146:, all inside a well-sealed box (the "case"). This carburizing package is then heated to a high temperature—but still under the melting point of the iron—and left at that temperature for a length of time. The longer the package is held at the high temperature, the deeper the carbon will diffuse into the surface. Different depths of hardening are desirable for different purposes: sharp tools need deep hardening to allow grinding and resharpening without exposing the soft core, while machine parts like gears might need only shallow hardening for increased wear resistance.

270:

a hot furnace for a variable length of time. Time and temperature determines how deep into the surface the hardening extends. However, the depth of hardening is ultimately limited by the inability of carbon to diffuse deeply into solid steel, and a typical depth of surface hardening with this method is up to 1.5 mm. Other techniques are also used in modern carburizing, such as heating in a carbon-rich atmosphere. Small items may be case-hardened by repeated heating with a torch and quenching in a carbon rich medium, such as the commercial products

535:. In order for the screws to be able to drill, cut and tap into other materials like steel, the drill point and the forming threads must be harder than the material(s) that it is drilling into. However, if the whole screw is uniformly hard, it will become very brittle and it will break easily. This is overcome by ensuring that only the surface is hardened, and the core remains relatively softer and thus less brittle. For screws and fasteners, case-hardening is achieved by a simple heat treatment consisting of heating and then quenching.

880:

302:

178:, generated by the breakdown of the carburising compound and the oxygen packed into the sealed box. This takes place with pure carbon but too slowly to be workable. Although oxygen is required for this process it is re-circulated through the CO cycle and so can be carried out inside a sealed box (the "case"). The sealing is necessary to stop the CO either leaking out or being oxidised to CO

38:

87:

This matrix then required re-heating and hammering to extract as much of the slag as possible, in order to produce a low-carbon malleable wrought iron which could then be forged into tools etc. Due to its low carbon content, wrought iron is quite soft, so something like a knife blade could not be kept very sharp; it would blunt quickly and bend easily.

329:

Typical uses are for the shackle of a lock, where the outer layer is hardened to be file resistant, and mechanical gears, where hard gear mesh surfaces are needed to maintain a long service life while toughness is required to maintain durability and resistance to catastrophic failure. Flame hardening

269:

is derived from the practicalities of the carburization process itself, which is essentially the same as the ancient process. The steel work piece is placed inside a case packed tight with a carbon-based case-hardening compound. This is collectively known as a carburizing pack. The pack is put inside

86:

which converted iron ore into metallic iron by heating it in a furnace which burnt wood and charcoal. Because the temperatures that could be achieved by this method were generally below the melting point of iron, it was not truly smelted, but instead converted into a spongy metallic iron/slag matrix.

66:

In order to produce a hard skin on steels which have less than ~0.2% carbon, carbon can be introduced into the surface by heating steel in the presence of some carbon rich substance such as powdered charcoal or hydrocarbon gas. This causes carbon to diffuse into the surface of the steel. The depth of

165:

Case-hardened steel combines extreme hardness and extreme toughness, which is not readily matched by homogeneous alloys since hard homogeneous steels tend to be brittle, especially those steels whose hardness relies on carbon content alone. Alloy steels containing nickel, chromium, or molybdenum can

453:

This process produces a thin, hard shell (between 0.25 and 0.75 mm; 0.0098 and 0.0295 in) that is harder than the one produced by carburizing, and can be completed in 20 to 30 minutes compared to several hours so the parts have less opportunity to become distorted. It is typically used on

391:

Nitriding heats the steel part to 482–621 °C (900–1,150 °F) in an atmosphere of ammonia gas and dissociated ammonia. The time the part spends in this environment dictates the depth of the case. The hardness is achieved by the formation of nitrides. Nitride forming elements must be present

362:

Carburization is a diffusion-controlled process, so the longer the steel is held in the carbon-rich environment the greater the carbon penetration will be and the higher the carbon content. The carburized section will have a carbon content high enough that it can be hardened again through flame or

149:

The resulting case-hardened part may show distinct surface discoloration, if the carbon material is mixed organic matter as described above. The steel darkens significantly and shows a mottled pattern of black, blue, and purple caused by the various compounds formed from impurities in the bone and

118:

but not very hard, nor capable of being hardened by heating and quenching. This led to the introduction of case hardening. The resulting case-hardened product combines much of the malleability and toughness of a low-carbon steel core with the hardness and resilience of the outer high-carbon steel

90:

As smelting techniques improved, higher furnace temperatures could be achieved which were sufficient to fully melt iron. However, in the process, the iron picked up carbon from the charcoal or coke used to heat it. This resulted in molten iron with a carbon content of around 3%, which was termed

325:

on the surface. A carbon content of 0.3–0.6 wt% C is needed for this type of hardening. Unlike other methods, flame or induction hardening does not change chemical composition of the material. Because it is merely a localized heat-treatment process, they are typically only useful on high-carbon

358:

Carburizing is a process used to case-harden steel with a carbon content between 0.1 and 0.3 wt% C. In this process iron is introduced to a carbon rich environment at elevated temperatures for a certain amount of time, and then quenched so that the carbon is locked in the structure; one of the

468:

Carbonitriding is similar to cyaniding except a gaseous atmosphere of ammonia and hydrocarbons is used instead of sodium cyanide. If the part is to be quenched, it is heated to 775–885 °C (1,427–1,625 °F); if not, then the part is heated to 649–788 °C (1,200–1,450 °F).

95:. This liquid iron could be cast into complex shapes, but due to its high carbon content, it was very brittle, not at all malleable, and totally unsuitable for something like a knife blade. Further processing was required to remove the excess carbon from cast iron and create malleable

67:

this high carbon layer depends on the exposure time, but 0.5mm is a typical case depth. Once this has been done the steel must be heated and quenched to harden this higher carbon 'skin'. Below this skin, the steel core will remain soft due to its low carbon content.

483:

Ferritic nitrocarburizing diffuses mostly nitrogen and some carbon into the case of a workpiece below the critical temperature, approximately 650 °C (1,202 °F). Under the critical temperature the workpiece's microstructure does not convert to an

58:

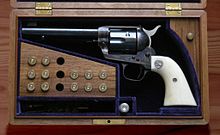

Iron which has a carbon content greater than ~0.02% is known as steel. Steel which has a carbon content greater than ~0.25% can be direct hardened by heating to around 600C and then quickly cooling, often by immersing in water, this being known as

519:

Firearms were a common item case-hardened in the past, as they required precision machining best done on low carbon alloys, yet needed the hardness and wear resistance of a higher carbon alloy. Many modern replicas of older firearms, particularly

538:

For theft prevention, lock shackles and chains are often case-hardened to resist cutting, whilst remaining less brittle inside to resist impact. As case-hardened components are difficult to machine, they are generally shaped before hardening.

241:

for more information). These mild steels are not normally hardenable due to the low quantity of carbon, so the surface of the steel is chemically altered to increase the hardenability. Case-hardened steel is formed by diffusing carbon

63:. Hardening is desirable for metal components because it gives increased strength and wear resistance, the trade off being that hardened steel is generally more brittle and less malleable than when it is in its softer state.

373:. Packing low carbon steel parts with a carbonaceous material and heating for some time diffuses carbon into the outer layers. A heating period of a few hours might form a high-carbon layer about one millimeter thick.

376:

Liquid carburizing involves placing parts in a bath of a molten carbon-containing material, often a metal cyanide; gas carburizing involves placing the parts in a furnace maintained with a methane-rich interior.

212:

fallacy that case-hardening was done with bone but this is misleading. Although bone was used, the main carbon donor was hoof and horn. Bone contains some carbonates but is mainly calcium phosphate (as

366:

It is possible to carburize only a portion of a part, either by protecting the rest by a process such as copper plating, or by applying a carburizing medium to only a section of the part.

404:. The advantage of this process is that it causes little distortion, so the part can be case-hardened after being quenched, tempered and machined. No quenching is done after nitriding.

412:

Cyaniding is a case-hardening process that is fast and efficient; it is mainly used on low-carbon steels. The part is heated to 871–954 °C (1,600–1,749 °F) in a bath of

55:

is the process of introducing carbon to the surface of a low carbon iron or much more commonly low carbon steel object in order to enable the surface to be hardened.

722:

122:

The traditional method of applying the carbon to the surface of the iron involved packing the iron in a mixture of carbon-rich material such as ground

359:

simpler procedures is repeatedly to heat a part with an acetylene torch set with a fuel-rich flame and quench it in a carbon-rich fluid such as oil.

674:

516:. In these cases, the surfaces requiring the hardness may be hardened selectively, leaving the bulk of the part in its original tough state.

330:

uses direct impingement of an oxy-gas flame onto a defined surface area. The result of the hardening process is controlled by four factors:

1228:

658:

715:

166:

have very high hardness, strength, or elongation values, but at a greater cost than a case-hardened item with a low-carbon core.

174:

Carbon itself is solid at case-hardening temperatures and so is immobile. Transport to the surface of the steel was as gaseous

454:

small parts such as bolts, nuts, screws and small gears. The major drawback of cyaniding is that cyanide salts are poisonous.

1190:

305:

A flame-hardened sprocket. The discoloration around the teeth delineates the area that was rapidly heated and then quenched.

262:) into the outer layer of the steel at high temperature, and then heat treating the surface layer to the desired hardness.

668:

678:

313:

are processes in which the surface of the steel is heated very rapidly to high temperatures (by direct application of an

708:

627:

602:

1208:

369:

The carbon can come from a solid, liquid or gaseous source; if it comes from a solid source the process is called

1249:

663:

17:

504:

Parts that are subject to high pressures and sharp impacts are still commonly case-hardened. Examples include

1218:

1198:

990:

31:

1151:

296:

1027:

682:

1223:

1075:

478:

675:"MIL-S-6090A, Military Specification: Process for Steels Used In Aircraft Carburizing and Nitriding"

642:

1166:

964:

217:). This does not have the beneficial effect of encouraging CO production and it can also introduce

1213:

1203:

1090:

752:

41:

1105:

1037:

1022:

1014:

980:

548:

104:

847:

844:

528:, which simulates the mottled pattern left by traditional charcoal and bone case-hardening.

110:

After the removal of almost all carbon from cast iron, the result was a metal that was very

1176:

1140:

1095:

985:

959:

573:

558:

8:

1145:

1135:

1131:

1080:

1070:

954:

933:

820:

787:

568:

553:

310:

850:

747:

532:

238:

100:

864:

623:

598:

318:

205:

increasing the overall abundance of CO and the activity of the carburising compound.

949:

928:

209:

186:

416:

and then is quenched and rinsed, in water or oil, to remove any residual cyanide.

1156:

909:

813:

278:

or "Cherry Red". Older formulations of these compounds contain potentially toxic

214:

175:

1060:

918:

914:

860:

509:

463:

413:

154:, providing a degree of corrosion resistance, as well as an attractive finish.

151:

597:. Engineering Metallurgy (5th ed.). Hodder & Stoughton. p. 474.

1243:

1004:

793:

521:

353:

243:

158:

refers to this pattern and is commonly encountered as a decorative finish on

52:

700:

1118:

1113:

879:

840:

836:

645:

Hemmings Sports & Exotic Car — MARCH 1, 2006 - BY CRAIG FITZGERALD

563:

96:

301:

233:

are suitable for case-hardening; typically mild steels are used, with low

1161:

1065:

922:

888:

586:

230:

531:

Another common application of case-hardening is on screws, particularly

1050:

893:

803:

505:

485:

397:

322:

321:) then cooled rapidly, generally using water; this creates a "case" of

218:

1171:

1085:

856:

808:

765:

386:

251:

111:

92:

60:

1055:

797:

783:

775:

513:

489:

401:

393:

259:

247:

159:

127:

83:

79:

282:

compounds, while the more recent types such as Cherry Red do not.

314:

279:

131:

115:

234:

735:

524:

revolvers, are still made with case-hardened frames, or with

255:

143:

37:

731:

326:

steels that will respond sufficiently to quench hardening.

139:

135:

123:

76:

185:

Adding an easily decomposed carbonate "energiser" such as

592:

27:Process of hardening the surface of a metal object

1241:

392:for this method to work; these elements include

150:charcoal. This oxide surface works similarly to

290:

730:

716:

617:

99:(the ultimate developments of this being the

472:

44:, showing discoloration from case-hardening

723:

709:

300:

36:

14:

1242:

343:Composition of the metal being treated

704:

237:content, usually less than 0.3% (see

221:as an impurity into the steel alloy.

679:United States Department of Defense

595:Part I: Applied Physical Metallurgy

24:

193:and this encourages the reaction:

25:

1261:

652:

492:phase, which is why it is called

457:

878:

673:

340:Target temperature to be reached

643:Case Hardening in a Home Garage

499:

669:Case Hardening Steel and Metal

636:

611:

347:

30:For the woodworking term, see

13:

1:

748:History of ferrous metallurgy

681:. 7 June 1971. Archived from

579:

224:

991:Argon oxygen decarburization

593:Higgins, Raymond A. (1983).

407:

380:

291:Flame or induction hardening

285:

169:

32:case hardening (woodworking)

7:

1152:Differential heat treatment

664:Surface Hardening of Steels

542:

297:Differential heat treatment

10:

1268:

476:

461:

384:

351:

294:

70:

29:

1189:

1127:

1104:

1076:Ferritic nitrocarburizing

1036:

1013:

1003:

973:

942:

902:

887:

876:

829:

774:

761:

743:

479:Ferritic nitrocarburizing

473:Ferritic nitrocarburizing

1167:Post weld heat treatment

488:phase, but stays in the

334:Design of the flame head

753:List of steel producers

197:C (from the donor) + CO

189:breaks down to BaO + CO

182:by excess outside air.

981:Electro-slag remelting

618:Roy F. Dunlap (1963).

549:Differential hardening

306:

45:

1250:Metal heat treatments

1191:Production by country

363:induction hardening.

304:

40:

1177:Superplastic forming

1096:Quench polish quench

986:Vacuum arc remelting

965:Basic oxygen process

960:Electric arc furnace

574:Von Stahel und Eysen

559:Quench polish quench

533:self-drilling screws

496:nitrocarburization.

130:or a combination of

1132:Cryogenic treatment

955:Open hearth furnace

943:Primary (Post-1850)

934:Cementation process

821:Direct reduced iron

622:. Stackpole Books.

569:Surface engineering

554:Diffusion hardening

337:Duration of heating

311:induction hardening

903:Primary (Pre-1850)

307:

239:plain-carbon steel

101:Bessemer converter

46:

1237:

1236:

1185:

1184:

999:

998:

874:

873:

865:Induction furnace

688:on 29 August 2019

512:faces, or engine

319:induction heating

16:(Redirected from

1257:

1011:

1010:

950:Bessemer process

900:

899:

882:

772:

771:

725:

718:

711:

702:

701:

697:

695:

693:

687:

646:

640:

634:

633:

615:

609:

608:

590:

371:pack carburizing

229:Both carbon and

210:common knowledge

187:barium carbonate

21:

1267:

1266:

1260:

1259:

1258:

1256:

1255:

1254:

1240:

1239:

1238:

1233:

1181:

1157:Decarburization

1123:

1100:

1041:

1032:

995:

969:

938:

910:Pattern welding

891:

883:

870:

825:

814:Anthracite iron

763:

762:Iron production

757:

739:

729:

691:

689:

685:

655:

650:

649:

641:

637:

630:

616:

612:

605:

591:

587:

582:

545:

502:

481:

475:

466:

460:

448:

442:

438:

434:

430:

423:

410:

389:

383:

356:

350:

299:

293:

288:

227:

215:hydroxylapatite

200:

192:

181:

176:carbon monoxide

172:

105:Siemens process

73:

42:Colt Peacemaker

35:

28:

23:

22:

15:

12:

11:

5:

1265:

1264:

1253:

1252:

1235:

1234:

1232:

1231:

1226:

1221:

1216:

1211:

1206:

1201:

1195:

1193:

1187:

1186:

1183:

1182:

1180:

1179:

1174:

1169:

1164:

1159:

1154:

1149:

1143:

1138:

1128:

1125:

1124:

1122:

1121:

1116:

1110:

1108:

1102:

1101:

1099:

1098:

1093:

1088:

1083:

1078:

1073:

1068:

1063:

1061:Carbonitriding

1058:

1053:

1047:

1045:

1043:Case-hardening

1034:

1033:

1031:

1030:

1025:

1019:

1017:

1008:

1005:Heat treatment

1001:

1000:

997:

996:

994:

993:

988:

983:

977:

975:

971:

970:

968:

967:

962:

957:

952:

946:

944:

940:

939:

937:

936:

931:

929:Tatara furnace

926:

919:Damascus steel

915:Crucible steel

912:

906:

904:

897:

885:

884:

877:

875:

872:

871:

869:

868:

861:Cupola furnace

854:

833:

831:

827:

826:

824:

823:

818:

817:

816:

811:

806:

791:

780:

778:

769:

759:

758:

756:

755:

750:

744:

741:

740:

728:

727:

720:

713:

705:

699:

698:

671:

666:

661:

659:Case Hardening

654:

653:External links

651:

648:

647:

635:

628:

610:

603:

584:

583:

581:

578:

577:

576:

571:

566:

561:

556:

551:

544:

541:

501:

498:

477:Main article:

474:

471:

464:Carbonitriding

462:Main article:

459:

458:Carbonitriding

456:

451:

450:

446:

443:

440:

436:

432:

428:

425:

421:

414:sodium cyanide

409:

406:

385:Main article:

382:

379:

352:Main article:

349:

346:

345:

344:

341:

338:

335:

295:Main article:

292:

289:

287:

284:

267:case-hardening

226:

223:

203:

202:

201:<—> 2 CO

198:

190:

179:

171:

168:

156:Case colouring

72:

69:

49:Case-hardening

26:

18:Case hardening

9:

6:

4:

3:

2:

1263:

1262:

1251:

1248:

1247:

1245:

1230:

1229:United States

1227:

1225:

1222:

1220:

1217:

1215:

1212:

1210:

1207:

1205:

1202:

1200:

1197:

1196:

1194:

1192:

1188:

1178:

1175:

1173:

1170:

1168:

1165:

1163:

1160:

1158:

1155:

1153:

1150:

1147:

1144:

1142:

1139:

1137:

1133:

1130:

1129:

1126:

1120:

1117:

1115:

1112:

1111:

1109:

1107:

1103:

1097:

1094:

1092:

1091:Precipitation

1089:

1087:

1084:

1082:

1079:

1077:

1074:

1072:

1069:

1067:

1064:

1062:

1059:

1057:

1054:

1052:

1049:

1048:

1046:

1044:

1039:

1035:

1029:

1028:Short circuit

1026:

1024:

1021:

1020:

1018:

1016:

1012:

1009:

1006:

1002:

992:

989:

987:

984:

982:

979:

978:

976:

972:

966:

963:

961:

958:

956:

953:

951:

948:

947:

945:

941:

935:

932:

930:

927:

924:

920:

916:

913:

911:

908:

907:

905:

901:

898:

895:

890:

886:

881:

866:

862:

858:

855:

852:

849:

846:

845:Reverberatory

842:

838:

835:

834:

832:

828:

822:

819:

815:

812:

810:

807:

805:

802:

801:

799:

795:

794:Blast furnace

792:

789:

785:

782:

781:

779:

777:

773:

770:

767:

760:

754:

751:

749:

746:

745:

742:

737:

733:

726:

721:

719:

714:

712:

707:

706:

703:

684:

680:

676:

672:

670:

667:

665:

662:

660:

657:

656:

644:

639:

631:

629:0-8117-0770-9

625:

621:

614:

606:

604:0-340-28524-9

600:

596:

589:

585:

575:

572:

570:

567:

565:

562:

560:

557:

555:

552:

550:

547:

546:

540:

536:

534:

529:

527:

526:case coloring

523:

522:single action

517:

515:

511:

507:

497:

495:

491:

487:

480:

470:

465:

455:

444:

426:

419:

418:

417:

415:

405:

403:

399:

395:

388:

378:

374:

372:

367:

364:

360:

355:

354:Carburization

342:

339:

336:

333:

332:

331:

327:

324:

320:

317:flame, or by

316:

312:

303:

298:

283:

281:

277:

273:

268:

263:

261:

257:

253:

249:

245:

244:carburization

240:

236:

232:

222:

220:

216:

211:

206:

196:

195:

194:

188:

183:

177:

167:

163:

161:

157:

153:

147:

145:

141:

137:

133:

129:

125:

120:

117:

113:

108:

106:

102:

98:

94:

88:

85:

81:

78:

68:

64:

62:

56:

54:

53:carburization

50:

43:

39:

33:

19:

1119:Martempering

1114:Austempering

1042:

1023:Low hydrogen

841:Finery forge

837:Wrought iron

690:. Retrieved

683:the original

638:

619:

613:

594:

588:

564:Shot peening

537:

530:

525:

518:

503:

500:Applications

493:

482:

467:

452:

411:

390:

375:

370:

368:

365:

361:

357:

328:

308:

275:

271:

266:

264:

231:alloy steels

228:

207:

204:

184:

173:

164:

155:

148:

121:

109:

97:wrought iron

89:

82:made use of

74:

65:

57:

48:

47:

1162:Forming gas

1066:Carburizing

923:Wootz steel

889:Steelmaking

788:sponge iron

620:Gunsmithing

506:firing pins

348:Carburizing

1219:Luxembourg

1199:Bangladesh

1141:Deflashing

1051:Ausforming

894:Steel mill

804:Cold blast

796:(produces

786:(produces

738:production

580:References

510:rifle bolt

486:austenitic

427:2NaCNO + O

398:molybdenum

323:martensite

225:Modern use

219:phosphorus

84:bloomeries

1172:Quenching

1146:Hardening

1136:Deburring

1106:Tempering

1086:Nitriding

1081:Induction

1071:Cryogenic

1038:Hardening

1015:Annealing

974:Secondary

857:Cast iron

830:Secondary

809:Hot blast

766:Ironworks

514:camshafts

420:2NaCN + O

408:Cyaniding

387:Nitriding

381:Nitriding

309:Flame or

286:Processes

265:The term

252:nitriding

170:Chemistry

112:malleable

93:cast iron

61:quenching

1244:Category

1056:Boriding

848:Puddling

798:pig iron

784:Bloomery

776:Smelting

543:See also

494:ferritic

490:ferritic

445:2CO → CO

439:+ CO + N

424:→ 2NaCNO

402:aluminum

394:chromium

276:Casenite

260:boriding

248:nitrogen

208:It is a

160:firearms

128:charcoal

103:and the

80:smelting

1224:Nigeria

1007:methods

851:Furnace

692:20 June

315:oxy-gas

280:cyanide

272:Kasenit

132:leather

116:ductile

71:History

626:

601:

400:, and

235:carbon

152:bluing

136:hooves

119:skin.

75:Early

1214:Italy

1209:India

1204:China

859:(via

839:(via

736:steel

686:(PDF)

256:boron

254:) or

144:urine

843:or

734:and

732:Iron

694:2012

624:ISBN

599:ISBN

508:and

431:→ Na

142:and

140:salt

126:and

124:bone

114:and

77:iron

863:or

449:+ C

246:),

107:).

51:or

1246::

1040:/

921:,

800:)

677:.

435:CO

396:,

274:/

162:.

138:,

134:,

1148:)

1134:(

925:)

917:(

896:)

892:(

867:)

853:)

790:)

768:)

764:(

724:e

717:t

710:v

696:.

632:.

607:.

447:2

441:2

437:3

433:2

429:2

422:2

258:(

250:(

242:(

199:2

191:2

180:2

34:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.