347:

20:

335:

107:

35:

131:

organisms can also be dependent on overall nutrient limitation, not just macro elements. This is especially the case in the 'feast/famine' cycle method for induction of PHA production, wherein carbon is periodically added and depleted to cause famine, which encourages cells to produce PHA during 'feast' as a storage method for periods of famine.

260:

As raw material for the fermentation, carbohydrates such as glucose and sucrose can be used, but also vegetable oil or glycerine from biodiesel production. Researchers in industry are working on methods with which transgenic crops will be developed that express PHA synthesis routes from bacteria and

130:

The biosynthesis of PHA is usually caused by deficiency conditions (e.g. lack of macro elements such as phosphorus, nitrogen, trace elements, or lack of oxygen) and the excess supply of carbon sources. However, the prevalence of PHA production within either a mono-culture or a set of mixed-microbial

126:

can be placed in a suitable medium and fed appropriate nutrients so that it multiplies rapidly. Once the population has reached a substantial level, the nutrient composition can be changed to force the micro-organism to synthesize PHA. The yield of PHA obtained from the intracellular granule

280:

PHA polymers are thermoplastic, can be processed on conventional processing equipment, and are, depending on their composition, ductile and more or less elastic. They differ in their properties according to their chemical composition (homo-or copolyester, contained hydroxy fatty acids).

323:(PP), has a good resistance to moisture and aroma barrier properties. Polyhydroxybutyric acid synthesized from pure PHB is relatively brittle and stiff. PHB copolymers, which may include other fatty acids such as beta-hydroxyvaleric acid, may be elastic.

155:

PHA synthases are the key enzymes of PHA biosynthesis. They use the coenzyme A - thioester of (r)-hydroxy fatty acids as substrates. The two classes of PHA synthases differ in the specific use of hydroxy fatty acids of short or medium chain length.

431:, tacks, staples, screws (including interference screws), bone plates and bone plating systems, surgical mesh, repair patches, slings, cardiovascular patches, orthopedic pins (including bone.lling augmentation material),

1060:

Mohapatra, S.; Sarkar, B.; Samantaray, D. P.; Daware, A.; Maity, S.; Pattnaik, S.; Bhattacharjee, S. (2017). "Bioconversion of fish solid waste into PHB using

Bacillus subtilis based submerged fermentation process".

981:

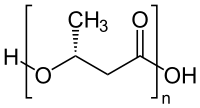

Amelia, Tan Suet May; Govindasamy, Sharumathiy; Tamothran, Arularasu

Muthaliar; Vigneswari, Sevakumaran; Bhubalan, Kesaven (2019), Kalia, Vipin Chandra (ed.), "Applications of PHA in Agriculture",

98:

of PHA can also be changed by blending, modifying the surface or combining PHA with other polymers, enzymes and inorganic materials, making it possible for a wider range of applications.

207:

Another even larger scale synthesis can be done with the help of soil organisms. For lack of nitrogen and phosphorus they produce a kilogram of PHA per three kilograms of sugar.

416:

There are potential applications for PHA produced by micro-organisms within the agricultural, medical and pharmaceutical industries, primarily due to their biodegradability.

851:

Cataldi, P. (July 2020). "Multifunctional

Biocomposites Based on Polyhydroxyalkanoate and Graphene/Carbon Nanofiber Hybrids for Electrical and Thermal Applications".

596:

953:

200:

72:

can be combined within this family to give materials with extremely different properties. These plastics are biodegradable and are used in the production of

134:

Polyesters are deposited in the form of highly refractive granules in the cells. Depending upon the microorganism and the cultivation conditions, homo- or

222:

In the industrial production of PHA, the polyester is extracted and purified from the bacteria by optimizing the conditions of microbial fermentation of

667:

Jacquel, Nicolas; Lo, Chi-Wei; Wei, Yu-Hong; Wu, Ho-Shing; Wang, Shaw S. (2008). "Isolation and purification of bacterial poly(3-hydroxyalkanoates)".

163:

Poly (HA SCL) from hydroxy fatty acids with short chain lengths including three to five carbon atoms are synthesized by numerous bacteria, including

1098:

Mohapatra, Swati; Maity, Sudipta; Dash, Hirak Ranjan; Das, Surajit; Pattnaik, Swati; Rath, Chandi Charan; Samantaray, Deviprasad (December 2017).

261:

so produce PHA as energy storage in their tissues. Several companies are working to develop methods of producing PHA from waste water, including

204:, synthesize copolyester from the above two types of hydroxy fatty acids, or at least possess enzymes that are capable of part of this synthesis.

563:

Bhubalan, Kesaven; Lee, Wing-Hin; Sudesh, Kumar (2011-05-03), Domb, Abraham J.; Kumar, Neeraj; Ezra, Aviva (eds.), "Polyhydroxyalkanoate",

410:

242:

776:

808:

182:

Poly (HA MCL) from hydroxy fatty acids with medium chain lengths including six to 14 carbon atoms, can be made for example, by

998:

705:

635:

580:

547:

492:

Lu, Jingnan; Tappel, Ryan C.; Nomura, Christopher T. (2009-08-05). "Mini-Review: Biosynthesis of Poly(hydroxyalkanoates)".

346:

300:

can lie in the range of a few to 70%. Processability, impact strength and flexibility improves with a higher percentage of

334:

413:(small business category) for their development and commercialisation of a cost-effective method for manufacturing PHAs.

138:

with different hydroxyalkanoic acids are generated. PHA granules are then recovered by disrupting the cells. Recombinant

600:

369:

as a means to create plastics from non-fossil fuel sources. Furthermore, active research is being carried out for the

249:

obtained via fermentation that was named "Biopol". It was sold under the name "Biopol" and distributed in the U.S. by

964:

402:(poly(3-hydroxybutyrate-co-3-hydroxyvalerate)) is less stiff and tougher, and it may be used as packaging material.

68:. When produced by bacteria they serve as both a source of energy and as a carbon store. More than 150 different

1021:

Chen, Guo-Qiang; Wu, Qiong (2005). "The application of polyhydroxyalkanoates as tissue engineering materials".

272:

PHAs are processed mainly via injection molding, extrusion and extrusion bubbles into films and hollow bodies.

837:

238:

148:

str. pBE2C1AB were used in production of polyhydroxyalkanoates (PHA) and it was shown that they could use

365:

with novel properties, much interest exists to develop the use of PHA-based materials. PHA fits into the

265:

subsidiary

Anoxkaldnes. and start-ups, Micromidas, Mango Materials, Full Cycle Bioplastics, Newlight and

57:

961:

The

Presidential Green Chemistry Challenge Awards Program: Summary of 2005 Award Entries and Recipients

752:

382:

301:

1183:

729:

1168:

695:

1173:

448:

194:

792:

8:

1178:

1146:"A Strategic Review on Use of Polyhydroxyalkanoates as an Immunostimulant in Aquaculture"

211:

176:

165:

122:

24:

120:

To induce PHA production in a laboratory setting, a culture of a micro-organism such as

1128:

1099:

1086:

1034:

1004:

878:

860:

517:

424:

391:

210:

The simplest and most commonly occurring form of PHA is the fermentative production of

184:

1145:

1133:

1078:

1038:

1008:

994:

882:

701:

649:

641:

631:

576:

543:

509:

370:

171:

140:

112:

521:

1123:

1115:

1090:

1070:

1030:

986:

909:

870:

838:"Paques Biomaterials investeert 58 miljoen in demo-installatie en fabriek in Emmen"

676:

623:

568:

501:

432:

358:

95:

1074:

898:"Solubility of polyhydroxyalkanoates by experiment and thermodynamic correlations"

990:

896:

Jacquel, Nicolas; Lo, Chi-Wei; Wu, Ho-Shing; Wei, Yu-Hong; Wang, Shaw S. (2007).

420:

309:

289:

1119:

313:

680:

572:

505:

1162:

645:

513:

378:

366:

320:

297:

231:

88:

80:

627:

19:

1137:

1082:

1042:

874:

653:

386:

1153:

456:

285:

135:

106:

73:

34:

471:

substitutes, bone graft substitutes, bone dowels, wound dressings, and

468:

362:

305:

914:

897:

822:

809:"Full Cycle Bioplastics Turns Bacteria Waste into "Nature's Plastic""

464:

440:

406:

374:

266:

254:

84:

50:

980:

865:

472:

460:

250:

54:

614:

Kim, Y. B.; Lenz, R. W. (2001). "Polyesters from microorganisms".

451:

repair devices, pericardial patches, bulking and filling agents,

227:

69:

53:

produced in nature by numerous microorganisms, including through

1059:

565:

Biodegradable

Polymers in Clinical Use and Clinical Development

444:

304:

in the material. PHAs are soluble in halogenated solvents such

288:

stable, in contrast to other bioplastics from polymers such as

262:

214:, which consists of 1000 to 30000 hydroxy fatty acid monomers.

127:

inclusions can be as high as 80% of the organism's dry weight.

436:

428:

223:

65:

61:

954:"The Presidential Green Chemistry Challenge Awards Program"

756:

452:

399:

149:

963:. Environmental Protection Agency: 8. 2005. Archived from

152:

waste as carbon source for lower cost of PHA production.

38:

Chemical structures of P3HB, PHV and their copolymer PHBV

1144:

Adhithya Sankar

Santhosh; Mridul Umesh (December 2020).

439:, guided tissue repair/regeneration devices, articular

983:

929:

467:

cell implants, spinal fusion cages, skin substitutes,

1152:, Vol. 8 No. 1 (2021), 14 December 2020 , Page 1-18.

1097:

777:

Mango

Materials selected for Phase II STTR NASA award

116:

bacteria can be used to produce polyhydroxyalkanoates

419:

Fixation and orthopaedic applications have included

835:

616:Advances in Biochemical Engineering/Biotechnology

567:, John Wiley & Sons, Inc., pp. 247–315,

562:

1160:

727:

750:

538:Doi, Yoshiharu; Steinbuchel, Alexander (2002).

895:

666:

597:"Polyhydroxyalkanoates for tissue engineering"

537:

491:

319:PHB is similar in its material properties to

411:Presidential Green Chemistry Challenge Award

753:"Micromidas to test sludge-to-plastic tech"

693:

533:

531:

459:scaffolds, meniscus regeneration devices,

352:Structure of poly-4-hydroxybutyrate (P4HB)

296:, and show a low permeation of water. The

1127:

1104:and biopolymer: Prospects and challenges"

913:

864:

687:

595:Michael, Anne John (September 12, 2004).

340:Structure of poly-3-hydroxyvalerate (PHV)

23:Structure of poly-(R)-3-hydroxybutyrate (

985:, Springer Singapore, pp. 347–361,

793:How Close Are We to Reinventing Plastic?

217:

105:

33:

18:

1154:https://doi.org/10.22037/afb.v8i1.31255

850:

613:

594:

528:

159:The resulting PHA is of the two types:

1161:

1020:

728:Seb Egerton-Read (September 9, 2015).

275:

1108:Biochemistry and Biophysics Reports

13:

1053:

1035:10.1016/j.biomaterials.2005.04.036

14:

1195:

292:, partial ca. temperatures up to

751:Martin Lamonica (May 27, 2010).

542:. Weinheim, Germany: Wiley-VCH.

345:

333:

91:ranging from 40 to 180 °C.

1014:

974:

946:

922:

889:

844:

829:

815:

801:

786:

770:

669:Biochemical Engineering Journal

326:

101:

744:

721:

660:

607:

588:

556:

485:

443:repair devices, nerve guides,

94:The mechanical properties and

1:

1075:10.1080/09593330.2017.1291759

853:ACS Applied Polymer Materials

823:"Paques biomaterials website"

697:Compostable Polymer Materials

694:Ewa Rudnik (3 January 2008).

478:

991:10.1007/978-981-13-3759-8_13

239:Imperial Chemical Industries

7:

1120:10.1016/j.bbrep.2017.10.001

730:"A New Way to Make Plastic"

10:

1200:

1150:Applied Food Biotechnology

836:Provincie Drenthe (2022).

383:polyethylene terephthalate

192:A few bacteria, including

681:10.1016/j.bej.2007.11.029

573:10.1002/9781118015810.ch8

506:10.1080/15583720903048243

405:In June 2005, US company

212:poly-beta-hydroxybutyrate

1063:Environmental Technology

700:. Elsevier. p. 21.

361:and potential to create

628:10.1007/3-540-40021-4_2

409:, Inc. received the US

398:A PHA copolymer called

243:poly(3-hydroxybutyrate-

875:10.1021/acsapm.0c00539

117:

39:

31:

218:Industrial production

109:

43:Polyhydroxyalkanoates

37:

22:

603:on January 28, 2007.

449:atrial septal defect

423:, suture fasteners,

201:Thiococcus pfennigii

195:Aeromonas hydrophila

29:polyhydroxyalkanoate

781:BioplasticsMagazine

463:and tendon grafts,

276:Material properties

267:Paques Biomaterials

247:-3-hydroxyvalerate)

166:Cupriavidus necator

123:Cupriavidus necator

110:Certain strains of

79:They can be either

392:Pseudomonas putida

185:Pseudomonas putida

118:

40:

32:

1000:978-981-13-3758-1

930:"Homepage - P4SB"

915:10.1002/aic.11274

707:978-0-08-045371-2

637:978-3-540-41141-3

582:978-1-118-01581-0

549:978-3-527-30225-3

433:adhesion barriers

389:) into PHA using

371:biotransformation

172:Alcaligenes latus

146:Bacillus subtilis

141:Bacillus subtilis

113:Bacillus subtilis

1191:

1141:

1131:

1094:

1047:

1046:

1018:

1012:

1011:

978:

972:

971:

969:

958:

950:

944:

943:

941:

940:

926:

920:

919:

917:

893:

887:

886:

868:

859:(8): 3525–3534.

848:

842:

841:

833:

827:

826:

819:

813:

812:

805:

799:

790:

784:

774:

768:

767:

765:

763:

748:

742:

741:

739:

737:

725:

719:

718:

716:

714:

691:

685:

684:

664:

658:

657:

611:

605:

604:

599:. Archived from

592:

586:

585:

560:

554:

553:

535:

526:

525:

489:

447:repair devices,

427:repair devices,

359:biodegradability

349:

337:

295:

144:str. pBE2C1 and

96:biocompatibility

87:materials, with

16:Polyester family

1199:

1198:

1194:

1193:

1192:

1190:

1189:

1188:

1159:

1158:

1056:

1054:Further reading

1051:

1050:

1029:(33): 6565–78.

1019:

1015:

1001:

979:

975:

967:

956:

952:

951:

947:

938:

936:

928:

927:

923:

908:(10): 2704–14.

894:

890:

849:

845:

834:

830:

821:

820:

816:

811:. 11 July 2019.

807:

806:

802:

795:(Dec 18, 2019)

791:

787:

779:(10. Aug 2017)

775:

771:

761:

759:

749:

745:

735:

733:

726:

722:

712:

710:

708:

692:

688:

665:

661:

638:

612:

608:

593:

589:

583:

561:

557:

550:

536:

529:

494:Polymer Reviews

490:

486:

481:

353:

350:

341:

338:

329:

310:dichloromethane

293:

290:polylactic acid

278:

220:

104:

17:

12:

11:

5:

1197:

1187:

1186:

1184:Thermoplastics

1181:

1176:

1171:

1157:

1156:

1142:

1095:

1055:

1052:

1049:

1048:

1013:

999:

973:

970:on 2012-07-08.

945:

921:

888:

843:

828:

814:

800:

785:

769:

743:

720:

706:

686:

659:

636:

606:

587:

581:

555:

548:

527:

500:(3): 226–248.

483:

482:

480:

477:

355:

354:

351:

344:

342:

339:

332:

328:

325:

314:dichloroethane

277:

274:

237:In the 1980s,

219:

216:

190:

189:

180:

103:

100:

89:melting points

15:

9:

6:

4:

3:

2:

1196:

1185:

1182:

1180:

1177:

1175:

1172:

1170:

1167:

1166:

1164:

1155:

1151:

1147:

1143:

1139:

1135:

1130:

1125:

1121:

1117:

1113:

1109:

1105:

1103:

1096:

1092:

1088:

1084:

1080:

1076:

1072:

1068:

1064:

1058:

1057:

1044:

1040:

1036:

1032:

1028:

1024:

1017:

1010:

1006:

1002:

996:

992:

988:

984:

977:

966:

962:

955:

949:

935:

931:

925:

916:

911:

907:

903:

902:AIChE Journal

899:

892:

884:

880:

876:

872:

867:

862:

858:

854:

847:

839:

832:

824:

818:

810:

804:

798:

794:

789:

782:

778:

773:

758:

754:

747:

731:

724:

709:

703:

699:

698:

690:

682:

678:

674:

670:

663:

655:

651:

647:

643:

639:

633:

629:

625:

621:

617:

610:

602:

598:

591:

584:

578:

574:

570:

566:

559:

551:

545:

541:

534:

532:

523:

519:

515:

511:

507:

503:

499:

495:

488:

484:

476:

474:

470:

466:

462:

458:

454:

450:

446:

442:

438:

434:

430:

426:

422:

417:

414:

412:

408:

403:

401:

396:

394:

393:

388:

384:

380:

379:plastic waste

376:

372:

368:

367:green economy

364:

360:

348:

343:

336:

331:

330:

324:

322:

321:polypropylene

317:

315:

311:

307:

303:

299:

298:crystallinity

291:

287:

282:

273:

270:

268:

264:

258:

256:

252:

248:

246:

240:

235:

233:

232:vegetable oil

229:

225:

215:

213:

208:

205:

203:

202:

197:

196:

187:

186:

181:

178:

174:

173:

168:

167:

162:

161:

160:

157:

153:

151:

147:

143:

142:

137:

132:

128:

125:

124:

115:

114:

108:

99:

97:

92:

90:

86:

82:

81:thermoplastic

77:

75:

71:

67:

63:

59:

56:

52:

48:

44:

36:

30:

26:

21:

1169:Biomaterials

1149:

1111:

1107:

1101:

1066:

1062:

1026:

1023:Biomaterials

1022:

1016:

982:

976:

965:the original

960:

948:

937:. Retrieved

933:

924:

905:

901:

891:

856:

852:

846:

831:

817:

803:

796:

788:

780:

772:

760:. Retrieved

746:

734:. Retrieved

723:

711:. Retrieved

696:

689:

675:(1): 15–27.

672:

668:

662:

619:

615:

609:

601:the original

590:

564:

558:

539:

497:

493:

487:

418:

415:

404:

397:

390:

387:polyurethane

356:

327:Applications

318:

283:

279:

271:

259:

244:

236:

221:

209:

206:

199:

193:

191:

183:

170:

164:

158:

154:

145:

139:

136:copolyesters

133:

129:

121:

119:

111:

102:Biosynthesis

93:

78:

58:fermentation

46:

42:

41:

28:

1174:Bioplastics

1069:(24): 1–8.

934:www.p4sb.eu

762:October 23,

736:October 23,

732:. Circulate

540:Biopolymers

457:bone marrow

363:bioplastics

357:Due to its

85:elastomeric

74:bioplastics

1179:Polyesters

1163:Categories

1114:: 206–13.

939:2017-10-26

866:2005.08525

479:References

395:bacteria.

306:chloroform

253:and later

241:developed

51:polyesters

1009:139827723

883:218673849

646:0724-6145

622:: 51–79.

514:1558-3724

473:hemostats

441:cartilage

407:Metabolix

375:upcycling

284:They are

255:Metabolix

55:bacterial

1138:29090283

1102:Bacillus

1083:28162048

1043:15946738

654:11217417

522:96937618

461:ligament

455:valves,

425:meniscus

302:valerate

251:Monsanto

70:monomers

1129:5651552

1091:1080507

713:10 July

421:sutures

381:(e.g.,

228:glucose

1136:

1126:

1089:

1081:

1041:

1007:

997:

881:

797:Seeker

704:

652:

644:

634:

579:

546:

520:

512:

465:ocular

445:tendon

437:stents

429:rivets

294:180 °C

263:Veolia

66:lipids

62:sugars

1087:S2CID

1005:S2CID

968:(PDF)

957:(PDF)

879:S2CID

861:arXiv

518:S2CID

469:dural

377:" of

230:, or

224:sugar

27:), a

1134:PMID

1079:PMID

1039:PMID

995:ISBN

783:.com

764:2015

757:CNET

738:2015

715:2012

702:ISBN

650:PMID

642:ISSN

632:ISBN

577:ISBN

544:ISBN

510:ISSN

453:vein

400:PHBV

385:and

198:and

169:and

150:malt

49:are

47:PHAs

25:P3HB

1124:PMC

1116:doi

1071:doi

1031:doi

987:doi

910:doi

871:doi

677:doi

624:doi

569:doi

502:doi

312:or

177:PHB

83:or

64:or

60:of

45:or

1165::

1148:.

1132:.

1122:.

1112:12

1110:.

1106:.

1085:.

1077:.

1067:38

1065:.

1037:.

1027:26

1025:.

1003:,

993:,

959:.

932:.

906:53

904:.

900:.

877:.

869:.

855:.

755:.

673:39

671:.

648:.

640:.

630:.

620:71

618:.

575:,

530:^

516:.

508:.

498:49

496:.

475:.

435:,

316:.

308:,

286:UV

269:.

257:.

245:co

234:.

226:,

179:).

76:.

1140:.

1118::

1100:"

1093:.

1073::

1045:.

1033::

989::

942:.

918:.

912::

885:.

873::

863::

857:2

840:.

825:.

766:.

740:.

717:.

683:.

679::

656:.

626::

571::

552:.

524:.

504::

373:"

188:.

175:(

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.