167:

136:

20:

151:

283:

166:

320:

150:

344:

248:

53:. After a processing step, the workpiece may be moved on to further steps of processing. For example, a part can made out of

313:

215:

135:

306:

226:

34:

is a piece, often made of a single material, that is being processed into another desired shape (such as

119:

249:

10 Things

Beginning CNC Milling Machine Users Need to Succeed - CNCCookbook: Be A Better CNC'er

35:

237:

8:

73:

339:

157:

96:

191:

58:

294:

81:

290:

69:

268:

264:

Video demonstration of workpieces being attached to faceplates and angleplates

263:

92:

333:

50:

196:

46:

216:

Machining: A Beginner's Guide to

Machining Processes - Monroe Engineering

177:

173:

108:

104:

77:

42:

23:

19:

238:

Understanding the CNC Milling

Process: A Beginner’s Guide | Get It Made

88:

is another example of a simple type of fixture used to fix workpieces.

65:

41:

The workpiece is usually a piece of relatively rigid material such as

126:

54:

269:

Video demonstration of different methods of filing a metal workpiece

111:, etc. It may also receive various surface treatments and finishes.

122:, and connects the work or treatment and the object to be treated.

100:

91:

A workpiece may be subjected to various cutting operations, like

282:

142:

115:

64:

The workpiece is often attached to the tool being used via a

129:

is often used to hold a workpiece steady during work on it.

85:

289:

This article about a mechanical engineering topic is a

227:

Turning for beginners, Part 1 - Woodturning technique

114:The term "workpiece" has established itself within

331:

314:

321:

307:

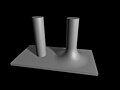

160:pole (right) and non-filleted pole (left)

18:

16:Piece being processed into another shape

332:

277:

176:hole (left) and a workpiece with a

13:

14:

356:

257:

281:

165:

149:

134:

141:A mechanical workpiece made of

242:

231:

220:

209:

1:

202:

345:Mechanical engineering stubs

293:. You can help Knowledge by

7:

185:

57:and later become part of a

10:

361:

276:

72:, like for example to a

26:of a workpiece of wood.

120:manufacturing industry

80:, or to a lathe via a

27:

59:semi-finished product

22:

172:A workpiece with a

156:A workpiece with a

28:

302:

301:

192:Surface finishing

352:

323:

316:

309:

285:

278:

251:

246:

240:

235:

229:

224:

218:

213:

169:

153:

138:

360:

359:

355:

354:

353:

351:

350:

349:

330:

329:

328:

327:

274:

260:

255:

254:

247:

243:

236:

232:

225:

221:

214:

210:

205:

188:

181:

170:

161:

154:

145:

139:

82:lathe faceplate

74:milling machine

36:building blocks

17:

12:

11:

5:

358:

348:

347:

342:

326:

325:

318:

311:

303:

300:

299:

286:

272:

271:

266:

259:

258:External links

256:

253:

252:

241:

230:

219:

207:

206:

204:

201:

200:

199:

194:

187:

184:

183:

182:

171:

164:

162:

155:

148:

146:

140:

133:

105:countersinking

49:, plastic, or

15:

9:

6:

4:

3:

2:

357:

346:

343:

341:

338:

337:

335:

324:

319:

317:

312:

310:

305:

304:

298:

296:

292:

287:

284:

280:

279:

275:

270:

267:

265:

262:

261:

250:

245:

239:

234:

228:

223:

217:

212:

208:

198:

195:

193:

190:

189:

179:

175:

168:

163:

159:

152:

147:

144:

137:

132:

131:

130:

128:

123:

121:

117:

112:

110:

109:counterboring

106:

102:

98:

94:

89:

87:

83:

79:

75:

71:

67:

62:

60:

56:

52:

48:

44:

39:

37:

33:

25:

21:

295:expanding it

288:

273:

244:

233:

222:

211:

197:Metalworking

180:hole (right)

178:counterbored

124:

113:

90:

63:

40:

31:

29:

174:countersunk

78:angle plate

334:Categories

203:References

340:Machining

127:workbench

95:, making

55:bar stock

32:workpiece

186:See also

158:filleted

118:and the

101:chamfers

97:fillets

76:via an

70:fixture

24:Turning

116:crafts

93:truing

143:steel

51:stone

47:metal

291:stub

86:vise

84:. A

43:wood

68:or

66:jig

38:).

336::

125:A

107:,

103:,

99:,

61:.

45:,

30:A

322:e

315:t

308:v

297:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.