388:

to 10 mg/L. Operators should monitor the tank for low DO bacteria, such as S. natans, type 1701 and H. hydrossis, which indicate low DO conditions by elevated effluent turbidity and dark activated sludge with foul odours. Many plants have on-line monitoring equipment that continuously measures and records DO levels at specific points within the aeration tank. These on-line analysers send data to the SCADA system and allow automatic control of the aeration system to maintain a predetermined DO level. Whether generated automatically or taken manually, regular monitoring is necessary to favour organisms that settle well rather than filaments. However, operating the aeration system involves finding a balance between sufficient oxygen for proper treatment and the energy cost, which represents approximately 90% of the total treatment cost.

121:

20:

1128:

1157:

200:(aeration compartment). Facultative bacteria then reduce the nitrate to nitrogen gas in anoxic conditions (anoxic compartment). Moreover, the organisms used for the phosphorus uptake (Polyphosphate Accumulating Organisms) are more efficient under anoxic conditions. These microorganisms accumulate large amounts of phosphates in their cells and are settled in the secondary clarifier. The settled sludge is either disposed of as waste activated sludge or reused in the aeration tank as return activated sludge. Some sludge must always be returned to the aeration tanks to maintain an adequate population of organisms.

137:

954:

plants, a biotic floc is created which provides the required substrate. Package plants are designed and fabricated by specialty engineering firms in dimensions that allow for their transportation to the job site in public highways, typically width and height of 3.7 by 3.7 metres (12 ft × 12 ft). Length varies with capacity with larger plants being fabricated in pieces and welded on site. Steel is preferred over synthetic materials (e.g., plastic) for its durability. Package plants are commonly variants of

1267:

380:

in grams per liter. The MCRT is the total mass (in kilograms or pounds) of mixed liquor suspended solids in the aerator and clarifier divided by the mass flow rate (in kilograms/pounds per day) of mixed liquor suspended solids leaving as WAS and final effluent. The F/M is the ratio of food fed to the microorganisms each day to the mass of microorganisms held under aeration. Specifically, it is the amount of BOD fed to the aerator (in kilograms/pounds per day) divided by the amount (in kilograms or pounds) of

129:

347:

activated sludge process produces about 70–100 grams per cubic metre (1.9–2.7 oz/cu yd) of waste activated sludge (that is grams of dry solids produced per cubic metre of wastewater treated). 80 grams per cubic metre (2.2 oz/cu yd) is regarded as being typical. In addition, about 110–170 grams per cubic metre (3.0–4.6 oz/cu yd) of primary sludge is produced in the primary sedimentation tanks which most - but not all - of the activated sludge process configurations use.

2548:

113:

1002:

the oxygen forced into solution by the pressure at the base of the shaft breaks out as molecular oxygen providing a highly efficient source of oxygen for the activated sludge biota. The rising oxygen and injected return sludge provide the physical mechanism for mixing of the sewage and sludge. Mixed sludge and sewage is decanted at the surface and separated into supernatant and sludge components. The efficiency of deep shaft treatment can be high.

392:

aeration tank. It usually includes a pump that draws the portion back. The RAS line is designed considering the potential for clogging, settling, and other relatable issues that manage to impact the flow of the activated sludge back to the aeration tank. This line must handle the required flow of the plant and has to be designed to minimize the risk of solids settling or accumulating.

1169:

attached to the inner surface. When the tube is rotated, the vanes spin liquor up and out of the cones drawing new sewage liquor from the base of the tank. In many works, each cone is located in a separate cell that can be isolated from the remaining cells if required for maintenance. Some works may have two cones to a cell and some large works may have 4 cones per cell.

973:. This refers to the way the biological load is processed. In high charged systems, the biological stage is presented with a high organic load and the combined floc and organic material is then oxygenated for a few hours before being charged again with a new load. In the low charged system the biological stage contains a low organic load and is combined with

1110:(SBRs) treat wastewater in batches within the same vessel. This means that the bioreactor and final clarifier are not separated in space but in a timed sequence. The installation consists of at least two identically equipped tanks with a common inlet, which can be alternated between them. While one tank is in settle/decant mode the other is

276:, and other microorganisms - which produces a sludge that is difficult to settle and can result in the sludge blanket decanting over the weirs in the settlement tank to severely contaminate the final effluent quality. This material is often described as sewage fungus but true fungal communities are relatively uncommon.

1059:

1177:

Pure oxygen activated sludge aeration systems are sealed-tank reactor vessels with surface aerator type impellers mounted within the tanks at the oxygen carbon liquor surface interface. The amount of oxygen entrainment, or DO (Dissolved Oxygen), can be controlled by a weir adjusted level control, and

1040:

process. In the UK it is found at three sites: Tilbury, Anglian water, treating a wastewater with a high industrial contribution; Southport, United

Utilities, because of land space issues; and Billingham, ICI, again treating industrial effluent, and built (after the Tilbury shafts) by ICI to help the

961:

To use less space, treat difficult waste, and intermittent flows, a number of designs of hybrid treatment plants have been produced. Such plants often combine at least two stages of the three main treatment stages into one combined stage. In the UK, where a large number of wastewater treatment plants

400:

Ammonium can have toxic effort on aquatic organism. Nitrification also takes places in bodies of water, which leads to oxygen depletion. Furthermore, nitrate and ammonium are eutophying (fertilizing) nutrients that can impair water bodies. For these reasons, nitrification and, in many cases, nitrogen

1253:

Activated sludge plants are wholly dependent on an electrical supply to power the aerators to transfer settled solids back to the aeration tank inlet, and in many cases to pump waste sludge and final effluent. In some works untreated sewage is lifted by pumps to the head-works to provide sufficient

1001:

Where land is in short supply sewage may be treated by injection of oxygen into a pressured return sludge stream which is injected into the base of a deep columnar tank buried in the ground. Such shafts may be up to 100 metres (330 ft) deep and are filled with sewage liquor. As the sewage rises

387:

To ensure good bacterial settlement and to avoid sedimentation problems caused by filamentous bacteria, plants using atmospheric air as an oxygen source should maintain a dissolved oxygen (DO) level of about 2 mg/L in the aeration tank. In pure oxygen systems, DO levels are usually in the range of 4

379:

The SVI is the volume of settled sludge occupied by a given mass of dry sludge solids. It is calculated by dividing the volume of settled sludge in a mixed liquor sample, measured in milliliters per liter of sample (after 30 minutes of settling), by the MLSS (Mixed Liquor

Suspended Solids), measured

203:

The yield of PAOs (Polyphosphate

Accumulating Organisms) is reduced between 70 and 80% under aerobic conditions. Even though the phosphorus can be removed upstream of the aeration tank by chemical precipitation (adding metal ions such as: calcium, aluminum or iron), the biological phosphorus removal

99:

can occur which makes activated sludge difficult to settle and frequently has an adverse impact on final effluent quality. Treating sludge bulking and managing the plant to avoid a recurrence requires skilled management and may require full-time staffing of a works to allow immediate intervention. A

85:

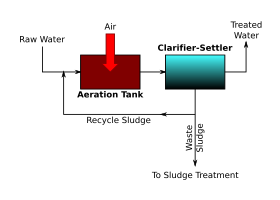

The activated sludge process for removing carbonaceous pollution begins with an aeration tank where air (or oxygen) is injected into the waste water. This is followed by a settling tank to allow the biological flocs (the sludge blanket) to settle, thus separating the biological sludge from the clear

1194:

process which produces a granular sludge that settles very well (the sludge volume index is reduced from 200–300 to 40 millilitres per gram (192–288 to 38 US fl oz/oz)). A new process reactor system is created to take advantage of this quick settling sludge and is integrated into the

812:

b) Denitrification: Reduction of nitrate nitrogen to molecular nitrogen, which escapes from the wastewater into the atmosphere. This step can be carried out by microorganism commonly found in sewage treatment plants. However, these only use the nitrate as an electron acceptor if no dissolved oxygen

1217:

can occur which makes activated sludge difficult to settle and frequently has an adverse impact on final effluent quality. Treating sludge bulking and managing the plant to avoid a recurrence requires skilled management and may require full-time staffing of a works to allow immediate intervention.

932:

In order for denitrification to take place in the activated sludge process, an electron source, a reductant, must therefore also be present that can reduce sufficient nitrate to N2. If there is too little substrate in the raw wastewater, this can be added artificially. In addition, denitrification

1073:

In an aerated basin system, the aerators provide two functions: they transfer air into the basins required by the biological oxidation reactions, and they provide the mixing required for dispersing the air and for contacting the reactants (that is, oxygen, wastewater and microbes). Typically, the

953:

There are a wide range of types of package plants, often serving small communities or industrial plants that may use hybrid treatment processes often involving the use of aerobic sludge to treat the incoming sewage. In such plants the primary settlement stage of treatment may be omitted. In these

199:

Treatment of nitrogenous or phosphorous matter comprises the addition of an anoxic compartment inside the aeration tank in order to perform the nitrification-denitrification process more efficiently. First, ammonia is oxidized to nitrite, which is then converted into nitrate in aerobic conditions

1168:

Vertically mounted tubes of up to 1-metre (3.3 ft) diameter extending from just above the base of a deep concrete tank to just below the surface of the sewage liquor. A typical shaft might be 10 metres (33 ft) high. At the surface end, the tube is formed into a cone with helical vanes

346:

The amount of sewage sludge produced from the activated sludge process is directly proportional to the amount of wastewater treated. The total sludge production consists of the sum of primary sludge from the primary sedimentation tanks as well as waste activated sludge from the bioreactors. The

326:

Activated sludge is also the name given to the active biological material produced by activated sludge plants. Excess sludge is called "surplus activated sludge" or "waste activated sludge" and is removed from the treatment process to keep "food to biomass" (F/M) ratio in balance (where biomass

391:

Based on these control methods, the amount of settled solids in the mixed liquor can be varied by wasting activated sludge (WAS) or returning activated sludge (RAS). The returning activated sludge is designed to recycle a portion of the activated sludge from the secondary clarifier back t the

1147:

tanks but on a much larger scale. Air is pumped through the blocks and the curtain of bubbles formed both oxygenates the liquor and also provides the necessary mixing action. Where capacity is limited or the sewage is unusually strong or difficult to treat, oxygen may be used instead of air.

985:

In some areas, where more land is available, sewage is treated in large round or oval ditches with one or more horizontal aerators typically called brush or disc aerators which drive the mixed liquor around the ditch and provide aeration. These are oxidation ditches, often referred to by

1310:. Not until much later was it realized that what had actually occurred was a means to concentrate biological organisms, decoupling the liquid retention time (ideally, low, for a compact treatment system) from the solids retention time (ideally, fairly high, for an effluent low in BOD

936:

Nitrification and denitrification are in considerable contradiction with regard to the required environmental conditions. Nitrification requires oxygen and CO2. Denitrification only takes place in the absence of dissolved oxygen and with a sufficient supply of oxidizable substances.

384:(MLVSS) under aeration. Note: Some references use MLSS (Mixed Liquor Suspended Solids) for expedience, but MLVSS is considered more accurate for the measure of microorganisms. Again, due to expedience, COD is generally used, in lieu of BOD, as BOD takes five days for results.

1092:

Biological oxidation processes are sensitive to temperature and, between 0 and 40 °C (32 and 104 °F), the rate of biological reactions increase with temperature. Most surface aerated vessels operate at between 4 and 32 °C (39 and 90 °F).

313:

to transfer nitrified mixed liquor from the aeration zone to the anoxic zone for denitrification. These pumps are often referred to as internal mixed liquor recycle pumps (IMLR pumps). The raw sewage, the RAS, and the nitrified mixed liquor are mixed by

986:

manufacturer's trade names such as

Pasveer, Orbal, or Carrousel. They have the advantage that they are relatively easy to maintain and are resilient to shock loads that often occur in smaller communities (i.e. at breakfast time and in the evening).

1302:, which produced a highly treated effluent. They aerated the waste-water continuously for about a month and were able to achieve a complete nitrification of the sample material. Believing that the sludge had been activated (in a similar manner to

553:

805:

376:). In the reactor/aerator and clarifier system, the sludge blanket is measured from the bottom of the clarifier to the level of settled solids in the clarifier's water column; this, in large plants, can be done up to three times a day.

1249:

The activated sludge process is an example for a more high-tech, energy intensive or "mechanized" process that is relatively expensive compared to some other wastewater treatment systems. It can provide a very high level of treatment.

928:

355:

The general process control method is to monitor sludge blanket level, SVI (Sludge Volume Index), MCRT (Mean Cell

Residence Time), F/M (Food to Microorganism), as well as the biota of the activated sludge and the major nutrients DO

664:

1195:

aeration tank instead of having a separate unit outside. About 30 Nereda wastewater treatment plants worldwide are operational, under construction or under design, varying in size from 5,000 up to 858,000 person equivalent.

183:

entrapping fine particulate matter as they do so. It thereby produces a liquid that is relatively free from suspended solids and organic material, and flocculated particles that will readily settle out and can be removed.

962:

serve small populations, package plants are a viable alternative to building a large structure for each process stage. In the US, package plants are typically used in rural areas, highway rest stops and trailer parks.

1884:

194:

Settling tank (usually referred to as "final clarifier" or "secondary settling tank") to allow the biological flocs (the sludge blanket) to settle, thus separating the biological sludge from the clear treated

1089:/kWh). However, they do not provide as good mixing as is normally achieved in activated sludge systems and therefore aerated basins do not achieve the same performance level as activated sludge units.

407:

a) Nitrification: Oxidation of ammonium nitrogen and organically bound nitrogen to nitrate. Nitrification is very sensitive to inhibitors and can lead to a pH value in poorly buffered water.

1070:

with retention times of 1 to 10 days. The basins may range in depth from 1.5 to 5.0 metres (4.9 to 16.4 ft) and utilize motor-driven aerators floating on the surface of the wastewater.

1066:

Most biological oxidation processes for treating industrial wastewaters have in common the use of oxygen (or air) and microbial action. Surface-aerated basins achieve 80 to 90% removal of

1182:, or other methods. These systems are used where wastewater plant space is at a premium and high sewage throughput is required as high energy costs are involved in purifying oxygen.

1643:

306:

to remove some wastewater from the mixed liquor prior to treatment. This results in a more concentrated waste product that can then be treated using the activated sludge process.

809:

Nitrification is associated with the production of acid (H+). This puts a strain on the buffering capacity of the water or a pH value shift may occur, which impairs the process.

993:

of 24 – 48 hours, and a sludge age of 12 – 20 days. This compares with nitrifying activated sludge plants having a retention time of 8 hours, and a sludge age of 8 – 12 days.

1746:

1881:

416:

1298:

involving the aeration of sewage in a bottle that had been coated with algae. Fowler's engineering colleagues, Ardern and

Lockett, experimented on treating sewage in a

958:, to promote the "fit and forget" approach required for small communities without dedicated operational staff. There are various standards to assist with their design.

674:

818:

86:

treated water. Part of the waste sludge is recycled to the aeration tank and the remaining waste sludge is removed for further treatment and ultimate disposal.

1723:

283:. In all activated sludge plants, once the wastewater has received sufficient treatment, excess mixed liquor is discharged into settling tanks and the treated

1032:

However, the costs of construction are high. Deep Shaft has seen the greatest uptake in Japan, because of the land area issues. Deep Shaft was developed by

559:

1900:

Saikaly PE, Oerther DB (2011). "Diversity of dominant bacterial taxa in activated sludge promotes functional resistance following toxic shock loading".

933:

corrects the change in H+ concentration (pH value shift) that occurs during nitrification. This is particularly important for poorly buffered water.

2131:

1479:

1777:

1504:

1839:

2071:

1337:. By the late 1930s, the activated sludge treatment became a well-known biological wastewater treatment process in those countries where

1279:

2437:

1454:

1384:

1037:

1044:

DeepShaft is a patented, licensed, process. The licensee has changed several times and currently (2015) Noram

Engineering sells it.

1282:

by two engineers, Edward Ardern and W.T. Lockett, who were conducting research for the

Manchester Corporation Rivers Department at

1538:"Simultaneous oligonucleotide probe hybridization and immunostaining for in situ detection of Gordona species in activated sludge"

1754:

2151:

381:

2146:

2043:

1317:

Their results were published in their seminal 1914 paper, and the first full-scale continuous-flow system was installed at

1792:

1254:

fall through the works to enable a satisfactory discharge head for the final effluent. Alternative technologies such as

1127:

187:

The general arrangement of an activated sludge process for removing carbonaceous pollution includes the following items:

2578:

2432:

2302:

2003:

1617:

1588:

2392:

2362:

2332:

1462:

1379:

47:

19:

2106:

1238:

120:

89:

Plant types include package plants, oxidation ditch, deep shaft/vertical treatment, surface-aerated basins, and

1209:

989:

Oxidation ditches are installed commonly as 'fit & forget' technology, with typical design parameters of a

93:(SBRs). Aeration methods include diffused aeration, surface aerators (cones) or, rarely, pure oxygen aeration.

1178:

a vent gas oxygen controlled oxygen feed valve. Oxygen is generated on site by cryogenic distillation of air,

2583:

2382:

2206:

2166:

1660:

1394:

1160:

Surface aerator for aeration tank at activated sludge sewage treatment plant (at Morro Alto

Treatment Plant,

1033:

1131:

Fine bubble diffusers in aeration tank of activated sludge sewage treatment plant near

Adelaide, Australia

2307:

1156:

2447:

2214:

256:

and a range of other filter-feeding species. Other important constituents include motile and sedentary

2219:

1244:

1179:

1067:

369:

66:, which deals with the removal of biodegradable organic matter and suspended solids. It uses air (or

1074:

floating surface aerators are rated to deliver the amount of air equivalent to 1.8 to 2.7 kilograms

2136:

2036:

1774:

1374:

1369:

1299:

1291:

1107:

1102:

990:

548:{\displaystyle \mathrm {\ NH_{4}^{+}+1,5\ O_{2}\longrightarrow \ NO_{2}^{-}+2H^{+}+H_{2}O+Energy} }

90:

1511:

216:

being introduced into a mixture of screened, and primary treated sewage or industrial wastewater (

2407:

2347:

2274:

2116:

1843:

800:{\displaystyle \mathrm {\ NH_{4}^{+}+2\ O_{2}\longrightarrow \ NO_{3}^{-}+2H^{+}+H_{2}O+Energy} }

332:

1580:

2264:

2259:

2224:

1816:

1354:

1342:

1283:

373:

136:

24:

233:

1572:

1271:

1266:

295:

system to re-seed the new wastewater entering the tank. This fraction of the floc is called

287:

is run off to undergo further treatment before discharge. Part of the settled material, the

2473:

2284:

1909:

1827:

272:

39:

1005:

Surface aerators are commonly quoted as having an aeration efficiency of 0.5–1.5 kg O

923:{\displaystyle \mathrm {\ 2\ NO_{3}^{-}+2\ H^{+}+10\ H\longrightarrow \ N_{2}+6\ H_{2}O} }

8:

2387:

2372:

2327:

2126:

2029:

1389:

1364:

1287:

336:

303:

266:

75:

63:

1913:

2513:

2478:

2422:

2342:

2317:

2086:

2066:

1933:

1554:

1537:

1404:

1318:

331:

is usually mixed with primary sludge from the primary clarifiers and undergoes further

2573:

2552:

2337:

2234:

2081:

1999:

1974:

1925:

1728:

1654:

1584:

1573:

1136:

955:

659:{\displaystyle \mathrm {\ NO_{2}^{-}+0,5\ O_{2}\longrightarrow \ NO_{3}^{-}+Energy} }

315:

1937:

1674:

1609:

1510:. University of Virginia - National small flows clearing house. 2003. Archived from

2468:

2427:

2412:

2312:

1964:

1917:

1804:

1549:

1303:

1255:

357:

176:

124:

Activated sludge addition (seeding) to a pilot scale membrane bioreactor in Germany

1139:

grid aeration systems that are attached to the floor. These are like the diffused

2503:

2377:

2091:

1993:

1888:

1781:

1322:

310:

232:. This material, which in healthy sludge is a brown floc, is largely composed of

152:

1427:

179:

micro-organisms that can digest organic matter in sewage, and clump together by

2528:

2508:

2498:

2493:

2483:

2463:

2402:

2297:

2229:

2171:

2156:

2101:

1399:

1359:

1338:

1214:

1053:

225:

128:

96:

55:

1921:

2567:

2186:

2111:

1978:

1295:

1294:, observed experiments being conducted at the Lawrence Experiment Station at

1144:

1082:

328:

71:

1274:, where the activated sludge process was developed in the early 20th century

2533:

2417:

2367:

2239:

2196:

1929:

974:

221:

180:

79:

1969:

1579:(4th ed.). Metcalf & Eddy, Inc., McGraw Hill, USA. 2003. p.

302:

The space required for a sewage treatment plant can be reduced by using a

2523:

2518:

2442:

2397:

2357:

2254:

2161:

1952:

284:

1480:"First of three Nereda wastewater treatment plants in Ireland took flow"

1058:

945:

There are a variety of types of activated sludge plants. These include:

2488:

2352:

2052:

1161:

1062:

A Typical Surface-Aerated Basing (using motor-driven floating aerators)

340:

279:

The combination of wastewater and biological mass is commonly known as

253:

245:

217:

62:. It is one of several biological wastewater treatment alternatives in

2322:

2269:

2121:

1258:

treatment requires much less power and can operate on gravity alone.

1222:

365:

249:

164:

112:

191:

Aeration tank where air (or oxygen) is injected in the mixed liquor.

27:, UK. The white bubbles are due to the diffused air aeration system.

2249:

2141:

2076:

1455:"Mark van Loosdrecht - Professor at Delft University of Technology"

1140:

1111:

361:

292:

261:

237:

160:

156:

59:

51:

1535:

2176:

1330:

1326:

257:

149:

104:

process which produces a granular sludge that settles very well.

16:

Wastewater treatment process using aeration and a biological floc

1807:

Wastewater Technology Fact Sheet. Document no. EPA 832-F-00-016.

1732:

116:

A generalized, schematic diagram of an activated sludge process.

2191:

2181:

1871:

Beychok, M.R. (1971). "Performance of surface-aerated basins".

1334:

1325:

the new treatment method spread rapidly, especially to the US,

1226:

1191:

1075:

288:

241:

229:

213:

141:

101:

67:

43:

2096:

2021:

1995:

The Culture of Flushing: A Social and Legal History of Sewage

148:

The activated sludge process is a biological process used to

1148:

Typically, the air is generated by some type of air blower.

1536:

Oerther DB, de los Reyes FL, Hernandez M, Raskin L (1999).

1278:

The activated sludge process was discovered in 1913 in the

1225:

to treatment plants designed primarily to treat domestic

1190:

A new development of the activated sludge process is the

318:

in the anoxic zones in order to achieve denitrification.

140:

Aerial photo of Kuryanovo wastewater treatment plant in

2244:

1449:

1447:

100:

new development of the activated sludge process is the

1724:

Aqueous Wastes from Petroleum and Petrochemical Plants

821:

677:

562:

419:

404:

Two special steps are required for nitrogen removal:

1953:"Wastewater Characteristics, Treatment and Disposal"

1444:

1239:

Sewage treatment § Types of treatment processes

395:

1096:

1991:

1720:

996:

922:

799:

658:

547:

220:) combined with organisms to develop a biological

1575:Wastewater engineering : treatment and reuse

260:. In poorly managed activated sludge, a range of

207:

204:is more economic due to the saving of chemicals.

78:organic pollutants, producing a waste sludge (or

2565:

1638:

1636:

1634:

1210:Secondary treatment § Design considerations

410:Nitrification takes places in following steps:

1899:

1873:Chemical Engineering Progress Symposium Series

1232:

2037:

1870:

1631:

1013:/kWh), diffused aeration as 1.5–2.5 kg O

264:filamentous bacteria can develop - including

1950:

1797:

1727:(1st ed.). John Wiley & Sons Ltd.

1649:. Archived from the original on 2012-09-07.

1151:

2044:

2030:

1716:

1714:

1712:

1710:

1135:Sewage liquor is run into deep tanks with

1968:

1553:

1505:"Explaining the Activated Sludge Process"

1385:List of wastewater treatment technologies

1321:two years later. In the aftermath of the

1245:Sewage treatment § Process selection

1047:

1866:

1864:

1862:

1860:

1775:Review of UK and international standards

1675:"Lesson 8: The Activated Sludge Process"

1265:

1155:

1126:

1057:

135:

127:

119:

111:

18:

1944:

1707:

1172:

155:, oxidising nitrogenous matter (mainly

2566:

1644:"Mathematics For Wastewater Operators"

1604:

1602:

1600:

1185:

1021:/kWh). Deep Shaft claims 5–8 kg O

382:Mixed Liquor Volatile Suspended Solids

339:, followed by thickening, dewatering,

327:refers to the activated sludge). This

170:

2025:

1857:

1840:"NORAM VERTREAT (VERtical TREATment)"

965:Package plants may be referred to as

163:) in biological matter, and removing

132:Activated sludge under the microscope

1567:

1565:

1474:

1472:

1422:

1420:

1122:

321:

82:) containing the oxidized material.

1597:

1117:

240:flora component mainly composed of

13:

2433:Ultraviolet germicidal irradiation

1698:

1614:Water/Wastewater Distance Learning

1555:10.1111/j.1574-6941.1999.tb00604.x

1221:The discharge of toxic industrial

980:

916:

907:

888:

878:

860:

836:

832:

793:

790:

787:

784:

781:

778:

772:

763:

750:

729:

725:

710:

686:

682:

652:

649:

646:

643:

640:

637:

620:

616:

601:

571:

567:

541:

538:

535:

532:

529:

526:

520:

511:

498:

477:

473:

458:

428:

424:

350:

14:

2595:

2303:Agricultural wastewater treatment

1882:Available at CSA Illumina website

1618:Mountain Empire Community College

1562:

1469:

1417:

1272:Davyhulme Sewage Works Laboratory

1203:

948:

396:Nitrification and Denitrification

309:Many sewage treatment plants use

291:, is returned to the head of the

23:Activated sludge tank at Beckton

2547:

2546:

1486:. Partners for Water. 2015-09-10

1097:Sequencing batch reactors (SBRs)

2363:Industrial wastewater treatment

2333:Decentralized wastewater system

1985:

1893:

1832:

1821:

1810:

1786:

1768:

1739:

1701:Nitrifikation-Ammoniakoxidation

1692:

1463:International Water Association

1380:Industrial wastewater treatment

997:Deep shaft / Vertical treatment

175:The process takes advantage of

2051:

1667:

1529:

1497:

940:

881:

719:

610:

467:

208:Bioreactor and final clarifier

153:carbonaceous biological matter

1:

2383:Rotating biological contactor

1793:British Standard BS 6297:1983

1410:

1395:Rotating biological contactor

1803:EPA. Washington, DC (2000).

1610:"Lesson 7: Activated Sludge"

212:The process involves air or

7:

1992:Benidickson, Jamie (2011).

1780:September 28, 2007, at the

1721:Beychok, Milton R. (1967).

1348:

1233:Costs and technology choice

1229:can create process upsets.

1036:, as a spin-off from their

167:(nitrogen and phosphorus).

10:

2600:

2448:Wastewater treatment plant

2215:Adsorbable organic halides

1428:"Activated Sludge Process"

1261:

1242:

1236:

1207:

1100:

1051:

236:but also has an important

107:

2579:Environmental engineering

2542:

2456:

2283:

2220:Biochemical oxygen demand

2205:

2059:

1957:Water Intelligence Online

1951:Von Sperling, M. (2015).

1922:10.1007/s00248-010-9783-6

1659:: CS1 maint: unfit URL (

1542:FEMS Microbiology Ecology

1198:

1180:pressure swing adsorption

1108:Sequencing batch reactors

370:Biochemical oxygen demand

91:sequencing batch reactors

58:composed of bacteria and

1375:Aerobic treatment system

1370:Aerobic granular reactor

1306:) the process was named

1292:University of Manchester

1152:Surface aerators (cones)

1103:Sequencing batch reactor

991:hydraulic retention time

38:is a type of biological

2408:Sewage sludge treatment

2348:Fecal sludge management

2308:API oil–water separator

2275:Wastewater surveillance

1817:Vertical Shaft Projects

1343:sewage treatment plants

1017:/kWh (3.3–5.5 lb O

1009:/kWh (1.1–3.3 lb O

297:return activated sludge

2265:Total suspended solids

2260:Total dissolved solids

2225:Chemical oxygen demand

1355:Activated sludge model

1284:Davyhulme Sewage Works

1275:

1165:

1132:

1063:

1048:Surface-aerated basins

924:

801:

660:

549:

401:removal is necessary.

374:Chemical oxygen demand

343:and land application.

145:

133:

125:

117:

48:industrial wastewaters

28:

25:sewage treatment plant

2132:Industrial wastewater

1970:10.2166/9781780402086

1300:draw-and-fill reactor

1290:, a scientist at the

1269:

1243:Further information:

1237:Further information:

1208:Further information:

1159:

1130:

1085:(4.0 to 6.0 lb O

1061:

1052:Further information:

1025:/kWh (11–18 lb O

925:

802:

661:

550:

234:Saprotrophic bacteria

139:

131:

123:

115:

42:process for treating

22:

2584:Chemical engineering

2474:Groundwater recharge

1828:Tilbury construction

1173:Pure oxygen aeration

819:

675:

560:

417:

76:biologically oxidize

40:wastewater treatment

2388:Secondary treatment

2373:Membrane bioreactor

2328:Constructed wetland

2127:Infiltration/Inflow

1914:2011MicEc..61..557S

1747:"Code of Practice,

1390:Membrane bioreactor

1365:Aerobic granulation

1186:Recent developments

849:

742:

699:

633:

584:

490:

441:

337:anaerobic digestion

304:membrane bioreactor

267:Sphaerotilus natans

171:Process description

64:secondary treatment

2553:Category: Sewerage

2514:Septic drain field

2479:Infiltration basin

2423:Stabilization pond

2343:Facultative lagoon

2207:Quality indicators

2087:Blackwater (waste)

2067:Acid mine drainage

1887:2007-11-14 at the

1484:Dutch Water Sector

1405:Thermal hydrolysis

1276:

1166:

1133:

1064:

977:for longer times.

920:

835:

797:

728:

685:

656:

619:

570:

545:

476:

427:

316:submersible mixers

224:which reduces the

146:

134:

126:

118:

29:

2561:

2560:

2338:Extended aeration

2285:Treatment options

2235:Oxygen saturation

2082:Blackwater (coal)

2060:Sources and types

1963:: 9781780402086.

1902:Microbial Ecology

1805:"Package Plants."

1749:Flows and Loads-2

1699:Mohren, Andreas.

1517:on 17 August 2012

1123:Diffused aeration

1041:agent sell more.

956:extended aeration

905:

886:

877:

858:

831:

825:

724:

708:

681:

669:this results in:

615:

599:

566:

472:

456:

423:

322:Sludge production

54:and a biological

2591:

2550:

2549:

2469:Evaporation pond

2457:Disposal options

2428:Trickling filter

2413:Sewage treatment

2313:Carbon filtering

2293:Activated sludge

2046:

2039:

2032:

2023:

2022:

2016:

2015:

2013:

2012:

1989:

1983:

1982:

1972:

1948:

1942:

1941:

1897:

1891:

1880:

1868:

1855:

1854:

1852:

1851:

1842:. Archived from

1836:

1830:

1825:

1819:

1814:

1808:

1801:

1795:

1790:

1784:

1772:

1766:

1765:

1763:

1762:

1753:. Archived from

1751:, British Water"

1743:

1737:

1736:

1718:

1705:

1704:

1696:

1690:

1689:

1687:

1685:

1671:

1665:

1664:

1658:

1650:

1648:

1640:

1629:

1628:

1626:

1625:

1606:

1595:

1594:

1578:

1569:

1560:

1559:

1557:

1533:

1527:

1526:

1524:

1522:

1516:

1509:

1501:

1495:

1494:

1492:

1491:

1476:

1467:

1466:

1451:

1442:

1441:

1439:

1438:

1424:

1308:activated sludge

1304:activated carbon

1256:trickling filter

1118:Aeration methods

929:

927:

926:

921:

919:

915:

914:

903:

896:

895:

884:

875:

868:

867:

856:

848:

843:

829:

823:

806:

804:

803:

798:

796:

771:

770:

758:

757:

741:

736:

722:

718:

717:

706:

698:

693:

679:

665:

663:

662:

657:

655:

632:

627:

613:

609:

608:

597:

583:

578:

564:

554:

552:

551:

546:

544:

519:

518:

506:

505:

489:

484:

470:

466:

465:

454:

440:

435:

421:

358:Dissolved oxygen

333:sludge treatment

311:axial flow pumps

33:activated sludge

2599:

2598:

2594:

2593:

2592:

2590:

2589:

2588:

2564:

2563:

2562:

2557:

2538:

2504:Reclaimed water

2452:

2378:Reverse osmosis

2279:

2201:

2167:Reverse osmosis

2092:Boiler blowdown

2055:

2050:

2020:

2019:

2010:

2008:

2006:

1990:

1986:

1949:

1945:

1898:

1894:

1889:Wayback Machine

1879:(107): 322–339.

1869:

1858:

1849:

1847:

1838:

1837:

1833:

1826:

1822:

1815:

1811:

1802:

1798:

1791:

1787:

1782:Wayback Machine

1773:

1769:

1760:

1758:

1745:

1744:

1740:

1719:

1708:

1697:

1693:

1683:

1681:

1673:

1672:

1668:

1652:

1651:

1646:

1642:

1641:

1632:

1623:

1621:

1608:

1607:

1598:

1591:

1571:

1570:

1563:

1534:

1530:

1520:

1518:

1514:

1507:

1503:

1502:

1498:

1489:

1487:

1478:

1477:

1470:

1453:

1452:

1445:

1436:

1434:

1426:

1425:

1418:

1413:

1351:

1323:First World War

1313:

1264:

1247:

1241:

1235:

1212:

1206:

1201:

1188:

1175:

1154:

1125:

1120:

1105:

1099:

1088:

1079:

1056:

1050:

1028:

1024:

1020:

1016:

1012:

1008:

999:

983:

981:Oxidation ditch

951:

943:

910:

906:

891:

887:

863:

859:

844:

839:

822:

820:

817:

816:

766:

762:

753:

749:

737:

732:

713:

709:

694:

689:

678:

676:

673:

672:

628:

623:

604:

600:

579:

574:

563:

561:

558:

557:

514:

510:

501:

497:

485:

480:

461:

457:

436:

431:

420:

418:

415:

414:

398:

353:

351:Process control

335:for example by

324:

228:content of the

210:

173:

110:

17:

12:

11:

5:

2597:

2587:

2586:

2581:

2576:

2559:

2558:

2556:

2555:

2543:

2540:

2539:

2537:

2536:

2531:

2529:Surface runoff

2526:

2521:

2516:

2511:

2509:Sanitary sewer

2506:

2501:

2499:Marine outfall

2496:

2494:Marine dumping

2491:

2486:

2484:Injection well

2481:

2476:

2471:

2466:

2464:Combined sewer

2460:

2458:

2454:

2453:

2451:

2450:

2445:

2440:

2435:

2430:

2425:

2420:

2415:

2410:

2405:

2403:Settling basin

2400:

2395:

2390:

2385:

2380:

2375:

2370:

2365:

2360:

2355:

2350:

2345:

2340:

2335:

2330:

2325:

2320:

2315:

2310:

2305:

2300:

2298:Aerated lagoon

2295:

2289:

2287:

2281:

2280:

2278:

2277:

2272:

2267:

2262:

2257:

2252:

2247:

2242:

2237:

2232:

2230:Coliform index

2227:

2222:

2217:

2211:

2209:

2203:

2202:

2200:

2199:

2194:

2189:

2184:

2179:

2174:

2172:Sanitary sewer

2169:

2164:

2159:

2157:Produced water

2154:

2149:

2144:

2139:

2134:

2129:

2124:

2119:

2114:

2109:

2104:

2102:Combined sewer

2099:

2094:

2089:

2084:

2079:

2074:

2069:

2063:

2061:

2057:

2056:

2049:

2048:

2041:

2034:

2026:

2018:

2017:

2004:

1984:

1943:

1908:(3): 557–567.

1892:

1856:

1831:

1820:

1809:

1796:

1785:

1767:

1738:

1706:

1691:

1679:water.mecc.edu

1666:

1630:

1596:

1589:

1561:

1548:(2): 129–136.

1528:

1496:

1468:

1443:

1432:web.deu.edu.tr

1415:

1414:

1412:

1409:

1408:

1407:

1402:

1400:Sludge bulking

1397:

1392:

1387:

1382:

1377:

1372:

1367:

1362:

1360:Aerated lagoon

1357:

1350:

1347:

1314:and ammonia.)

1311:

1288:Gilbert Fowler

1280:United Kingdom

1263:

1260:

1234:

1231:

1215:Sludge bulking

1205:

1204:Process upsets

1202:

1200:

1197:

1187:

1184:

1174:

1171:

1153:

1150:

1124:

1121:

1119:

1116:

1101:Main article:

1098:

1095:

1086:

1077:

1054:Aerated lagoon

1049:

1046:

1026:

1022:

1018:

1014:

1010:

1006:

998:

995:

982:

979:

950:

949:Package plants

947:

942:

939:

918:

913:

909:

902:

899:

894:

890:

883:

880:

874:

871:

866:

862:

855:

852:

847:

842:

838:

834:

828:

795:

792:

789:

786:

783:

780:

777:

774:

769:

765:

761:

756:

752:

748:

745:

740:

735:

731:

727:

721:

716:

712:

705:

702:

697:

692:

688:

684:

667:

666:

654:

651:

648:

645:

642:

639:

636:

631:

626:

622:

618:

612:

607:

603:

596:

593:

590:

587:

582:

577:

573:

569:

555:

543:

540:

537:

534:

531:

528:

525:

522:

517:

513:

509:

504:

500:

496:

493:

488:

483:

479:

475:

469:

464:

460:

453:

450:

447:

444:

439:

434:

430:

426:

397:

394:

352:

349:

323:

320:

209:

206:

197:

196:

192:

172:

169:

109:

106:

97:Sludge bulking

72:microorganisms

15:

9:

6:

4:

3:

2:

2596:

2585:

2582:

2580:

2577:

2575:

2572:

2571:

2569:

2554:

2545:

2544:

2541:

2535:

2532:

2530:

2527:

2525:

2522:

2520:

2517:

2515:

2512:

2510:

2507:

2505:

2502:

2500:

2497:

2495:

2492:

2490:

2487:

2485:

2482:

2480:

2477:

2475:

2472:

2470:

2467:

2465:

2462:

2461:

2459:

2455:

2449:

2446:

2444:

2441:

2439:

2436:

2434:

2431:

2429:

2426:

2424:

2421:

2419:

2416:

2414:

2411:

2409:

2406:

2404:

2401:

2399:

2396:

2394:

2393:Sedimentation

2391:

2389:

2386:

2384:

2381:

2379:

2376:

2374:

2371:

2369:

2366:

2364:

2361:

2359:

2356:

2354:

2351:

2349:

2346:

2344:

2341:

2339:

2336:

2334:

2331:

2329:

2326:

2324:

2321:

2319:

2316:

2314:

2311:

2309:

2306:

2304:

2301:

2299:

2296:

2294:

2291:

2290:

2288:

2286:

2282:

2276:

2273:

2271:

2268:

2266:

2263:

2261:

2258:

2256:

2253:

2251:

2248:

2246:

2243:

2241:

2238:

2236:

2233:

2231:

2228:

2226:

2223:

2221:

2218:

2216:

2213:

2212:

2210:

2208:

2204:

2198:

2195:

2193:

2190:

2188:

2187:Sewage sludge

2185:

2183:

2180:

2178:

2175:

2173:

2170:

2168:

2165:

2163:

2160:

2158:

2155:

2153:

2150:

2148:

2145:

2143:

2140:

2138:

2135:

2133:

2130:

2128:

2125:

2123:

2120:

2118:

2115:

2113:

2112:Cooling water

2110:

2108:

2107:Cooling tower

2105:

2103:

2100:

2098:

2095:

2093:

2090:

2088:

2085:

2083:

2080:

2078:

2075:

2073:

2072:Ballast water

2070:

2068:

2065:

2064:

2062:

2058:

2054:

2047:

2042:

2040:

2035:

2033:

2028:

2027:

2024:

2007:

2005:9780774841382

2001:

1998:. UBC Press.

1997:

1996:

1988:

1980:

1976:

1971:

1966:

1962:

1958:

1954:

1947:

1939:

1935:

1931:

1927:

1923:

1919:

1915:

1911:

1907:

1903:

1896:

1890:

1886:

1883:

1878:

1874:

1867:

1865:

1863:

1861:

1846:on 2015-07-03

1845:

1841:

1835:

1829:

1824:

1818:

1813:

1806:

1800:

1794:

1789:

1783:

1779:

1776:

1771:

1757:on 2009-03-26

1756:

1752:

1750:

1742:

1734:

1730:

1726:

1725:

1717:

1715:

1713:

1711:

1702:

1695:

1680:

1676:

1670:

1662:

1656:

1645:

1639:

1637:

1635:

1619:

1615:

1611:

1605:

1603:

1601:

1592:

1590:0-07-112250-8

1586:

1582:

1577:

1576:

1568:

1566:

1556:

1551:

1547:

1543:

1539:

1532:

1513:

1506:

1500:

1485:

1481:

1475:

1473:

1465:. 2015-10-13.

1464:

1460:

1456:

1450:

1448:

1433:

1429:

1423:

1421:

1416:

1406:

1403:

1401:

1398:

1396:

1393:

1391:

1388:

1386:

1383:

1381:

1378:

1376:

1373:

1371:

1368:

1366:

1363:

1361:

1358:

1356:

1353:

1352:

1346:

1345:were common.

1344:

1340:

1339:sewer systems

1336:

1332:

1328:

1324:

1320:

1315:

1309:

1305:

1301:

1297:

1296:Massachusetts

1293:

1289:

1285:

1281:

1273:

1268:

1259:

1257:

1251:

1246:

1240:

1230:

1228:

1224:

1219:

1216:

1211:

1196:

1193:

1183:

1181:

1170:

1163:

1158:

1149:

1146:

1145:tropical fish

1142:

1138:

1129:

1115:

1114:and filling.

1113:

1109:

1104:

1094:

1090:

1084:

1080:

1071:

1069:

1060:

1055:

1045:

1042:

1039:

1035:

1030:

1003:

994:

992:

987:

978:

976:

972:

968:

963:

959:

957:

946:

938:

934:

930:

911:

900:

897:

892:

872:

869:

864:

853:

850:

845:

840:

826:

814:

810:

807:

775:

767:

759:

754:

746:

743:

738:

733:

714:

703:

700:

695:

690:

670:

634:

629:

624:

605:

594:

591:

588:

585:

580:

575:

556:

523:

515:

507:

502:

494:

491:

486:

481:

462:

451:

448:

445:

442:

437:

432:

413:

412:

411:

408:

405:

402:

393:

389:

385:

383:

377:

375:

371:

367:

363:

359:

348:

344:

342:

338:

334:

330:

329:sewage sludge

319:

317:

312:

307:

305:

300:

298:

294:

290:

286:

282:

277:

275:

274:

269:

268:

263:

259:

255:

251:

247:

243:

239:

235:

231:

227:

223:

219:

215:

205:

201:

193:

190:

189:

188:

185:

182:

178:

168:

166:

162:

158:

154:

151:

143:

138:

130:

122:

114:

105:

103:

98:

94:

92:

87:

83:

81:

77:

73:

69:

65:

61:

57:

53:

49:

45:

41:

37:

34:

26:

21:

2534:Vacuum sewer

2418:Sewer mining

2368:Ion exchange

2318:Chlorination

2292:

2240:Heavy metals

2197:Urban runoff

2137:Ion exchange

2117:Fecal sludge

2009:. Retrieved

1994:

1987:

1960:

1956:

1946:

1905:

1901:

1895:

1876:

1872:

1848:. Retrieved

1844:the original

1834:

1823:

1812:

1799:

1788:

1770:

1759:. Retrieved

1755:the original

1748:

1741:

1722:

1700:

1694:

1682:. Retrieved

1678:

1669:

1622:. Retrieved

1620:. 2013-03-19

1613:

1574:

1545:

1541:

1531:

1519:. Retrieved

1512:the original

1499:

1488:. Retrieved

1483:

1458:

1435:. Retrieved

1431:

1316:

1307:

1277:

1252:

1248:

1220:

1213:

1189:

1176:

1167:

1134:

1106:

1091:

1072:

1065:

1043:

1031:

1004:

1000:

988:

984:

970:

967:high charged

966:

964:

960:

952:

944:

935:

931:

815:

813:is present.

811:

808:

671:

668:

409:

406:

403:

399:

390:

386:

378:

372:), and COD (

354:

345:

325:

308:

301:

296:

281:mixed liquor

280:

278:

271:

265:

262:mucilaginous

254:Vorticellids

211:

202:

198:

186:

181:flocculation

174:

147:

95:

88:

84:

35:

32:

30:

2524:Storm drain

2519:Sewage farm

2443:Vermifilter

2398:Septic tank

2358:Imhoff tank

2255:Temperature

2162:Return flow

2152:Papermaking

1286:. In 1912,

971:low charged

941:Plant types

285:supernatant

246:Spirotrichs

2568:Categories

2489:Irrigation

2353:Filtration

2053:Wastewater

2011:2013-02-07

1850:2015-08-13

1761:2007-09-08

1624:2022-02-19

1521:6 February

1490:2016-05-03

1459:The Source

1437:2019-12-27

1411:References

1162:Vespasiano

975:flocculate

341:composting

299:(R.A.S.).

252:including

250:Peritrichs

218:wastewater

2323:Clarifier

2270:Turbidity

2122:Greywater

1979:1476-1777

1684:19 August

1319:Worcester

1223:pollution

1164:, Brazil)

882:⟶

846:−

739:−

720:⟶

630:−

611:⟶

581:−

487:−

468:⟶

366:phosphate

238:protozoan

165:nutrients

2574:Sewerage

2250:Salinity

2142:Leachate

2077:Bathroom

1938:38062767

1930:21153808

1885:Archived

1778:Archived

1733:67019834

1655:cite web

1349:See also

1143:used in

1141:airstone

1137:diffuser

1112:aerating

362:nitrogen

293:aeration

273:Gordonia

258:Rotifers

161:nitrogen

157:ammonium

144:, Russia

60:protozoa

52:aeration

2177:Septage

1910:Bibcode

1331:Germany

1327:Denmark

1262:History

1038:Pruteen

1029:/kWh).

368:, BOD (

242:amoebae

226:organic

177:aerobic

150:oxidise

108:Purpose

36:process

2551:

2192:Toilet

2182:Sewage

2147:Manure

2002:

1977:

1936:

1928:

1731:

1587:

1335:Canada

1227:sewage

1199:Issues

1192:Nereda

904:

885:

876:

857:

830:

824:

723:

707:

680:

614:

598:

565:

471:

455:

422:

289:sludge

230:sewage

214:oxygen

195:water.

142:Moscow

102:Nereda

70:) and

68:oxygen

50:using

44:sewage

2097:Brine

1934:S2CID

1647:(PDF)

1515:(PDF)

1508:(PDF)

2438:UASB

2000:ISBN

1975:ISSN

1926:PMID

1729:LCCN

1686:2024

1661:link

1585:ISBN

1581:1456

1523:2022

1341:and

1333:and

1270:The

222:floc

159:and

80:floc

56:floc

31:The

1965:doi

1918:doi

1550:doi

1083:kWh

1068:BOD

1034:ICI

969:or

360:),

74:to

46:or

2570::

2245:pH

1973:.

1959:.

1955:.

1932:.

1924:.

1916:.

1906:61

1904:.

1877:67

1875:.

1859:^

1709:^

1677:.

1657:}}

1653:{{

1633:^

1616:.

1612:.

1599:^

1583:.

1564:^

1546:29

1544:.

1540:.

1482:.

1471:^

1461:.

1457:.

1446:^

1430:.

1419:^

1329:,

873:10

364:,

270:,

248:,

244:,

2045:e

2038:t

2031:v

2014:.

1981:.

1967::

1961:6

1940:.

1920::

1912::

1853:.

1764:.

1735:.

1703:.

1688:.

1663:)

1627:.

1593:.

1558:.

1552::

1525:.

1493:.

1440:.

1312:5

1087:2

1081:/

1078:2

1076:O

1027:2

1023:2

1019:2

1015:2

1011:2

1007:2

917:O

912:2

908:H

901:6

898:+

893:2

889:N

879:H

870:+

865:+

861:H

854:2

851:+

841:3

837:O

833:N

827:2

794:y

791:g

788:r

785:e

782:n

779:E

776:+

773:O

768:2

764:H

760:+

755:+

751:H

747:2

744:+

734:3

730:O

726:N

715:2

711:O

704:2

701:+

696:+

691:4

687:H

683:N

653:y

650:g

647:r

644:e

641:n

638:E

635:+

625:3

621:O

617:N

606:2

602:O

595:5

592:,

589:0

586:+

576:2

572:O

568:N

542:y

539:g

536:r

533:e

530:n

527:E

524:+

521:O

516:2

512:H

508:+

503:+

499:H

495:2

492:+

482:2

478:O

474:N

463:2

459:O

452:5

449:,

446:1

443:+

438:+

433:4

429:H

425:N

356:(

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.