102:

25:

422:

203:

234:

180:, a hybrid technology developed by EWI and MTI, which "uses an external energy source to raise the interface temperature of the two parts being joined, thereby reducing the process forces required to make a solid-state weld compared to traditional friction welding". The process applies to both linear and rotary friction welding.

486:

Friction welding may unintentionally occur at sliding surfaces like bearings. This happens in particular if the lubricating oil film between sliding surfaces becomes thinner than the surface roughness, which may be due to low speed, low temperature, oil starvation, excessive clearance, low viscosity

241:

Friction stir welding (FSW) is a solid-state joining process that uses a non-consumable tool to join two facing workpieces without melting the workpiece material. Heat is generated by friction between the rotating tool and the workpiece material, which leads to a softened region near the FSW tool.

256:

Friction surfacing is a process derived from friction welding where a coating material is applied to a substrate. A rod composed of the coating material (called a mechtrode) is rotated under pressure, generating a plasticized layer in the rod at the interface with the substrate.

210:

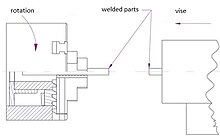

Rotary friction welding (RFW) is one of the main methods of friction welding. One welded element is rotated relative to the other and pressed down. The heating of the material is caused by friction work and creates a non-separable weld.

612:- interval time in the friction welding cycle in which the heat necessary for making a weld is generated by relative motion and the friction forces between the components i.e. from contact of components to the start of deceleration,

1276:

Buzzatti, Diogo Trento; Chludzinki, Mariane; Santos, Rafael

Eugenio dos; Buzzatti, Jonas Trento; Lemos, Guilherme Vieira Braga; Mattei, Fabiano; Marinho, Ricardo Reppold; Paes, Marcelo Torres Piza; Reguly, Afonso (2019).

276:

In linear vibration welding, the materials are placed in contact and put under pressure. An external vibration force is then applied to slip the pieces relative to each other, perpendicular to the pressure being applied.

129:

took place in the Soviet Union in 1956, when a machinist named A. J. Chdikov researched scientific studies and suggested the use of the welding method as a commercial process. The process was introduced to the

439:

Technically, the WCZ and the TMAZ are both "thermo-mechanically affected zones"; due to the different microstructures they possess, they are often considered separately. The WCZ experiences significant

109:

Some applications and patents connected with friction welding dates back to the turn of the 20th century, and rotary friction welding is the oldest of the methods. W. Richter patented the method of

242:

While the tool is traversed along the joint line, it mechanically intermixes the two pieces of metal and forges the hot and softened metal by the mechanical pressure which is applied by the tool.

66:

between workpieces in relative motion to one another. The process is used with the addition of a lateral force called "upset" to plastically displace and fuse the materials. Friction welding is a

448:

is not deformed mechanically but is affected by the heat. The region from one TMAZ/HAZ boundary to the other is often referred to as the "TMAZ thickness" or the plastically affected zone (PAZ).

696:

381:

In addition to changing the grain structure during metal joining cycles, by methods where high temperature affected zone was occur, are phase transformations structure. For example, in

157:

and

Thompson launched rotary friction welding for industrial applications in 1966, developed a direct-drive process, and in 1974, built the rRS6 double spindle machine for heavy truck

490:

The seizure resistance is the ability of a material to resist friction welding. It is a fundamental property of bearing surfaces and in general of sliding surfaces under load.

161:. Another method was invented in the Soviet Union by Yu. Klimenko in the mid-1960s and patented in 1967, experimentally proven and developed into a commercial technology at

337:

289:, but uses a more complex machine to produce an orbital motion in which the moving part rotates in a small circle, much smaller than the size of the joint as a whole.

918:

Thomas, W.M., Nicholas, E.D., Needham, J.C., Murch, M.G., Templesmith, P., Dawes, C. J., 1991. Improvements to

Friction Welding. GB Patent Application No. 91259788.

1773:

1318:

Buzzatti, Diogo Trento; Buzzatti, Jonas Trento; Santos, Rafael

Eugenio dos; Mattei, Fabiano; Chludzinski, Mariane; Strohaecker, Telmo Roberto (2015).

672:- succession of operations carried out by the machine to make a weldment and return to the initial position, excluding component-handling operations,

173:(FSW) process, is a solid-state joining process that uses a non-consumable tool to join two facing workpieces without melting the workpiece material.

89:

of friction welding is EN ISO 15620:2019, which contains information about the basic terms, definitions, and tables of the weldability of metals and

1551:

1455:

847:

802:

219:

Linear friction welding (LFW) is the act of moving a single component in a linear reciprocating motion across the face of a stationary component.

413:). In order to avoid changes, solid state welding may be desired and large heat affected zone is not needed if weakens the material properties.

520:

86:

1735:

359:

Quality requirements of welded joints depend on the form of application, e.g. in the space or flight industry, weld errors are not allowed.

624:- time during which relative movement between the components takes place at rotational speed and under application of the friction forces,

1235:

Pissanti, Daniela

Ramminger; Scheid, Adriano; Kanan, Luis Fernando; Dalpiaz, Giovani; Kwietniewski, Carlos Eduardo Fortis (January 2019).

1184:

Orłowska, Marta; Olejnik, Lech; Campanella, Davide; Buffa, Gianluca; Morawiński, Łukasz; Fratini, Livan; Lewandowska, Małgorzata (2020).

1471:"The Influence of Heat Treatment on Microstructure and Tribological Properties of Resistance Butt Welds Made of a Cast Bainitic Steel"

1652:

576:- force applied normal to the faying surfaces at the time when relative movement between the components is ceasing or has ceased,

660:- loss of length that occurs as a result of friction welding, i.e. the sum of the burn-off length and the forge burn-off length,

1022:

153:

In the United States, Caterpillar Inc. and

Manufacturing Technology Inc. (MTI) developed an inertia process in 1962. In Europe,

1766:

1070:

606:- force applied perpendicularly to the faying surfaces during the time that there is relative movement between the components,

1046:

866:

150:

and the Soviet Union. The first studies of friction welding in

England were carried out by the Welding Institute in 1961.

1564:

1759:

1728:

1678:"Study on the Bonding Performance of the Moso Bamboo Dowel Welded to a Poplar Substrate Joint by High-Speed Rotation"

1395:

354:

648:- interval in the friction welding cycle in which the relative motion of the components is decelerated to zero,

1578:

1140:

McAndrew, Anthony R.; Colegrove, Paul A.; Bühr, Clement; Flipo, Bertrand C.D.; Vairis, Achilleas (2018-10-03).

588:- interval time in the friction welding cycle between the start and finish of application of the forge force,

582:- amount by which the overall length of the components is reduced during the application of the forge force,

1911:

1721:

143:

1856:

1420:

570:- surface of one component that is to be in contact with a surface of another component to form a joint,

1833:

1510:

Clement Bühr, Paul A.Colegrove, Bertrand C.D.Flipo, Achilleas Vairis, Anthony R.McAndrew (2018-03-01).

642:- distance a component sticks out from the fixture, or chuck in the direction of the mating component,

371:

309:

433:

1848:

441:

1509:

2076:

1823:

410:

332:

327:

271:

957:

2050:

1798:

1632:

618:- pressure (force per unit area) on the faying surfaces resulting from the axial friction force,

197:

126:

110:

630:- contact area developed between the faying surfaces after completion of the welding operation,

1906:

1813:

360:

139:

594:- pressure (force per unit area) on the faying surfaces resulting from the axial forge force,

432:

Anthony R. McAndrew, Paul A. Colegrove, Clement Bühr, Bertrand C.D., Flipo

Achilleas Vairis, "

101:

1891:

1886:

1861:

1838:

1818:

1545:

1449:

796:

500:

303:

228:

170:

162:

1957:

1901:

723:

524:

1676:

Li, Suxia; Zhang, Haiyang; Shu, Biqing; Cheng, Liangsong; Ju, Zehui; Lu, Xiaoning (2021).

8:

1866:

1418:

932:

654:- time required by the moving component to decelerate from friction speed to zero speed,

177:

1279:"Toughness properties of a friction hydro pillar processed offshore mooring chain steel"

755:

188:

Friction welding takes many forms but the following are the most popular methods used.

121:. The description of the process was vague and H. Klopstock patented the process in the

38:

Please help update this article to reflect recent events or newly available information.

1983:

1921:

1896:

1871:

1828:

1803:

1608:

980:

459:

445:

390:

375:

251:

2025:

2020:

1699:

1612:

1600:

1595:

1533:

1492:

1401:

1391:

1351:

1300:

1258:

1217:

1163:

1117:

984:

841:

780:

1577:

Wang, Kaifeng; Khan, Haris Ali; Li, Zhiyi; Lyu, Sinuo; Li, Jingjing (October 2018).

2081:

1782:

1689:

1590:

1523:

1482:

1435:

1341:

1331:

1290:

1248:

1207:

1197:

1153:

1107:

998:

976:

972:

135:

1528:

1511:

1336:

1319:

1158:

1141:

890:

1993:

1419:

T. Chmielewski, W. Pachla, M. Kulczyk, J. Skiba, W. Presz, B. Skowrońska (2019).

1253:

1236:

1202:

1185:

429:

Individual thermomechanical zones can be described by citing an example article:

118:

1186:"Application of linear friction welding for joining ultrafine grained aluminium"

830:

558:- reduction in rotational speed resulting from friction between the interfaces,

1988:

1952:

1295:

1278:

166:

75:

1626:

1487:

1470:

958:"Analysis of low force friction welding process in the industrial environment"

507:. which does not mean that it is safe and recommended for the milling machine.

421:

2070:

1967:

1962:

1926:

1876:

1808:

1703:

1694:

1677:

1604:

1537:

1496:

1440:

1405:

1355:

1304:

1262:

1221:

1167:

1121:

298:

131:

79:

71:

67:

546:- rate of shortening of the components during the friction welding process,

348:

146:

all developed machines for the process. Patents were also issued throughout

1947:

1916:

1744:

781:"Linear Friction Welding Of High Strength Chains: Modelling And Validation"

286:

122:

1385:

1237:"Pipeline girth friction welding of the UNS S32205 duplex stainless steel"

1112:

1095:

202:

1998:

1790:

1096:"Effect of Tool Shape on Temperature Field in Friction Stir Spot Welding"

504:

367:

1346:

1212:

105:

Historical photo of a double spindle machine for rotary friction welding

2045:

2040:

406:

176:

An improved modification of the standard friction welding technique is

1094:

Lacki, P.; Kucharczyk, Z.; Śliwa, R.E.; Gałaczyński, T. (2013-06-01).

487:

of the oil, high roughness of the surfaces, or a combination thereof.

416:

233:

2035:

2030:

1942:

402:

386:

1320:"Friction Hydro Pillar Processing: Characteristics and Applications"

829:

Mehmet UZKUT, Bekir Sadık ÜNLÜ, Selim Sarper YILMAZ, Mustafa AKDAĞ.

370:

structure of alloy or metal which is obtained by techniques such as

666:- time elapsed between component contact and end of forging phase,

525:

ISO 15620:2019(en) Welding — Friction welding of metallic materials

394:

63:

2055:

2015:

1579:"Micro friction stir welding of multilayer aluminum alloy sheets"

1047:"What is Friction Stir Welding (FSW)? - Process and Applications"

475:

398:

114:

59:

1275:

1713:

1093:

600:- time for which the forge force is applied to the components,

374:

is desirable, and not changed by the high temperature, a large

147:

1183:

965:

International

Journal of Engineering and Innovative Technology

382:

90:

1317:

564:- braking located externally reducing the rotational speed,

534:- force in axial direction between components to be welded,

292:

779:

J. LOPERA, K. MUCIC, F. FUCHS, N. ENZINGER (October 2012).

158:

154:

82:

in a wide variety of aviation and automotive applications.

62:

and bonding process that generates heat through mechanical

1512:"A literature review of Ti-6Al-4V linear friction welding"

1234:

1142:"A literature review of Ti-6Al-4V linear friction welding"

1139:

125:

in 1924. The first description and experiments related to

636:- number of revolutions per minute of rotating component

349:

Welds tests for friction welding and description of zones

831:"Friction Welding And Its Applications In Today's World"

514:

434:

A literature review of Ti-6Al-4V linear friction welding

697:"Friction Welding - an overview | ScienceDirect Topics"

363:

is performed, with measurements and numerical methods.

510:

Friction welding has also been shown to work on wood.

417:

Heat and mechanical affected zones in friction weld

1421:"Friction Weldability Of UFG 316L Stainless Steel"

891:"SU195846A1 - Method of welding metal by Friction"

521:the International Organization for Standardization

78:process, Friction welding is used with metals and

321:Friction hydro pillar overlap processing (FHPPOW)

2068:

318:Friction welding of pipeline girth welds (FRIEX)

1675:

1468:

1628:Wood Welding, How is it possible? Youtube link

1368:

1767:

1729:

1576:

425:Picture shows weld zones in friction welding.

1550:: CS1 maint: multiple names: authors list (

1454:: CS1 maint: multiple names: authors list (

1283:Journal of Materials Research and Technology

999:"Friction Welding 101: Whiteboard Wednesday"

846:: CS1 maint: multiple names: authors list (

801:: CS1 maint: multiple names: authors list (

540:- loss of length during the friction phase,

1383:

933:"Low Force Friction Welding -- What is it?"

678:- two or more components joined by welding.

280:

265:

1774:

1760:

1736:

1722:

1583:Journal of Materials Processing Technology

444:(DRX), the TMAZ does not. The material in

260:

214:

191:

1693:

1594:

1527:

1486:

1439:

1345:

1335:

1294:

1252:

1211:

1201:

1157:

1111:

1023:"Rotary Friction Welding - Job Knowledge"

778:

293:Method list connected to friction welding

1565:Requirements to engine bearing materials

1469:Parzych, S.; Krawczyk, J. (2012-01-01).

955:

828:

785:Mathematical Modelling of Weld Phenomena

464:TMAZ – Thermo-mechanically affected zone

420:

232:

222:

201:

100:

1373:(in Polish). Warszawa: Wydawnictwo WNT.

753:

324:Friction hydro pillar processing (FHHP)

285:Orbital friction welding is similar to

2069:

1135:

1133:

1131:

914:

912:

1755:

1717:

1387:Severe plastic deformation technology

1179:

1177:

861:

859:

857:

824:

822:

820:

818:

816:

814:

812:

774:

772:

515:Terms and definitions, name shortcuts

481:

245:

1475:Archives of Metallurgy and Materials

1228:

1100:Archives of Metallurgy and Materials

1087:

926:

924:

756:"Flywheel Friction Welding Research"

749:

747:

745:

743:

718:

716:

343:

18:

1653:"TWI Develops Wood Welding Process"

1371:Poradnik inżyniera 1 – spawalnictwo

1362:

1128:

956:Zurawski, Pawel (January 7, 2022).

909:

467:BM – base material, parent material

183:

13:

1190:Journal of Manufacturing Processes

1174:

1071:"What is Linear Friction Welding?"

867:"Rotary friction welding machines"

854:

809:

769:

14:

2093:

1369:Pilarczyk, J.; Piotr, A. (2013).

930:

921:

763:Supplement to the Welding Journal

740:

713:

1743:

1596:10.1016/j.jmatprotec.2018.05.029

169:and patented again in 1991: the

134:in 1960. The American companies

23:

1834:Shielded metal (Stick/MMA/SMAW)

1824:Gas tungsten (Heliarc/TIG/GTAW)

1669:

1645:

1635:from the original on 2021-12-12

1619:

1570:

1558:

1503:

1462:

1412:

1377:

1311:

1269:

1063:

1039:

1015:

991:

949:

355:Weld tests for friction welding

1819:Gas metal (Microwire/MIG/GMAW)

1682:Journal of Renewable Materials

977:10.51456/IJEIT.2022.v11i07.001

883:

689:

552:- single item before welding,

493:

144:American Manufacturing Foundry

1:

1529:10.1016/j.pmatsci.2017.10.003

1516:Progress in Materials Science

1384:Rosochowski, Andrzej (2013).

1159:10.1016/j.pmatsci.2017.10.003

1146:Progress in Materials Science

682:

503:) was also performed using a

315:Linear friction welding (LFW)

1799:Atomic hydrogen (Athydo/AHW)

1254:10.1016/j.matdes.2018.11.046

1203:10.1016/j.jmapro.2020.05.012

754:Wen Lin, K. K. Wang (1974).

361:Weld quality tests assurance

7:

1781:

1337:10.1590/0104-9224/si2003.04

366:For example, an ultra-fine

136:Caterpillar Tractor Company

16:Solid-state welding process

10:

2098:

1296:10.1016/j.jmrt.2019.04.002

499:Frictional welding (micro

474:Similar terms are used in

372:severe plastic deformation

352:

338:Low force friction welding

310:Friction stir spot welding

269:

249:

226:

195:

178:low force friction welding

96:

2011:

1976:

1935:

1857:Electric resistance (ERW)

1847:

1789:

1751:

1488:10.2478/v10172-012-0020-9

658:total length loss (upset)

556:component induced braking

442:dynamic recrystallisation

411:Iron-carbon phase diagram

113:(LFW) process in 1924 in

32:This article needs to be

1695:10.32604/jrm.2021.014364

1441:10.24425/amm.2019.129494

1196:. Elsevier BV: 540–549.

333:Spin welding of polymers

328:Linear vibration welding

281:Orbital friction welding

272:Linear vibration welding

266:Linear vibration welding

1390:. Whittles Publishing.

1324:Soldagem & Inspeção

261:Thermoplastic technique

215:Linear friction welding

206:Rotary friction welding

198:Rotary friction welding

192:Rotary friction welding

127:rotary friction welding

111:linear friction welding

1241:Materials & Design

680:

426:

238:

207:

140:Rockwell International

106:

56:Friction welding (FWR)

2051:Tools and terminology

1113:10.2478/amm-2013-0043

701:www.sciencedirect.com

580:forge burn-off length

529:

501:friction stir welding

455:WCZ– weld center zone

424:

304:Friction stir welding

237:Friction stir welding

236:

229:Friction stir welding

223:Friction stir welding

205:

171:friction stir welding

163:The Welding Institute

138:(Caterpillar - CAT),

104:

70:technique similar to

1887:Friction stir (FSW)

1862:Electron-beam (EBW)

1428:Arch. Metall. Mater

1003:blog.mtiwelding.com

937:blog.mtiwelding.com

724:"EN ISO 15620:2019"

68:solid-state welding

1984:Heat-affected zone

1912:Oxyacetylene (OAW)

1657:www.twi-global.com

1075:www.twi-global.com

1051:www.twi-global.com

1027:www.twi-global.com

646:deceleration phase

482:Seizure resistance

460:heat affected zone

427:

376:heat affected zone

252:Friction surfacing

246:Friction surfacing

239:

208:

107:

2064:

2063:

2007:

2006:

1867:Electroslag (ESW)

1814:Flux-cored (FCAW)

652:deceleration time

616:friction pressure

344:Other information

58:is a solid-state

53:

52:

2089:

1897:Laser beam (LBW)

1804:Electrogas (EGW)

1776:

1769:

1762:

1753:

1752:

1738:

1731:

1724:

1715:

1714:

1708:

1707:

1697:

1688:(7): 1225–1237.

1673:

1667:

1666:

1664:

1663:

1649:

1643:

1642:

1641:

1640:

1623:

1617:

1616:

1598:

1574:

1568:

1562:

1556:

1555:

1549:

1541:

1531:

1507:

1501:

1500:

1490:

1466:

1460:

1459:

1453:

1445:

1443:

1425:

1416:

1410:

1409:

1381:

1375:

1374:

1366:

1360:

1359:

1349:

1339:

1315:

1309:

1308:

1298:

1289:(3): 2625–2637.

1273:

1267:

1266:

1256:

1232:

1226:

1225:

1215:

1205:

1181:

1172:

1171:

1161:

1137:

1126:

1125:

1115:

1091:

1085:

1084:

1082:

1081:

1067:

1061:

1060:

1058:

1057:

1043:

1037:

1036:

1034:

1033:

1019:

1013:

1012:

1010:

1009:

995:

989:

988:

962:

953:

947:

946:

944:

943:

928:

919:

916:

907:

906:

904:

902:

887:

881:

880:

878:

877:

863:

852:

851:

845:

837:

835:

826:

807:

806:

800:

792:

776:

767:

766:

760:

751:

738:

737:

735:

734:

720:

711:

710:

708:

707:

693:

634:rotational speed

562:external braking

378:is unnecessary.

184:Metal techniques

117:and 1929 in the

48:

45:

39:

27:

26:

19:

2097:

2096:

2092:

2091:

2090:

2088:

2087:

2086:

2077:Plastic welding

2067:

2066:

2065:

2060:

2003:

1994:Residual stress

1972:

1931:

1849:Other processes

1843:

1839:Submerged (SAW)

1785:

1780:

1747:

1742:

1712:

1711:

1674:

1670:

1661:

1659:

1651:

1650:

1646:

1638:

1636:

1625:

1624:

1620:

1575:

1571:

1563:

1559:

1543:

1542:

1508:

1504:

1467:

1463:

1447:

1446:

1423:

1417:

1413:

1398:

1382:

1378:

1367:

1363:

1316:

1312:

1274:

1270:

1233:

1229:

1182:

1175:

1138:

1129:

1092:

1088:

1079:

1077:

1069:

1068:

1064:

1055:

1053:

1045:

1044:

1040:

1031:

1029:

1021:

1020:

1016:

1007:

1005:

997:

996:

992:

960:

954:

950:

941:

939:

929:

922:

917:

910:

900:

898:

897:. 20 April 2006

889:

888:

884:

875:

873:

865:

864:

855:

839:

838:

833:

827:

810:

794:

793:

777:

770:

758:

752:

741:

732:

730:

722:

721:

714:

705:

703:

695:

694:

690:

685:

664:total weld time

538:burn-off length

517:

496:

484:

419:

357:

351:

346:

295:

283:

274:

268:

263:

254:

248:

231:

225:

217:

200:

194:

186:

119:Weimar Republic

99:

74:. Instead of a

49:

43:

40:

37:

28:

24:

17:

12:

11:

5:

2095:

2085:

2084:

2079:

2062:

2061:

2059:

2058:

2053:

2048:

2043:

2038:

2033:

2028:

2023:

2018:

2012:

2009:

2008:

2005:

2004:

2002:

2001:

1996:

1991:

1989:Photokeratitis

1986:

1980:

1978:

1974:

1973:

1971:

1970:

1965:

1960:

1955:

1950:

1945:

1939:

1937:

1933:

1932:

1930:

1929:

1924:

1919:

1914:

1909:

1907:Magnetic pulse

1904:

1899:

1894:

1889:

1884:

1879:

1874:

1869:

1864:

1859:

1853:

1851:

1845:

1844:

1842:

1841:

1836:

1831:

1826:

1821:

1816:

1811:

1806:

1801:

1795:

1793:

1787:

1786:

1779:

1778:

1771:

1764:

1756:

1749:

1748:

1741:

1740:

1733:

1726:

1718:

1710:

1709:

1668:

1644:

1618:

1569:

1557:

1502:

1461:

1411:

1396:

1376:

1361:

1330:(3): 287–299.

1310:

1268:

1227:

1173:

1127:

1106:(2): 595–599.

1086:

1062:

1038:

1014:

990:

948:

931:Jones, Simon.

920:

908:

895:Google Patents

882:

853:

808:

768:

739:

712:

687:

686:

684:

681:

610:friction phase

604:friction force

592:forge pressure

568:faying surface

516:

513:

512:

511:

508:

495:

492:

483:

480:

472:

471:

468:

465:

462:

456:

418:

415:

353:Main article:

350:

347:

345:

342:

341:

340:

335:

330:

325:

322:

319:

316:

313:

307:

301:

294:

291:

282:

279:

270:Main article:

267:

264:

262:

259:

250:Main article:

247:

244:

227:Main article:

224:

221:

216:

213:

196:Main article:

193:

190:

185:

182:

167:United Kingdom

98:

95:

80:thermoplastics

76:fusion welding

51:

50:

31:

29:

22:

15:

9:

6:

4:

3:

2:

2094:

2083:

2080:

2078:

2075:

2074:

2072:

2057:

2054:

2052:

2049:

2047:

2044:

2042:

2039:

2037:

2034:

2032:

2029:

2027:

2024:

2022:

2019:

2017:

2014:

2013:

2010:

2000:

1997:

1995:

1992:

1990:

1987:

1985:

1982:

1981:

1979:

1977:Related terms

1975:

1969:

1968:Shielding gas

1966:

1964:

1961:

1959:

1956:

1954:

1951:

1949:

1946:

1944:

1941:

1940:

1938:

1934:

1928:

1925:

1923:

1920:

1918:

1915:

1913:

1910:

1908:

1905:

1903:

1900:

1898:

1895:

1893:

1892:Friction stud

1890:

1888:

1885:

1883:

1880:

1878:

1875:

1873:

1870:

1868:

1865:

1863:

1860:

1858:

1855:

1854:

1852:

1850:

1846:

1840:

1837:

1835:

1832:

1830:

1827:

1825:

1822:

1820:

1817:

1815:

1812:

1810:

1807:

1805:

1802:

1800:

1797:

1796:

1794:

1792:

1788:

1784:

1777:

1772:

1770:

1765:

1763:

1758:

1757:

1754:

1750:

1746:

1739:

1734:

1732:

1727:

1725:

1720:

1719:

1716:

1705:

1701:

1696:

1691:

1687:

1683:

1679:

1672:

1658:

1654:

1648:

1634:

1630:

1629:

1622:

1614:

1610:

1606:

1602:

1597:

1592:

1588:

1584:

1580:

1573:

1566:

1561:

1553:

1547:

1539:

1535:

1530:

1525:

1521:

1517:

1513:

1506:

1498:

1494:

1489:

1484:

1480:

1476:

1472:

1465:

1457:

1451:

1442:

1437:

1434:: 1051–1058.

1433:

1429:

1422:

1415:

1407:

1403:

1399:

1397:9781849951197

1393:

1389:

1388:

1380:

1372:

1365:

1357:

1353:

1348:

1343:

1338:

1333:

1329:

1325:

1321:

1314:

1306:

1302:

1297:

1292:

1288:

1284:

1280:

1272:

1264:

1260:

1255:

1250:

1246:

1242:

1238:

1231:

1223:

1219:

1214:

1209:

1204:

1199:

1195:

1191:

1187:

1180:

1178:

1169:

1165:

1160:

1155:

1151:

1147:

1143:

1136:

1134:

1132:

1123:

1119:

1114:

1109:

1105:

1101:

1097:

1090:

1076:

1072:

1066:

1052:

1048:

1042:

1028:

1024:

1018:

1004:

1000:

994:

986:

982:

978:

974:

970:

966:

959:

952:

938:

934:

927:

925:

915:

913:

896:

892:

886:

872:

868:

862:

860:

858:

849:

843:

832:

825:

823:

821:

819:

817:

815:

813:

804:

798:

790:

786:

782:

775:

773:

764:

757:

750:

748:

746:

744:

729:

725:

719:

717:

702:

698:

692:

688:

679:

677:

673:

671:

670:welding cycle

667:

665:

661:

659:

655:

653:

649:

647:

643:

641:

637:

635:

631:

629:

625:

623:

622:friction time

619:

617:

613:

611:

607:

605:

601:

599:

595:

593:

589:

587:

583:

581:

577:

575:

571:

569:

565:

563:

559:

557:

553:

551:

547:

545:

544:burn-off rate

541:

539:

535:

533:

528:

526:

522:

509:

506:

502:

498:

497:

491:

488:

479:

477:

469:

466:

463:

461:

457:

454:

453:

452:

449:

447:

443:

437:

435:

430:

423:

414:

412:

408:

404:

400:

396:

392:

388:

384:

379:

377:

373:

369:

364:

362:

356:

339:

336:

334:

331:

329:

326:

323:

320:

317:

314:

311:

308:

305:

302:

300:

299:Forge welding

297:

296:

290:

288:

278:

273:

258:

253:

243:

235:

230:

220:

212:

204:

199:

189:

181:

179:

174:

172:

168:

165:(TWI) in the

164:

160:

156:

151:

149:

145:

141:

137:

133:

132:United States

128:

124:

120:

116:

112:

103:

94:

92:

88:

83:

81:

77:

73:

72:forge welding

69:

65:

61:

57:

47:

35:

30:

21:

20:

1958:Power supply

1948:Filler metal

1902:Laser-hybrid

1881:

1829:Plasma (PAW)

1745:Metalworking

1685:

1681:

1671:

1660:. Retrieved

1656:

1647:

1637:, retrieved

1627:

1621:

1586:

1582:

1572:

1560:

1546:cite journal

1519:

1515:

1505:

1478:

1474:

1464:

1450:cite journal

1431:

1427:

1414:

1386:

1379:

1370:

1364:

1347:10183/132809

1327:

1323:

1313:

1286:

1282:

1271:

1244:

1240:

1230:

1213:10447/421431

1193:

1189:

1149:

1145:

1103:

1099:

1089:

1078:. Retrieved

1074:

1065:

1054:. Retrieved

1050:

1041:

1030:. Retrieved

1026:

1017:

1006:. Retrieved

1002:

993:

968:

964:

951:

940:. Retrieved

936:

899:. Retrieved

894:

885:

874:. Retrieved

870:

797:cite journal

788:

784:

762:

731:. Retrieved

727:

704:. Retrieved

700:

691:

675:

674:

669:

668:

663:

662:

657:

656:

651:

650:

645:

644:

639:

638:

633:

632:

627:

626:

621:

620:

615:

614:

609:

608:

603:

602:

597:

596:

591:

590:

585:

584:

579:

578:

573:

572:

567:

566:

561:

560:

555:

554:

549:

548:

543:

542:

537:

536:

531:

530:

519:From ISO's (

518:

489:

485:

473:

450:

438:

431:

428:

380:

365:

358:

287:spin welding

284:

275:

255:

240:

218:

209:

187:

175:

152:

123:Soviet Union

108:

84:

55:

54:

41:

33:

2021:Fabrication

1999:Weldability

1791:Arc welding

1589:: 137–145.

1522:: 225–257.

1247:: 198–209.

1152:: 225–257.

728:www.iso.org

586:forge phase

574:forge force

532:axial force

505:CNC machine

494:Curiosities

2071:Categories

2041:Metallurgy

1922:Ultrasonic

1917:Spot (RSW)

1872:Exothermic

1662:2021-04-06

1639:2021-04-06

1567:, SubsTech

1080:2023-07-06

1056:2023-07-06

1032:2023-07-06

1008:2023-07-06

971:(7): 1–9.

942:2020-12-28

876:2020-12-27

733:2020-12-28

706:2023-05-10

683:References

598:forge time

407:martensite

44:March 2023

2036:Machining

2031:Jewellery

1943:Electrode

1936:Equipment

1704:2164-6341

1613:140028992

1605:0924-0136

1538:0079-6425

1497:1733-3490

1406:968912427

1356:0104-9224

1305:2238-7854

1263:0264-1275

1222:1526-6125

1168:0079-6425

1122:1733-3490

985:247075337

640:stick-out

628:interface

550:component

436:", 2018.

403:cementite

387:austenite

2046:Smithing

1882:Friction

1633:archived

842:cite web

676:weldment

409:, (See:

395:pearlite

385:between

87:ISO norm

64:friction

2082:Welding

2056:Welding

2026:Forming

2016:Casting

1783:Welding

871:KUKA AG

476:welding

451:Zones:

399:bainite

391:ferrite

155:KUKA AG

115:England

97:History

60:welding

34:updated

1953:Helmet

1702:

1611:

1603:

1536:

1495:

1404:

1394:

1354:

1303:

1261:

1220:

1166:

1120:

983:

901:22 May

458:HAZ –

405:, and

312:(FSSW)

148:Europe

142:, and

91:alloys

1963:Robot

1927:Upset

1877:Forge

1809:Flash

1609:S2CID

1481:(1).

1424:(PDF)

981:S2CID

961:(PDF)

834:(PDF)

759:(PDF)

470:Flash

383:steel

368:grain

306:(FSW)

159:axles

1700:ISSN

1601:ISSN

1552:link

1534:ISSN

1493:ISSN

1456:link

1402:OCLC

1392:ISBN

1352:ISSN

1301:ISSN

1259:ISSN

1218:ISSN

1164:ISSN

1118:ISSN

903:2023

848:link

803:link

523:) -

85:The

1690:doi

1591:doi

1587:260

1524:doi

1483:doi

1436:doi

1342:hdl

1332:doi

1291:doi

1249:doi

1245:162

1208:hdl

1198:doi

1154:doi

1108:doi

973:doi

446:HAZ

2073::

1698:.

1684:.

1680:.

1655:.

1631:,

1607:.

1599:.

1585:.

1581:.

1548:}}

1544:{{

1532:.

1520:92

1518:.

1514:.

1491:.

1479:57

1477:.

1473:.

1452:}}

1448:{{

1432:64

1430:.

1426:.

1400:.

1350:.

1340:.

1328:20

1326:.

1322:.

1299:.

1285:.

1281:.

1257:.

1243:.

1239:.

1216:.

1206:.

1194:56

1192:.

1188:.

1176:^

1162:.

1150:92

1148:.

1144:.

1130:^

1116:.

1104:58

1102:.

1098:.

1073:.

1049:.

1025:.

1001:.

979:.

969:11

967:.

963:.

935:.

923:^

911:^

893:.

869:.

856:^

844:}}

840:{{

811:^

799:}}

795:{{

789:10

787:.

783:.

771:^

761:.

742:^

726:.

715:^

699:.

527::

478:.

401:,

397:,

393:,

389:,

93:.

1775:e

1768:t

1761:v

1737:e

1730:t

1723:v

1706:.

1692::

1686:9

1665:.

1615:.

1593::

1554:)

1540:.

1526::

1499:.

1485::

1458:)

1444:.

1438::

1408:.

1358:.

1344::

1334::

1307:.

1293::

1287:8

1265:.

1251::

1224:.

1210::

1200::

1170:.

1156::

1124:.

1110::

1083:.

1059:.

1035:.

1011:.

987:.

975::

945:.

905:.

879:.

850:)

836:.

805:)

791:.

765:.

736:.

709:.

46:)

42:(

36:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.