177:

165:

153:

22:

122:

In most cases, the slag can be discarded, perhaps after some cleaning, and the matte is further treated in converters to produce blister copper. In some cases where the flash furnaces are fed with concentrate containing a sufficiently high copper content, the concentrate is converted directly to

91:

Flash smelting with oxygen-enriched air (the 'reaction gas') makes use of the energy contained in the concentrate to supply most of the energy required by the furnaces. The concentrate must be dried before it is injected into the furnaces and, in the case of the

Outokumpu process, some of the

87:

has a water-cooled reaction shaft at one end of the vessel and a waste gas off-take at the other end. While the INCO flash furnace at

Sudbury was the first commercial use of oxygen flash smelting, fewer smelters use the INCO flash furnace than the Outokumpu flash furnace.

176:

164:

233:

152:

459:

929:

268:

Ilkka V. Kojo; Ari

Jokilaakso; Pekka Hanniala (February 2000). "Flash smelting and converting furnaces: A 50 year retrospect".

389:

136:, formerly the technology division of Outokumpu, now holds Outokumpu's patents to the technology and licenses it worldwide.

452:

244:

432:

480:

1088:

559:

554:

445:

25:

Development of flash smelting in the copper industry, related to the number of smelters using this technology.

833:

719:

1103:

196:

1108:

843:

1002:

103:. The reacted particles fall into a bath at the bottom of the furnace, where the iron oxides react with

21:

358:

Ed. J P Hager (The

Minerals, Metals and Materials Society: Warrendale, Pennsylvania, 1991), 1125–1145.

216:

182:

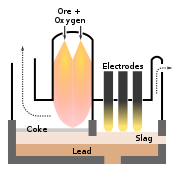

Kivcet flash furnace, mainly designed for lead smelting (also efficient for copper and zinc smelting)

219:. Collins English Dictionary - Complete & Unabridged 11th Edition. Retrieved November 03, 2012.

606:

728:

354:

S Ellor, M Chamberland and H Davies, 'Development of models of INCO's smelting processes,' in:

896:

864:

815:

616:

468:

140:

170:

Inco flash furnace, mainly designed for nickel smelting (also efficient for copper smelting)

79:') and has a different concentrate feed design compared to the Outokumpu flash furnace. The

681:

277:

628:

611:

8:

949:

838:

724:

671:

477:

127:

281:

779:

676:

488:

381:

301:

96:

92:

furnaces use an optional heater to warm the reaction gas typically to 100–450 °C.

83:

has end-wall concentrate injection burners and a central waste gas off-take, while the

1098:

976:

714:

507:

385:

305:

293:

104:

1057:

962:

934:

522:

512:

377:

285:

75:

A second flash smelting system was developed by the

International Nickel Company ('

33:

321:

319:

317:

315:

1093:

1083:

1047:

1007:

883:

699:

691:

338:

336:

334:

410:

398:

997:

828:

758:

666:

549:

537:

373:

312:

100:

331:

289:

1077:

1052:

957:

939:

924:

919:

914:

909:

789:

784:

297:

123:

blister in a single

Outokumpu furnace and further converting is unnecessary.

989:

709:

704:

661:

76:

49:

859:

823:

651:

583:

267:

126:

The sulfur dioxide produced by flash smelting is typically captured in a

437:

1062:

1012:

805:

744:

734:

591:

532:

61:

904:

869:

739:

623:

566:

240:

112:

53:

64:

plant in 1949 for smelting copper ore. It has also been adapted for

1032:

799:

771:

596:

41:

656:

633:

601:

527:

133:

57:

1037:

544:

108:

65:

45:

416:

404:

367:

342:

325:

571:

368:

Davenport, W G; King, M; Schlesinger, M; Biswas, A K (2002).

158:

Outokumpu flash furnace, mainly designed for copper smelting

95:

The reactions in the flash smelting furnaces produce copper

1042:

116:

69:

270:

JOM: Journal of the

Minerals, Metals and Materials Society

517:

130:, removing the major environmental effect of smelting.

1075:

453:

988:

228:

226:

16:Smelting process for sulfur-containing ores

460:

446:

467:

38:Liekkisulatus, literally "flame-smelting"

223:

20:

1076:

209:

441:

13:

382:10.1016/B978-0-08-044029-3.X5000-X

14:

1120:

481:Non-ferrous extractive metallurgy

426:

372:(4th ed.). Oxford, England:

175:

163:

151:

433:Metallugical Processes – Copper

370:Extractive Metallurgy of Copper

52:. The process was developed by

361:

348:

261:

139:INCO was acquired by Brazil's

1:

834:Bottom-blown oxygen converter

276:(2). Springer Boston: 57–61.

202:

197:Copper extraction techniques

7:

243:. p. 2. Archived from

190:

48:-containing ores including

10:

1125:

234:"Outokumpu Flash Smelting"

1025:

975:

948:

895:

882:

852:

814:

770:

757:

690:

644:

582:

500:

487:

475:

290:10.1007/s11837-000-0049-5

60:and first applied at the

560:Underground in soft rock

555:Underground in hard rock

1089:Metallurgical processes

417:Davenport et al. (2002)

405:Davenport et al. (2002)

343:Davenport et al. (2002)

326:Davenport et al. (2002)

85:Outokumpu flash furnace

37:

26:

888:(by aqueous solution)

720:Gravity Concentration

469:Extractive metallurgy

24:

1003:Hall–Héroult process

682:Mechanical screening

1104:Industrial furnaces

725:Magnetic separation

672:Cyclonic separation

493:(by physical means)

478:Metallurgical assay

419:, pp. 217–246.

407:, pp. 187–198.

282:2000JOM....52b..57K

128:sulfuric acid plant

1109:Finnish inventions

806:Refractory linings

677:Gyratory equipment

489:Mineral processing

356:EPD Congress 1992,

328:, pp. 91–102.

99:, iron oxides and

81:Inco flash furnace

27:

1071:

1070:

1021:

1020:

982:

977:Electrometallurgy

971:

970:

930:Gold chlorination

889:

878:

877:

764:

753:

752:

715:Jig concentrators

513:Natural resources

508:Geological survey

494:

391:978-0-08-044029-3

345:, pp. 73–90.

1116:

986:

985:

981:(by electricity)

980:

963:Pan amalgamation

935:Gold cyanidation

925:In situ leaching

893:

892:

887:

768:

767:

762:

523:Economic geology

498:

497:

492:

462:

455:

448:

439:

438:

420:

414:

408:

402:

396:

395:

365:

359:

352:

346:

340:

329:

323:

310:

309:

265:

259:

258:

256:

255:

249:

238:

230:

221:

220:

217:"flash smelting"

213:

179:

167:

155:

1124:

1123:

1119:

1118:

1117:

1115:

1114:

1113:

1074:

1073:

1072:

1067:

1017:

1008:Castner process

979:

967:

944:

886:

884:Hydrometallurgy

874:

848:

844:IsaKidd process

810:

761:

749:

700:Froth flotation

686:

640:

578:

491:

483:

471:

466:

429:

424:

423:

415:

411:

403:

399:

392:

366:

362:

353:

349:

341:

332:

324:

313:

266:

262:

253:

251:

250:on 24 July 2011

247:

236:

232:

231:

224:

215:

214:

210:

205:

193:

188:

187:

186:

183:

180:

171:

168:

159:

156:

17:

12:

11:

5:

1122:

1112:

1111:

1106:

1101:

1096:

1091:

1086:

1069:

1068:

1066:

1065:

1060:

1055:

1050:

1045:

1040:

1035:

1029:

1027:

1023:

1022:

1019:

1018:

1016:

1015:

1010:

1005:

1000:

998:Electrowinning

994:

992:

983:

973:

972:

969:

968:

966:

965:

960:

954:

952:

946:

945:

943:

942:

937:

932:

927:

922:

917:

912:

907:

901:

899:

890:

880:

879:

876:

875:

873:

872:

867:

862:

856:

854:

850:

849:

847:

846:

841:

836:

831:

829:Parkes process

826:

820:

818:

812:

811:

809:

808:

803:

797:

795:Flash smelting

792:

787:

782:

776:

774:

765:

759:Pyrometallurgy

755:

754:

751:

750:

748:

747:

742:

737:

732:

722:

717:

712:

707:

702:

696:

694:

688:

687:

685:

684:

679:

674:

669:

664:

659:

654:

648:

646:

642:

641:

639:

638:

637:

636:

631:

621:

620:

619:

614:

609:

599:

594:

588:

586:

580:

579:

577:

576:

575:

574:

564:

563:

562:

557:

552:

542:

541:

540:

538:Precious metal

535:

530:

525:

515:

510:

504:

502:

495:

485:

484:

476:

473:

472:

465:

464:

457:

450:

442:

436:

435:

428:

427:External links

425:

422:

421:

409:

397:

390:

374:Pergamon Press

360:

347:

330:

311:

260:

222:

207:

206:

204:

201:

200:

199:

192:

189:

185:

184:

181:

174:

172:

169:

162:

160:

157:

150:

147:

146:

145:

101:sulfur dioxide

30:Flash smelting

15:

9:

6:

4:

3:

2:

1121:

1110:

1107:

1105:

1102:

1100:

1097:

1095:

1092:

1090:

1087:

1085:

1082:

1081:

1079:

1064:

1061:

1059:

1056:

1054:

1051:

1049:

1046:

1044:

1041:

1039:

1036:

1034:

1031:

1030:

1028:

1024:

1014:

1011:

1009:

1006:

1004:

1001:

999:

996:

995:

993:

991:

987:

984:

978:

974:

964:

961:

959:

958:Patio process

956:

955:

953:

951:

947:

941:

940:Bayer process

938:

936:

933:

931:

928:

926:

923:

921:

920:Tank leaching

918:

916:

915:Dump leaching

913:

911:

910:Heap leaching

908:

906:

903:

902:

900:

898:

894:

891:

885:

881:

871:

868:

866:

863:

861:

858:

857:

855:

851:

845:

842:

840:

837:

835:

832:

830:

827:

825:

822:

821:

819:

817:

813:

807:

804:

801:

798:

796:

793:

791:

790:Zinc smelting

788:

786:

785:Lead smelting

783:

781:

780:Iron smelting

778:

777:

775:

773:

769:

766:

760:

756:

746:

743:

741:

738:

736:

733:

730:

726:

723:

721:

718:

716:

713:

711:

708:

706:

703:

701:

698:

697:

695:

693:

692:Concentration

689:

683:

680:

678:

675:

673:

670:

668:

665:

663:

660:

658:

655:

653:

650:

649:

647:

643:

635:

632:

630:

627:

626:

625:

622:

618:

615:

613:

610:

608:

605:

604:

603:

600:

598:

595:

593:

590:

589:

587:

585:

581:

573:

570:

569:

568:

565:

561:

558:

556:

553:

551:

548:

547:

546:

543:

539:

536:

534:

531:

529:

526:

524:

521:

520:

519:

516:

514:

511:

509:

506:

505:

503:

499:

496:

490:

486:

482:

479:

474:

470:

463:

458:

456:

451:

449:

444:

443:

440:

434:

431:

430:

418:

413:

406:

401:

393:

387:

383:

379:

375:

371:

364:

357:

351:

344:

339:

337:

335:

327:

322:

320:

318:

316:

307:

303:

299:

295:

291:

287:

283:

279:

275:

271:

264:

246:

242:

235:

229:

227:

218:

212:

208:

198:

195:

194:

178:

173:

166:

161:

154:

149:

148:

144:

142:

137:

135:

131:

129:

124:

120:

118:

114:

110:

106:

102:

98:

93:

89:

86:

82:

78:

73:

71:

67:

63:

59:

55:

51:

47:

43:

39:

35:

31:

23:

19:

990:Electrolysis

950:Amalgamation

794:

705:Jameson cell

662:Hydrocyclone

412:

400:

369:

363:

355:

350:

273:

269:

263:

252:. Retrieved

245:the original

211:

138:

132:

125:

121:

115:, to form a

94:

90:

84:

80:

74:

72:production.

50:chalcopyrite

44:process for

29:

28:

18:

1026:Co-products

860:Calcination

824:Cupellation

740:Dry washing

729:Magnetation

652:Ore sorting

617:Pebble mill

584:Comminution

1078:Categories

1063:Stamp sand

1013:Downs cell

745:Buddle pit

735:Rocker box

592:Stamp mill

533:Base metal

501:Extraction

254:2009-05-06

203:References

107:, such as

62:Harjavalta

905:Lixiviant

870:Liquation

763:(by heat)

624:Ball mill

567:Recycling

306:110355049

298:1047-4838

241:Outokumpu

143:in 2006.

113:limestone

54:Outokumpu

1099:Smelting

1033:Tailings

897:Leaching

865:Roasting

816:Refining

800:ISASMELT

772:Smelting

629:Rod mill

612:SAG mill

597:Arrastra

191:See also

42:smelting

1058:Red mud

1048:Clinker

802:furnace

710:Panning

667:Trommel

657:Vanning

634:IsaMill

607:AG mill

602:Crusher

550:Surface

528:Mineral

278:Bibcode

134:Outotec

58:Finland

40:) is a

34:Finnish

1094:Sulfur

1084:Copper

1038:Gangue

839:Poling

645:Sizing

545:Mining

388:

304:

296:

109:silica

105:fluxes

66:nickel

46:sulfur

853:Other

572:Scrap

302:S2CID

248:(PDF)

237:(PDF)

97:matte

1053:Chat

1043:Slag

386:ISBN

294:ISSN

141:Vale

117:slag

111:and

77:INCO

70:lead

68:and

518:Ore

378:doi

286:doi

56:in

1080::

384:.

376:.

333:^

314:^

300:.

292:.

284:.

274:52

272:.

239:.

225:^

119:.

36::

731:)

727:(

461:e

454:t

447:v

394:.

380::

308:.

288::

280::

257:.

32:(

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.