402:

318:

25:

390:

378:

330:

366:

342:

1195:

354:

90:

98:

204:

191:

and Fritz Hull came upon the idea of pumping concrete through pipes. They pumped concrete to a height of 38 meters (125 ft) and a distance of 120 meters (130 yd). Shortly after, a concrete pump was patented in

Holland in 1932 by Jacob Cornelius Kweimn (Jacobus Cornelius Kooijman). This

217:

Usually, piston pumps are used, because they can produce hundreds of atmospheres of pressure. Such piston-style pumps can push cylinders of heterogenous concrete mixes (aggregate + cement). At present, double-piston pumps are predominantly used, which are hydraulically driven by electric or diesel

233:

The return pressure piston of one pressure cylinder creates a vacuum, the medium from the feed funnel is sucked into the cylinder. At the same time, the advancing delivery piston pushes the contents of the other delivery cylinder through the transfer tube into the delivery line. At the end of the

151:

to be manually attached to the outlet of the machine and feed the concrete to the place of application. The length of the hoses varies, typical hose lengths are 3.0, 3.8, 7.6, and 15.2 metres (10, 12.5, 25, and 50 ft), depending on the diameter. Due to their lower pump

208:

207:

276:

209:

263:

For these reasons, many options have existed side by side for a long time. Nowadays, fluid pressures of up to 400 bar (5,800 psi) and flow rates of up to 200 m/h (260 cu yd/h) can be achieved, while using piston-type pumps.

206:

389:

401:

93:

Because it is a fluid, concrete can be pumped to where it is needed. Here, a concrete transport truck is feeding concrete to a concrete pumper, which is pumping it to where a slab is being poured.

139:

The second main type of concrete pump, commonly referred to as a "line pump" or trailer-mounted concrete pump, is either mounted on a truck or placed on a trailer. This pump requires

205:

237:

Concrete pump drives are now exclusively hydraulic, so control options vary between individual manufacturers. Each system has certain advantages and disadvantages.

234:

stroke, the pump switches, i.e., the transfer tube turns in front of the other filled pressure cylinders, and the pressure pistons change their movement direction.

200:

Concrete pump designers face many challenges because concrete is heavy, viscous, abrasive, contains pieces of hard rock, and solidifies if not kept moving.

218:

engines using oil pumps. The pressure pistons are hydraulically connected to each other through the drive cylinders and operate in a two-stroke mode.

1133:

377:

395:

Photo showing a concrete pump working a large foundation pour, showing deployed outriggers, rebar mats, and concrete mixer delivering concrete.

54:

317:

1154:

871:

581:

329:

187:, either in wheelbarrows or in buckets lifted by cranes. This required a lot of time and labor. In 1927, the German engineers

1022:

132:) to place concrete accurately. It is attached to a truck or a semi-trailer. Boom pumps are capable of pumping at very high

696:

1113:

418:

120:

A common type of concrete pump for large scale construction projects is known as a boom concrete pump, because it uses a

455:

76:

445:

47:

881:

1224:

424:

611:

341:

183:

Until the early 20th century, concrete was mixed on the job site and transported from the cement mixer to the

1087:

654:

574:

1128:

1103:

1017:

984:

1229:

1082:

896:

606:

167:

and rail mounted concrete pumps, but these are uncommon and only used on specialized jobsites such as

1118:

1060:

979:

919:

734:

649:

37:

1239:

1234:

567:

41:

33:

365:

891:

636:

136:

and are less labor intensive to operate when compared to line or other types of concrete pumps.

989:

866:

790:

681:

676:

513:

58:

1072:

815:

353:

1108:

1009:

1004:

964:

876:

739:

133:

407:

Fully deployed concrete pump, showing outriggers and boom in use while receiving concrete.

8:

1055:

974:

744:

686:

969:

886:

1219:

1198:

954:

949:

924:

906:

820:

800:

621:

488:

451:

152:

volume, line pumps are used for smaller volume concrete placing applications such as

121:

1077:

1050:

959:

825:

785:

664:

626:

222:

994:

845:

749:

659:

1067:

999:

840:

759:

729:

724:

616:

538:

716:

272:

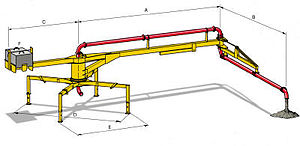

To illustrate, below are data on a typical concrete sample pump BRF 42.14 H:

1213:

1040:

939:

929:

153:

148:

944:

830:

805:

598:

754:

1045:

764:

701:

1149:

934:

914:

706:

164:

1180:

188:

144:

1164:

1159:

795:

590:

184:

157:

110:

89:

1123:

691:

293:

Concrete pressure: 112 bar (11,200 kPa; 1,624 psi)

97:

850:

810:

644:

383:

Putzmeister brand positive displacement mortar and plaster pump

172:

168:

769:

671:

476:

140:

125:

192:

patent incorporated the developer's previous German patent.

101:

Pumping concrete into aluminium concrete formwork in Mexico.

559:

160:, single family home concrete slabs and most ground slabs.

114:

275:

16:

Machine used for transferring liquid concrete by pumping

287:

Horizontal reach of boom: 38.0 meters (124.7 ft)

213:

Operating principle of piston pump with seat valves

302:Number of substitutions of strokes per minute: 27

284:Vertical reach of boom: 41.9 meters (137 ft)

1211:

1134:International Federation for Structural Concrete

539:"Concrete pumping: advantages and disadvantages"

443:

290:Pumping rate: 30 m/h (39 cu yd/h)

46:but its sources remain unclear because it lacks

335:A Putzmeister concrete pump in Germany in 1985

117:. There are different types of concrete pumps.

267:

575:

299:Cylinder diameter: 210 mm (8.3 in)

296:Cylinder length: 2,100 mm (83 in)

582:

568:

109:is a machine used for transferring liquid

77:Learn how and when to remove this message

274:

202:

96:

88:

1212:

563:

447:Movement and Distribution of Concrete

421:- concrete pump technology in general

697:Ground granulated blast-furnace slag

323:Construction site with concrete pump

18:

1114:Institution of Structural Engineers

240:Important performance factors are:

13:

347:Concrete pump folded for transport

14:

1251:

1194:

1193:

425:Concrete mixing transport trucks

400:

388:

376:

364:

352:

340:

328:

316:

23:

228:

612:Roman architectural revolution

531:

506:

481:

470:

437:

1:

518:concretepumpingauckland.co.nz

430:

589:

450:. McGraw-Hill. p. 132.

305:Number of outriggers legs: 4

195:

7:

1129:Portland Cement Association

1104:American Concrete Institute

412:

268:Example of pump performance

10:

1256:

607:Ancient Roman architecture

309:

178:

1189:

1173:

1142:

1119:Indian Concrete Institute

1096:

1033:

905:

859:

778:

715:

635:

597:

444:Illingworth J.R. (1972).

419:High-density solids pump

32:This article includes a

489:"How a gear pump works"

61:more precise citations.

1225:Construction equipment

897:Alkali–silica reaction

655:Energetically modified

280:

214:

102:

94:

278:

212:

100:

92:

882:Environmental impact

740:Reversing drum mixer

221:For lower pressures

514:"Piston-type pumps"

985:Self-consolidating

677:Water–cement ratio

359:Boom concrete pump

281:

244:discharge pressure

215:

103:

95:

34:list of references

1230:German inventions

1207:

1206:

1199:Category:Concrete

980:Roller-compacting

801:Climbing formwork

650:Calcium aluminate

622:Roman engineering

259:system complexity

223:peristaltic pumps

210:

147:concrete placing

122:remote-controlled

87:

86:

79:

1247:

1197:

1196:

1109:Concrete Society

920:Fiber-reinforced

735:Volumetric mixer

627:Roman technology

584:

577:

570:

561:

560:

554:

553:

551:

549:

535:

529:

528:

526:

524:

510:

504:

503:

501:

499:

485:

479:

477:Intex Pool Pumps

474:

468:

467:

465:

464:

441:

404:

392:

380:

368:

356:

344:

332:

320:

279:BRF 42.14 H pump

211:

82:

75:

71:

68:

62:

57:this article by

48:inline citations

27:

26:

19:

1255:

1254:

1250:

1249:

1248:

1246:

1245:

1244:

1240:1928 in science

1235:1928 in Germany

1210:

1209:

1208:

1203:

1185:

1169:

1138:

1092:

1029:

901:

855:

774:

750:Flow table test

711:

631:

593:

588:

558:

557:

547:

545:

537:

536:

532:

522:

520:

512:

511:

507:

497:

495:

487:

486:

482:

475:

471:

462:

460:

458:

442:

438:

433:

415:

408:

405:

396:

393:

384:

381:

372:

369:

360:

357:

348:

345:

336:

333:

324:

321:

312:

270:

231:

203:

198:

181:

163:There are also

83:

72:

66:

63:

52:

38:related reading

28:

24:

17:

12:

11:

5:

1253:

1243:

1242:

1237:

1232:

1227:

1222:

1205:

1204:

1202:

1201:

1190:

1187:

1186:

1184:

1183:

1177:

1175:

1171:

1170:

1168:

1167:

1162:

1157:

1152:

1146:

1144:

1140:

1139:

1137:

1136:

1131:

1126:

1121:

1116:

1111:

1106:

1100:

1098:

1094:

1093:

1091:

1090:

1085:

1080:

1075:

1070:

1068:Concrete block

1065:

1064:

1063:

1058:

1056:voided biaxial

1053:

1048:

1037:

1035:

1031:

1030:

1028:

1027:

1026:

1025:

1020:

1012:

1007:

1002:

997:

992:

987:

982:

977:

972:

967:

962:

957:

952:

947:

942:

937:

932:

927:

922:

917:

911:

909:

903:

902:

900:

899:

894:

889:

884:

879:

874:

869:

863:

861:

857:

856:

854:

853:

848:

843:

838:

833:

828:

823:

818:

813:

808:

803:

798:

793:

788:

782:

780:

776:

775:

773:

772:

767:

762:

760:Concrete cover

757:

752:

747:

742:

737:

732:

730:Concrete mixer

727:

721:

719:

713:

712:

710:

709:

704:

699:

694:

689:

684:

679:

674:

669:

668:

667:

662:

657:

652:

641:

639:

633:

632:

630:

629:

624:

619:

617:Roman concrete

614:

609:

603:

601:

595:

594:

587:

586:

579:

572:

564:

556:

555:

543:hpdconsult.com

530:

505:

480:

469:

457:978-0070942363

456:

435:

434:

432:

429:

428:

427:

422:

414:

411:

410:

409:

406:

399:

397:

394:

387:

385:

382:

375:

373:

370:

363:

361:

358:

351:

349:

346:

339:

337:

334:

327:

325:

322:

315:

311:

308:

307:

306:

303:

300:

297:

294:

291:

288:

285:

269:

266:

261:

260:

256:

255:

251:

250:

249:machine weight

246:

245:

230:

227:

197:

194:

180:

177:

154:swimming pools

128:arm (called a

85:

84:

42:external links

31:

29:

22:

15:

9:

6:

4:

3:

2:

1252:

1241:

1238:

1236:

1233:

1231:

1228:

1226:

1223:

1221:

1218:

1217:

1215:

1200:

1192:

1191:

1188:

1182:

1179:

1178:

1176:

1172:

1166:

1163:

1161:

1158:

1156:

1153:

1151:

1148:

1147:

1145:

1141:

1135:

1132:

1130:

1127:

1125:

1122:

1120:

1117:

1115:

1112:

1110:

1107:

1105:

1102:

1101:

1099:

1097:Organizations

1095:

1089:

1086:

1084:

1081:

1079:

1076:

1074:

1071:

1069:

1066:

1062:

1061:slab on grade

1059:

1057:

1054:

1052:

1049:

1047:

1044:

1043:

1042:

1039:

1038:

1036:

1032:

1024:

1021:

1019:

1016:

1015:

1013:

1011:

1008:

1006:

1003:

1001:

998:

996:

993:

991:

990:Self-leveling

988:

986:

983:

981:

978:

976:

973:

971:

968:

966:

963:

961:

958:

956:

953:

951:

948:

946:

943:

941:

938:

936:

933:

931:

928:

926:

923:

921:

918:

916:

913:

912:

910:

908:

904:

898:

895:

893:

890:

888:

885:

883:

880:

878:

875:

873:

870:

868:

865:

864:

862:

858:

852:

849:

847:

844:

842:

839:

837:

834:

832:

829:

827:

824:

822:

819:

817:

814:

812:

809:

807:

804:

802:

799:

797:

794:

792:

791:Cast-in-place

789:

787:

784:

783:

781:

777:

771:

768:

766:

763:

761:

758:

756:

753:

751:

748:

746:

743:

741:

738:

736:

733:

731:

728:

726:

723:

722:

720:

718:

714:

708:

705:

703:

700:

698:

695:

693:

690:

688:

687:Reinforcement

685:

683:

680:

678:

675:

673:

670:

666:

663:

661:

658:

656:

653:

651:

648:

647:

646:

643:

642:

640:

638:

634:

628:

625:

623:

620:

618:

615:

613:

610:

608:

605:

604:

602:

600:

596:

592:

585:

580:

578:

573:

571:

566:

565:

562:

544:

540:

534:

519:

515:

509:

494:

490:

484:

478:

473:

459:

453:

449:

448:

440:

436:

426:

423:

420:

417:

416:

403:

398:

391:

386:

379:

374:

371:Concrete pump

367:

362:

355:

350:

343:

338:

331:

326:

319:

314:

313:

304:

301:

298:

295:

292:

289:

286:

283:

282:

277:

273:

265:

258:

257:

253:

252:

248:

247:

243:

242:

241:

238:

235:

226:

224:

219:

201:

193:

190:

186:

176:

174:

170:

166:

161:

159:

155:

150:

146:

142:

137:

135:

131:

127:

124:articulating

123:

118:

116:

112:

108:

107:concrete pump

99:

91:

81:

78:

70:

60:

56:

50:

49:

43:

39:

35:

30:

21:

20:

1073:Step barrier

1034:Applications

945:Nanoconcrete

835:

831:Power trowel

816:Power screed

806:Slip forming

779:Construction

546:. Retrieved

542:

533:

521:. Retrieved

517:

508:

496:. Retrieved

492:

483:

472:

461:. Retrieved

446:

439:

271:

262:

239:

236:

232:

229:How it works

225:are common.

220:

216:

199:

182:

165:skid mounted

162:

138:

129:

119:

106:

104:

73:

64:

53:Please help

45:

1051:hollow-core

1010:Waste light

1005:Translucent

965:Prestressed

892:Segregation

877:Degradation

765:Cover meter

702:Silica fume

637:Composition

493:web.mit.edu

59:introducing

1214:Categories

1150:Eurocode 2

1088:Structures

975:Reinforced

935:Lunarcrete

915:AstroCrete

872:Durability

867:Properties

745:Slump test

717:Production

707:Metakaolin

463:2012-06-18

431:References

1181:Hempcrete

1143:Standards

970:Ready-mix

887:Recycling

682:Aggregate

665:Rosendale

196:Mechanism

189:Max Giese

158:sidewalks

67:July 2014

1220:Concrete

1174:See also

1165:EN 10080

1160:EN 206-1

1155:EN 197-1

1014:Aerated

955:Polished

950:Pervious

925:Filigree

821:Finisher

796:Formwork

660:Portland

591:Concrete

548:July 12,

523:July 12,

498:July 12,

413:See also

185:formwork

145:flexible

111:concrete

1124:Nanocem

1083:Columns

960:Polymer

860:Science

826:Grinder

786:Precast

692:Fly ash

599:History

310:Gallery

179:History

173:tunnels

134:volumes

126:robotic

115:pumping

55:improve

1046:waffle

995:Sulfur

851:Tremie

846:Sealer

811:Screed

755:Curing

645:Cement

454:

1078:Roads

1000:Tabby

907:Types

841:Float

770:Rebar

725:Plant

672:Water

254:price

169:mines

149:hoses

141:steel

40:, or

1041:Slab

1023:RAAC

940:Mass

930:Foam

836:Pump

550:2022

525:2022

500:2022

452:ISBN

171:and

130:boom

1018:AAC

143:or

113:by

1216::

541:.

516:.

491:.

175:.

156:,

105:A

44:,

36:,

583:e

576:t

569:v

552:.

527:.

502:.

466:.

80:)

74:(

69:)

65:(

51:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.