185:

44:

56:

20:

152:

A critical factor in

Tainter gate design is the amount of stress transferred from the skinplate through the radial arms and to the trunnion, with calculations pertaining to the resulting friction encountered when raising or lowering the gate. Some older systems have had to be modified to allow for

32:

132:

Pressure forces on a submerged body act perpendicular to the body's surface. The design of the

Tainter gate results in every pressure force acting through the centre of the imaginary circle of which the gate is a section, so that all resulting pressure force acts through the

140:

When a

Tainter gate is closed, water bears on the convex (upstream) side. When the gate is rotated, the rush of water passing under the gate helps to open and close the gate. The rounded face, long radial arms and

115:

with the curved part of the piece facing the source or upper pool of water and the tip pointing toward the destination or lower pool. The curved face or skinplate of the gate takes the form of a wedge section of

281:

252:

124:

arms, extend back from each end of the cylinder section and meet at a trunnion which serves as a pivot point when the gate rotates.

145:

allow it to close with less effort than a flat gate. Tainter gates are usually controlled from above with a chain/gearbox/

184:

322:

292:

177:

basin has 195. A Tainter gate is also used to divert the flow of water to San

Fernando Power Plant on the

260:

157:

which the original design did not anticipate. In 1995, too much stress during an opening resulted in a

89:

342:

170:

24:

189:

158:

197:

178:

96:

8:

117:

86:

337:

48:

43:

142:

36:

327:

174:

146:

332:

316:

59:

234:

100:

169:

The

Tainter gate is used in water control dams and locks worldwide. The

55:

47:

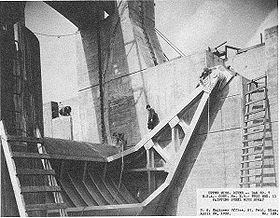

Tainter gate being constructed, in 1936, on the upper

Mississippi River,

209:

193:

79:

19:

83:

71:

99:, invented the gate in 1886 for use on the company's dam that forms

154:

134:

121:

23:

Side view cut-away diagram of the radial arm of the

Tainter gate,

31:

112:

82:

to control water flow. It is named for its inventor, the

75:

137:

of the gate, making construction and design easier.

62:

Tainter Gate on the

Housatonic River in Connecticut.

111:A side view of a Tainter gate resembles a slice of

314:

35:Tainter gate from the back, or spillway, on the

51:(Onalaska Dam), La Crescent, Minnesota (USACE)

120:. The straight sides of the pie shape, the

173:basin alone has 321 Tainter gates, and the

282:"Tuttle Creek Dam Spillway Tainter Gates"

245:

289:Corps of Engineers, Kansas City District

183:

95:Tainter, an employee of the lumber firm

54:

42:

30:

27:, Snake River, Pasco, Washington (USACE)

18:

315:

229:

227:

225:

274:

257:Providence RI Dept. of Public Works

222:

13:

14:

354:

239:Dunn County Historical Society

106:

1:

253:"Fox Point Hurricane Barrier"

215:

127:

16:Type of radial arm floodgate

7:

291:. June 2001. Archived from

203:

39:, Boydton, Virginia (USACE)

10:

359:

159:gate failure at Folsom Dam

161:in northern California.

90:Jeremiah Burnham Tainter

70:is a type of radial arm

171:Upper Mississippi River

323:Structural engineering

200:

164:

103:in the United States.

63:

52:

40:

28:

187:

58:

46:

34:

22:

198:Louisville, Kentucky

179:Los Angeles Aqueduct

97:Knapp, Stout and Co.

87:structural engineer

235:"The Tainter Gate"

201:

64:

53:

49:Lock and Dam No. 7

41:

29:

155:frictional forces

350:

307:

306:

304:

303:

297:

286:

278:

272:

271:

269:

268:

259:. Archived from

249:

243:

242:

231:

188:Tainter gate at

37:John H. Kerr Dam

358:

357:

353:

352:

351:

349:

348:

347:

313:

312:

311:

310:

301:

299:

295:

284:

280:

279:

275:

266:

264:

251:

250:

246:

233:

232:

223:

218:

206:

167:

130:

109:

17:

12:

11:

5:

356:

346:

345:

343:Flood barriers

340:

335:

330:

325:

309:

308:

273:

244:

220:

219:

217:

214:

213:

212:

205:

202:

175:Columbia River

166:

163:

147:electric motor

129:

126:

108:

105:

25:Ice Harbor Dam

15:

9:

6:

4:

3:

2:

355:

344:

341:

339:

336:

334:

331:

329:

326:

324:

321:

320:

318:

298:on 2005-12-17

294:

290:

283:

277:

263:on 2006-03-24

262:

258:

254:

248:

240:

236:

230:

228:

226:

221:

211:

208:

207:

199:

195:

191:

186:

182:

180:

176:

172:

162:

160:

156:

150:

148:

144:

138:

136:

125:

123:

119:

114:

104:

102:

98:

93:

91:

88:

85:

81:

77:

73:

69:

61:

60:Stevenson Dam

57:

50:

45:

38:

33:

26:

21:

300:. Retrieved

293:the original

288:

276:

265:. Retrieved

261:the original

256:

247:

238:

190:McAlpine Dam

168:

151:

139:

131:

110:

101:Lake Menomin

94:

68:Tainter gate

67:

65:

135:pivot point

107:Description

80:canal locks

317:Categories

302:2006-04-14

267:2006-04-14

216:References

210:Roller dam

194:Ohio River

149:assembly.

338:Hydrology

128:Principle

84:Wisconsin

72:floodgate

204:See also

143:bearings

122:trunnion

118:cylinder

74:used in

328:Canals

296:(PDF)

285:(PDF)

333:Dams

78:and

76:dams

66:The

181:.

165:Use

113:pie

319::

287:.

255:.

237:.

224:^

196:,

192:,

92:.

305:.

270:.

241:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.