154:

112:

362:

305:

200:

31:

329:

167:

further qualification is still understood to refer to this type. The formative decades for this class of machine were the 1840s through 1860s, when the basic idea of mounting an indexable turret on a bench lathe or engine lathe was born, developed, and disseminated from the originating shops to many other factories. Some important tool-builders in this development were

Stephen Fitch; Gay, Silver & Co.;

341:

208:

1860s, when semi-automatic turret lathes were developed, they were sometimes called "automatic". What we today would call "automatics", that is, fully automatic machines, had not been developed yet. During that era both manual and semi-automatic turret lathes were sometimes called "screw machines", although we today reserve that term for fully automatic machines.

317:

222:

During the 1870s through 1890s, the mechanically automated "automatic" turret lathe was developed and disseminated. These machines can execute many part-cutting cycles without human intervention. Thus the duties of the operator, which were already greatly reduced by the manual turret lathe, were even

166:

In the late 1830s a "capstan lathe" with a turret was patented in

Britain. The first American turret lathe was invented by Stephen Fitch in 1845. The archetypical turret lathe, and the first in order of historical appearance, is the horizontal-bed, manual turret lathe. The term "turret lathe" without

439:

Turrets can be added to non-turret lathes (bench lathes, engine lathes, toolroom lathes, etc.) by mounting them on the toolpost, tailstock, or both. Often these turrets are not as large as a turret lathe's, and they usually do not offer the sliding and stopping that a turret lathe's turret does; but

373:

with "turret lathe". In other times and places it has been held in technical contradistinction to "turret lathe", with the difference being in whether the turret's slide is fixed to the bed (ram-type turret) or slides on the bed's ways (saddle-type turret). The difference in terminology is mostly a

207:

Sometimes machines similar to those above, but with power feeds and automatic turret-indexing at the end of the return stroke, are called "semi-automatic turret lathes". This nomenclature distinction is blurry and not consistently observed. The term "turret lathe" encompasses them all. During the

414:

turret and making it hollow, allowing the part to pass into it during the cut, analogously to how the part would pass over the flat turret. In both cases, the main idea is to increase rigidity by allowing a relatively long part to be turned without the tool overhang that would be needed with a

149:

There are many variants of the turret lathe. They can be most generally classified by size (small, medium, or large); method of control (manual, automated mechanically, or automated via computer (numerical control (NC) or computer numerical control (CNC)); and bed orientation (horizontal or

88:

The name derives from the way early turrets took the general form of a flattened cylindrical block mounted to the lathe's cross-slide, capable of rotating about the vertical axis and with toolholders projecting out to all sides, and thus vaguely resembled a swiveling

125:

The first turret lathe was built by

Stephen Fitch in 1845 to manufacture screws for pistol percussion parts. In the mid-nineteenth century, the need for interchangeable parts for Colt revolvers enhanced the role of turret lathes in achieving this goal as part of the

298:. This is useful for the handling of very large, heavy, short workpieces. Vertical lathes in general are also called "vertical boring mills" or often simply "boring mills"; therefore a vertical turret lathe is a vertical boring mill equipped with a turret.

153:

69:, in easy, rapid succession, with no need for the operator to perform set-up tasks in between (such as installing or uninstalling tools) or to control the toolpath. The latter is due to the toolpath's being controlled by the machine, either in

130:" of manufacturing arms. Clock-making and bicycle manufacturing had similar requirements. Christopher Spencer invented the first fully automated turret lathe in 1873, which led to designs using cam action or hydraulic mechanisms.

281:

may be horizontal or vertical in orientation and mount six separate tools on one or more turrets. Such machine tools can work in two axes per turret, with up to six axes being feasible for complex work.

402:

of Jones & Lamson, and first disseminated in the 1890s, it was developed to provide more rigidity via requiring less overhang in the tool setup, especially when the part is relatively long.

262:

was poised to develop from a colossal laboratory curiosity into a practical technology that could begin to disseminate into business and industry. The advent of computer-based automation in

423:

The term "monitor lathe" formerly (1860s–1940s) referred to the class of small- to medium-sized manual turret lathes used on relatively small work. The name was inspired by the

133:

From the late-19th through mid-20th centuries, turret lathes, both manual and automatic (i.e., screw machines and chuckers), were one of the most important classes of

111:

862:

1039:

304:

242:

Machine tools of the "automatic" variety, which in the pre-computer era meant mechanically automated, had already reached a highly advanced state by

369:

The term "capstan lathe" overlaps in sense with the term "turret lathe" to a large extent. In many times and places, it has been understood to be

316:

1032:

239:" or "automatic screw machines", while larger ones are usually called "automatic chucking lathes", "automatic chuckers", or "chuckers".

918:

274:(CNC) displaced to a large extent, but not at all completely, the previously existing manual and mechanically automated machines.

1243:

1025:

1253:

985:

953:

876:

534:

510:

483:

328:

787:

1218:

361:

864:

From the

American System to Mass Production, 1800–1932: The Development of Manufacturing Technology in the United States

502:

From the

American System to Mass Production, 1800-1932: The Development of Manufacturing Technology in the United States

598:

588:

176:

841:

727:

683:

633:

548:

340:

53:

that is used for repetitive production of duplicate parts, which by the nature of their cutting process are usually

127:

290:

Vertical turret lathes have the workpiece held vertically, which allows the headstock to sit on the floor and the

431:

DSM-59 and its many clones, are still common, but the name "monitor lathe" is no longer current in the industry.

236:

172:

868:

1300:

17:

1009:

Movement of the turret and the taking of various cuts on a manual engine lathe retrofitted with a CNC turret

278:

1149:

912:

1290:

99:

is the usual name in the UK and

Commonwealth, though the two terms are also used in contrast: see below,

122:

Turret lathes became indispensable to the production of interchangeable parts and for mass production.

271:

235:

performs an automated theater show. Small- to medium-sized automatic turret lathes are usually called "

82:

394:

A subtype of horizontal turret lathe is the flat-turret lathe. Its turret is flat (and analogous to a

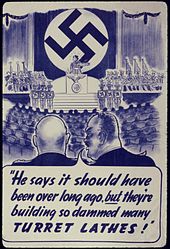

179:; Frederick W. Howe, Richard S. Lawrence, and Henry D. Stone of Robbins & Lawrence; J.R. Brown of

1258:

500:

473:

1079:

66:

231:. Thus, they execute the part-cutting cycle somewhat analogously to the way in which an elaborate

1223:

1213:

1208:

1164:

379:

1248:

1238:

809:

719:

657:

570:

73:-like fashion, via the mechanical limits placed on it by the turret's slide and stops, or via

1228:

1154:

54:

831:

750:

711:

427:, which the monitor lathe's turret resembled. Today, lathes of such appearance, such as the

1268:

1263:

65:

toolholder that allows multiple cutting operations to be performed, each with a different

8:

1233:

1144:

410:

Hollow-hexagon turret lathes competed with flat-turret lathes by taking the conventional

228:

74:

141:. They were used extensively in the mass production for the war effort in World War II.

858:

797:

645:

558:

188:

227:

to automate the sliding and indexing of the turret and the opening and closing of the

1003:

Movement of the turrets and the taking of various cuts on a CNC vertical turret lathe

974:

959:

930:

922:

890:

882:

872:

837:

733:

723:

712:

689:

679:

594:

530:

506:

479:

424:

295:

267:

180:

62:

905:(4th ed.), Dale Road, Bournbrook, Birmingham, England: H.W. Ward & Co., Ltd

1104:

1074:

184:

714:

CNC programming handbook : a comprehensive guide to practical CNC programming

1295:

1179:

1069:

1017:

527:

Building

Victory: Aircraft Manufacturing in the Los Angeles Area in World War II,

291:

224:

217:

138:

1159:

1139:

827:

428:

399:

375:

277:

Numerically controlled turrets allow automated selection of tools on a turret.

168:

78:

34:

1008:

1002:

996:

894:

1284:

1094:

949:

383:

263:

191:. Various designers at these and other firms later made further refinements.

50:

737:

693:

1129:

1052:

1048:

934:

395:

255:

232:

134:

115:

963:

1174:

1134:

1099:

1084:

1064:

310:

CNC VTL, 46" (1168 mm) Bullard High Column

Dynatrol, built mid-1960s

243:

322:

CNC VTL, 88" (2235 mm) Niles

Vertical Turret Lathe, built mid-1950s

940:

638:

Reading working drawings. Arithmetic. Measuring instruments. Lathe work

90:

70:

30:

1119:

440:

they do offer the ability to index through successive tool settings.

38:

199:

157:

1920 Cincinnati Ames turret lathe. The round turret is on the right.

1184:

1089:

259:

1194:

1114:

1109:

411:

370:

978:

926:

886:

223:

further reduced, and productivity increased. These machines use

203:

Turret lathe operator machining parts for transport planes, 1942

1169:

914:

James

Hartness: A Representative of the Machine Age at Its Best

1124:

398:), allowing the turret to pass beneath the part. Patented by

37:

3x36 flat turret lathe with cross-sliding head, equipped for

997:

Example cycle on a manual turret lathe, narrated by operator

294:

to become a horizontal rotating table, analogous to a huge

836:, Springfield, Vermont: Jones and Lamson Machine Company,

57:. It evolved from earlier lathes with the addition of the

434:

334:

CNC VTL, King Vertical Turret Lathe Model 100, built 1955

900:

792:. American Society of Mechanical Engineers. p. 456.

761:

678:. Vol. 1. New Delhi: Tata McGraw-Hill. p. 57.

718:(2nd ed.). New York: Industrial Press. pp.

971:

Tools for the Job: a Short History of Machine Tools

161:

1047:

415:conventional turret, which is not flat or hollow.

612:

610:

1282:

607:

593:. Bloomington, Indiana: Xlibris. p. 144.

1033:

478:. Springer Nature. pp. 128, 177–9, 429.

249:

958:, Cambridge, Massachusetts, USA: MIT Press,

673:

640:. Colliery Engineer Company. pp. 3–11.

346:CNC VTL, 16' Rockford Open Side, built 1980

1040:

1026:

100:

857:

789:A.S.M.E. Mechanical Catalog and Directory

498:

471:

919:American Society of Mechanical Engineers

826:

472:Zhang, Ce; Yang, Jianming (2020-01-03).

456:

360:

356:

198:

152:

110:

29:

785:

631:

586:

546:

14:

1283:

582:

580:

435:Toolpost turrets and tailstock turrets

1021:

705:

703:

968:

948:

709:

669:

667:

627:

625:

616:

467:

465:

910:

773:

577:

475:A History of Mechanical Engineering

351:

24:

700:

25:

1312:

990:

901:H.W. Ward & Co., Ltd (1938),

833:Hartness Flat Turret Lathe Manual

664:

622:

462:

405:

194:

955:A Short History of Machine Tools

418:

339:

327:

315:

303:

162:Archetypical: horizontal, manual

820:

779:

767:

755:

744:

529:p. 81, 123, Cypress, CA, 2013.

365:Turret lathe operator, US, 1942

869:Johns Hopkins University Press

751:Capstan and Turret differences

540:

519:

492:

450:

13:

1:

762:H.W. Ward & Co., Ltd 1938

505:. JHU Press. pp. 48–50.

443:

911:Roe, Joseph Wickham (1937),

587:Crosher, William P. (2014).

211:

7:

553:. McGraw-Hill. p. 273.

285:

10:

1317:

973:, London: B. T. Batsford,

967:. Co-edition published as

272:computer numerical control

250:Computer numerical control

215:

106:

83:computer numerical control

1203:

1060:

499:Hounshell, David (1985).

1244:Machine and metalworking

144:

1254:Measuring and alignment

1165:Rotary transfer machine

969:Rolt, L. T. C. (1965),

867:, Baltimore, Maryland:

676:Manufacturing processes

389:

1150:Oxy-fuel cutting torch

425:monitor-class warships

366:

204:

158:

119:

42:

364:

357:Capstan versus turret

202:

175:; J.D. Alvord of the

156:

114:

101:Capstan versus turret

33:

1301:Industrial equipment

1219:Cutting and abrasive

903:Operators' Hand-book

710:Smid, Peter (2003).

674:Bawa, H. S. (2004).

634:"Part 5: Lathe Work"

859:Hounshell, David A.

258:ended, the digital

189:Pratt & Whitney

1291:Industrial history

808:has generic name (

656:has generic name (

569:has generic name (

550:American Machinist

367:

205:

181:Brown & Sharpe

159:

120:

51:metalworking lathe

43:

27:Metalworking lathe

1278:

1277:

878:978-0-8018-2975-8

776:, pp. 34–36.

590:A Gear Chronology

535:978-0-9897906-0-4

512:978-0-8018-3158-4

485:978-981-15-0833-2

268:numerical control

16:(Redirected from

1308:

1105:Grinding machine

1075:Ball-peen hammer

1042:

1035:

1028:

1019:

1018:

981:

966:

938:

906:

897:

853:

852:

850:

814:

813:

807:

803:

801:

793:

786:Editors (1921).

783:

777:

771:

765:

759:

753:

748:

742:

741:

717:

707:

698:

697:

671:

662:

661:

655:

651:

649:

641:

632:Editors (1901).

629:

620:

614:

605:

604:

584:

575:

574:

568:

564:

562:

554:

547:Editors (1924).

544:

538:

525:Parker, Dana T.

523:

517:

516:

496:

490:

489:

469:

460:

454:

352:Other variations

343:

331:

319:

307:

185:Francis A. Pratt

21:

1316:

1315:

1311:

1310:

1309:

1307:

1306:

1305:

1281:

1280:

1279:

1274:

1273:

1199:

1180:Thread restorer

1070:Automatic lathe

1056:

1046:

1015:

993:

879:

848:

846:

844:

828:Hartness, James

823:

818:

817:

805:

804:

795:

794:

784:

780:

772:

768:

760:

756:

749:

745:

730:

708:

701:

686:

672:

665:

653:

652:

643:

642:

630:

623:

615:

608:

601:

585:

578:

566:

565:

556:

555:

545:

541:

524:

520:

513:

497:

493:

486:

470:

463:

455:

451:

446:

437:

421:

408:

392:

359:

354:

347:

344:

335:

332:

323:

320:

311:

308:

288:

252:

220:

218:Automatic lathe

214:

197:

164:

147:

139:mass production

128:American system

109:

79:servomechanisms

55:interchangeable

28:

23:

22:

15:

12:

11:

5:

1314:

1304:

1303:

1298:

1293:

1276:

1275:

1272:

1271:

1266:

1261:

1256:

1251:

1246:

1241:

1236:

1231:

1226:

1221:

1216:

1211:

1209:Types of tools

1205:

1204:

1201:

1200:

1198:

1197:

1192:

1187:

1182:

1177:

1172:

1167:

1162:

1157:

1152:

1147:

1142:

1140:Milling cutter

1137:

1132:

1127:

1122:

1117:

1112:

1107:

1102:

1097:

1092:

1087:

1082:

1077:

1072:

1067:

1061:

1058:

1057:

1045:

1044:

1037:

1030:

1022:

1013:

1012:

1006:

1000:

992:

991:External links

989:

988:

987:

983:

950:Rolt, L. T. C.

945:

944:

908:

898:

877:

855:

842:

822:

819:

816:

815:

778:

766:

754:

743:

728:

699:

684:

663:

621:

619:, p. 165.

606:

600:978-1499071146

599:

576:

539:

518:

511:

491:

484:

461:

448:

447:

445:

442:

436:

433:

420:

417:

407:

406:Hollow-hexagon

404:

400:James Hartness

391:

388:

376:United Kingdom

358:

355:

353:

350:

349:

348:

345:

338:

336:

333:

326:

324:

321:

314:

312:

309:

302:

296:potter's wheel

287:

284:

270:(NC) and then

251:

248:

237:screw machines

216:Main article:

213:

210:

196:

195:Semi-automatic

193:

169:Elisha K. Root

163:

160:

146:

143:

108:

105:

61:, which is an

26:

9:

6:

4:

3:

2:

1313:

1302:

1299:

1297:

1294:

1292:

1289:

1288:

1286:

1270:

1267:

1265:

1262:

1260:

1257:

1255:

1252:

1250:

1247:

1245:

1242:

1240:

1237:

1235:

1232:

1230:

1227:

1225:

1222:

1220:

1217:

1215:

1212:

1210:

1207:

1206:

1202:

1196:

1193:

1191:

1188:

1186:

1183:

1181:

1178:

1176:

1173:

1171:

1168:

1166:

1163:

1161:

1160:Plasma cutter

1158:

1156:

1153:

1151:

1148:

1146:

1143:

1141:

1138:

1136:

1133:

1131:

1128:

1126:

1123:

1121:

1118:

1116:

1113:

1111:

1108:

1106:

1103:

1101:

1098:

1096:

1095:English wheel

1093:

1091:

1088:

1086:

1083:

1081:

1078:

1076:

1073:

1071:

1068:

1066:

1063:

1062:

1059:

1054:

1050:

1043:

1038:

1036:

1031:

1029:

1024:

1023:

1020:

1016:

1010:

1007:

1004:

1001:

998:

995:

994:

986:

984:

980:

976:

972:

965:

961:

957:

956:

951:

947:

946:

942:

936:

932:

928:

924:

920:

916:

915:

909:

904:

899:

896:

892:

888:

884:

880:

874:

870:

866:

865:

860:

856:

845:

843:9780282208783

839:

835:

834:

829:

825:

824:

811:

799:

791:

790:

782:

775:

770:

763:

758:

752:

747:

739:

735:

731:

729:0-8311-3158-6

725:

721:

716:

715:

706:

704:

695:

691:

687:

685:0-07-053525-6

681:

677:

670:

668:

659:

647:

639:

635:

628:

626:

618:

613:

611:

602:

596:

592:

591:

583:

581:

572:

560:

552:

551:

543:

536:

532:

528:

522:

514:

508:

504:

503:

495:

487:

481:

477:

476:

468:

466:

458:

457:Hartness 1910

453:

449:

441:

432:

430:

426:

419:Monitor lathe

416:

413:

403:

401:

397:

387:

385:

384:United States

382:usage versus

381:

377:

372:

363:

342:

337:

330:

325:

318:

313:

306:

301:

300:

299:

297:

293:

283:

280:

275:

273:

269:

265:

264:machine tools

261:

257:

247:

245:

240:

238:

234:

230:

226:

219:

209:

201:

192:

190:

186:

182:

178:

177:Sharps Armory

174:

170:

155:

151:

142:

140:

136:

135:machine tools

131:

129:

123:

117:

113:

104:

102:

98:

97:Capstan lathe

94:

92:

86:

84:

80:

76:

72:

68:

64:

60:

56:

52:

49:is a form of

48:

40:

36:

32:

19:

18:Capstan lathe

1190:Turret lathe

1189:

1130:Machine tool

1053:metalworking

1014:

1011:from YouTube

1005:from YouTube

999:from YouTube

970:

954:

917:, New York:

913:

902:

863:

847:, retrieved

832:

821:Bibliography

788:

781:

769:

757:

746:

713:

675:

637:

589:

549:

542:

526:

521:

501:

494:

474:

452:

438:

422:

409:

396:rotary table

393:

380:Commonwealth

368:

289:

276:

256:World War II

253:

241:

233:cuckoo clock

221:

206:

165:

148:

132:

124:

121:

116:World War II

96:

95:

87:

67:cutting tool

58:

47:turret lathe

46:

44:

1269:Woodworking

1175:Tap and die

1135:Metal lathe

1100:Gear shaper

1085:Drill press

1065:Arbor press

849:26 February

806:|last=

654:|last=

567:|last=

244:World War I

150:vertical).

1285:Categories

941:HathiTrust

939:link from

895:1104810110

444:References

374:matter of

371:synonymous

279:CNC lathes

91:gun turret

77:-directed

41:work, 1910

1120:Jig borer

798:cite book

646:cite book

617:Rolt 1965

559:cite book

292:faceplate

212:Automatic

75:digitally

63:indexable

1224:Forestry

1214:Cleaning

1185:Tool bit

1090:End mill

979:65080822

952:(1965),

927:37016470

887:83016269

861:(1984),

830:(1910),

774:Roe 1937

738:52364066

694:57660758

429:Hardinge

286:Vertical

260:computer

85:lathes.

35:Hartness

1249:Masonry

1239:Kitchen

1110:Hacksaw

1049:Machine

935:3456642

412:hexagon

386:usage.

107:History

1296:Lathes

1259:Mining

1229:Garden

1195:Welder

1170:Shaper

1155:Planer

1080:Broach

977:

964:250074

962:

933:

925:

893:

885:

875:

840:

736:

726:

692:

682:

597:

533:

509:

482:

183:; and

118:poster

59:turret

1264:Power

1125:Lathe

1055:tools

722:–14.

254:When

229:chuck

145:Types

1234:Hand

1145:Mill

1051:and

975:LCCN

960:OCLC

931:OCLC

923:LCCN

891:OCLC

883:LCCN

873:ISBN

851:2016

838:ISBN

810:help

734:OCLC

724:ISBN

690:OCLC

680:ISBN

658:help

595:ISBN

571:help

531:ISBN

507:ISBN

480:ISBN

390:Flat

378:and

266:via

225:cams

173:Colt

137:for

81:for

1115:Hob

187:of

171:of

71:jig

39:bar

1287::

929:,

921:,

889:,

881:,

871:,

802::

800:}}

796:{{

732:.

720:11

702:^

688:.

666:^

650::

648:}}

644:{{

636:.

624:^

609:^

579:^

563::

561:}}

557:{{

464:^

246:.

103:.

93:.

45:A

1041:e

1034:t

1027:v

982:.

943:.

937:.

907:.

854:.

812:)

764:.

740:.

696:.

660:)

603:.

573:)

537:.

515:.

488:.

459:.

126:"

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.