

1920:.

1895:.

1883:.

1879:.

1852:13

1850:.

1827:.

1817:.

1805:.

1801:.

1774:^

1741:^

1174:.

261:.

237:,

129:,

42:,

34:A

2570:)

2530:e

2523:t

2516:v

2463:.

2416:.

2412::

2404::

2377:.

2373::

2365::

2319:.

2315::

2307::

2280:.

2268::

2241:.

2237::

2213:.

2209::

2182:.

2178::

2156:.

2154:.

2142::

2124::

2101:.

2097::

2074:.

2059:.

2045::

2037::

2029::

2006:.

1971:.

1965::

1959:2

1938:.

1932::

1926:3

1905:.

1899::

1891::

1885:6

1835:.

1821::

1813::

1807:9

1720:.

1034:d

1031:e

1028:e

1025:f

1021:Q

1015:e

1012:t

1009:a

1006:r

1003:t

1000:n

997:e

994:c

991:n

988:o

985:c

981:Q

972:1

969:=

962:d

959:e

956:e

953:f

949:Q

943:e

940:t

937:a

934:e

931:m

928:r

925:e

922:p

918:Q

912:=

909:S

834:c

830:C

821:c

817:Q

813:+

808:p

804:C

795:p

791:Q

787:=

782:f

778:C

769:f

765:Q

739:c

735:Q

731:+

726:p

722:Q

718:=

713:f

709:Q

672:f

668:C

663:)

658:p

654:C

645:f

641:C

637:(

631:=

628:r

612:p

608:c

604:f

581:p

577:P

568:2

564:)

559:c

555:P

551:+

546:f

542:P

538:(

532:=

527:P

524:M

521:T

517:P

486:P

483:M

480:T

476:P

470:w

466:F

460:=

457:k

441:w

424:A

416:w

412:F

408:=

403:p

399:Q

23:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.