207:

133:

36:

329:. Users would select the type of tool, machining process and paths to be used. While an engineer may have a working knowledge of G-code programming, small optimization and wear issues compound over time. Mass-produced items that require machining are often initially created through casting or some other non-machine method. This enables hand-written, short, and highly optimized G-code that could not be produced in a CAM package.

1026:

510:

and spindle speeds are generally increased in order to maintain a target surface speed (SFM). A light chip load at high feed and RPM is often referred to as High Speed

Machining (HSM), and can provide quick machining times with high quality results. The result of these lighter passes is a highly accurate part, with a uniformly high

523:

tangent to the ideal part features. This produces an excellent surface finish with high dimensional accuracy. This process is commonly used to machine complex organic shapes such as turbine and impeller blades, which due to their complex curves and overlapping geometry, are impossible to machine with only three axis machines.

289:

set for increased flexibility. In some cases, such as improperly set up CAM software or specific tools, the CNC machine required manual editing before the program will run properly. None of these issues were so insurmountable that a thoughtful engineer or skilled machine operator could not overcome

183:

and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material (thus minimizing waste), while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a

509:

Finishing involves many light passes across the material in fine steps to produce the finished part. When finishing a part, the steps between passes is minimal to prevent tool deflection and material spring back. In order to reduce the lateral tool load, tool engagement is reduced, while feed rates

453:

To ensure ease of use appropriate to user objectives, modern CAM solutions are scalable from a stand-alone CAM system to a fully integrated multi-CAD 3D solution-set. These solutions are created to meet the full needs of manufacturing personnel including part planning, shop documentation, resource

332:

At least in the United States, there is a shortage of young, skilled machinists entering the workforce able to perform at the extremes of manufacturing; high precision and mass production. As CAM software and machines become more complicated, the skills required of a machinist or machine operator

522:

In milling applications on hardware with rotary table and/or rotary head axes, a separate finishing process called contouring can be performed. Instead of stepping down in fine-grained increments to approximate a surface, the work piece or tool is rotated to make the cutting surfaces of the tool

481:

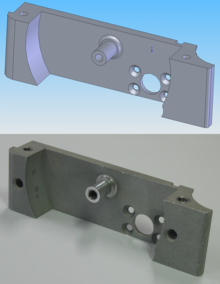

or steps, because the strategy has taken multiple "steps" down the part as it removes material. This takes the best advantage of the machine's ability by cutting material horizontally. Common strategies are zig-zag clearing, offset clearing, plunge roughing, rest-roughing, and trochoidal milling

492:

This process begins with a roughed part that unevenly approximates the model and cuts to within a fixed offset distance from the model. The semi-finishing pass must leave a small amount of material (called the scallop) so the tool can cut accurately, but not so little that the tool and material

441:. Today’s CAM user can easily generate streamlined tool paths, optimized tool axis tilt for higher feed rates, better tool life and surface finish, and ideal cutting depth. In addition to programming cutting operations, modern CAM softwares can additionally drive non-cutting operations such as

514:. In addition to modifying speeds and feeds, machinists will often have finishing specific endmills, which never used as roughing endmills. This is done to protect the endmill from developing chips and flaws in the cutting surface, which would leave streaks and blemishes on the final part.

397:

For the user who is just getting started as a CAM user, out-of-the-box capabilities providing

Process Wizards, templates, libraries, machine tool kits, automated feature based machining and job function specific tailorable user interfaces build user confidence and speed the learning

482:(adaptive clearing). The goal at this stage is to remove the most material in the least time, without much concern for overall dimensional accuracy. When roughing a part, a small amount of extra material is purposely left behind to be removed in subsequent finishing operation(s).

265:. Alexander Hammer at DeLaval Steam Turbine Company invented a technique to progressively drill turbine blades out of a solid metal block of metal with the drill controlled by a punch card reader in 1950. Boeing first obtained NC machines in 1956, made by companies such as

284:

machinists. Fallows created the first CAD software but this had severe shortcomings and was promptly taken back into the developing stage. CAM software would output code for the least capable machine, as each machine tool control added on to the standard

290:

for prototyping or small production runs; G-Code is a simple language. In high production or high precision shops, a different set of problems were encountered where an experienced CNC machinist must both hand-code programs and run CAM software.

915:

313:

formats that are supported by a wide variety of software. The output from the CAM software is usually a simple text file of G-code/M-codes, sometimes many thousands of commands long, that is then transferred to a machine tool using a

238:. CAM leverages both the value of the most skilled manufacturing professionals through advanced productivity tools, while building the skills of new professionals through visualization, simulation and optimization tools.

409:

The manufacturing environment is increasingly complex. The need for CAM and PLM tools by the manufacturing engineer, NC programmer or machinist is similar to the need for computer assistance by the pilot of modern

1164:

Yong, Loong Tee; Moy, Peter K. (September 2008). "Complications of

Computer-Aided-Design/Computer-Aided-Machining-Guided (NobelGuide™) Surgical Implant Placement: An Evaluation of Early Clinical Results".

678:

Yong, Loong Tee; Moy, Peter K. (2008). "Complications of

Computer-Aided-Design/Computer-Aided-Machining-Guided (NobelGuide™) Surgical Implant Placement: An Evaluation of Early Clinical Results".

919:

466:

Most machining progresses through many stages, each of which is implemented by a variety of basic and sophisticated strategies, depending on the part design, material, and software available.

373:

Over time, the historical shortcomings of CAM are being attenuated, both by providers of niche solutions and by providers of high-end solutions. This is occurring primarily in three arenas:

192:(CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the machine tool. CAM is used in many schools alongside CAD to create objects.

968:

401:

User confidence is further built on 3D visualization through a closer integration with the 3D CAD environment, including error-avoiding simulations and optimizations.

450:

Integration with PLM and the extended enterprise LM to integrate manufacturing with enterprise operations from concept through field support of the finished product.

477:, or a rough casting which a CNC machine cuts roughly to shape of the final model, ignoring the fine details. In milling, the result often gives the appearance of

1127:

Gomes, Jefferson de

Oliveira; Almeida Jr, Adelson Ribeiro de; Silva, Alex Sandro de Araújo; Souza, Guilherme Oliveira de; Nunes, Acson Machado (September 2010).

1064:

Agrawal, Rajneesh Kumar; Pratihar, D.K.; Roy

Choudhury, A. (June 2006). "Optimization of CNC isoscallop free form surface machining using a genetic algorithm".

171:

of work pieces. This is not the only definition for CAM, but it is the most common. It may also refer to the use of a computer to assist in all operations of a

1256:

1199:

Amin, S.G.; Ahmed, M.H.M.; Youssef, H.A. (December 1995). "Computer-aided design of acoustic horns for ultrasonic machining using finite-element analysis".

537:

1322:

541:

1284:

53:

100:

17:

72:

2031:

1950:

384:

79:

1092:

280:

Historically, CAM software was seen to have several shortcomings that necessitated an overly high level of involvement by skilled

582:

325:

CAM packages could not, and still cannot, reason as a machinist can. They could not optimize toolpaths to the extent required of

1900:

1315:

442:

86:

2036:

2026:

898:

871:

844:

817:

787:

761:

734:

454:

management and data management and exchange. To prevent these solutions from detailed tool specific information a dedicated

1340:

629:

Mörmann, W. H.; Bindl, A. (2002). "All-ceramic, chair-side computer-aided design/computer-aided machining restorations".

68:

301:. Usually it had been necessary to force the CAD operator to export the data in one of the common data formats, such as

1390:

253:

Early commercial applications of CAM were in large companies in the automotive and aerospace industries; for example,

226:(NC) programming tool, wherein two-dimensional (2-D) or three-dimensional (3-D) models of components are generated in

1308:

1277:

1036:

559:

119:

588:

565:

1250:

720:

230:. As with other "computer-aided" technologies, CAM does not eliminate the need for skilled professionals such as

1581:

57:

1453:

576:

1270:

993:

294:

241:

A CAM tool generally converts a model to a language the target machine in question understands, typically

93:

1503:

1428:

1893:

1744:

189:

1586:

1443:

1232:

201:

1576:

570:

315:

1244:

1929:

1862:

1666:

1651:

1591:

1553:

1493:

46:

1226:

1696:

1676:

1571:

807:

474:

231:

888:

861:

777:

751:

1955:

1886:

1795:

1656:

1355:

724:

533:

478:

227:

206:

185:

176:

245:. The numerical control can be applied to machining tools, or more recently to 3D printers.

1780:

1686:

1385:

969:"America's Skilled Trades Dilemma: Shortages Loom As Most-In-Demand Group Of Workers Ages"

8:

1709:

1636:

1488:

603:

422:

355:

266:

172:

1238:

1103:

1800:

1606:

1563:

1468:

1331:

609:

180:

1077:

642:

1837:

1832:

1370:

1212:

1182:

1178:

1032:

1001:

894:

867:

840:

813:

783:

757:

730:

695:

691:

646:

599:

306:

298:

270:

223:

1145:

1128:

1785:

1548:

1538:

1513:

1508:

1375:

1350:

1208:

1174:

1140:

1073:

687:

638:

426:

1193:

942:

664:

547:

254:

132:

1483:

1418:

1413:

834:

455:

326:

1051:

1759:

1719:

1641:

1518:

511:

498:

434:

211:

715:

414:

systems. The modern machinery cannot be properly used without this assistance.

2020:

1775:

1739:

1724:

1543:

1498:

1478:

1473:

1005:

716:

494:

430:

168:

164:

1960:

1754:

1734:

1621:

1293:

1253:

Purdue

Research and Education Centre for Information Systems in Engineering

1186:

803:

699:

650:

438:

337:

and engineer rather than eliminating the CNC machinist from the workforce.

1704:

1631:

1523:

1433:

179:, transportation and storage. Its primary purpose is to create a faster

1985:

1857:

1852:

1729:

1646:

1438:

1133:

Journal of the

Brazilian Society of Mechanical Sciences and Engineering

1129:"Evaluation of 5-axis HSC dynamic behavior when milling TiAl6V4 blades"

417:

Today's CAM systems support the full range of machine tools including:

334:

1980:

1965:

1847:

1842:

1810:

1805:

1626:

1616:

1601:

1533:

1408:

310:

235:

35:

2000:

1995:

1990:

1924:

1596:

1463:

1423:

1398:

411:

274:

160:

1093:"HIGH SPEED MACHINING (HSM) – THE EFFECTIVE WAY OF MODERN CUTTING"

1970:

1867:

1827:

1749:

1681:

1611:

1528:

594:

418:

262:

258:

2005:

1975:

1878:

1714:

1671:

1661:

1365:

1262:

493:

deflect away from the cutting surfaces. Common strategies are

286:

242:

215:

1945:

1790:

1403:

1063:

293:

The integration of CAD with other components of CAD/CAM/CAE

302:

346:

High-Speed

Machining, including streamlining of tool paths

1126:

319:

281:

137:

1066:

International

Journal of Machine Tools and Manufacture

318:(DNC) program or in modern Controllers using a common

887:

Boothroyd, Geoffrey; Knight, Winston Anthony (2006).

473:

This process usually begins with raw stock, known as

368:

839:(2nd ed.). Butterworth-Heinemann. p. 229.

782:(5 ed.). Oxford University Press. p. 102.

665:"Method and apparatus for computer aided machining"

606:– solid freeform fabrication direct from CAD models

538:

List of computer-aided manufacturing (CAM) Software

60:. Unsourced material may be challenged and removed.

1100:International Workshop CA Systems and Technologies

859:

546:For 3D CAM software for personal 3D printers, see

2018:

1198:

261:in the 1960s for car body design and tooling at

1194:https://patents.google.com/patent/US5933353A/en

1167:Clinical Implant Dentistry and Related Research

886:

749:

680:Clinical Implant Dentistry and Related Research

497:, waterline passes, constant step-over passes,

27:Use of software to control industrial processes

542:Category:Computer-aided manufacturing software

1894:

1316:

1278:

860:Pichler, Franz; Moreno-Díaz, Roberto (1992).

750:Hosking, Dian Marie; Anderson, Neil (1992),

628:

1330:

890:Fundamentals of machining and machine tools

1901:

1887:

1323:

1309:

1285:

1271:

1201:Journal of Materials Processing Technology

809:The CRC handbook of mechanical engineering

527:

1144:

120:Learn how and when to remove this message

1054:. CNC Cookbook. Retrieved on 2012-01-17.

893:(3rd ed.). CRC Press. p. 401.

832:

775:

297:(PLM) environment requires an effective

257:work developing the CAD/CAM application

205:

184:subsequent computer-aided process after

131:

1245:Pocket Machining Based on Offset Curves

1163:

991:

769:

677:

583:Integrated Computer-Aided Manufacturing

14:

2019:

802:

1882:

1304:

1266:

1241:reviewed toolpath algorithms in 1997.

1090:

756:, Taylor & Francis, p. 240,

726:Computerized manufacturing automation

711:

709:

1024:

753:Organizational change and innovation

461:

202:Printed circuit board § PCB CAM

58:adding citations to reliable sources

29:

940:

210:Chrome-cobalt disc with crowns for

24:

1157:

966:

918:. The SAGA-project. Archived from

913:

706:

369:Overcoming historical shortcomings

25:

2048:

2032:Information technology management

1220:

1078:10.1016/j.ijmachtools.2005.07.028

943:"A Possible First Use of CAM/CAD"

836:Aeronautical engineer's data book

560:Computer-integrated manufacturing

361:Automation of Machining processes

1908:

1292:

1235:about Software CAD/CAM CimatronE

1179:10.1111/j.1708-8208.2007.00082.x

992:Hagerty, James R. (2013-06-10).

729:. Diane Publishing. p. 48.

692:10.1111/j.1708-8208.2007.00082.x

589:Manufacturing process management

566:Digital modeling and fabrication

34:

1146:10.1590/S1678-58782010000300003

1120:

1084:

1057:

1045:

1018:

985:

960:

934:

907:

880:

721:Office of Technology Assessment

631:Dental Clinics of North America

45:needs additional citations for

1582:Electrical discharge machining

1371:Numerical control (NC and CNC)

853:

826:

796:

743:

671:

657:

622:

333:advance to approach that of a

69:"Computer-aided manufacturing"

13:

1:

863:Computer aided systems theory

643:10.1016/S0011-8532(01)00007-6

615:

577:Flexible manufacturing system

2037:Product lifecycle management

2027:Computer-aided manufacturing

1257:How to evaluate a CAM system

1213:10.1016/0924-0136(95)02015-2

295:Product lifecycle management

222:Traditionally, CAM has been

145:Computer-aided manufacturing

18:Computer aided manufacturing

7:

1429:List of drill and tap sizes

1259:Sheetmetalworld.com article

1031:. Pearson Education India.

833:Matthews, Clifford (2005).

812:. CRC Press. p. 15-1.

553:

548:3D_printing § Printing

387:and the extended enterprise

195:

10:

2053:

1745:Magnetic switchable device

994:"Help Wanted. A Lot of It"

545:

531:

248:

199:

190:computer-aided engineering

1938:

1917:

1823:

1768:

1695:

1587:Electrochemical machining

1562:

1452:

1384:

1339:

1300:

866:. Springer. p. 602.

779:A dictionary of computing

571:Direct numerical control

406:Manufacturing complexity

380:Manufacturing complexity

349:Multi-function Machining

341:Typical areas of concern

316:direct numerical control

157:computer-aided machining

1930:Open Cascade Technology

1667:Rotary transfer machine

1652:Photochemical machining

1592:Electron-beam machining

1554:Tool and cutter grinder

1052:CAM Toolpath Strategies

1028:Basic Civil Engineering

776:Daintith, John (2004).

528:Software: large vendors

275:Thompson Ramo Waldridge

232:manufacturing engineers

153:computer-aided modeling

219:

175:, including planning,

141:

1863:Tools and terminology

1091:Pasko, Rafal (1999).

534:List of CAM companies

234:, NC programmers, or

214:, manufactured using

209:

186:computer-aided design

135:

1781:Machining vibrations

1687:Ultrasonic machining

916:"The History of CAD"

667:. 16 September 1997.

443:machine tool probing

188:(CAD) and sometimes

54:improve this article

1801:Tool and die making

1489:Cylindrical grinder

1025:Gopi (2010-01-01).

998:Wall Street Journal

637:(2): 405–26, viii.

604:rapid manufacturing

356:Feature recognition

335:computer programmer

267:Kearney and Trecker

173:manufacturing plant

1469:Abrasive machining

1239:Dragomatz and Mann

922:on 2 November 2012

610:CNC pocket milling

220:

181:production process

142:

2014:

2013:

1956:Creo Elements/Pro

1876:

1875:

1819:

1818:

1251:Purdue University

941:Sanders, Norman.

900:978-1-57444-659-3

873:978-3-540-55354-0

846:978-0-7506-5125-7

819:978-0-8493-9418-8

789:978-0-19-860877-6

763:978-0-415-06314-2

736:978-1-4289-2364-5

600:Rapid prototyping

462:Machining process

383:Integration with

299:CAD data exchange

271:Stromberg-Carlson

224:numerical control

130:

129:

122:

104:

16:(Redirected from

2044:

1903:

1896:

1889:

1880:

1879:

1786:Speeds and feeds

1539:Sharpening stone

1514:Grinding machine

1509:Grinding dresser

1376:Stewart platform

1325:

1318:

1311:

1302:

1301:

1287:

1280:

1273:

1264:

1263:

1216:

1207:(3–4): 254–260.

1190:

1151:

1150:

1148:

1124:

1118:

1117:

1115:

1114:

1108:

1102:. Archived from

1097:

1088:

1082:

1081:

1072:(7–8): 811–819.

1061:

1055:

1049:

1043:

1042:

1022:

1016:

1015:

1013:

1012:

989:

983:

982:

980:

979:

967:Wright, Joshua.

964:

958:

957:

955:

953:

947:Hal Portal Inria

938:

932:

931:

929:

927:

911:

905:

904:

884:

878:

877:

857:

851:

850:

830:

824:

823:

800:

794:

793:

773:

767:

766:

747:

741:

740:

713:

704:

703:

675:

669:

668:

661:

655:

654:

626:

423:5 axis machining

352:5 Axis Machining

322:Storage Device.

151:) also known as

125:

118:

114:

111:

105:

103:

62:

38:

30:

21:

2052:

2051:

2047:

2046:

2045:

2043:

2042:

2041:

2017:

2016:

2015:

2010:

1934:

1913:

1907:

1877:

1872:

1815:

1764:

1691:

1558:

1549:Surface grinder

1484:Coated abrasive

1455:

1448:

1419:Drill bit sizes

1414:Drill bit shank

1389:

1380:

1342:

1335:

1329:

1296:

1291:

1233:Cimatron Brazil

1223:

1160:

1158:Further reading

1155:

1154:

1125:

1121:

1112:

1110:

1106:

1095:

1089:

1085:

1062:

1058:

1050:

1046:

1039:

1023:

1019:

1010:

1008:

990:

986:

977:

975:

965:

961:

951:

949:

939:

935:

925:

923:

912:

908:

901:

885:

881:

874:

858:

854:

847:

831:

827:

820:

801:

797:

790:

774:

770:

764:

748:

744:

737:

714:

707:

676:

672:

663:

662:

658:

627:

623:

618:

556:

551:

544:

530:

519:Contour milling

464:

456:tool management

371:

327:mass production

251:

212:dental implants

204:

198:

126:

115:

109:

106:

63:

61:

51:

39:

28:

23:

22:

15:

12:

11:

5:

2050:

2040:

2039:

2034:

2029:

2012:

2011:

2009:

2008:

2003:

1998:

1993:

1988:

1983:

1978:

1973:

1968:

1963:

1958:

1953:

1948:

1942:

1940:

1936:

1935:

1933:

1932:

1927:

1921:

1919:

1915:

1914:

1906:

1905:

1898:

1891:

1883:

1874:

1873:

1871:

1870:

1865:

1860:

1855:

1850:

1845:

1840:

1835:

1830:

1824:

1821:

1820:

1817:

1816:

1814:

1813:

1808:

1803:

1798:

1793:

1788:

1783:

1778:

1772:

1770:

1766:

1765:

1763:

1762:

1757:

1752:

1747:

1742:

1737:

1732:

1727:

1722:

1717:

1712:

1707:

1701:

1699:

1693:

1692:

1690:

1689:

1684:

1679:

1674:

1669:

1664:

1659:

1654:

1649:

1644:

1642:Milling cutter

1639:

1634:

1629:

1624:

1619:

1614:

1609:

1604:

1599:

1594:

1589:

1584:

1579:

1574:

1568:

1566:

1560:

1559:

1557:

1556:

1551:

1546:

1541:

1536:

1531:

1526:

1521:

1519:Grinding wheel

1516:

1511:

1506:

1501:

1496:

1491:

1486:

1481:

1476:

1471:

1466:

1460:

1458:

1450:

1449:

1447:

1446:

1441:

1436:

1431:

1426:

1421:

1416:

1411:

1406:

1401:

1395:

1393:

1382:

1381:

1379:

1378:

1373:

1368:

1363:

1358:

1353:

1347:

1345:

1341:Computer-aided

1337:

1336:

1328:

1327:

1320:

1313:

1305:

1298:

1297:

1290:

1289:

1282:

1275:

1267:

1261:

1260:

1254:

1248:

1247:by Martin Held

1242:

1236:

1230:

1222:

1221:External links

1219:

1218:

1217:

1196:

1191:

1173:(3): 123–127.

1159:

1156:

1153:

1152:

1139:(3): 208–217.

1119:

1083:

1056:

1044:

1037:

1017:

984:

959:

933:

906:

899:

879:

872:

852:

845:

825:

818:

795:

788:

768:

762:

742:

735:

705:

686:(3): 123–127.

670:

656:

620:

619:

617:

614:

613:

612:

607:

597:

592:

586:

580:

574:

568:

563:

555:

552:

529:

526:

525:

524:

520:

516:

515:

512:surface finish

507:

503:

502:

499:pencil milling

489:

488:

487:Semi-finishing

484:

483:

471:

463:

460:

459:

458:

451:

447:

446:

435:plasma cutting

415:

407:

403:

402:

399:

394:

393:

389:

388:

381:

378:

370:

367:

366:

365:

362:

359:

353:

350:

347:

343:

342:

255:Pierre Béziers

250:

247:

197:

194:

159:is the use of

136:CAD model and

128:

127:

42:

40:

33:

26:

9:

6:

4:

3:

2:

2049:

2038:

2035:

2033:

2030:

2028:

2025:

2024:

2022:

2007:

2004:

2002:

1999:

1997:

1994:

1992:

1989:

1987:

1984:

1982:

1979:

1977:

1974:

1972:

1969:

1967:

1964:

1962:

1959:

1957:

1954:

1952:

1949:

1947:

1944:

1943:

1941:

1937:

1931:

1928:

1926:

1923:

1922:

1920:

1916:

1911:

1904:

1899:

1897:

1892:

1890:

1885:

1884:

1881:

1869:

1866:

1864:

1861:

1859:

1856:

1854:

1851:

1849:

1846:

1844:

1841:

1839:

1836:

1834:

1831:

1829:

1826:

1825:

1822:

1812:

1809:

1807:

1804:

1802:

1799:

1797:

1794:

1792:

1789:

1787:

1784:

1782:

1779:

1777:

1776:Cutting fluid

1774:

1773:

1771:

1767:

1761:

1758:

1756:

1753:

1751:

1748:

1746:

1743:

1741:

1740:Machine taper

1738:

1736:

1733:

1731:

1728:

1726:

1725:Indexing head

1723:

1721:

1718:

1716:

1713:

1711:

1708:

1706:

1703:

1702:

1700:

1698:

1697:Machine tools

1694:

1688:

1685:

1683:

1680:

1678:

1675:

1673:

1670:

1668:

1665:

1663:

1660:

1658:

1655:

1653:

1650:

1648:

1645:

1643:

1640:

1638:

1635:

1633:

1630:

1628:

1625:

1623:

1620:

1618:

1615:

1613:

1610:

1608:

1605:

1603:

1600:

1598:

1595:

1593:

1590:

1588:

1585:

1583:

1580:

1578:

1575:

1573:

1570:

1569:

1567:

1565:

1561:

1555:

1552:

1550:

1547:

1545:

1544:Spark testing

1542:

1540:

1537:

1535:

1532:

1530:

1527:

1525:

1522:

1520:

1517:

1515:

1512:

1510:

1507:

1505:

1502:

1500:

1499:Flick grinder

1497:

1495:

1494:Diamond plate

1492:

1490:

1487:

1485:

1482:

1480:

1479:Bench grinder

1477:

1475:

1474:Angle grinder

1472:

1470:

1467:

1465:

1462:

1461:

1459:

1457:

1451:

1445:

1442:

1440:

1437:

1435:

1432:

1430:

1427:

1425:

1422:

1420:

1417:

1415:

1412:

1410:

1407:

1405:

1402:

1400:

1397:

1396:

1394:

1392:

1387:

1383:

1377:

1374:

1372:

1369:

1367:

1364:

1362:

1359:

1357:

1354:

1352:

1349:

1348:

1346:

1344:

1338:

1334:and computing

1333:

1326:

1321:

1319:

1314:

1312:

1307:

1306:

1303:

1299:

1295:

1288:

1283:

1281:

1276:

1274:

1269:

1268:

1265:

1258:

1255:

1252:

1249:

1246:

1243:

1240:

1237:

1234:

1231:

1228:

1225:

1224:

1214:

1210:

1206:

1202:

1197:

1195:

1192:

1188:

1184:

1180:

1176:

1172:

1168:

1162:

1161:

1147:

1142:

1138:

1134:

1130:

1123:

1109:on 2018-11-23

1105:

1101:

1094:

1087:

1079:

1075:

1071:

1067:

1060:

1053:

1048:

1040:

1038:9788131729885

1034:

1030:

1029:

1021:

1007:

1003:

999:

995:

988:

974:

970:

963:

948:

944:

937:

921:

917:

914:Dokken, Tor.

910:

902:

896:

892:

891:

883:

875:

869:

865:

864:

856:

848:

842:

838:

837:

829:

821:

815:

811:

810:

805:

804:Kreith, Frank

799:

791:

785:

781:

780:

772:

765:

759:

755:

754:

746:

738:

732:

728:

727:

722:

718:

717:U.S. Congress

712:

710:

701:

697:

693:

689:

685:

681:

674:

666:

660:

652:

648:

644:

640:

636:

632:

625:

621:

611:

608:

605:

601:

598:

596:

593:

590:

587:

584:

581:

578:

575:

572:

569:

567:

564:

561:

558:

557:

549:

543:

539:

535:

521:

518:

517:

513:

508:

505:

504:

500:

496:

495:raster passes

491:

490:

486:

485:

480:

476:

472:

469:

468:

467:

457:

452:

449:

448:

444:

440:

436:

432:

428:

424:

420:

416:

413:

408:

405:

404:

400:

396:

395:

391:

390:

386:

382:

379:

377:Ease of usage

376:

375:

374:

363:

360:

358:and machining

357:

354:

351:

348:

345:

344:

340:

339:

338:

336:

330:

328:

323:

321:

317:

312:

308:

304:

300:

296:

291:

288:

283:

278:

276:

272:

268:

264:

260:

256:

246:

244:

239:

237:

233:

229:

225:

217:

213:

208:

203:

193:

191:

187:

182:

178:

174:

170:

169:manufacturing

166:

165:machine tools

162:

158:

154:

150:

146:

140:machined part

139:

134:

124:

121:

113:

102:

99:

95:

92:

88:

85:

81:

78:

74:

71: –

70:

66:

65:Find sources:

59:

55:

49:

48:

43:This article

41:

37:

32:

31:

19:

1909:

1755:Rotary table

1735:Lathe center

1622:Machine tool

1454:Grinding and

1360:

1294:Metalworking

1204:

1200:

1170:

1166:

1136:

1132:

1122:

1111:. Retrieved

1104:the original

1099:

1086:

1069:

1065:

1059:

1047:

1027:

1020:

1009:. Retrieved

997:

987:

976:. Retrieved

972:

962:

950:. Retrieved

946:

936:

924:. Retrieved

920:the original

909:

889:

882:

862:

855:

835:

828:

808:

798:

778:

771:

752:

745:

725:

683:

679:

673:

659:

634:

630:

624:

465:

372:

331:

324:

292:

279:

252:

240:

221:

156:

152:

148:

144:

143:

116:

110:October 2009

107:

97:

90:

83:

76:

64:

52:Please help

47:verification

44:

1939:Proprietary

1918:Open source

1833:Fabrication

1769:Terminology

1705:Angle plate

1632:Metal lathe

1524:Jig grinder

1434:Tap and die

1343:engineering

392:Ease in use

364:Ease of Use

163:to control

2021:Categories

1986:Siemens NX

1853:Metallurgy

1647:Pantograph

1439:Tap wrench

1229:CAD Models

1227:CADSite.ru

1113:2018-06-02

1011:2018-06-02

978:2023-04-14

952:30 October

616:References

532:See also:

236:machinists

200:See also:

177:management

80:newspapers

1981:PowerMILL

1966:Mastercam

1848:Machining

1843:Jewellery

1811:Workpiece

1806:Tramp oil

1796:Tolerance

1627:Machining

1617:Jig borer

1602:Engraving

1577:Broaching

1564:Machining

1444:Threading

1409:Drill bit

1391:threading

1332:Machining

1006:0099-9660

506:Finishing

311:Parasolid

2001:VoluMill

1996:SprutCAM

1991:SmartCAM

1951:Easymill

1925:LinuxCNC

1912:software

1858:Smithing

1597:End mill

1504:Grinding

1464:Abrasive

1424:Drilling

1399:Die head

1386:Drilling

1187:18241215

806:(1998).

723:(1984).

700:18241215

651:12014040

554:See also

479:terraces

470:Roughing

439:wire EDM

427:waterjet

412:aircraft

196:Overview

161:software

1971:MazaCAM

1868:Welding

1838:Forming

1828:Casting

1760:Wiggler

1750:Mandrel

1720:Fixture

1682:Turning

1677:Skiving

1637:Milling

1612:Hobbing

1534:Sanding

1529:Lapping

1456:lapping

595:STEP-NC

419:turning

263:Renault

259:UNISURF

249:History

167:in the

94:scholar

2006:WorkNC

1976:NC-CAM

1715:Collet

1672:Shaper

1662:Reamer

1657:Planer

1607:Facing

1572:Boring

1366:G-code

1185:

1035:

1004:

973:Forbes

926:17 May

897:

870:

843:

816:

786:

760:

733:

698:

649:

585:(ICAM)

540:, and

475:billet

437:, and

398:curve.

287:G-code

243:G-code

216:WorkNC

96:

89:

82:

75:

67:

1961:FORAN

1946:CATIA

1791:Swarf

1710:Chuck

1404:Drill

1107:(PDF)

1096:(PDF)

591:(MPM)

579:(FMS)

573:(DNC)

562:(CIM)

431:laser

101:JSTOR

87:books

1351:2.5D

1183:PMID

1033:ISBN

1002:ISSN

954:2023

928:2012

895:ISBN

868:ISBN

841:ISBN

814:ISBN

784:ISBN

758:ISBN

731:ISBN

696:PMID

647:PMID

602:and

303:IGES

273:and

73:news

1910:CAM

1730:Jig

1388:and

1361:CAM

1356:CAD

1209:doi

1175:doi

1141:doi

1074:doi

688:doi

639:doi

385:PLM

320:USB

309:or

307:STL

305:or

282:CNC

228:CAD

218:CAM

155:or

149:CAM

138:CNC

56:by

2023::

1205:55

1203:.

1181:.

1171:10

1169:.

1137:32

1135:.

1131:.

1098:.

1070:46

1068:.

1000:.

996:.

971:.

945:.

719:,

708:^

694:.

684:10

682:.

645:.

635:46

633:.

536:,

433:/

429:,

425:,

421:,

277:.

269:,

1902:e

1895:t

1888:v

1324:e

1317:t

1310:v

1286:e

1279:t

1272:v

1215:.

1211::

1189:.

1177::

1149:.

1143::

1116:.

1080:.

1076::

1041:.

1014:.

981:.

956:.

930:.

903:.

876:.

849:.

822:.

792:.

739:.

702:.

690::

653:.

641::

550:.

501:.

445:.

147:(

123:)

117:(

112:)

108:(

98:·

91:·

84:·

77:·

50:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.