351:

644:

853:

451:

application) or near the break in the brake pipe (in the case of loss of brake pipe integrity). Farther away from the source of the emergency application, the rate of reduction can be reduced to the point where triple valves will not detect the application as an emergency reduction. To prevent this, each triple valve's emergency portion contains an auxiliary vent port, which, when activated by an emergency application, also locally vents the brake pipe's pressure directly to atmosphere. This serves to more rapidly vent the brake pipe and hasten the propagation of the emergency reduction rate along the entire length of the train.

541:

straight-air trainline much more rapidly and evenly than possible by simply supplying air directly from the locomotive. The relay valve was equipped with four diaphragms, magnet valves, electric control equipment, and an axle-mounted speed sensor, so that at speeds over 60 mph (97 km/h) full braking force was applied, and reduced in steps at 60, 40 and 20 mph (97, 64 and 32 km/h), bringing the train to a gentle stop. Each axle was also equipped with anti-lock brake equipment. The combination minimized braking distances, allowing more full-speed running between stops. The straight-air

227:

868:

77:

215:

447:

faster emergency reduction of train line pressure. In addition, each car's air brake reservoir is divided into two sections—the service portion and the emergency portion—and is known as the "dual-compartment reservoir”. Normal service applications transfer air pressure from the service section to the brake cylinder, while emergency applications cause the triple valve to direct all air in both the sections of the dual-compartment reservoir to the brake cylinder, resulting in a 20 to 30 percent stronger application.

699:, to ensure that brake pipe continuity exists throughout the entire train. When brake pipe continuity exists throughout the train, failure of the brakes to apply or release on one or more cars is an indication that the cars' triple valves are malfunctioning. Depending on the location of the air test, the repair facilities available, and regulations governing the number of inoperative brakes permitted in a train, the car may be set out for repair or taken to the next terminal where it can be repaired.

139:

419:

several seconds for the brakes to apply throughout the train. The speed of pressure changes during a service reduction is limited by the compressed air's ability to overcome the flow resistance of the relatively-small-diameter pipe and numerous elbows throughout the length of the train, and the relatively-small exhaust port on the head-end locomotive, which means the brakes of the rear-most cars will apply sometime after those of the forward-most cars apply, so some

336:

838:

823:

372:, the brake cylinder exhaust portal is closed and air from the car's reservoir is fed into the brake cylinder. Pressure increases in the cylinder, applying the brakes, while decreasing in the reservoir. This action continues until equilibrium between the brake pipe pressure and reservoir pressure is achieved. At that point, the airflow from the reservoir to the brake cylinder is lapped off and the cylinder is maintained at a constant pressure.

608:

36:

276:

480:

America, a fully charged brake pipe typically operates at 70–90 psi (4.8–6.2 bar; 480–620 kPa) for freight trains and 110 psi (7.6 bar; 760 kPa) AAA for passenger trains. The brakes are applied when the engineer moves the automatic brake handle to a "service" position, which causes a reduction in brake pipe pressure.

384:

brake, the locomotive brake valve portal to atmosphere is closed, allowing the train line to be recharged by the compressor of the locomotive. The subsequent increase of train line pressure causes the triple valves on each car to discharge the contents of the brake cylinder to the atmosphere, releasing the brakes and recharging the reservoirs.

695:

hoses, charging up the brake system, setting the brakes and manually inspecting the cars to ensure the brakes are applied, and then releasing the brakes and manually inspecting the cars to ensure the brakes are released. Particular attention is usually paid to the rearmost car of the train, either by manual inspection or via an automated

552:. It is routed through various "governors" (switches operated by air pressure) which monitor critical components such as compressors, brake pipes and air reservoirs. Also if the train divides the wire will be broken, ensuring that all motors are switched off and both portions of the train have an immediate

896:

However, the maximum pressure in a vacuum system is limited to atmospheric pressure, so all the equipment has to be much larger and heavier to compensate. That disadvantage is made worse at high altitude. The vacuum brake is also considerably slower to both apply and release the brake, which requires

892:

The main competitor to the air brake is the vacuum brake, which operates on negative pressure. The vacuum brake is a little simpler than the air brake. Instead of an air compressor, steam engines have an ejector with no moving parts, and diesel or electric locomotives have a mechanical or electrical

694:

There are a number of safeguards that are usually taken to prevent this sort of accident from happening. Railroads have strict government-approved procedures for testing the air brake systems when making up trains in a yard or picking up cars en route. These generally involve connecting the air brake

904:

Electro-vacuum brakes have been used with considerable success on South

African electric multiple unit trains. Despite requiring larger and heavier equipment, as stated above, the performance of the electro-vacuum brake approached that of contemporary electro-pneumatic brakes. However, their use has

900:

A primary fault of vacuum brakes is the inability to find leaks easily. In a positive air system, a leak is quickly found due to the escaping pressurized air. Discovering a vacuum leak is more difficult, although it is easier to repair, because a piece of rubber (for example) can just be tied around

531:

streamlined passenger trains. This was an electrically controlled overlay on conventional D-22 passenger and 24-RL locomotive brake equipment. On the conventional side, the control valve set a reference pressure in a volume, which set brake cylinder pressure via a relay valve. On the electric side,

446:

An emergency brake application brings in an additional component of each car's air brake system. The triple valve is divided into two portions: the service section, which contains the mechanism used during brake applications made during service reductions, and the emergency section, which senses the

434:

The independent brake is a "straight air" system that makes brake applications on the head-of-train locomotive consist independently of the automatic brake, providing for more nuanced train control. The two braking systems may interact differently as a matter of preference by the locomotive builder

383:

When the engine operator applies the brake by operating the locomotive brake valve, the train line vents to atmosphere at a controlled rate, reducing the train line pressure and in turn triggering the triple valve on each car to feed air into its brake cylinder. When the engine operator releases the

723:

The modern air brake is not identical with the original airbrake as there have been slight changes in the design of the triple valve, which are not completely compatible between versions, and which must therefore be introduced in phases. However, the basic air brakes used on railways worldwide are

579:

If the brakes must be applied before recharging has been completed, a larger brake pipe reduction will be required in order to achieve the desired amount of braking effort, as the system is starting out at a lower point of equilibrium (lower overall pressure). If many brake pipe reductions are made

575:

The

Westinghouse air brake system is very reliable but not infallible. The car reservoirs recharge only when the brake pipe pressure is higher than the reservoir pressure. Fully recharging the reservoirs on a long train can require considerable time (8 to 10 minutes in some cases), during which the

442:

In the event the train needs to make an emergency stop, the engine operator can make an "emergency application," which will rapidly vent all of the brake pipe pressure to atmosphere, resulting in a faster application of the train's brakes. An emergency application also results when the integrity of

450:

The emergency portion of each triple valve is activated by the higher rate of reduction of brake pipe pressure. Due to the length of trains and the small diameter of the brake pipe, the rate of reduction is highest near the front of the train (in the case of an engine operator-initiated emergency

358:

The triple valve is so named because it performs three functions: It allows air into an air tank ready to be used, it applies the brakes, and it releases them. In so doing, it supports certain other actions (i.e. it 'holds' or maintains the application and it permits the exhaust of brake cylinder

483:

During normal service, the pressure in the brake pipe is never reduced to zero and in fact, the smallest reduction that will cause a satisfactory brake response is used to conserve brake pipe pressure. A sudden and substantial pressure reduction caused by a loss of brake pipe integrity (e.g., a

418:

When the train brakes are applied during normal operation, the engine operator makes a "service application" or a "service rate reduction”, which means that the brake pipe pressure reduces at a controlled rate. It takes several seconds for the brake pipe pressure to reduce and consequently takes

587:

In the event of a loss of braking due to reservoir depletion, the engine driver may be able to regain control with an emergency brake application, as the emergency portion of each car's dual-compartment reservoir should be fully charged—it is not affected by normal service reductions. The

479:

The locomotive's air compressor typically charges the main reservoir with air at 125–140 psi (8.6–9.7 bar; 860–970 kPa). The train brakes are released by admitting reduced and regulated main reservoir air pressure to the brake pipe through the engineer's automatic brake valve. In

604:, the simultaneous application of dynamic and train brakes, will be used to maintain a safe speed and keep the slack bunched on descending grades. Care would then be given when releasing the service and dynamic brakes to prevent draw-gear damage caused by a sudden run out of the train's slack.

592:

of brake pipe pressure reduction. Therefore, as long as a sufficient volume of air can be rapidly vented from the brake pipe, each car's triple valve will cause an emergency brake application. However, if the brake pipe pressure is too low due to an excessive number of brake applications, an

540:

in the controlling locomotive. This controller compared the pressure in the straight air trainline with that supplied by a self-lapping portion of the engineers valve, signaling all of the "apply" or "release" magnets valves in the train to open simultaneously, changing the pressure in the

375:

If the pressure in the train line is higher than that of the reservoir, the triple valve connects the train line to the reservoir feed, causing the air pressure in the reservoir to increase. The triple valve also causes the brake cylinder to be exhausted to the atmosphere, releasing the

897:

a greater level of skill and anticipation from the driver. Conversely, the vacuum brake originally had the advantage of allowing gradual release, whereas the

Westinghouse automatic air brake was originally available in only the direct-release form still common in freight service.

261:

The

Westinghouse system uses air pressure to charge air reservoirs (tanks) on each car. Full air pressure causes each car to release the brakes. A subsequent reduction or loss of air pressure causes each car to apply its brakes, using the compressed air stored in its reservoirs.

363:

feeding reservoir air to the brake cylinder, the reservoir charging valve, and the brake cylinder release valve. Westinghouse soon improved the device by removing the poppet valve action. These three components became the piston valve, the slide valve, and the graduating valve.

496:

Electro-pneumatic or EP brakes are a type of air brake that allows for immediate application of brakes throughout the train instead of the sequential application. EP brakes have been in

British practice since 1949 and also used in German high-speed trains (most notably the

303:

made up of pipes beneath each car and hoses between cars. The principal problem with the straight air braking system is that any separation between hoses and pipes causes loss of air pressure and hence the loss of the force applying the brakes. This could easily cause a

488:. On the other hand, a slow leak that gradually reduces brake pipe pressure to zero, something that might happen if the air compressor is inoperative and therefore not maintaining main reservoir pressure, will not cause an emergency brake application.

580:

in short succession ("fanning the brake" in railroad slang), a point may be reached where car reservoir pressure will be severely depleted, resulting in substantially reduced brake cylinder piston force, causing the brakes to fail. On a descending

660:

fitted. These valves cut off the air from the train line and vent the coupling hoses for uncoupling cars. The air brake only operates if the angle cocks are open except the ones at the front of the locomotive and at the end of the train.

639:

Main reservoir pipe pressure can also be used to supply air for auxiliary systems such as pneumatic door operators or air suspension. Nearly all passenger trains (all in the UK and USA), and many freights, now have the two-pipe system.

391:—any failure in the train line, including a separation ("break-in-two") of the train, will cause a loss of train line pressure, causing the brakes to be applied and bringing the train to a stop, thus preventing a runaway train.

635:

to prevent backfeeding into the pipe. This arrangement helps to reduce the above described pressure loss problems, and also reduces the time required for the brakes to release, since the brake pipe only has to recharge itself.

359:

pressure and the recharging of the reservoir during the release). In his patent application, Westinghouse refers to his 'triple-valve device' because of the three component valvular parts comprising it: the diaphragm-operated

959:

Railway regulations consider "Westinghouse" as a standalone brake system, however to distinguish from

Westinghouse company and other Westinghouse brake systems, railway staff often borrow letter "W" from signs on UIC rolling

732:

European brake systems may vary, depending on the country, but the working principle is the same as for the

Westinghouse air brake. European passenger cars used on national wide-spread railway networks have to comply with

295:

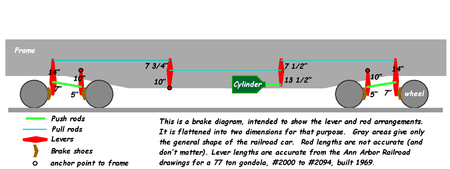

that can rub on the train wheels, using the resulting friction to slow the train. The mechanical linkage can become quite elaborate, as it evenly distributes force from one pressurized air cylinder to 8 or 12 wheels.

867:

435:

or the railroad. In some systems, the automatic and independent applications will be additive; in some systems the greater of the two will apply to the locomotive consist. The independent system also provides a

619:

Another solution to loss of brake pressure is the two-pipe system, fitted on most locomotive-hauled passenger stock and many freight wagons. In addition to the traditional brake pipe, this enhancement adds the

470:

Many modern air brake systems use distributors instead of triple valves. These serve the same function as triple valves, but have additional functionality such as the ability to partially release the brakes.

702:

A different kind of accident can occur if a malfunction in the air brake system (such as a broken air brake hose) causes the air brakes to engage unexpectedly. An example of this problem can be seen in the

800:

In the steam era, Britain's railways were divided – some using vacuum brakes and some using air brakes – but there was a gradual standardization on the vacuum brake. Some locomotives, e.g. on the

969:

Railway regulations consider "knorr" as a standalone brake system, however to distinguish from Knorr company and other Knorr brake systems, railway staff often borrow letter "K" from signs on UIC rolling

350:

664:

The air brake can fail if one of the angle cocks is accidentally closed. In this case, the brakes on the wagons behind the closed cock will fail to respond to the driver's command. This happened in the

548:

Later systems replace the automatic air brake with an electrical wire which runs in a circle round the whole train and has to be kept energized to keep the brakes off. In the UK it is known as a

1038:

The new

Westinghouse brakes were explained to the railroad workers in many books. See, for example, A Textbook on the Westinghouse Air Brake (Scranton: International Textbook School, 1900).

643:

379:

As the pressure in the train line and that of the reservoir equalize, the triple valve closes, causing the air in the reservoir to be sealed in, and the brake cylinder is not pressurized.

852:

320:

In order to design a system without the shortcomings of the straight air system, Westinghouse invented a system wherein each piece of railroad rolling stock was equipped with an

631:

Since the main reservoir pipe is kept constantly pressurized by the locomotive, the car reservoirs can be charged independently of the brake pipe, this being accomplished via a

430:

and provides service and emergency braking control for the entire train. The locomotive(s) at the head of the train (the "lead consist") have a secondary system called the

462:

radio signal from the engine operator in the front locomotive commands the distant units to initiate brake pressure reductions that propagate quickly through nearby cars.

545:, anti-lock, and speed graduating portions of the system were not dependent on each other in any way, and any or all of these options could be supplied separately.

414:

braking rapidly applies the brakes in the event of a brake pipe failure or an emergency application by the engine operator or passenger emergency alarm/cord/handle.

1479:

502:

593:

emergency application will not produce a large enough volume of air flow to trip the triple valves, leaving the engine driver with no means to stop the train.

1162:"DIRECTIVE (EU) 2016/797 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 11 May 2016 on the interoperability of the rail system within the European Union"

484:

blown hose), the train breaking in two and uncoupling air hoses, or the engineer moving the automatic brake valve to the emergency position, will cause an

1276:

1243:

458:(i.e., remotely controlled locomotive units mid-train and/or at the rear end) somewhat mitigates the time-lag problem with long trains, because a

516:

Passenger trains have had for a long time a three-wire version of the electro-pneumatic brake, which gives up to seven levels of braking force.

149:

532:

pressure from a second straight-air trainline controlled the relay valve via a two-way check valve. This "straight air" trainline was charged

734:

793:

Historically, and according to UIC 540 we distinguish systems technically approved even since 1927-1932 such as: Westinghouse W, Knorr K,

624:

pipe, which is continuously charged with air directly from the locomotive's main reservoir. The main reservoir is where the locomotive's

1474:

560:

258:

was subsequently organized to manufacture and sell

Westinghouse's invention. In various forms, it has been nearly universally adopted.

1211:

1307:

873:

802:

893:"exhauster". Disconnection taps at the ends of cars are not required because the loose hoses are sucked onto a mounting block.

1271:

666:

439:

mechanism, which releases the brakes on the lead locomotives without affecting the brake application on the rest of the train.

1443:

1194:

567:, which allows individual control of the brakes on each wagon, and the reporting back of performance of each wagon's brakes.

1236:

1078:

647:

Knorr-Bremse air brake system on a Greek train OSE Class 621 (Bombardier

Transportation / Hellenic Shipyards Skaramagas)

536:

and released by magnet valves on each car, controlled electrically by a three-wire trainline, in turn controlled by an

49:

17:

1252:

671:

201:

183:

120:

98:

63:

91:

809:

so that they could work with either vacuum- or air-braked trains. In the diesel era, the process was reversed and

1589:

742:

1438:

524:

255:

219:

1555:

1048:

1300:

822:

308:. Straight air brakes are still used on locomotives, although as a dual circuit system, usually with each

1584:

837:

687:, causing the train to crash into the passenger concourse and fall through the floor. Similarly, in the

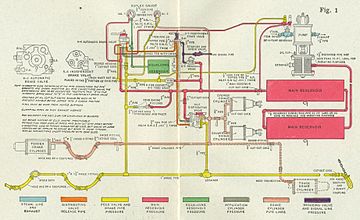

621:

426:

Modern locomotives employ two air brake systems. The system which controls the brake pipe is called the

688:

615:. Left needle shows air supplied by the main reservoir pipe, right needle shows brake cylinder pressure

1469:

708:

299:

The pressurized air comes from an air compressor in the locomotive and is sent from car to car by a

1510:

1144:

914:

843:

749:

696:

680:

165:

85:

226:

1579:

1484:

1293:

920:

553:

485:

410:

876:

locomotive. Note the three pipes, one for vacuum brake, one for air brake and one for steam heat

745:

leaflet 540. Those documents allows following brake design types for newly built rolling stock:

597:

423:

run-in can be expected. The gradual reduction in brake pipe pressure will mitigate this effect.

1330:

612:

161:

102:

55:

628:

output is stored, and is ultimately the source of compressed air for all systems that use it.

1545:

1350:

676:

1525:

1392:

1215:

741:

14198:2004 standard, which derives and links to ratified by many train operating companies

712:

157:

8:

1489:

1385:

1365:

936:

251:

1161:

933: – Interlocking hose coupling fitted to hoses supplying pressurized air for braking

704:

214:

1432:

1423:

1345:

1335:

930:

925:

806:

783:

1370:

1248:

1190:

828:

794:

773:

738:

563:

where the brakes of all the wagons (cars) and locomotives are connected by a kind of

455:

1103:

810:

684:

498:

737:

LOC&PAS law which says in point 4.2.4.3 that all brake systems must comply to

443:

the brake pipe is lost, as all air will also be immediately vented to atmosphere.

1594:

1540:

1494:

1360:

1340:

600:

can be utilized so the locomotive(s) will assist in retarding the train. Often,

1535:

1233:

Air Brake and Train Handling Manual. Copyright 2006 Alaska Railroad Corporation

625:

243:

1573:

1515:

1355:

1316:

601:

581:

520:

506:

369:

321:

305:

239:

1018:

1005:

1464:

1428:

1407:

887:

761:

707:

that caused the death of John Luther "Casey" Jones on 30 April 1900 on the

528:

510:

420:

360:

27:

Fail-safe power braking system with compressed air as the operating medium

1402:

1397:

632:

335:

1550:

1530:

1380:

861:

electromechanic Dako BSE train valve and Dako BP locomotive brake valve

691:, a valve was accidentally closed by the crew, reducing braking power.

292:

813:

switched from vacuum-braked to air-braked rolling stock in the 1960s.

576:

brake pipe pressure will be lower than locomotive reservoir pressure.

1459:

755:

607:

459:

388:

291:

in a cylinder. The piston is connected through mechanical linkage to

247:

347:

in air pressure in the train line to indirectly apply the brakes.

1285:

1056:

406:

braking applies and releases the brakes during normal operations.

994:(second ed.). New York: The Norman W. Henley Publishing Co.

275:

777:

343:

Unlike the straight air system, the Westinghouse system uses a

288:

1520:

527:

supplied high-speed control brake equipment for several post-

309:

858:

368:

If the pressure in the train line is lower than that of the

505:. As of 2005, electro-pneumatic brakes were in testing in

679:

passenger train which became a runaway while heading into

992:

Wood's Westinghouse E-T Air Brake Instruction Pocket Book

901:

the leak and will be firmly held in place by the vacuum.

588:

triple valves detect an emergency reduction based on the

250:

air brake system that is based upon a design patented by

1480:

Electro-pneumatic brake system on British railway trains

503:

Electro-pneumatic brake system on British railway trains

941:

Pages displaying short descriptions of redirect targets

1189:. Paris: International Union of Railways (UIC). 2020.

230:

Control handle and valve for a Westinghouse air brake

758:

SW 4, C3WR, WU-C, GF4 SS1, GF4 SS2, GF6 SS1, GF6 SS2

596:

To prevent a runaway due to loss of brake pressure,

501:) since the late 1980s; they are fully described in

1187:

UIC TECHNICAL SOLUTIONS FOR THE OPERATIONAL RAILWAY

246:as the operating medium. Modern trains rely upon a

1571:

1168:. European Parliament and the Council. Article 1

1212:"British Railway Air braked wagon development"

1019:"SDRM Train Air Brake Description and History"

399:Modern air brake systems serve two functions:

1301:

1150:. Western Pacific Railroad Museum. p. 9.

1145:"Air brake principles and specific equipment"

786:SW4S and similar, FT SS1 / FT SS2 and similar

283:In the air brake's simplest form, called the

146:The examples and perspective in this article

917: – Type of friction brake for vehicles

339:Rotair Valve Westinghouse Air brake Company

64:Learn how and when to remove these messages

1475:Electronically controlled pneumatic brakes

1470:Diesel electric locomotive dynamic braking

1308:

1294:

561:electronically controlled pneumatic brakes

315:

202:Learn how and when to remove this message

184:Learn how and when to remove this message

121:Learn how and when to remove this message

874:London, Brighton and South Coast Railway

803:London, Brighton and South Coast Railway

797:, Drolshammer, Bozic, Hildebrand-Knorr.

642:

606:

513:on captive service ore and coal trains.

349:

334:

274:

225:

213:

84:This article includes a list of general

14:

1572:

1209:

667:1953 Pennsylvania Railroad train wreck

1444:Westinghouse Brake and Signal Company

1289:

1239:. Copyright 2003 BNSF Railway Company

1214:. Myweb.tiscali.co.uk. Archived from

270:

222:6-ET Air Brake system on a locomotive

1055:. September 11, 2008. Archived from

989:

789:Keschwari Electronic Systems EDS 300

656:At both ends of each car, there are

474:

279:A comparatively simple brake linkage

132:

70:

29:

1237:Air Brake and Train Handling Manual

727:

538:electro-pneumatic master controller

24:

1315:

1247:Compressed Air Operations manual,

1123:Westinghouse 24RL air brake manual

1076:

1041:

718:

90:it lacks sufficient corresponding

25:

1606:

1259:

1242:AAR wheel dynamometer – braking:

770:MZT HEPOS MH3f/HBG310 and similar

394:

45:This article has multiple issues.

1133:EMD Enginemen's Operating Manual

881:

866:

851:

836:

821:

611:Duplex brake gauge on a British

584:, the result will be a runaway.

387:The Westinghouse system is thus

312:(truck) having its own circuit.

137:

75:

34:

1203:

1179:

1154:

1137:

1049:"Welcome to Saskrailmuseum.org"

963:

953:

491:

465:

53:or discuss these issues on the

1556:Railroad Safety Appliance Act

1439:Westinghouse Air Brake Company

1282:1951 article with illustration

1126:

1117:

1096:

1070:

1032:

1011:

998:

983:

570:

525:Westinghouse Air Brake Company

354:1918 drawing of a triple valve

256:Westinghouse Air Brake Company

218:Piping diagram from 1909 of a

13:

1:

1083:The Railway Technical Website

977:

543:(electro-pneumatic trainline)

534:(from reservoirs on each car)

287:, compressed air pushes on a

651:

598:dynamic (rheostatic) braking

559:More recent innovations are

7:

908:

554:emergency brake application

486:emergency brake application

265:

160:, discuss the issue on the

10:

1611:

1255:, McGraw Hill Book Company

885:

689:Gare de Lyon rail accident

242:power braking system with

1503:

1452:

1416:

1323:

1104:"The Automatic Air Brake"

817:Air brakes and components

709:Illinois Central Railroad

946:

915:Air brake (road vehicle)

780:MBF-01A, MBF-01B, MBF-02

681:Washington Union Station

254:on April 13, 1869. The

1485:Emergency brake (train)

939: – Part of a brake

831:brake system (diagram)

724:remarkably compatible.

105:more precise citations.

1590:1872 in rail transport

1331:Counter-pressure brake

846:FV4a train brake valve

764:KKL II, KE and similar

648:

616:

613:electric multiple unit

355:

340:

316:Westinghouse air brake

280:

231:

223:

1351:Electromagnetic brake

677:Pennsylvania Railroad

646:

610:

353:

338:

278:

229:

217:

1278:How Your Train Stops

990:Wood, W.W. (1920) .

921:Driver's brake valve

752:ESG 121, ESH 100/200

713:Vaughan, Mississippi

166:create a new article

158:improve this article

148:may not represent a

1465:Diesel brake tender

1270:Railway-Technical:

1059:on October 15, 2008

937:Railway tread brake

905:not been repeated.

697:end-of-train device

285:straight air system

252:George Westinghouse

1585:1872 introductions

1546:Pearson's Coupling

1433:New York Air Brake

1424:Faiveley Transport

1393:Regenerative brake

1386:Railway disc brake

1346:Eddy current brake

1336:Countersteam brake

1006:U.S. patent 88,929

931:Gladhand connector

784:Faiveley Transport

649:

617:

565:local area network

432:independent brake.

356:

341:

328:, also known as a

281:

271:Straight air brake

232:

224:

18:Westinghouse brake

1567:

1566:

1526:Dead man's switch

1376:Railway air brake

1371:Kunze-Knorr brake

1196:978-2-7461-3017-3

1166:eur-lex.europa.eu

475:Working pressures

456:distributed power

236:railway air brake

212:

211:

204:

194:

193:

186:

168:, as appropriate.

131:

130:

123:

68:

16:(Redirected from

1602:

1559:

1310:

1303:

1296:

1287:

1286:

1280:, by Bill Reiche

1227:

1226:

1224:

1223:

1207:

1201:

1200:

1183:

1177:

1176:

1174:

1173:

1158:

1152:

1151:

1149:

1141:

1135:

1130:

1124:

1121:

1115:

1114:

1112:

1111:

1100:

1094:

1093:

1091:

1089:

1074:

1068:

1067:

1065:

1064:

1045:

1039:

1036:

1030:

1029:

1027:

1026:

1015:

1009:

1008:

1002:

996:

995:

987:

971:

967:

961:

957:

942:

870:

855:

840:

825:

811:British Railways

728:European systems

685:Washington, D.C.

207:

200:

189:

182:

178:

175:

169:

141:

140:

133:

126:

119:

115:

112:

106:

101:this article by

92:inline citations

79:

78:

71:

60:

38:

37:

30:

21:

1610:

1609:

1605:

1604:

1603:

1601:

1600:

1599:

1570:

1569:

1568:

1563:

1558:(United States)

1557:

1541:Hydraulic brake

1499:

1495:Dowty retarders

1448:

1412:

1361:Heberlein brake

1319:

1314:

1262:

1230:

1221:

1219:

1208:

1204:

1197:

1185:

1184:

1180:

1171:

1169:

1160:

1159:

1155:

1147:

1143:

1142:

1138:

1131:

1127:

1122:

1118:

1109:

1107:

1102:

1101:

1097:

1087:

1085:

1077:Connor, Piers.

1075:

1071:

1062:

1060:

1047:

1046:

1042:

1037:

1033:

1024:

1022:

1017:

1016:

1012:

1004:

1003:

999:

988:

984:

980:

975:

974:

968:

964:

958:

954:

949:

940:

911:

890:

884:

877:

871:

862:

856:

847:

841:

832:

826:

730:

721:

719:Standardisation

672:Federal Express

654:

602:blended braking

573:

494:

477:

468:

428:automatic brake

397:

318:

273:

268:

208:

197:

196:

195:

190:

179:

173:

170:

155:

142:

138:

127:

116:

110:

107:

97:Please help to

96:

80:

76:

39:

35:

28:

23:

22:

15:

12:

11:

5:

1608:

1598:

1597:

1592:

1587:

1582:

1580:Railway brakes

1565:

1564:

1562:

1561:

1553:

1548:

1543:

1538:

1536:Engine braking

1533:

1528:

1523:

1518:

1513:

1507:

1505:

1504:Related topics

1501:

1500:

1498:

1497:

1492:

1487:

1482:

1477:

1472:

1467:

1462:

1456:

1454:

1450:

1449:

1447:

1446:

1441:

1436:

1426:

1420:

1418:

1414:

1413:

1411:

1410:

1405:

1400:

1395:

1390:

1389:

1388:

1378:

1373:

1368:

1363:

1358:

1353:

1348:

1343:

1338:

1333:

1327:

1325:

1321:

1320:

1317:Railway brakes

1313:

1312:

1305:

1298:

1290:

1284:

1283:

1274:

1261:

1260:External links

1258:

1257:

1256:

1245:

1240:

1234:

1229:

1228:

1202:

1195:

1178:

1153:

1136:

1125:

1116:

1095:

1069:

1040:

1031:

1010:

997:

981:

979:

976:

973:

972:

962:

951:

950:

948:

945:

944:

943:

934:

928:

923:

918:

910:

907:

886:Main article:

883:

880:

879:

878:

872:

865:

863:

857:

850:

848:

842:

835:

833:

827:

820:

818:

791:

790:

787:

781:

771:

768:

765:

759:

753:

729:

726:

720:

717:

669:involving the

653:

650:

626:air compressor

622:main reservoir

572:

569:

535:

493:

490:

476:

473:

467:

464:

416:

415:

407:

396:

395:Modern systems

393:

381:

380:

377:

373:

317:

314:

272:

269:

267:

264:

244:compressed air

210:

209:

192:

191:

152:of the subject

150:worldwide view

145:

143:

136:

129:

128:

83:

81:

74:

69:

43:

42:

40:

33:

26:

9:

6:

4:

3:

2:

1607:

1596:

1593:

1591:

1588:

1586:

1583:

1581:

1578:

1577:

1575:

1560:

1554:

1552:

1549:

1547:

1544:

1542:

1539:

1537:

1534:

1532:

1529:

1527:

1524:

1522:

1519:

1517:

1516:Bicycle brake

1514:

1512:

1509:

1508:

1506:

1502:

1496:

1493:

1491:

1488:

1486:

1483:

1481:

1478:

1476:

1473:

1471:

1468:

1466:

1463:

1461:

1458:

1457:

1455:

1453:Other aspects

1451:

1445:

1442:

1440:

1437:

1434:

1430:

1427:

1425:

1422:

1421:

1419:

1417:Manufacturers

1415:

1409:

1406:

1404:

1401:

1399:

1396:

1394:

1391:

1387:

1384:

1383:

1382:

1379:

1377:

1374:

1372:

1369:

1367:

1364:

1362:

1359:

1357:

1356:Exhaust brake

1354:

1352:

1349:

1347:

1344:

1342:

1341:Dynamic brake

1339:

1337:

1334:

1332:

1329:

1328:

1326:

1322:

1318:

1311:

1306:

1304:

1299:

1297:

1292:

1291:

1288:

1281:

1279:

1275:

1273:

1269:

1268:

1267:

1266:

1254:

1253:0-07-147526-5

1250:

1246:

1244:

1241:

1238:

1235:

1232:

1231:

1218:on 2013-04-18

1217:

1213:

1206:

1198:

1192:

1188:

1182:

1167:

1163:

1157:

1146:

1140:

1134:

1129:

1120:

1105:

1099:

1084:

1080:

1073:

1058:

1054:

1050:

1044:

1035:

1020:

1014:

1007:

1001:

993:

986:

982:

966:

956:

952:

938:

935:

932:

929:

927:

924:

922:

919:

916:

913:

912:

906:

902:

898:

894:

889:

882:Vacuum brakes

875:

869:

864:

860:

854:

849:

845:

839:

834:

830:

824:

819:

816:

815:

814:

812:

808:

804:

798:

796:

788:

785:

782:

779:

775:

772:

769:

766:

763:

760:

757:

754:

751:

748:

747:

746:

744:

740:

736:

725:

716:

714:

711:main line at

710:

706:

700:

698:

692:

690:

686:

682:

678:

674:

673:

668:

662:

659:

645:

641:

637:

634:

629:

627:

623:

614:

609:

605:

603:

599:

594:

591:

585:

583:

577:

568:

566:

562:

557:

555:

551:

546:

544:

539:

533:

530:

526:

522:

521:North America

517:

514:

512:

508:

507:North America

504:

500:

489:

487:

481:

472:

463:

461:

457:

452:

448:

444:

440:

438:

433:

429:

424:

422:

413:

412:

408:

405:

402:

401:

400:

392:

390:

385:

378:

374:

371:

367:

366:

365:

362:

352:

348:

346:

337:

333:

331:

330:control valve

327:

323:

322:air reservoir

313:

311:

307:

306:runaway train

302:

297:

294:

290:

286:

277:

263:

259:

257:

253:

249:

245:

241:

240:railway brake

237:

228:

221:

216:

206:

203:

188:

185:

177:

167:

163:

159:

153:

151:

144:

135:

134:

125:

122:

114:

104:

100:

94:

93:

87:

82:

73:

72:

67:

65:

58:

57:

52:

51:

46:

41:

32:

31:

19:

1429:Knorr-Bremse

1408:Vacuum brake

1375:

1277:

1264:

1263:

1220:. Retrieved

1216:the original

1210:Mike Smith.

1205:

1186:

1181:

1170:. Retrieved

1165:

1156:

1139:

1132:

1128:

1119:

1108:. Retrieved

1098:

1086:. Retrieved

1082:

1072:

1061:. Retrieved

1057:the original

1052:

1043:

1034:

1023:. Retrieved

1013:

1000:

991:

985:

965:

955:

903:

899:

895:

891:

888:Vacuum brake

799:

792:

731:

722:

701:

693:

670:

663:

657:

655:

638:

630:

618:

595:

589:

586:

578:

574:

564:

558:

549:

547:

542:

537:

529:World War II

518:

515:

511:South Africa

495:

492:Enhancements

482:

478:

469:

466:Distributors

453:

449:

445:

441:

436:

431:

427:

425:

417:

409:

403:

398:

386:

382:

361:poppet valve

357:

344:

342:

329:

326:triple valve

325:

319:

300:

298:

284:

282:

260:

235:

233:

220:Westinghouse

198:

180:

171:

147:

117:

108:

89:

61:

54:

48:

47:Please help

44:

1403:Track brake

1398:Steam brake

1265:Information

1088:10 February

829:Kunze-Knorr

807:dual-fitted

795:Kunze-Knorr

658:angle cocks

633:check valve

571:Limitations

460:telemetered

293:brake shoes

174:August 2023

103:introducing

1574:Categories

1551:Pneumatics

1531:Drum brake

1381:Disc brake

1366:Hand brake

1272:Air Brakes

1222:2013-07-14

1172:2023-08-11

1110:2013-07-14

1106:. Sdrm.org

1063:2008-10-03

1053:Contact Us

1025:2013-07-14

1021:. Sdrm.org

978:References

926:Dual brake

767:Dako CV1nD

550:train wire

301:train line

86:references

50:improve it

1511:Air brake

1460:Brake van

756:SAB-WABCO

652:Accidents

411:Emergency

389:fail-safe

370:reservoir

345:reduction

248:fail-safe

162:talk page

111:July 2013

56:talk page

1490:Retarder

1079:"Brakes"

909:See also

844:Oerlikon

750:Oerlikon

705:accident

437:bail off

266:Overview

156:You may

805:, were

454:Use of

404:Service

376:brakes.

99:improve

1595:Wabtec

1251:

1193:

778:Fablok

523:, the

324:and a

289:piston

88:, but

1521:Brake

1324:Types

1148:(PDF)

970:stock

960:stock

947:Notes

774:Bumar

762:Knorr

582:grade

421:slack

310:bogie

238:is a

164:, or

1249:ISBN

1191:ISBN

1090:2024

675:, a

590:rate

509:and

743:UIC

735:TSI

683:in

519:In

499:ICE

1576::

1164:.

1081:.

1051:.

859:ČD

739:EN

715:.

556:.

332:.

234:A

59:.

1435:)

1431:(

1309:e

1302:t

1295:v

1225:.

1199:.

1175:.

1113:.

1092:.

1066:.

1028:.

776:-

205:)

199:(

187:)

181:(

176:)

172:(

154:.

124:)

118:(

113:)

109:(

95:.

66:)

62:(

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.