233:

249:"waste" steps, another type. He calls the value stream the process and the non-value streams the operations. The thinking here is that the non–value-adding steps are often preparatory or tidying up to the value-adding step and are closely associated with the person or machine/workstation that executes that value-adding step. Therefore, each vertical line is the "story" of a person or workstation whilst the horizontal line represents the "story" of the product being created.

42:-management method for analyzing the current state and designing a future state for the series of events that take a product or service from the beginning of the specific process until it reaches the customer. A value stream map is a visual tool that displays all critical steps in a specific process and easily quantifies the time and volume taken at each stage. Value stream maps show the flow of both materials and information as they progress through the process.

20:

904:

248:

suggests that the value-adding steps be drawn across the centre of the map and the non–value-adding steps be represented in vertical lines at right angles to the value stream. Thus, the activities become easily separated into the value stream, which is the focus of one type of attention, and the

66:

The purpose of value-stream mapping is to identify and remove or reduce "waste" in value streams, thereby increasing the efficiency of a given value stream. Waste removal is intended to increase productivity by creating leaner operations which in turn make waste and quality problems easier to

229:. The current state value stream map is used to determine what the process currently looks like, the future state value stream map focuses on what the process will ideally look like after process improvements have occurred to the value stream.

240:

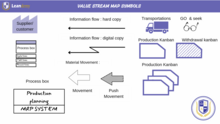

The current state value stream map must be created before the future state map and is created by observing the process and tracking the information and material flow. The value stream map is then created using the following symbols:

57:

diagram shows an overview of all activities within a company. Other business activities may be represented in "value stream diagrams" and/or other kinds of diagram that represent business processes that create and use business data.

144:: an overly complex solution for a simple procedure. Previously referred to as inappropriate processing, and includes unsafe production. This typically leads to poor layout and communication, and unnecessary motion.

259:

Value-stream mapping analyzes both material (artifact) and information flow. The following two resources exemplify the use of VSM in the context of software process improvement in industrial settings:

206:

NNVA activities may also be referred to as "sustaining non-value adding", i.e. they have to be done, or they are necessary to sustain the business but do not contribute to customer requirements.

150:: an overabundance of inventory which results in greater lead times, increased difficulty identifying problems, and significant storage costs. Previously referred to as unnecessary inventory.

156:: ergonomic waste that requires employees to use excess energy such as picking up objects, bending, or stretching. Previously referred to as unnecessary movements, and usually avoidable.

126:: creating too much of a good or service that damages production flow, quality, and productivity. Previously referred to as overproduction, and leads to storage and lead time waste.

768:

23:

Value-stream mapping usually employs standard symbols to represent items and processes, therefore knowledge of these symbols is essential to correctly interpret the

788:

Ali NB, Petersen K, Breno

Bernard Nicolau de França. Evaluation of simulation-assisted value-stream mapping for software product development: Two industrial cases.

383:

82:

Although value-stream mapping is often associated with manufacturing, it is also used in logistics, supply chain, service related industries, healthcare,

683:

263:"Artifact analysis": analysis of software artifacts like requirements, use case, change request or defect report through the development process

1073:

888:

138:: the process by which goods are moved around. Previously referred to as transport, and includes double-handling and excessive movement.

945:

779:

Rother, Mike, and John Shook. Learning to see: value stream mapping to add value and eliminate muda. Lean

Enterprise Institute, 2003.

769:

http://www.isixsigma.com/index.php?option=com_k2&view=itemlist&layout=category&task=category&id=90&Itemid=222#

908:

872:

308:: line graphs showing the customer demand and production, allowing visualisation of supply and demand and potential delays.

790:

289:

1031:

843:

627:

600:

575:

548:

521:

494:

442:

752:

593:

Mastering lean product development: a practical, event-driven process for maximizing speed, profits and quality

283:

282:: the initial step of constructing a map which consists of a study of process flows, waste identification, and

938:

362:

459:

391:

1123:

1078:

709:

103:

Daniel T. Jones (1995) identifies seven commonly accepted types of waste. These terms are updated from

83:

804:

1000:

931:

696:

395:

342:

304:

112:

1118:

411:

409:

407:

405:

312:

744:

738:

1052:

974:

24:

402:

914:

116:

805:

FLOW-assisted value-stream mapping in the early phases of large-scale software development

619:

The

Complete Lean Enterprise: Value Stream Mapping for Administrative and Office Processes

300:: helps draw connections to other industries that may have solutions to existing problems.

79:

environments to analyze and design flows at the system level (across multiple processes).

8:

1026:

699:. Karlskrona: Department of Software Engineering, Blekinge Institute of Technology; 2015.

697:

Operationalization of lean thinking through value-stream mapping with simulation and FLOW

87:

669:

Toyota

Production System - An Integrated Approach to Just-In-Time | Y. Monden | Springer

1005:

882:

710:"Value Stream Mapping symbols : From Clarity to Chaos The Unintended consequences"

347:

210:

76:

39:

868:

839:

748:

651:

623:

617:

596:

571:

565:

544:

538:

517:

511:

490:

484:

438:

266:"Information flow analysis": analysis of information flows in the development process

1083:

1036:

513:

Healthcare Kaizen: Engaging Front-Line Staff in

Sustainable Continuous Improvements

50:

16:

Lean-management method for analyzing the current state and designing a future state

969:

833:

667:

253:

232:

108:

192:): actions that are wasteful but necessary under current operating procedures.

1112:

734:

323:

245:

162:: any cost associated with defects or the resources required to correct them.

1010:

357:

275:

Hines and Rich (1997) defined seven value-stream mapping tools. These are:

46:

486:

Lean

Hospitals: Improving Quality, Patient Safety, and Employee Engagement

352:

54:

435:

Learning to See: value-stream mapping to create value and eliminate muda

19:

1088:

954:

835:

Integral

Logistic Structures: Developing Customer-oriented Goods Flow

294:: identifying critical bottlenecks for processes in a simple diagram.

332:: combined model that overviews supply chain from an industry level.

867:. Project Management Institute (7th ed.). Newtown Square, PA.

75:

Value-stream mapping has supporting methods that are often used in

923:

865:

A guide to the project management body of knowledge (PMBOK guide)

1057:

903:

104:

90:, project management, and administrative and office processes.

202:): conversion or processing of raw materials via manual labor.

1099:

984:

171:

Yasuhiro Monden (1994) identifies three types of operations:

862:

415:

252:

Value-stream mapping is a recognised method used as part of

428:

426:

424:

316:: locates product and service defects in the supply chain.

567:

Lean IT: Enabling and

Sustaining Your Lean Transformation

460:"34 for Quality : John Bicheno : 9780951382943"

421:

132:: any time goods are not being transported or worked on.

437:. Brookline, Massachusetts: Lean Enterprise Institute.

743:. Stamford, Connecticut: Productivity Press. pp.

182:): actions that should be eliminated, such as waiting.

540:

Lean

Management Principles for Information Technology

807:. Journal of Systems and Software. 2016;111:213-27.

595:. Northridge, California: Technology Perspectives.

684:Business Process Improvement: the Hambleton Story

1110:

817:Rich, Nick; Esain, Ann; Bateman, Nicola (1997).

816:

740:A Revolution in Manufacturing: The SMED System

270:

939:

831:

509:

727:

615:

564:Bell, Steven; Orzen, Michael (2010-09-14).

432:

166:

946:

932:

887:: CS1 maint: location missing publisher (

819:Lean Evolution: Lessons from the Workplace

590:

221:There are two kinds of value stream maps,

649:

563:

53:that adds value to a material product, a

920:at the Lean Enterprise Institute website

231:

18:

767:"Value Stream Mapping" Article Source:

650:Hines, Peter; Rich, Nick (1997-01-01).

536:

1111:

733:

482:

457:

384:"Value Stream Mapping—an Introduction"

36:material- and information-flow mapping

927:

863:Project Management Institute (2021).

832:Hoekstra, Sjoerd; Romme, Jac (1992).

645:

643:

641:

639:

510:Graban, Mark; Swartz, Joseph (2011).

381:

653:The seven value stream mapping tools

93:

953:

791:Information and Software Technology

322:: determines inflection points for

236:Value stream mapping common symbols

216:

209:For additional views on waste, see

13:

636:

616:Keyte, Beau; Locher, Drew (2004).

570:. Boca Raton, Florida: CRC Press.

543:. Boca Raton, Florida: CRC Press.

516:. Boca Raton, Florida: CRC Press.

489:. Boca Raton, Florida: CRC Press.

433:Rother, Mike; Shook, John (1999).

14:

1135:

1032:Failure mode and effects analysis

896:

803:Ali NB, Petersen K, Schneider K.

416:Project Management Institute 2021

244:In a build-to-the-standard form,

98:

902:

622:. New York: Productivity Press.

825:

810:

797:

782:

773:

761:

702:

689:

676:

660:

609:

284:business process re-engineering

70:

584:

557:

530:

503:

476:

451:

375:

186:Necessary but non-value adding

1:

856:

821:. Cambridge University Press.

363:Value-stream-mapping software

113:Toyota Production System, TPS

392:American Society for Quality

368:

291:Supply chain response matrix

7:

1079:Statistical process control

591:Mascitelli, Ronald (2011).

336:

271:Associated analysis methods

176:Non-value adding operations

10:

1142:

330:Physical structure mapping

124:Faster-than-necessary pace

61:

1097:

1066:

1045:

1019:

993:

962:

686:, accessed 13 August 2020

537:Plenert, Gerhard (2011).

394:. p. 64 – via

382:Manos, Tony (June 2006).

298:Production variety funnel

115:) original nomenclature (

1001:Business process mapping

838:. Industrial Press Inc.

418:, §4.6.6 Focus on Value.

396:University of Washington

343:Business process mapping

305:Forrester effect mapping

280:Process activity mapping

167:Waste removal operations

320:Decision point analysis

464:www.bookdepository.com

313:Quality filter mapping

237:

160:Correction of mistakes

49:map represents a core

28:

1053:Design of experiments

975:Voice of the customer

483:Graban, Mark (2011).

235:

22:

980:Value-stream mapping

916:Value-stream mapping

911:at Wikimedia Commons

909:Value stream mapping

326:in the supply chain.

324:push-and-pull demand

84:software development

32:Value-stream mapping

1027:Root cause analysis

88:product development

1124:Lean manufacturing

1006:Process capability

458:Depository, Book.

348:Lean manufacturing

238:

211:Lean manufacturing

154:Unnecessary motion

29:

1106:

1105:

907:Media related to

874:978-1-62825-664-2

107:operating model "

94:Identifying waste

34:, also known as

25:production system

1131:

1037:Multi-vari chart

948:

941:

934:

925:

924:

906:

892:

886:

878:

850:

849:

829:

823:

822:

814:

808:

801:

795:

786:

780:

777:

771:

765:

759:

758:

731:

725:

724:

722:

721:

706:

700:

693:

687:

680:

674:

673:

664:

658:

657:

647:

634:

633:

613:

607:

606:

588:

582:

581:

561:

555:

554:

534:

528:

527:

507:

501:

500:

480:

474:

473:

471:

470:

455:

449:

448:

430:

419:

413:

400:

399:

388:Quality Progress

379:

217:Using the method

51:business process

1141:

1140:

1134:

1133:

1132:

1130:

1129:

1128:

1109:

1108:

1107:

1102:

1093:

1062:

1041:

1015:

989:

970:Project charter

958:

952:

899:

880:

879:

875:

859:

854:

853:

846:

830:

826:

815:

811:

802:

798:

787:

783:

778:

774:

766:

762:

755:

732:

728:

719:

717:

708:

707:

703:

694:

690:

681:

677:

666:

665:

661:

656:. Vol. 17.

648:

637:

630:

614:

610:

603:

589:

585:

578:

562:

558:

551:

535:

531:

524:

508:

504:

497:

481:

477:

468:

466:

456:

452:

445:

431:

422:

414:

403:

380:

376:

371:

339:

273:

256:methodologies.

219:

169:

101:

96:

73:

64:

17:

12:

11:

5:

1139:

1138:

1127:

1126:

1121:

1119:Business terms

1104:

1103:

1098:

1095:

1094:

1092:

1091:

1086:

1081:

1076:

1070:

1068:

1064:

1063:

1061:

1060:

1055:

1049:

1047:

1043:

1042:

1040:

1039:

1034:

1029:

1023:

1021:

1017:

1016:

1014:

1013:

1008:

1003:

997:

995:

991:

990:

988:

987:

982:

977:

972:

966:

964:

960:

959:

951:

950:

943:

936:

928:

922:

921:

918:– Lexicon term

912:

898:

897:External links

895:

894:

893:

873:

858:

855:

852:

851:

844:

824:

809:

796:

781:

772:

760:

753:

735:Shingo, Shigeo

726:

701:

688:

675:

659:

635:

628:

608:

601:

583:

576:

556:

549:

529:

522:

502:

495:

475:

450:

443:

420:

401:

373:

372:

370:

367:

366:

365:

360:

355:

350:

345:

338:

335:

334:

333:

327:

317:

309:

301:

295:

287:

272:

269:

268:

267:

264:

254:Lean Six Sigma

218:

215:

204:

203:

193:

183:

168:

165:

164:

163:

157:

151:

145:

139:

133:

127:

109:The Toyota Way

100:

99:Types of waste

97:

95:

92:

72:

69:

63:

60:

15:

9:

6:

4:

3:

2:

1137:

1136:

1125:

1122:

1120:

1117:

1116:

1114:

1101:

1096:

1090:

1087:

1085:

1082:

1080:

1077:

1075:

1072:

1071:

1069:

1067:Control phase

1065:

1059:

1056:

1054:

1051:

1050:

1048:

1046:Improve phase

1044:

1038:

1035:

1033:

1030:

1028:

1025:

1024:

1022:

1020:Analyse phase

1018:

1012:

1009:

1007:

1004:

1002:

999:

998:

996:

994:Measure phase

992:

986:

983:

981:

978:

976:

973:

971:

968:

967:

965:

961:

956:

949:

944:

942:

937:

935:

930:

929:

926:

919:

917:

913:

910:

905:

901:

900:

890:

884:

876:

870:

866:

861:

860:

847:

845:9780831130374

841:

837:

836:

828:

820:

813:

806:

800:

794:. 2015;68:45.

793:

792:

785:

776:

770:

764:

756:

750:

746:

742:

741:

736:

730:

715:

711:

705:

698:

692:

685:

679:

671:

670:

663:

655:

654:

646:

644:

642:

640:

631:

629:9781563273018

625:

621:

620:

612:

604:

602:9780966269741

598:

594:

587:

579:

577:9781439817568

573:

569:

568:

560:

552:

550:9781420078602

546:

542:

541:

533:

525:

523:9781439872963

519:

515:

514:

506:

498:

496:9781439870433

492:

488:

487:

479:

465:

461:

454:

446:

444:0-9667843-0-8

440:

436:

429:

427:

425:

417:

412:

410:

408:

406:

397:

393:

389:

385:

378:

374:

364:

361:

359:

356:

354:

351:

349:

346:

344:

341:

340:

331:

328:

325:

321:

318:

315:

314:

310:

307:

306:

302:

299:

296:

293:

292:

288:

285:

281:

278:

277:

276:

265:

262:

261:

260:

257:

255:

250:

247:

246:Shigeo Shingo

242:

234:

230:

228:

224:

223:current state

214:

212:

207:

201:

197:

194:

191:

187:

184:

181:

177:

174:

173:

172:

161:

158:

155:

152:

149:

146:

143:

140:

137:

134:

131:

128:

125:

122:

121:

120:

118:

114:

110:

106:

91:

89:

85:

80:

78:

68:

59:

56:

52:

48:

43:

41:

37:

33:

26:

21:

1074:Control plan

1011:Pareto chart

979:

963:Define phase

915:

864:

834:

827:

818:

812:

799:

789:

784:

775:

763:

739:

729:

718:. Retrieved

716:. 2023-09-08

713:

704:

691:

678:

668:

662:

652:

618:

611:

592:

586:

566:

559:

539:

532:

512:

505:

485:

478:

467:. Retrieved

463:

453:

434:

387:

377:

358:Value stream

329:

319:

311:

303:

297:

290:

279:

274:

258:

251:

243:

239:

227:future state

226:

222:

220:

208:

205:

199:

196:Value-adding

195:

189:

185:

179:

175:

170:

159:

153:

148:Excess stock

147:

141:

135:

129:

123:

102:

81:

74:

71:Applications

65:

47:value stream

44:

35:

31:

30:

353:Value chain

55:value chain

1113:Categories

857:References

754:0915299097

720:2024-01-13

695:Ali N.B.,

682:Cain, M.,

469:2018-03-22

142:Processing

136:Conveyance

67:identify.

45:Whereas a

1089:Poka-yoke

955:Six Sigma

883:cite book

369:Citations

27:problems.

737:(1985).

714:Leandemy

337:See also

105:Toyota's

130:Waiting

62:Purpose

38:, is a

1058:Kaizen

871:

842:

751:

626:

599:

574:

547:

520:

493:

441:

1100:DMAIC

985:SIPOC

957:tools

889:link

869:ISBN

840:ISBN

749:ISBN

624:ISBN

597:ISBN

572:ISBN

545:ISBN

518:ISBN

491:ISBN

439:ISBN

225:and

190:NNVA

117:muda

77:lean

40:lean

180:NVA

119:):

111:" (

1115::

1084:5S

885:}}

881:{{

747:.

712:.

638:^

462:.

423:^

404:^

390:.

386:.

213:.

200:VA

86:,

947:e

940:t

933:v

891:)

877:.

848:.

757:.

745:5

723:.

672:.

632:.

605:.

580:.

553:.

526:.

499:.

472:.

447:.

398:.

286:.

198:(

188:(

178:(

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.