185:

54:

131:. The properties of the membrane -such as average pore diameter and membrane thickness- can be finely tuned by changing the dimensions of the spinneret, temperature and composition of "dope" (polymer) and "bore" (solvent) solutions, length of air gap (for dry-jet wet spinning), temperature and composition of the coagulant, as well as the speed at which produced fiber is collected by a motorized spool. Extrusion of the polymer and solvent through the spinneret can be accomplished either through the use of gas-extrusion or a metered pump. Some of the polymers most commonly used for fabricating HFMs include

45:

62:

225:

74:

82:

127:, a device containing a needle through which solvent is extruded and an annulus through which a polymer solution is extruded. As the polymer is extruded through the annulus of the spinneret, it retains a hollow cylindrical shape. As the polymer exits the spinneret, it solidifies into a membrane through a process known as

199:

Industrial water filters are mainly equipped with ultrafiltration hollow fiber membranes. Domestic water filtration systems have microfiltration hollow fiber membranes. In microfiltration a membrane pore diameter of 0.1 micrometers cuts-off microorganisms like germs and bacteria, Giardia cysts and

150:

After fibers are created, they are typically assembled together in a membrane module, with many fibers in parallel. Fiber ends are fixed together in a resin or epoxy at both ends. This part may be cut clean through to more readily expose their entrance/exits. Typically, these are place inside a

40:

applications, hollow fiber membranes have since become prevalent in water treatment, desalination, cell culture, medicine, and tissue engineering. Most commercial hollow fiber membranes are packed into cartridges which can be used for a variety of liquid and gaseous separations.

159:

The properties of HFMs can be characterized using the same techniques commonly used for other types of membranes. The primary properties of interest for HFMs are average pore diameter and pore distribution, measurable via a technique known as

151:

cylinder, which has inlets and outlets on opposite sides for the bore (Lumen) side, and side ports for allowing flow to go over the membranes on the shell side. Typically, the higher pressure feed is on the bore side, to avoid fiber collapse.

48:

Schematic diagram of a hollow fiber membrane, including a view of the membrane module and call outs for a cross section (top right), membrane transport (bottom left) and partial pressure of the solute. Modified by authors from

458:

Krantz, William B.; Greenberg, Alan R.; Kujundzic, Elmira; Yeo, Adrian; Hosseini, Seyed S. (July 2013). "Evapoporometry: A novel technique for determining the pore-size distribution of membranes".

307:

Oh, Jinwoo; Fix, Andrew J.; Ziviani, Davide; Braun, James E.; Warsinger, David M. (2024). "Design optimization of hollow fiber membranes for passive air dehumidification in drying applications".

448:

A.B. Abell, K.L. Willis and D.A. Lange, "Mercury

Intrusion Porosimetry and Image Analysis of Cement-Based Materials", Journal of Colloid and Interface Science, 211, pp. 39-44 (1999).

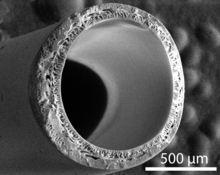

176:. Depending on the diameters of pores in an HFM, scanning electron microscopy or transmission electron microscopy can be used to yield a qualitative perspective of pore size.

397:

Feng, C.Y.; Khulbe, K.C.; Matsuura, T.; Ismail, A.F. (June 2013). "Recent progresses in polymeric hollow fiber membrane preparation, characterization and applications".

485:

Merriman, Lauren; Moix, Alex; Beitle, Robert; Hestekin, Jamie (October 2014). "Carbon dioxide gas delivery to thin-film aqueous systems via hollow fiber membranes".

207:, with the ability of some hollow fiber cartridges to culture billions of anchorage-dependent cells within a relatively low (<100 mL) bioreactor volume.

210:

Hollow fibers can be used for drug efficacy testing in cancer research, as an alternative to the traditional, but more expensive, xenograft model.

116:

Dry-Jet Wet

Spinning, in which a polymer is dissolved in an appropriate solvent and extruded into air and a subsequent coagulant (usually water).

539:

Nakatsuka, Shuji; Nakate, Ichiro; Miyano, Tadaaki (August 1, 1996). "Drinking water treatment by using ultrafiltration hollow fiber membranes".

200:

other intestinal parasites, as well removing sediments. Ultrafiltration membranes are capable of removing not only bacteria, but also viruses.

582:

Sheu, Jonathan; Beltzer, Jim; Fury, Brian; Wilczek, Katarzyna; Tobin, Steve; Falconer, Danny; Nolta, Jan; Bauer, Gerhard (January 1, 2015).

639:

Decker, S.; Hollingshead, M.; Bonomi, C.A.; Carter, J.P.; Sausville, E.A. (April 2004). "The hollow fibre model in cancer drug screening".

164:, a feature of several laboratory instruments used for measuring pore size. Pore diameter can also be measured via a technique known as

228:

A longitudinal cross section of a polysulfone hollow fiber membrane intraluminally cultured with 3T3 fibroblasts and stained with DAPI.

520:

291:

218:

284:

Encyclopedia of Life

Support Systems (Eolss): v.1 : Desalination and Water Resources (Desware): Membrane Processes

381:

351:

196:

Hollow fiber membranes are ubiquitously used in industrial separations, especially the filtration of drinking water.

113:

Dry

Spinning, in which a polymer is dissolved in an appropriate solvent and extruded through a spinneret into air.

430:. Research reporting series: Environmental protection technology. U.S. Government Printing Office. p. 2

98:. The specific production methods involved are heavily dependent on the type of polymer used as well as its

685:

57:

SEM cross-section of a polysulfone hollow fiber membrane fabricated by nonsolvent-induced phase separation.

128:

184:

680:

243:

95:

53:

119:

Wet spinning, in which a polymer is dissolved and extruded directly into a coagulant (usually water).

204:

144:

102:. HFM production, commonly referred to as "spinning", can be divided into four general types:

425:

548:

494:

124:

107:

66:

8:

214:

189:

584:"Large-scale production of lentiviral vector in a closed system hollow fiber bioreactor"

552:

498:

616:

583:

29:

560:

656:

621:

603:

564:

377:

347:

324:

287:

132:

65:

Extrusion of nascent hollow fiber membrane polymer solution through the annulus of a

648:

611:

595:

556:

502:

467:

406:

320:

316:

140:

99:

372:

Wang, Lawrence; Chen, Jiaping; Hung, Yung-Tse; Shammas, Nazih (December 1, 2010).

61:

44:

471:

410:

263:

258:

248:

173:

106:

Melt

Spinning, in which a thermoplastic polymer is melted and extruded through a

37:

652:

253:

165:

506:

16:

Class of artificial membranes containing a semi-permeable hollow fiber barrier

674:

660:

607:

568:

328:

77:

An example dry-jet wet spinning hollow fiber fabrication system in operation.

625:

161:

136:

599:

169:

73:

36:

in the form of a hollow fiber. Originally developed in the 1960s for

342:

Imsail, Ahmad; Khulbe, Kailash; Matsuura, Takeshi (April 28, 2015).

224:

221:

which oxygenates blood, replacing lungs in critically ill patients.

238:

33:

172:

through the pores of a membrane is related to pore-size via the

638:

188:

A reinforced immersed hollow fiber membrane cassette used in

81:

522:

MBR-The reliable solution for difficult to treat

Wastewaters

457:

484:

367:

365:

363:

396:

360:

581:

528:. OWEA NE Industrial Waste Seminar. February 20, 2014.

588:

Molecular

Therapy: Methods & Clinical Development

538:

427:

Hollow Fiber

Technology for Advanced Waste Treatment

341:

423:

371:

424:Bashaw, J.D.; Lawson, J.K.; Orofino, T.A. (1972).

344:Gas Separation Membranes: Polymeric and Inorganic

306:

672:

123:Common to each of these methods is the use of a

85:An example of a hollow fiber membrane cartridge.

203:Hollow fibers are commonly used substrates for

615:

376:. Springer Science & Business Media.

300:

286:. Oxford: EOLSS Publishers Co Ltd. 2010.

223:

183:

80:

72:

60:

52:

43:

673:

399:Separation and Purification Technology

374:Membrane and Desalination Technologies

417:

219:extracorporeal membrane oxygenation

213:Hollow fiber membranes are used in

154:

13:

14:

697:

110:into air and subsequently cooled.

94:HFMs are commonly produced using

309:Energy Conversion and Management

89:

632:

575:

532:

513:

179:

478:

451:

442:

390:

335:

321:10.1016/j.enconman.2024.118097

276:

205:specialized bioreactor systems

1:

561:10.1016/S0011-9164(96)00092-6

269:

487:Chemical Engineering Journal

472:10.1016/j.memsci.2013.03.045

411:10.1016/j.seppur.2013.03.017

7:

460:Journal of Membrane Science

232:

192:process for water treatment

10:

702:

653:10.1016/j.ejca.2003.11.029

641:European Journal of Cancer

244:List of synthetic polymers

168:, in which evaporation of

507:10.1016/j.cej.2014.04.075

315:. Elsevier BV: 118097.

145:polyvinylidene fluoride

229:

193:

86:

78:

70:

58:

50:

34:semi-permeable barrier

22:Hollow fiber membranes

227:

187:

84:

76:

64:

56:

47:

215:Membrane oxygenators

30:artificial membranes

686:Membrane technology

600:10.1038/mtm.2015.20

553:1996Desal.106...55N

499:2014ChEnJ.253..165M

190:membrane bioreactor

96:artificial polymers

230:

194:

87:

79:

71:

59:

51:

681:Polymer chemistry

293:978-1-84826-877-7

133:cellulose acetate

28:) are a class of

693:

665:

664:

636:

630:

629:

619:

579:

573:

572:

536:

530:

529:

527:

517:

511:

510:

482:

476:

475:

455:

449:

446:

440:

439:

437:

435:

421:

415:

414:

394:

388:

387:

369:

358:

357:

339:

333:

332:

304:

298:

297:

280:

155:Characterization

141:polyethersulfone

100:molecular weight

701:

700:

696:

695:

694:

692:

691:

690:

671:

670:

669:

668:

637:

633:

580:

576:

537:

533:

525:

519:

518:

514:

483:

479:

456:

452:

447:

443:

433:

431:

422:

418:

395:

391:

384:

370:

361:

354:

340:

336:

305:

301:

294:

282:

281:

277:

272:

264:Microfiltration

259:Ultrafiltration

249:Reverse Osmosis

235:

182:

174:Kelvin equation

157:

129:phase inversion

92:

38:reverse osmosis

17:

12:

11:

5:

699:

689:

688:

683:

667:

666:

647:(6): 821–826.

631:

574:

531:

512:

477:

450:

441:

416:

389:

382:

359:

352:

334:

299:

292:

274:

273:

271:

268:

267:

266:

261:

256:

254:Nanofiltration

251:

246:

241:

234:

231:

181:

178:

166:evapoporometry

156:

153:

121:

120:

117:

114:

111:

91:

88:

15:

9:

6:

4:

3:

2:

698:

687:

684:

682:

679:

678:

676:

662:

658:

654:

650:

646:

642:

635:

627:

623:

618:

613:

609:

605:

601:

597:

593:

589:

585:

578:

570:

566:

562:

558:

554:

550:

546:

542:

535:

524:

523:

516:

508:

504:

500:

496:

492:

488:

481:

473:

469:

465:

461:

454:

445:

429:

428:

420:

412:

408:

404:

400:

393:

385:

383:9781597452786

379:

375:

368:

366:

364:

355:

353:9783319010953

349:

345:

338:

330:

326:

322:

318:

314:

310:

303:

295:

289:

285:

279:

275:

265:

262:

260:

257:

255:

252:

250:

247:

245:

242:

240:

237:

236:

226:

222:

220:

216:

211:

208:

206:

201:

197:

191:

186:

177:

175:

171:

167:

163:

152:

148:

146:

142:

138:

134:

130:

126:

118:

115:

112:

109:

105:

104:

103:

101:

97:

90:Manufacturing

83:

75:

68:

63:

55:

46:

42:

39:

35:

32:containing a

31:

27:

23:

19:

644:

640:

634:

591:

587:

577:

547:(1): 55–61.

544:

541:Desalination

540:

534:

521:

515:

490:

486:

480:

463:

459:

453:

444:

432:. Retrieved

426:

419:

402:

398:

392:

373:

346:. Springer.

343:

337:

312:

308:

302:

283:

278:

212:

209:

202:

198:

195:

180:Applications

158:

149:

122:

93:

25:

21:

20:

18:

493:: 165–173.

466:: 153–166.

162:porosimetry

137:polysulfone

675:Categories

594:: 15020–.

270:References

170:2-propanol

661:0959-8049

608:2329-0501

569:0011-9164

405:: 43–71.

329:0196-8904

125:spinneret

108:spinneret

67:spinneret

626:26151065

434:July 19,

239:Membrane

233:See also

617:4470365

549:Bibcode

495:Bibcode

659:

624:

614:

606:

567:

380:

350:

327:

290:

143:, and

526:(PDF)

657:ISSN

622:PMID

604:ISSN

565:ISSN

436:2024

378:ISBN

348:ISBN

325:ISSN

288:ISBN

26:HFMs

649:doi

612:PMC

596:doi

557:doi

545:106

503:doi

491:253

468:doi

464:438

407:doi

403:111

317:doi

313:302

217:in

677::

655:.

645:40

643:.

620:.

610:.

602:.

590:.

586:.

563:.

555:.

543:.

501:.

489:.

462:.

401:.

362:^

323:.

311:.

147:.

139:,

135:,

663:.

651::

628:.

598::

592:2

571:.

559::

551::

509:.

505::

497::

474:.

470::

438:.

413:.

409::

386:.

356:.

331:.

319::

296:.

69:.

24:(

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.