533:(who acquired Tektronix's printer division). Printers like the Xerox Phaser 8400 use 1 cubic inch (16 cm) rectangular solid-state ink blocks (similar in consistency to candle wax), which are loaded into a system similar to a stapler magazine in the top of the printer. The ink blocks are melted, and the ink is transferred onto a rotating oil-coated print drum using a piezo inkjet head. The paper then passes over the print drum, at which time the image is transferred, or transfixed, to the page. This system is similar to water-based inkjets, provided that the ink has low viscosity at the jetting temperature 60 °C (140 °F). Printout properties are similar to those mentioned above, although these printers can be configured to produce extremely high-quality results and are far more economical, as they only use the ink needed for the printout, rather than an entire ribbon panel. Costs of upkeep and ink are comparable to color laser printers, while "standby" power usage can be very high, about 200 W.

55:

513:. Currently, this type of printer is rarely used for full-page printing, but is now employed for industrial label printing due to its waterfastness and speed. These printers are considered highly reliable due to their small number of moving parts. Printouts from color thermal printers using wax are sensitive to abrasion, as the wax ink can be scraped, rubbed off, or smeared. However, wax-resin compounds and full resins can be used on materials such as polypropylene or polyester in order to increase durability.

471:

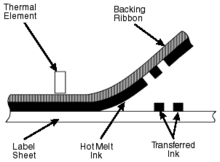

the ribbon film facing the substrate, and this process, in combination with the constant pressure being applied by the print-head locking mechanism immediately transfers it onto the substrate. When a dot "turns off", that element of the print head immediately cools down, and that part of the ribbon thereby stops melting/printing. As the substrate comes out of the printer, it is completely dry and can be used immediately.

475:

one were to hold a strip of used carbon ribbon up to the light, one would see an exact negative of the images that have been printed. The main benefit of using a one-trip thermal transfer ribbon is that providing the correct settings are applied prior to printing, a 100% density of printed image is guaranteed, in contrast to a pre-inked ribbon on a dot-matrix impact printer ribbon, which gradually fades with usage.

31:

470:

Print heads are available in 203 dpi, 300 dpi and 600 dpi resolution options. Each dot is addressed independently, and when a dot is electronically addressed, it immediately heats up to a pre-set (adjustable) temperature. The heated element immediately melts the wax- or resin-based ink on the side of

474:

Carbon ribbons are on rolls and are fitted onto a spindle or reel holder within the printer. The used ribbon is rewound by a take-up spindle, forming a roll of "used" ribbon. It is termed a "one-trip" ribbon because once it has been rewound, the used roll is discarded and replaced with a new one. If

488:

Thermal-printing technology can be used to produce color images by adhering a wax-based ink onto paper. As the paper and ribbon travel in unison beneath the thermal print head, the wax-based ink from the transfer ribbon melts onto the paper. When cooled, the wax is permanently adhered to the paper.

462:

Thermal-transfer printing is done by melting wax within the print heads of a specialized printer. The thermal-transfer print process utilises three main components: a non-movable print head, a carbon ribbon (the ink) and a substrate to be printed, which would typically be paper, synthetics, card or

581:

Barcode printers typically come in fixed sizes of 4, 6 or 8 inches (100, 150 or 200 mm) wide. Although a number of manufacturers have made differing sizes in the past, most have now standardised on these sizes. The main application of these printers is to produce barcode labels for

450:

Thermal transfer is preferred over direct thermal printing on surfaces that are heat-sensitive or when higher durability of printed matter (especially against heat) is desired. Thermal transfer is a popular print process particularly used for the printing of identification labels. It is the most

551:

of Japan. It is a wax/resin-transfer system using individual colored thermal ribbon cartridges and can print in process color using cyan, magenta, yellow, and black cartridges, as well as such spot-color cartridges as white, metallic silver, and metallic gold, on a wide variety of paper and

489:

This type of thermal printer uses a like-sized panel of ribbon for each page to be printed, regardless of the contents of the page. Monochrome printers have a black panel for each page to be printed, while color printers have either three (

463:

textile materials. These three components effectively form a sandwich with the ribbon in the middle. A thermally compliant print head, in combination with the electrical properties of the ribbon and the correct

451:

widely used printing process in the world for the printing of high-quality barcodes. Printers like label makers can laminate the print for added durability.

443:(or some other material) by melting a coating of ribbon so that it stays glued to the material on which the print is applied. It contrasts with direct

454:

Thermal transfer printing was invented by SATO corporation. The world's first thermal-transfer label printer SATO M-2311 was produced in 1981.

419:

17:

552:

transparency stock. Certain MicroDry printers can also operate in dye-sublimation mode, using special cartridges and paper.

412:

643:

638:

405:

633:

321:

498:

505:. Although acceptable in quality, the printouts from these printers cannot compare with modern

91:

211:

181:

231:

467:

properties of the ribbon ink are all essential in producing a high-quality printed image.

8:

599:

271:

46:

71:

261:

241:

171:

490:

444:

436:

386:

341:

301:

54:

568:

311:

251:

201:

141:

501:, these printers cannot vary the dot intensity, which means that images must be

506:

331:

291:

101:

627:

574:

548:

510:

30:

81:

376:

161:

571:

tend not to last long) and marking of clothing labels (shirt size etc.).

281:

221:

191:

526:

522:

356:

131:

542:

464:

151:

564:

116:

502:

530:

440:

494:

547:

MicroDry is a computer printing system developed by the

516:

457:

625:

577:with plastic, paper, and metal label materials.

447:, where no ribbon is present in the process.

413:

560:Usage of TT printers in industry includes:

420:

406:

53:

536:

525:" or "phaser" printers were developed by

483:

29:

497:) colored panels for each page. Unlike

439:method in which material is applied to

14:

626:

582:product and shipping identification.

24:

517:Tektronix/Xerox solid-ink printers

25:

655:

567:labels (as labels printed with a

458:Thermal-transfer printing process

592:

13:

1:

585:

346:

121:

106:

7:

478:

10:

660:

540:

433:Thermal-transfer printing

385:

375:

367:Thermal-transfer printing

365:

355:

340:

330:

320:

310:

300:

290:

280:

270:

260:

250:

240:

230:

220:

210:

200:

190:

180:

170:

160:

150:

140:

130:

115:

100:

90:

80:

70:

34:Thermal-transfer printing

499:dye-sublimation printers

242:Photostat and rectigraph

18:Thermal transfer printer

555:

41:Part of a series on the

27:Digital printing method

537:ALPS MicroDry printers

484:Color thermal printers

92:Intaglio (printmaking)

35:

212:Hot metal typesetting

33:

232:Daisy wheel printing

644:Packaging machinery

639:Non-impact printing

272:Dot matrix printing

47:History of printing

357:Solid ink printing

72:Woodblock printing

36:

634:Computer printers

600:"Company Profile"

430:

429:

395:

394:

262:Spirit duplicator

172:Chromolithography

16:(Redirected from

651:

618:

617:

615:

613:

604:

596:

445:thermal printing

437:digital printing

422:

415:

408:

387:Digital printing

351:

348:

342:Thermal printing

302:Phototypesetting

126:

123:

111:

108:

68:

67:

57:

38:

37:

21:

659:

658:

654:

653:

652:

650:

649:

648:

624:

623:

622:

621:

611:

609:

602:

598:

597:

593:

588:

569:thermal printer

558:

545:

539:

519:

507:inkjet printers

486:

481:

460:

426:

397:

396:

349:

322:Dye-sublimation

312:Inkjet printing

252:Screen printing

202:Offset printing

142:Relief printing

124:

109:

65:

28:

23:

22:

15:

12:

11:

5:

657:

647:

646:

641:

636:

620:

619:

590:

589:

587:

584:

579:

578:

575:Label printers

572:

557:

554:

541:Main article:

538:

535:

518:

515:

511:laser printers

485:

482:

480:

477:

459:

456:

428:

427:

425:

424:

417:

410:

402:

399:

398:

393:

392:

389:

383:

382:

379:

373:

372:

369:

363:

362:

359:

353:

352:

344:

338:

337:

334:

332:Laser printing

328:

327:

324:

318:

317:

314:

308:

307:

304:

298:

297:

294:

292:Spark printing

288:

287:

284:

278:

277:

274:

268:

267:

264:

258:

257:

254:

248:

247:

244:

238:

237:

234:

228:

227:

224:

218:

217:

214:

208:

207:

204:

198:

197:

194:

188:

187:

184:

178:

177:

174:

168:

167:

164:

158:

157:

154:

148:

147:

144:

138:

137:

134:

128:

127:

119:

113:

112:

104:

102:Printing press

98:

97:

94:

88:

87:

84:

78:

77:

74:

66:

63:

62:

59:

58:

50:

49:

43:

42:

26:

9:

6:

4:

3:

2:

656:

645:

642:

640:

637:

635:

632:

631:

629:

608:

601:

595:

591:

583:

576:

573:

570:

566:

563:

562:

561:

553:

550:

549:Alps Electric

544:

534:

532:

529:and later by

528:

524:

514:

512:

508:

504:

500:

496:

492:

476:

472:

468:

466:

455:

452:

448:

446:

442:

438:

434:

423:

418:

416:

411:

409:

404:

403:

401:

400:

390:

388:

384:

380:

378:

374:

370:

368:

364:

360:

358:

354:

345:

343:

339:

335:

333:

329:

325:

323:

319:

315:

313:

309:

305:

303:

299:

295:

293:

289:

285:

283:

279:

275:

273:

269:

265:

263:

259:

255:

253:

249:

245:

243:

239:

235:

233:

229:

225:

223:

219:

215:

213:

209:

205:

203:

199:

195:

193:

189:

185:

183:

179:

175:

173:

169:

165:

163:

159:

155:

153:

149:

145:

143:

139:

135:

133:

129:

120:

118:

114:

105:

103:

99:

95:

93:

89:

85:

83:

79:

75:

73:

69:

61:

60:

56:

52:

51:

48:

45:

44:

40:

39:

32:

19:

612:15 September

610:. Retrieved

606:

594:

580:

559:

546:

520:

487:

473:

469:

461:

453:

449:

432:

431:

366:

182:Rotary press

82:Movable type

607:Sato Global

521:So-called "

493:) or four (

465:rheological

377:3D printing

350: 1972

162:Lithography

125: 1515

110: 1440

628:Categories

586:References

509:and color

282:Xerography

222:Mimeograph

192:Hectograph

64:Techniques

527:Tektronix

523:solid ink

132:Mezzotint

543:MicroDry

503:dithered

479:Variants

152:Aquatint

565:Barcode

117:Etching

603:(PDF)

531:Xerox

441:paper

435:is a

614:2022

556:Uses

495:CMYK

391:1991

381:1986

371:1981

361:1972

336:1969

326:1957

316:1950

306:1949

296:1940

286:1938

276:1925

266:1923

256:1911

246:1907

236:1889

226:1885

216:1884

206:1875

196:1860

186:1843

176:1837

166:1796

156:1772

146:1690

136:1642

96:1430

86:1040

491:CMY

76:200

630::

605:.

347:c.

122:c.

107:c.

616:.

421:e

414:t

407:v

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.