70:

the arc. This type of FCAW is attractive because it is portable and generally has good penetration into the base metal. Also, windy conditions need not be considered. Some disadvantages are that this process can produce excessive, noxious smoke (making it difficult to see the weld pool). As with all welding processes, the proper electrode must be chosen to obtain the required mechanical properties. Operator skill is a major factor as improper electrode manipulation or machine setup can cause

78:

69:

One type of FCAW requires no shielding gas. This is made possible by the flux core in the tubular consumable electrode. However, this core contains more than just flux. It also contains various ingredients that when exposed to the high temperatures of welding generate a shielding gas for protecting

99:

or GMAW processes. In practice it also allows a higher production rate, since the operator does not need to stop periodically to fetch a new electrode, as is the case in SMAW. However, like GMAW, it cannot be used in a windy environment as the loss of the shielding gas from air flow will produce

85:

Another type of FCAW uses a shielding gas that must be supplied by an external source. This is known informally as "dual shield" welding. This type of FCAW was developed primarily for welding structural steels. In fact, since it uses both a flux-cored electrode and an external shielding gas, one

90:) and FCAW. The most often used shielding gases are either straight carbon dioxide or argon carbon dioxide blends. The most common blend used is 75% Argon 25% Carbon Dioxide. This particular style of FCAW is preferable for welding thicker and out-of-position metals. The

94:

created by the flux is also easy to remove. The main advantages of this process is that in a closed shop environment, it generally produces welds of better and more consistent mechanical properties, with fewer weld defects than either the

239:

57:

is sometimes used, but often the flux itself is relied upon to generate the necessary protection from the atmosphere, producing both gaseous protection and liquid

374:

213:

Porosity – the gases (specifically those from the flux-core) don’t escape the welded area before the metal hardens, leaving holes in the welded metal.

243:

267:

222:

Changing filler metals requires changing an entire spool. This can be slow and difficult as compared to changing filler metal for SMAW or GTAW.

130:

Reverse polarity (Electrode

Positive) is used for FCAW Gas-Shielded wire, Straight polarity (Electrode Negative) is used for self shielded FCAW

336:

297:

199:

Of course, all of the usual issues that occur in welding can occur in FCAW such as incomplete fusion between base metals, slag inclusion (

165:

Metallurgical benefits from the flux such as the weld metal being protected initially from external factors until the slag is chipped away

367:

283:"Flux Cored Welding." Welding Procedures & Techniques. 23 June 2006. American Metallurgical Consultants. 13 Sep 2006 <

207:

Melted contact tip – when the contact tip actually contacts the base metal, fusing the two and melting the hole on the end.

203:), and cracks in the welds. But there are a few concerns that come up with FCAW that are worth taking special note of:

360:

329:

290:

Groover, Mikell P. Fundamentals of Modern

Manufacturing. Second. New York City: John Wiley & Sons, INC, 2002.

512:

322:

457:

293:"Solid Wire Versus Flux-Cored Wire - When to Use Them and Why." Miller Electric Mfg. Co. 13 Sep 2006 <

434:

96:

146:

No shielding gas needed with some wires making it suitable for outdoor welding and/or windy conditions

449:

264:

424:

651:

399:

200:

507:

294:

492:

487:

462:

439:

419:

143:

FCAW may be an "all-position" process with the right filler metals (the consumable electrode)

677:

558:

502:

308:

149:

A high-deposition rate process (speed at which the filler metal is applied) in the 1G/1F/2F

50:

8:

467:

584:

522:

497:

472:

429:

404:

626:

621:

39:

482:

383:

47:

594:

301:

271:

589:

553:

58:

671:

568:

563:

527:

477:

409:

54:

548:

517:

345:

284:

599:

391:

219:

The amount of smoke generated can far exceed that of SMAW, GMAW, or GTAW.

31:

646:

641:

636:

631:

543:

35:

71:

656:

616:

43:

314:

77:

171:

Less equipment required, easier to move around (no gas bottle)

34:

process. FCAW requires a continuously-fed consumable tubular

295:

http://www.millerwelds.com/education/articles/article62.html

280:

American

Welding Society, Welding Handbook, Vol 2 (9th ed.)

156:

91:

87:

265:

Are

Welding Fumes an Occupational Health Risk Factor?

216:

More costly filler material/wire as compared to GMAW.

210:

Irregular wire feed – typically a mechanical problem.

240:""CHOOSING A SHIELDING GAS FOR FLUX-CORED WELDING""

152:Some "high-speed" (e.g., automotive) applications

86:might say that it is a combination of gas metal (

669:

16:Semi-automatic or automatic arc welding process

137:

368:

330:

159:, there is less skill required for operators.

375:

361:

337:

323:

285:http://www.weldingengineer.com/1flux.htm

76:

127:Shielding gas composition (if required)

670:

263:American Society of Safety Engineers,

356:

318:

103:

133:Contact tip to work distance (CTWD)

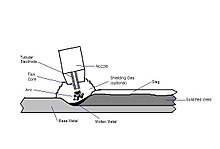

81:A drawing of FCAW at the weld point

30:) is a semi-automatic or automatic

13:

162:Less precleaning of metal required

14:

689:

344:

194:

190:Some wearfacing/surfacing alloys

435:Shielded metal (Stick/MMA/SMAW)

425:Gas tungsten (Heliarc/TIG/GTAW)

420:Gas metal (Microwire/MIG/GMAW)

257:

232:

46:or, less commonly, a constant-

1:

226:

176:Used on the following alloys:

400:Atomic hydrogen (Athydo/AHW)

7:

382:

138:Advantages and applications

10:

694:

53:. An externally supplied

612:

577:

536:

458:Electric resistance (ERW)

448:

390:

352:

181:Mild and low alloy steels

168:Porosity chances very low

155:As compared to SMAW and

64:

201:non-metallic inclusions

187:Some high nickel alloys

309:Flux Cored Arc Welding

100:porosity in the weld.

82:

20:Flux-cored arc welding

652:Tools and terminology

80:

61:protecting the weld.

51:welding power supply

488:Friction stir (FSW)

463:Electron-beam (EBW)

124:Electrode wire type

115:Electrode extension

585:Heat-affected zone

513:Oxyacetylene (OAW)

300:2006-10-15 at the

270:2013-07-21 at the

83:

665:

664:

608:

607:

468:Electroslag (ESW)

415:Flux-cored (FCAW)

104:Process variables

685:

498:Laser beam (LBW)

405:Electrogas (EGW)

377:

370:

363:

354:

353:

339:

332:

325:

316:

315:

311:before the 1950s

274:

261:

255:

254:

252:

251:

242:. Archived from

236:

184:Stainless steels

121:Electrode angles

693:

692:

688:

687:

686:

684:

683:

682:

668:

667:

666:

661:

604:

595:Residual stress

573:

532:

450:Other processes

444:

440:Submerged (SAW)

386:

381:

348:

343:

302:Wayback Machine

277:

272:Wayback Machine

262:

258:

249:

247:

238:

237:

233:

229:

197:

140:

109:Wire feed speed

106:

67:

42:and a constant-

17:

12:

11:

5:

691:

681:

680:

663:

662:

660:

659:

654:

649:

644:

639:

634:

629:

624:

619:

613:

610:

609:

606:

605:

603:

602:

597:

592:

590:Photokeratitis

587:

581:

579:

575:

574:

572:

571:

566:

561:

556:

551:

546:

540:

538:

534:

533:

531:

530:

525:

520:

515:

510:

508:Magnetic pulse

505:

500:

495:

490:

485:

480:

475:

470:

465:

460:

454:

452:

446:

445:

443:

442:

437:

432:

427:

422:

417:

412:

407:

402:

396:

394:

388:

387:

380:

379:

372:

365:

357:

350:

349:

342:

341:

334:

327:

319:

313:

312:

305:

291:

288:

281:

276:

275:

256:

230:

228:

225:

224:

223:

220:

217:

214:

211:

208:

196:

193:

192:

191:

188:

185:

182:

173:

172:

169:

166:

163:

160:

153:

150:

147:

144:

139:

136:

135:

134:

131:

128:

125:

122:

119:

116:

113:

110:

105:

102:

66:

63:

15:

9:

6:

4:

3:

2:

690:

679:

676:

675:

673:

658:

655:

653:

650:

648:

645:

643:

640:

638:

635:

633:

630:

628:

625:

623:

620:

618:

615:

614:

611:

601:

598:

596:

593:

591:

588:

586:

583:

582:

580:

578:Related terms

576:

570:

569:Shielding gas

567:

565:

562:

560:

557:

555:

552:

550:

547:

545:

542:

541:

539:

535:

529:

526:

524:

521:

519:

516:

514:

511:

509:

506:

504:

501:

499:

496:

494:

493:Friction stud

491:

489:

486:

484:

481:

479:

476:

474:

471:

469:

466:

464:

461:

459:

456:

455:

453:

451:

447:

441:

438:

436:

433:

431:

428:

426:

423:

421:

418:

416:

413:

411:

408:

406:

403:

401:

398:

397:

395:

393:

389:

385:

378:

373:

371:

366:

364:

359:

358:

355:

351:

347:

340:

335:

333:

328:

326:

321:

320:

317:

310:

306:

303:

299:

296:

292:

289:

286:

282:

279:

278:

273:

269:

266:

260:

246:on 2019-03-02

245:

241:

235:

231:

221:

218:

215:

212:

209:

206:

205:

204:

202:

195:Disadvantages

189:

186:

183:

180:

179:

178:

177:

170:

167:

164:

161:

158:

154:

151:

148:

145:

142:

141:

132:

129:

126:

123:

120:

117:

114:

111:

108:

107:

101:

98:

93:

89:

79:

75:

73:

62:

60:

56:

55:shielding gas

52:

49:

45:

41:

38:containing a

37:

33:

29:

25:

21:

559:Power supply

549:Filler metal

503:Laser-hybrid

430:Plasma (PAW)

414:

346:Metalworking

259:

248:. Retrieved

244:the original

234:

198:

175:

174:

118:Travel speed

84:

68:

27:

23:

19:

18:

678:Arc welding

622:Fabrication

600:Weldability

392:Arc welding

307:History Of

112:Arc voltage

32:arc welding

642:Metallurgy

523:Ultrasonic

518:Spot (RSW)

473:Exothermic

250:2019-03-02

227:References

637:Machining

632:Jewellery

544:Electrode

537:Equipment

36:electrode

672:Category

647:Smithing

483:Friction

298:Archived

268:Archived

72:porosity

657:Welding

627:Forming

617:Casting

384:Welding

48:current

44:voltage

554:Helmet

564:Robot

528:Upset

478:Forge

410:Flash

304:>.

287:>.

65:Types

157:GTAW

97:SMAW

92:slag

88:GMAW

59:slag

40:flux

24:FCAW

28:FCA

26:or

674::

74:.

376:e

369:t

362:v

338:e

331:t

324:v

253:.

22:(

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.