354:

346:

36:

338:

45:

330:

293:) is a group of similar methods of purifying crystals, in which a narrow region of a crystal is melted, and this molten zone is moved along the crystal. The molten region melts impure solid at its forward edge and leaves a wake of purer material solidified behind it as it moves through the ingot. The impurities concentrate in the melt, and are moved to one end of the ingot. Zone refining was invented by

382:

through a thin section of furnace very slowly, such that only a small region of the boule is molten at any time, the impurities will be segregated at the end of the crystal. Because of the lack of impurities in the leftover regions which solidify, the boule can grow as a perfect

455:

are used extensively in research facilities particularly for the production of insulators, but their use in industry is limited by the relatively low power of the lamps, which limits the size of crystals produced by this method. Zone melting can be done as a

460:, or it can be done continuously, with fresh impure material being continually added at one end and purer material being removed from the other, with impure zone melt being removed at whatever rate is dictated by the impurity of the feed stock.

414:

is placed in the molten zone, which is passed through the pure germanium. With the proper choice of rate of heating and other variables, the antimony can be spread evenly through the germanium. This technique is also used for the preparation of

378:(the ratio at equilibrium of an impurity in the solid phase to that in the liquid phase) is usually less than one. Therefore, at the solid/liquid boundary, the impurity atoms will diffuse to the liquid region. Thus, by passing a crystal

944:

1230:, in which two solutes are distributed through a pure metal. This is important in the manufacture of semiconductors, where two solutes of opposite conductivity type are used. For example, in germanium, pentavalent elements of

1162:

325:

system having an appreciable concentration difference between solid and liquid phases at equilibrium. This process is also known as the float zone process, particularly in semiconductor materials processing.

391:

is placed at the base to initiate a chosen direction of crystal growth. When high purity is required, such as in semiconductor industry, the impure end of the boule is cut off, and the refining is repeated.

466:

methods use an induction-heated tungsten ring to heat the ingot radiatively, and are useful when the ingot is of a high-resistivity semiconductor on which classical induction heating is ineffective.

333:

A diagram of the vertical zone refining process used to grow single-crystal ice from an initially polycrystalline material. The convection in the melt is a result of water's density maximum at 4 °C.

83:

1254:

produce positive (p-type) conduction. By melting a portion of such an ingot and slowly refreezing it, solutes in the molten region become distributed to form the desired n-p and p-n junctions.

431:

A variety of heaters can be used for zone melting, with their most important characteristic being the ability to form short molten zones that move slowly and uniformly through the ingot.

788:

1042:

989:

831:

685:

656:

605:

576:

525:

712:

495:

627:

547:

837:

1189:

is the highest among various manufacturing processes. Float-zone carrier lifetimes are around 1000 microseconds compared to 20–200 microseconds with

1048:

395:

In zone refining, solutes are segregated at one end of the ingot in order to purify the remainder, or to concentrate the impurities. In

265:

65:

coil melts a section of the metal bar in the tube. The coil moves slowly down the tube, moving the molten zone to the end of the bar.

1181:, float zone processing is particularly useful because the single-crystal silicon grown has desirable properties. The bulk charge

194:

439:, or gas flames are common methods. Another method is to pass an electric current directly through the ingot while it is in a

1436:

1309:

399:, the objective is to distribute solute evenly throughout the purified material, which may be sought in the form of a single

1340:

224:

497:, the number of impurities in the liquid change. Impurities are incorporated in the melting liquid and freezing solid.

1481:

447:

carefully set to be just equal to the weight in order to hold the liquid suspended. Optical heaters using high-powered

1350:

1476:

720:

169:

1486:

1471:

1397:

258:

174:

133:

17:

691:

The number of impurities in the liquid changes in accordance with the expression below during the movement

214:

995:

950:

317:, refined to one atom of impurity per ten billion, but the process can be extended to virtually any

251:

1269:

1194:

794:

204:

1373:

663:

634:

583:

554:

503:

8:

1274:

1263:

444:

294:

199:

939:{\displaystyle \int _{0}^{x}dx=\int _{I_{O}}^{I}{\frac {dI}{C_{O}-{\frac {k_{O}I}{L}}}}}

694:

477:

353:

1288:

1210:

1190:

1186:

612:

532:

420:

219:

179:

1466:

1442:

1432:

1346:

1305:

1299:

436:

209:

102:

62:

365:

single crystal, made by the floating-zone process (cylindrical object in the center)

1408:

1365:

1182:

457:

410:, an ingot of germanium is first purified by zone refining. Then a small amount of

358:

298:

143:

82:

345:

379:

234:

164:

123:

74:

452:

440:

432:

384:

229:

148:

128:

35:

1157:{\displaystyle C_{S}(x)=C_{O}\left(1-(1-k_{O})e^{-{\frac {k_{O}x}{L}}}\right)}

1460:

1446:

407:

306:

1426:

448:

388:

138:

1304:. Crystals. Vol. 12. Berlin, Heidelberg: Springer Berlin Heidelberg.

337:

1243:

189:

1198:

1178:

310:

107:

1247:

314:

302:

56:

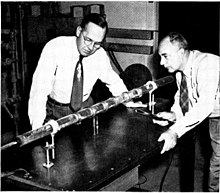

Pfann, at left, showing the first zone refining tube, Bell Labs, 1953

44:

469:

1242:

produce negative (n-type) conduction and the trivalent elements of

1235:

411:

362:

1239:

1231:

416:

400:

322:

184:

97:

329:

318:

578:: initial uniform impurity concentration of the solidified rod

27:

Purification process by moving a molten zone along a metal bar

1251:

404:

607:: concentration of impurities in the liquid melt per length

658:: number of impurities in zone when first formed at bottom

341:

Silicon crystal in the beginning of the growth process

1197:. A longer bulk lifetime increases the efficiency of

1051:

998:

953:

840:

797:

723:

697:

666:

637:

615:

586:

557:

535:

506:

480:

403:. For example, in the preparation of a transistor or

305:

as a method to prepare high-purity materials, mainly

1286:

1156:

1036:

983:

938:

825:

782:

706:

679:

650:

621:

599:

570:

541:

519:

489:

374:The principle is that the segregation coefficient

470:Mathematical expression of impurity concentration

1458:

1431:. M. K. Lee (3 ed.). New York, NY: Wiley.

1411:, Michael D. Deal, and Peter B. Griffin (2000)

687:: concentration of impurities in the solid rod

1428:Semiconductor devices: physics and technology

259:

1204:

783:{\displaystyle dI=(C_{O}-k_{O}C_{L})\,dx\;}

1033:

980:

822:

779:

266:

252:

1213:-based high-power semiconductor devices.

772:

474:When the liquid zone moves by a distance

352:

344:

336:

328:

14:

1459:

1297:

1388:, Volume 21, W-X-Y-Z, 1973, page 501.

1378:

1338:

1359:

1216:

629:: number of impurities in the liquid

1424:

225:Shaping processes in crystal growth

24:

1280:

1193:, and 1–30 microseconds with cast

369:

313:. Its first commercial use was in

61:Vertical zone refining, 1961. The

25:

1498:

1418:

1342:J. D. Bernal: The Sage of Science

1221:

1037:{\displaystyle C_{S}=k_{O}I/L\;}

81:

43:

34:

1167:

195:Fractional crystallization

1402:

1391:

1332:

1172:

1114:

1095:

1068:

1062:

984:{\displaystyle I_{O}=C_{O}L\;}

769:

733:

464:Indirect-heating floating zone

13:

1:

1325:

1287:Hermann Schildknecht (1966),

1339:Brown, Andrew (2005-11-24).

1301:Crystal Growth from the Melt

1209:It's used for production of

215:Laser-heated pedestal growth

7:

1386:The World Book Encyclopedia

1257:

1226:Another related process is

826:{\displaystyle C_{L}=I/L\;}

205:Hydrothermal synthesis

170:Bridgman–Stockbarger method

10:

1503:

1266:a.k.a. freeze distillation

426:

1482:Methods of crystal growth

1415:, Prentice Hall, page 129

1398:Float Zone Crystal Growth

1384:”Zone melting”, entry in

1293:, Weinheim: Verlag Chemie

527:: segregation coefficient

297:and further developed by

247:

175:Van Arkel–de Boer process

161:

156:

120:

115:

94:

89:

80:

73:

1205:High-resistivity devices

200:Fractional freezing

1477:Liquid-solid separation

1413:Silicon VLSI Technology

1270:Monocrystalline silicon

1195:polycrystalline silicon

349:Growing silicon crystal

291:floating-zone technique

180:Czochralski method

1158:

1038:

985:

940:

827:

784:

708:

681:

652:

623:

601:

572:

543:

521:

491:

366:

350:

342:

334:

157:Methods and technology

1374:John Wiley & Sons

1159:

1039:

986:

941:

828:

785:

709:

682:

680:{\displaystyle C_{S}}

653:

651:{\displaystyle I_{O}}

624:

602:

600:{\displaystyle C_{L}}

573:

571:{\displaystyle C_{O}}

544:

522:

520:{\displaystyle k_{O}}

492:

443:, with the resulting

356:

348:

340:

332:

1487:Semiconductor growth

1472:Industrial processes

1049:

996:

951:

838:

795:

721:

695:

664:

635:

613:

584:

555:

533:

504:

478:

309:, for manufacturing

287:floating-zone method

1425:Sze, S. M. (2012).

1298:Müller, G. (1988).

1275:Wafer (electronics)

1264:Fractional freezing

886:

855:

714:of the molten zone

445:magnetomotive force

421:integrated circuits

295:John Desmond Bernal

149:Single crystal

129:Crystal growth

1211:float-zone silicon

1191:Czochralski method

1187:float-zone silicon

1154:

1034:

981:

936:

865:

841:

823:

780:

707:{\displaystyle dx}

704:

677:

648:

619:

597:

568:

539:

517:

490:{\displaystyle dx}

487:

437:resistance heaters

367:

351:

343:

335:

220:Micro-pulling-down

1438:978-0-470-53794-7

1311:978-3-642-73210-2

1217:Related processes

1145:

934:

931:

622:{\displaystyle I}

542:{\displaystyle L}

276:

275:

210:Kyropoulos method

139:Seed crystal

134:Recrystallization

103:Crystal structure

63:induction heating

16:(Redirected from

1494:

1451:

1450:

1422:

1416:

1409:James D. Plummer

1406:

1400:

1395:

1389:

1382:

1376:

1366:William G. Pfann

1363:

1357:

1356:

1336:

1321:

1319:

1318:

1294:

1183:carrier lifetime

1163:

1161:

1160:

1155:

1153:

1149:

1148:

1147:

1146:

1141:

1137:

1136:

1126:

1113:

1112:

1083:

1082:

1061:

1060:

1043:

1041:

1040:

1035:

1029:

1021:

1020:

1008:

1007:

990:

988:

987:

982:

976:

975:

963:

962:

945:

943:

942:

937:

935:

933:

932:

927:

923:

922:

912:

907:

906:

896:

888:

885:

880:

879:

878:

854:

849:

832:

830:

829:

824:

818:

807:

806:

789:

787:

786:

781:

768:

767:

758:

757:

745:

744:

713:

711:

710:

705:

686:

684:

683:

678:

676:

675:

657:

655:

654:

649:

647:

646:

628:

626:

625:

620:

606:

604:

603:

598:

596:

595:

577:

575:

574:

569:

567:

566:

548:

546:

545:

540:

526:

524:

523:

518:

516:

515:

496:

494:

493:

488:

299:William G. Pfann

268:

261:

254:

144:Protocrystalline

85:

71:

70:

47:

38:

21:

1502:

1501:

1497:

1496:

1495:

1493:

1492:

1491:

1457:

1456:

1455:

1454:

1439:

1423:

1419:

1407:

1403:

1396:

1392:

1383:

1379:

1372:, 2nd edition,

1364:

1360:

1353:

1337:

1333:

1328:

1316:

1314:

1312:

1283:

1281:Further reading

1260:

1224:

1219:

1207:

1201:significantly.

1175:

1170:

1132:

1128:

1127:

1125:

1121:

1117:

1108:

1104:

1088:

1084:

1078:

1074:

1056:

1052:

1050:

1047:

1046:

1025:

1016:

1012:

1003:

999:

997:

994:

993:

971:

967:

958:

954:

952:

949:

948:

918:

914:

913:

911:

902:

898:

897:

889:

887:

881:

874:

870:

869:

850:

845:

839:

836:

835:

814:

802:

798:

796:

793:

792:

763:

759:

753:

749:

740:

736:

722:

719:

718:

696:

693:

692:

671:

667:

665:

662:

661:

642:

638:

636:

633:

632:

614:

611:

610:

591:

587:

585:

582:

581:

562:

558:

556:

553:

552:

534:

531:

530:

511:

507:

505:

502:

501:

479:

476:

475:

472:

433:Induction coils

429:

372:

370:Process details

357:A high-purity (

272:

235:Verneuil method

124:Crystallization

75:Crystallization

69:

68:

67:

66:

57:

50:

49:

48:

40:

39:

28:

23:

22:

15:

12:

11:

5:

1500:

1490:

1489:

1484:

1479:

1474:

1469:

1453:

1452:

1437:

1417:

1401:

1390:

1377:

1358:

1351:

1345:. OUP Oxford.

1330:

1329:

1327:

1324:

1323:

1322:

1310:

1295:

1282:

1279:

1278:

1277:

1272:

1267:

1259:

1256:

1228:zone remelting

1223:

1222:Zone remelting

1220:

1218:

1215:

1206:

1203:

1174:

1171:

1169:

1166:

1165:

1164:

1152:

1144:

1140:

1135:

1131:

1124:

1120:

1116:

1111:

1107:

1103:

1100:

1097:

1094:

1091:

1087:

1081:

1077:

1073:

1070:

1067:

1064:

1059:

1055:

1044:

1032:

1028:

1024:

1019:

1015:

1011:

1006:

1002:

991:

979:

974:

970:

966:

961:

957:

946:

930:

926:

921:

917:

910:

905:

901:

895:

892:

884:

877:

873:

868:

864:

861:

858:

853:

848:

844:

833:

821:

817:

813:

810:

805:

801:

790:

778:

775:

771:

766:

762:

756:

752:

748:

743:

739:

735:

732:

729:

726:

703:

700:

689:

688:

674:

670:

659:

645:

641:

630:

618:

608:

594:

590:

579:

565:

561:

550:

538:

528:

514:

510:

486:

483:

471:

468:

441:magnetic field

428:

425:

385:single crystal

371:

368:

307:semiconductors

274:

273:

271:

270:

263:

256:

248:

245:

244:

243:

242:

237:

232:

230:Skull crucible

227:

222:

217:

212:

207:

202:

197:

192:

187:

182:

177:

172:

167:

159:

158:

154:

153:

152:

151:

146:

141:

136:

131:

126:

118:

117:

113:

112:

111:

110:

105:

100:

92:

91:

87:

86:

78:

77:

52:

51:

42:

41:

33:

32:

31:

30:

29:

26:

9:

6:

4:

3:

2:

1499:

1488:

1485:

1483:

1480:

1478:

1475:

1473:

1470:

1468:

1465:

1464:

1462:

1448:

1444:

1440:

1434:

1430:

1429:

1421:

1414:

1410:

1405:

1399:

1394:

1387:

1381:

1375:

1371:

1367:

1362:

1354:

1352:9780198515449

1348:

1344:

1343:

1335:

1331:

1313:

1307:

1303:

1302:

1296:

1292:

1291:

1285:

1284:

1276:

1273:

1271:

1268:

1265:

1262:

1261:

1255:

1253:

1249:

1245:

1241:

1237:

1233:

1229:

1214:

1212:

1202:

1200:

1196:

1192:

1188:

1184:

1180:

1150:

1142:

1138:

1133:

1129:

1122:

1118:

1109:

1105:

1101:

1098:

1092:

1089:

1085:

1079:

1075:

1071:

1065:

1057:

1053:

1045:

1030:

1026:

1022:

1017:

1013:

1009:

1004:

1000:

992:

977:

972:

968:

964:

959:

955:

947:

928:

924:

919:

915:

908:

903:

899:

893:

890:

882:

875:

871:

866:

862:

859:

856:

851:

846:

842:

834:

819:

815:

811:

808:

803:

799:

791:

776:

773:

764:

760:

754:

750:

746:

741:

737:

730:

727:

724:

717:

716:

715:

701:

698:

672:

668:

660:

643:

639:

631:

616:

609:

592:

588:

580:

563:

559:

551:

549:: zone length

536:

529:

512:

508:

500:

499:

498:

484:

481:

467:

465:

461:

459:

458:batch process

454:

450:

446:

442:

438:

435:, ring-wound

434:

424:

422:

418:

413:

409:

408:semiconductor

406:

402:

398:

397:zone leveling

393:

390:

386:

381:

377:

364:

360:

355:

347:

339:

331:

327:

324:

320:

316:

312:

308:

304:

300:

296:

292:

288:

284:

283:zone refining

280:

269:

264:

262:

257:

255:

250:

249:

246:

241:

238:

236:

233:

231:

228:

226:

223:

221:

218:

216:

213:

211:

208:

206:

203:

201:

198:

196:

193:

191:

188:

186:

183:

181:

178:

176:

173:

171:

168:

166:

163:

162:

160:

155:

150:

147:

145:

142:

140:

137:

135:

132:

130:

127:

125:

122:

121:

119:

114:

109:

106:

104:

101:

99:

96:

95:

93:

88:

84:

79:

76:

72:

64:

60:

55:

46:

37:

19:

18:Zone refining

1427:

1420:

1412:

1404:

1393:

1385:

1380:

1370:Zone Melting

1369:

1361:

1341:

1334:

1315:. Retrieved

1300:

1290:Zone Melting

1289:

1227:

1225:

1208:

1176:

1168:Applications

690:

473:

463:

462:

430:

396:

394:

389:seed crystal

375:

373:

290:

286:

282:

279:Zone melting

278:

277:

240:Zone melting

239:

90:Fundamentals

58:

53:

1199:solar cells

1179:solar cells

1173:Solar cells

453:xenon lamps

423:("chips").

419:for use in

311:transistors

190:Flux method

1461:Categories

1326:References

1317:2023-11-23

108:Nucleation

1447:869833419

1248:aluminium

1244:group III

1123:−

1102:−

1093:−

909:−

867:∫

843:∫

747:−

315:germanium

303:Bell Labs

1467:Crystals

1258:See also

1246:such as

1236:antimony

1234:such as

412:antimony

363:tantalum

116:Concepts

1368:(1966)

1240:arsenic

1232:group V

449:halogen

427:Heaters

417:silicon

401:crystal

323:solvent

185:Epitaxy

98:Crystal

59:(right)

1445:

1435:

1349:

1308:

319:solute

165:Boules

54:(left)

1252:boron

405:diode

387:if a

380:boule

289:, or

285:, or

1443:OCLC

1433:ISBN

1347:ISBN

1306:ISBN

1250:and

1238:and

281:(or

1185:in

1177:In

451:or

301:in

1463::

1441:.

361:)

359:5N

1449:.

1355:.

1320:.

1151:)

1143:L

1139:x

1134:O

1130:k

1119:e

1115:)

1110:O

1106:k

1099:1

1096:(

1090:1

1086:(

1080:O

1076:C

1072:=

1069:)

1066:x

1063:(

1058:S

1054:C

1031:L

1027:/

1023:I

1018:O

1014:k

1010:=

1005:S

1001:C

978:L

973:O

969:C

965:=

960:O

956:I

929:L

925:I

920:O

916:k

904:O

900:C

894:I

891:d

883:I

876:O

872:I

863:=

860:x

857:d

852:x

847:0

820:L

816:/

812:I

809:=

804:L

800:C

777:x

774:d

770:)

765:L

761:C

755:O

751:k

742:O

738:C

734:(

731:=

728:I

725:d

702:x

699:d

673:S

669:C

644:O

640:I

617:I

593:L

589:C

564:O

560:C

537:L

513:O

509:k

485:x

482:d

376:k

321:–

267:e

260:t

253:v

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.