124:

27:

446:

305:. As the material is work hardened it becomes increasingly saturated with new dislocations, and more dislocations are prevented from nucleating (a resistance to dislocation-formation develops). This resistance to dislocation-formation manifests itself as a resistance to plastic deformation; hence, the observed strengthening.

687:

As shown in Figure 1 and the equation above, work hardening has a half root dependency on the number of dislocations. The material exhibits high strength if there are either high levels of dislocations (greater than 10 dislocations per m) or no dislocations. A moderate number of dislocations (between

696:

For an extreme example, in a tensile test a bar of steel is strained to just before the length at which it usually fractures. The load is released smoothly and the material relieves some of its strain by decreasing in length. The decrease in length is called the elastic recovery, and the result is a

358:

Work hardening is a consequence of plastic deformation, a permanent change in shape. This is distinct from elastic deformation, which is reversible. Most materials do not exhibit only one or the other, but rather a combination of the two. The following discussion mostly applies to metals, especially

324:

Such deformation increases the concentration of dislocations which may subsequently form low-angle grain boundaries surrounding sub-grains. Cold working generally results in a higher yield strength as a result of the increased number of dislocations and the Hall–Petch effect of the sub-grains, and a

412:

In materials science parlance, dislocations are defined as line defects in a material's crystal structure. The bonds surrounding the dislocation are already elastically strained by the defect compared to the bonds between the constituents of the regular crystal lattice. Therefore, these bonds break

1182:

as work progresses. If work continues beyond a certain hardness the metal will tend to fracture when worked and so it may be re-annealed periodically as shaping continues. Annealing is stopped when the workpiece is near its final desired shape, and so the final product will have a desired strength

171:, is the process by which a material's load-bearing capacity (strength) increases during plastic (permanent) deformation. This characteristic is what sets ductile materials apart from brittle materials. Work hardening may be desirable, undesirable, or inconsequential, depending on the application.

397:

Elastic deformation stretches the bonds between atoms away from their equilibrium radius of separation, without applying enough energy to break the inter-atomic bonds. Plastic deformation, on the other hand, breaks inter-atomic bonds, and therefore involves the rearrangement of atoms in a solid

366:

is widely used to study deformation mechanisms. This is because under compression, most materials will experience trivial (lattice mismatch) and non-trivial (buckling) events before plastic deformation or fracture occur. Hence the intermediate processes that occur to the material under uniaxial

496:

is the extent to which a material can undergo plastic deformation, that is, it is how far a material can be plastically deformed before fracture. A cold-worked material is, in effect, a normal (brittle) material that has already been extended through part of its allowed plastic deformation. If

472:

Yield strength is increased in a cold-worked material. Using lattice strain fields, it can be shown that an environment filled with dislocations will hinder the movement of any one dislocation. Because dislocation motion is hindered, plastic deformation cannot occur at normal

477:. Upon application of stresses just beyond the yield strength of the non-cold-worked material, a cold-worked material will continue to deform using the only mechanism available: elastic deformation, the regular scheme of stretching or compressing of electrical bonds (without

420:

fields. For example, there are compressively strained bonds directly next to an edge dislocation and strained in tension bonds beyond the end of an edge dislocation. These form compressive strain fields and tensile strain fields, respectively. Strain fields are analogous to

1063:

312:

within the material culminating in a lattice rearrangement as the dislocations propagate through the lattice. At normal temperatures the dislocations are not annihilated by annealing. Instead, the dislocations accumulate, interact with one another, and serve as

701:

in order to account for the drastic decrease in diameter in this tensile test.) The length recovered after removing a load from a material just before it breaks is equal to the length recovered after removing a load just before it enters plastic deformation.

359:

steels, which are well studied. Work hardening occurs most notably for ductile materials such as metals. Ductility is the ability of a material to undergo plastic deformations before fracture (for example, bending a steel rod until it finally breaks).

497:

dislocation motion and plastic deformation have been hindered enough by dislocation accumulation, and stretching of electronic bonds and elastic deformation have reached their limit, a third mode of deformation occurs: fracture.

1124:

955:

425:

in certain ways. Specifically, the strain fields of dislocations obey similar laws of attraction and repulsion; in order to reduce overall strain, compressive strains are attracted to tensile strains, and vice versa.

705:

The work-hardened steel bar has a large enough number of dislocations that the strain field interaction prevents all plastic deformation. Subsequent deformation requires a stress that varies linearly with the

632:

724:

The amount of plastic deformation possible is zero, which is less than the amount of plastic deformation possible for a non-work-hardened material. Thus, the ductility of the cold-worked bar is reduced.

460:

being done on a material; energy is added to the material. In addition, the energy is almost always applied fast enough and in large enough magnitude to not only move existing dislocations, but also to

865:

713:

The work-hardened steel bar fractures when the applied stress exceeds the usual fracture stress and the strain exceeds usual fracture strain. This may be considered to be the elastic limit and the

966:

1222:

Items made from aluminum and its alloys must be carefully designed to minimize or evenly distribute flexure, which can lead to work hardening and, in turn, stress cracking, possibly causing

386:, which is also known as the yield stress. At that point, the material is permanently deformed and fails to return to its original shape when the force is removed. This phenomenon is called

301:

Before work hardening, the lattice of the material exhibits a regular, nearly defect-free pattern (almost no dislocations). The defect-free lattice can be created or restored at any time by

780:

960:

The constant K is structure dependent and is influenced by processing while n is a material property normally lying in the range 0.2–0.5. The strain hardening index can be described by:

736:

There are two common mathematical descriptions of the work hardening phenomenon. Hollomon's equation is a power law relationship between the stress and the amount of plastic strain:

697:

work-hardened steel bar. The fraction of length recovered (length recovered/original length) is equal to the yield-stress divided by the modulus of elasticity. (Here we discuss

394:

up to a certain point, it will return to its original shape, but once it is stretched beyond the elastic limit, it will remain deformed and won't return to its original state.

308:

In metallic crystals, this is a reversible process and is usually carried out on a microscopic scale by defects called dislocations, which are created by fluctuations in local

870:

If a material has been subjected to prior deformation (at low temperature) then the yield stress will be increased by a factor depending on the amount of prior plastic strain

558:

1204:

Much gold jewelry is produced by casting, with little or no cold working; which, depending on the alloy grade, may leave the metal relatively soft and bendable. However, a

1226:. For this reason modern aluminum aircraft will have an imposed working lifetime (dependent upon the type of loads encountered), after which the aircraft must be retired.

1068:

This equation can be evaluated from the slope of a log(σ) – log(ε) plot. Rearranging allows a determination of the rate of strain hardening at a given stress and strain:

1392:

662:

682:

523:

210:

inadvertently work-harden the workpiece surface, causing damage to the cutter during the later passes. Certain alloys are more prone to this than others;

1166:

Copper was the first metal in common use for tools and containers since it is one of the few metals available in non-oxidized form, not requiring the

1074:

437:

dislocation motion. For example, the stretching of a steel rod in a tensile tester is accommodated through dislocation motion on the atomic scale.

1245:"Automated Calculation of Strain Hardening Parameters from Tensile Stress vs. Strain Data for Low Carbon Steel Exhibiting Yield Point Elongation"

1435:

Integration of

Mechanics into Materials Science Research: A Guide for Material Researchers in Analytical, Computational and Experimental Methods

883:

1544:

465:

a great number of new dislocations by jarring or working the material sufficiently enough. New dislocations are generated in proximity to a

1178:

state it may then be hammered, stretched and otherwise formed, progressing toward the desired final shape but becoming harder and less

1144:

is an important engineering material, used in many applications. Steel may be work hardened by deformation at low temperature, called

566:

1174:. Copper is easily softened by heating and then cooling (it does not harden by quenching, e.g., quenching in cool water). In this

814:

485:

is unchanged. Eventually the stress is great enough to overcome the strain-field interactions and plastic deformation resumes.

1510:

1491:

1443:

456:

Increase in the number of dislocations is a quantification of work hardening. Plastic deformation occurs as a consequence of

91:

1058:{\displaystyle n={\frac {d\log(\sigma )}{d\log(\epsilon )}}={\frac {\epsilon }{\sigma }}{\frac {d\sigma }{d\epsilon }}\,\!}

190:, including low-carbon steel, are often work-hardened. Some materials cannot be work-hardened at low temperatures, such as

63:

1378:

246:

230:

325:

decrease in ductility. The effects of cold working may be reversed by annealing the material at high temperatures where

1294:

Van Melick, H. G. H.; Govaert, L. E.; Meijer, H. E. H. (2003), "On the origin of strain hardening in glassy polymers",

1189:

exploits these properties of copper, enabling the construction of durable jewelry articles and sculptures (such as the

131:

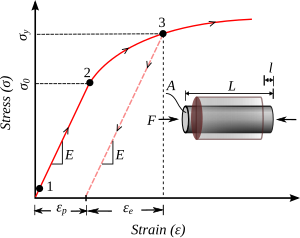

showing typical work hardening plastic behavior of materials in uniaxial compression. For work hardening materials the

70:

110:

742:

374:; the material returns quickly to its original shape when the deforming force is removed. This phenomenon is called

1534:

44:

77:

254:

48:

1529:

367:

compression before the incidence of plastic deformation make the compressive test fraught with difficulties.

59:

452:

The yield stress of an ordered material has a half-root dependency on the number of dislocations present.

1208:

may intentionally use work hardening to strengthen wearable objects that are exposed to stress, such as

253:

or cold forming processes. They are characterized by shaping the workpiece at a temperature below its

1149:

805:

353:

536:

249:

that intentionally induce plastic deformation to exact a shape change. These processes are known as

274:

207:

337:

270:

128:

37:

1185:

194:, however others can be strengthened only via work hardening, such as pure copper and aluminum.

1175:

640:

302:

262:

1433:

710:

observed, the slope of the graph of stress vs. strain is the modulus of elasticity, as usual.

1539:

667:

482:

466:

417:

326:

84:

1407:

1329:

1223:

508:

8:

1153:

290:

258:

136:

1411:

1333:

229:, specialized alloys are usually employed in order to avoid work hardening (a result of

186:

as well as several polymers can be strengthened in this fashion. Alloys not amenable to

1393:"Scaling approach to conical indentation in elastic-plastic solids with work hardening"

718:

707:

474:

234:

1307:

317:

or obstacles that significantly impede their motion. This leads to an increase in the

1506:

1487:

1439:

1264:

1190:

434:

430:

278:

219:

179:

123:

1415:

1337:

1303:

1256:

478:

237:, with specific heat treatments required to obtain the necessary characteristics.

457:

226:

1320:

Swenson, C. A. (1955), "Properties of Indium and

Thallium at low temperatures",

1119:{\displaystyle {\frac {d\sigma }{d\epsilon }}=n{\frac {\sigma }{\epsilon }}\,\!}

277:. Applications include the heading of bolts and cap screws and the finishing of

1260:

1209:

530:

422:

379:

318:

314:

187:

382:. Materials behave elastically until the deforming force increases beyond the

1523:

1341:

1268:

1244:

383:

333:

309:

183:

1145:

714:

664:

is the intrinsic strength of the material with low dislocation density and

363:

250:

132:

950:{\displaystyle \sigma =\sigma _{y}+K(\epsilon _{0}+\epsilon _{p})^{n}\,\!}

698:

526:

407:

391:

281:. In cold forming, metal is formed at high speed and high pressure using

261:. Cold forming techniques are usually classified into four major groups:

175:

728:

Substantial and prolonged cavitation can also produce strain hardening.

1243:

Scales, M.; Kornuta, J.A.; Switzner, N.; Veloo, P. (December 1, 2023).

282:

211:

370:

A material generally deforms elastically under the influence of small

1419:

1216:

1179:

493:

489:

416:

The strained bonds around a dislocation are characterized by lattice

203:

721:, which is much higher than a non-work-hardened steel yield stress.

26:

1167:

1148:. Typically, an increase in cold work results in a decrease in the

341:

139:. The strain can be decomposed into a recoverable elastic strain (

1205:

688:

10 and 10 dislocations per m) typically results in low strength.

286:

266:

215:

182:

of the material. Many non-brittle metals with a reasonably high

1160:

627:{\displaystyle \tau =\tau _{0}+G\alpha b\rho _{\perp }^{1/2}\ }

245:

An example of desirable work hardening is that which occurs in

191:

808:. Ludwik's equation is similar but includes the yield stress:

440:

413:

at relatively lower stresses, leading to plastic deformation.

1141:

1135:

371:

445:

289:

dies. The cold working of the metal increases the hardness,

1197:

529:

is dependent on the shear modulus, G, the magnitude of the

1242:

860:{\displaystyle \sigma =\sigma _{y}+K\epsilon _{p}^{n}\,\!}

1482:

Degarmo, E. Paul; Black, J T.; Kohser, Ronald A. (2003),

1171:

401:

321:

of the material and a subsequent decrease in ductility.

1293:

1129:

329:

and recrystallization reduce the dislocation density.

1077:

969:

886:

817:

745:

670:

643:

569:

539:

511:

1156:

tend to exhibit a lower strain hardening exponent .

16:

Strengthening a material through plastic deformation

500:

433:) results of plastic deformation are the result of

202:An example of undesirable work hardening is during

51:. Unsourced material may be challenged and removed.

1481:

1365:

1281:

1118:

1057:

949:

859:

774:

676:

656:

626:

552:

517:

347:

1196:

1115:

1054:

946:

856:

771:

684:is a correction factor specific to the material.

1521:

1503:Foundations of Materials Science and Engineering

222:machining strategies that take it into account.

178:movements and dislocation generation within the

793:is the strength index or strength coefficient,

1459:Hollomon, J.R. (1945). "Tensile deformation".

775:{\displaystyle \sigma =K\epsilon _{p}^{n}\,\!}

378:. This behavior in materials is described by

240:

197:

1500:

1353:

225:For metal objects designed to flex, such as

441:Increase of dislocations and work hardening

1501:Smith, William F.; Hashemi, Javad (2006),

1390:

492:of a work-hardened material is decreased.

1359:

1114:

1053:

945:

855:

770:

111:Learn how and when to remove this message

1484:Materials and Processes in Manufacturing

1458:

444:

122:

1431:

1379:"Cold Forming and Cold Heading Process"

1319:

1522:

731:

402:Dislocations and lattice strain fields

340:, or studied in context by performing

1545:Strengthening mechanisms of materials

174:This strengthening occurs because of

1130:Work hardening in specific materials

49:adding citations to reliable sources

20:

1391:Cheng, Y. T.; Cheng, C. M. (1998),

13:

533:, b, and the dislocation density,

390:. For example, if one stretches a

344:tests before and after a process.

153:). The stress at initial yield is

14:

1556:

1366:Degarmo, Black & Kohser 2003

1282:Degarmo, Black & Kohser 2003

501:Quantification of work hardening

336:can be predicted by analyzing a

25:

1475:

1452:

1183:and hardness. The technique of

348:Elastic and plastic deformation

36:needs additional citations for

1425:

1384:

1371:

1347:

1313:

1287:

1275:

1236:

1014:

1008:

994:

988:

936:

909:

553:{\displaystyle \rho _{\perp }}

481:) continues to occur, and the

1:

1505:(4th ed.), McGraw-Hill,

1308:10.1016/s0032-3861(03)00112-5

1229:

127:A phenomenological uniaxial

7:

1215:

146:) and an inelastic strain (

10:

1561:

1400:Journal of Applied Physics

1261:10.1007/s40799-023-00626-4

800:is the plastic strain and

691:

405:

351:

241:Intentional work hardening

198:Undesirable work hardening

135:increases with increasing

1200:and other precious metals

1159:

1150:strain hardening exponent

806:strain hardening exponent

657:{\displaystyle \tau _{0}}

354:Deformation (engineering)

296:

1354:Smith & Hashemi 2006

1342:10.1103/physrev.100.1607

1134:

293:, and tensile strength.

257:temperature, usually at

1535:Metallurgical processes

1486:(9th ed.), Wiley,

1432:Prawoto, Yunan (2013).

1249:Experimental Techniques

677:{\displaystyle \alpha }

206:when early passes of a

1120:

1059:

951:

861:

776:

678:

658:

628:

554:

519:

453:

247:metalworking processes

161:

1121:

1060:

952:

862:

777:

679:

659:

629:

555:

520:

518:{\displaystyle \tau }

483:modulus of elasticity

448:

126:

1530:Industrial processes

1461:Transactions of AIME

1224:catastrophic failure

1154:high strength steels

1075:

967:

884:

815:

743:

717:is now equal to the

668:

641:

567:

537:

509:

505:The shear strength,

45:improve this article

1412:1998JAP....84.1284C

1334:1955PhRv..100.1607S

854:

769:

732:Empirical relations

620:

388:plastic deformation

376:elastic deformation

338:stress–strain curve

259:ambient temperature

231:plastic deformation

137:plastic deformation

129:stress–strain curve

1116:

1055:

947:

857:

840:

772:

755:

719:fracture toughness

674:

654:

624:

598:

550:

515:

479:dislocation motion

454:

332:A material's work

162:

1512:978-0-07-295358-9

1493:978-0-471-65653-1

1445:978-1-300-71235-0

1191:Statue of Liberty

1112:

1096:

1051:

1031:

1018:

623:

467:Frank–Read source

279:cold rolled steel

255:recrystallization

220:materials science

180:crystal structure

121:

120:

113:

95:

1552:

1516:

1496:

1469:

1468:

1456:

1450:

1449:

1429:

1423:

1422:

1420:10.1063/1.368196

1406:(3): 1284–1291,

1397:

1388:

1382:

1381:, April 29, 2014

1375:

1369:

1363:

1357:

1351:

1345:

1344:

1328:(6): 1607–1614,

1317:

1311:

1310:

1302:(8): 2493–2502,

1291:

1285:

1279:

1273:

1272:

1255:(6): 1311–1322.

1240:

1125:

1123:

1122:

1117:

1113:

1105:

1097:

1095:

1087:

1079:

1064:

1062:

1061:

1056:

1052:

1050:

1042:

1034:

1032:

1024:

1019:

1017:

997:

977:

956:

954:

953:

948:

944:

943:

934:

933:

921:

920:

902:

901:

866:

864:

863:

858:

853:

848:

833:

832:

781:

779:

778:

773:

768:

763:

683:

681:

680:

675:

663:

661:

660:

655:

653:

652:

633:

631:

630:

625:

621:

619:

615:

606:

585:

584:

559:

557:

556:

551:

549:

548:

524:

522:

521:

516:

169:strain hardening

167:, also known as

159:

152:

145:

116:

109:

105:

102:

96:

94:

60:"Work hardening"

53:

29:

21:

1560:

1559:

1555:

1554:

1553:

1551:

1550:

1549:

1520:

1519:

1513:

1494:

1478:

1473:

1472:

1457:

1453:

1446:

1430:

1426:

1395:

1389:

1385:

1376:

1372:

1364:

1360:

1352:

1348:

1322:Physical Review

1318:

1314:

1292:

1288:

1280:

1276:

1241:

1237:

1232:

1220:

1202:

1164:

1139:

1132:

1104:

1088:

1080:

1078:

1076:

1073:

1072:

1043:

1035:

1033:

1023:

998:

978:

976:

968:

965:

964:

939:

935:

929:

925:

916:

912:

897:

893:

885:

882:

881:

875:

849:

844:

828:

824:

816:

813:

812:

798:

789:is the stress,

764:

759:

744:

741:

740:

734:

694:

669:

666:

665:

648:

644:

642:

639:

638:

611:

607:

602:

580:

576:

568:

565:

564:

544:

540:

538:

535:

534:

510:

507:

506:

503:

443:

423:electric fields

410:

404:

356:

350:

299:

243:

200:

158:

154:

151:

147:

144:

140:

117:

106:

100:

97:

54:

52:

42:

30:

17:

12:

11:

5:

1558:

1548:

1547:

1542:

1537:

1532:

1518:

1517:

1511:

1498:

1492:

1477:

1474:

1471:

1470:

1451:

1444:

1424:

1383:

1377:Deringer-Ney,

1370:

1368:, p. 375.

1358:

1356:, p. 246.

1346:

1312:

1286:

1274:

1234:

1233:

1231:

1228:

1219:

1214:

1201:

1195:

1163:

1158:

1138:

1133:

1131:

1128:

1127:

1126:

1111:

1108:

1103:

1100:

1094:

1091:

1086:

1083:

1066:

1065:

1049:

1046:

1041:

1038:

1030:

1027:

1022:

1016:

1013:

1010:

1007:

1004:

1001:

996:

993:

990:

987:

984:

981:

975:

972:

958:

957:

942:

938:

932:

928:

924:

919:

915:

911:

908:

905:

900:

896:

892:

889:

873:

868:

867:

852:

847:

843:

839:

836:

831:

827:

823:

820:

796:

783:

782:

767:

762:

758:

754:

751:

748:

733:

730:

693:

690:

673:

651:

647:

635:

634:

618:

614:

610:

605:

601:

597:

594:

591:

588:

583:

579:

575:

572:

547:

543:

531:Burgers vector

514:

502:

499:

442:

439:

406:Main article:

403:

400:

352:Main article:

349:

346:

319:yield strength

315:pinning points

298:

295:

291:yield strength

242:

239:

199:

196:

188:heat treatment

165:Work hardening

156:

149:

142:

119:

118:

101:September 2020

33:

31:

24:

15:

9:

6:

4:

3:

2:

1557:

1546:

1543:

1541:

1538:

1536:

1533:

1531:

1528:

1527:

1525:

1514:

1508:

1504:

1499:

1495:

1489:

1485:

1480:

1479:

1466:

1462:

1455:

1447:

1441:

1437:

1436:

1428:

1421:

1417:

1413:

1409:

1405:

1401:

1394:

1387:

1380:

1374:

1367:

1362:

1355:

1350:

1343:

1339:

1335:

1331:

1327:

1323:

1316:

1309:

1305:

1301:

1297:

1290:

1284:, p. 60.

1283:

1278:

1270:

1266:

1262:

1258:

1254:

1250:

1246:

1239:

1235:

1227:

1225:

1218:

1213:

1211:

1207:

1199:

1194:

1192:

1188:

1187:

1181:

1177:

1173:

1169:

1162:

1157:

1155:

1152:. Similarly,

1151:

1147:

1143:

1137:

1109:

1106:

1101:

1098:

1092:

1089:

1084:

1081:

1071:

1070:

1069:

1047:

1044:

1039:

1036:

1028:

1025:

1020:

1011:

1005:

1002:

999:

991:

985:

982:

979:

973:

970:

963:

962:

961:

940:

930:

926:

922:

917:

913:

906:

903:

898:

894:

890:

887:

880:

879:

878:

876:

850:

845:

841:

837:

834:

829:

825:

821:

818:

811:

810:

809:

807:

803:

799:

792:

788:

765:

760:

756:

752:

749:

746:

739:

738:

737:

729:

726:

722:

720:

716:

711:

709:

703:

700:

689:

685:

671:

649:

645:

616:

612:

608:

603:

599:

595:

592:

589:

586:

581:

577:

573:

570:

563:

562:

561:

545:

541:

532:

528:

512:

498:

495:

491:

486:

484:

480:

476:

470:

468:

464:

459:

451:

447:

438:

436:

432:

429:The visible (

427:

424:

419:

414:

409:

399:

395:

393:

389:

385:

384:elastic limit

381:

377:

373:

368:

365:

360:

355:

345:

343:

339:

335:

334:hardenability

330:

328:

322:

320:

316:

311:

310:stress fields

306:

304:

294:

292:

288:

284:

280:

276:

272:

268:

264:

260:

256:

252:

248:

238:

236:

235:metal fatigue

232:

228:

223:

221:

217:

213:

209:

205:

195:

193:

189:

185:

184:melting point

181:

177:

172:

170:

166:

138:

134:

130:

125:

115:

112:

104:

93:

90:

86:

83:

79:

76:

72:

69:

65:

62: –

61:

57:

56:Find sources:

50:

46:

40:

39:

34:This article

32:

28:

23:

22:

19:

1540:Metalworking

1502:

1483:

1476:Bibliography

1464:

1460:

1454:

1438:. Lulu.com.

1434:

1427:

1403:

1399:

1386:

1373:

1361:

1349:

1325:

1321:

1315:

1299:

1295:

1289:

1277:

1252:

1248:

1238:

1221:

1203:

1184:

1165:

1146:cold working

1140:

1067:

959:

871:

869:

801:

794:

790:

786:

784:

735:

727:

723:

715:yield stress

712:

704:

695:

686:

636:

504:

487:

471:

462:

455:

449:

428:

415:

411:

396:

387:

375:

369:

364:tensile test

361:

357:

331:

323:

307:

300:

251:cold working

244:

224:

201:

173:

168:

164:

163:

133:yield stress

107:

98:

88:

81:

74:

67:

55:

43:Please help

38:verification

35:

18:

699:true stress

527:dislocation

435:microscopic

431:macroscopic

408:Dislocation

392:coil spring

380:Hooke's Law

212:superalloys

176:dislocation

1524:Categories

1467:: 268–277.

1230:References

398:material.

283:tool steel

71:newspapers

1269:1747-1567

1110:ϵ

1107:σ

1093:ϵ

1085:σ

1048:ϵ

1040:σ

1029:σ

1026:ϵ

1012:ϵ

1006:

992:σ

986:

927:ϵ

914:ϵ

895:σ

888:σ

842:ϵ

826:σ

819:σ

757:ϵ

747:σ

672:α

646:τ

604:⊥

600:ρ

593:α

578:τ

571:τ

546:⊥

542:ρ

513:τ

494:Ductility

490:ductility

488:However,

450:Figure 1:

303:annealing

263:squeezing

204:machining

1217:Aluminum

1186:repoussé

1176:annealed

1168:smelting

475:stresses

342:hardness

327:recovery

275:shearing

218:require

214:such as

1408:Bibcode

1330:Bibcode

1296:Polymer

1206:jeweler

1180:ductile

804:is the

692:Example

525:, of a

463:produce

287:carbide

271:drawing

267:bending

227:springs

216:Inconel

85:scholar

1509:

1490:

1442:

1267:

1170:of an

1161:Copper

785:where

708:strain

637:where

622:

418:strain

372:forces

297:Theory

273:, and

233:) and

208:cutter

192:indium

87:

80:

73:

66:

58:

1396:(PDF)

1210:rings

1142:Steel

1136:Steel

92:JSTOR

78:books

1507:ISBN

1488:ISBN

1440:ISBN

1265:ISSN

1198:Gold

458:work

362:The

64:news

1465:162

1416:doi

1338:doi

1326:100

1304:doi

1257:doi

1193:).

1172:ore

1003:log

983:log

285:or

47:by

1526::

1463:.

1414:,

1404:84

1402:,

1398:,

1336:,

1324:,

1300:44

1298:,

1263:.

1253:47

1251:.

1247:.

1212:.

877::

560::

469:.

269:,

265:,

1515:.

1497:.

1448:.

1418::

1410::

1340::

1332::

1306::

1271:.

1259::

1102:n

1099:=

1090:d

1082:d

1045:d

1037:d

1021:=

1015:)

1009:(

1000:d

995:)

989:(

980:d

974:=

971:n

941:n

937:)

931:p

923:+

918:0

910:(

907:K

904:+

899:y

891:=

874:0

872:ε

851:n

846:p

838:K

835:+

830:y

822:=

802:n

797:p

795:ε

791:K

787:σ

766:n

761:p

753:K

750:=

650:0

617:2

613:/

609:1

596:b

590:G

587:+

582:0

574:=

160:.

157:0

155:σ

150:p

148:ε

143:e

141:ε

114:)

108:(

103:)

99:(

89:·

82:·

75:·

68:·

41:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.