47:) involves a heated mold which is filled with a charge or shot weight of the material. It is then slowly rotated (usually around two perpendicular axes), causing the softened material to disperse and stick to the walls of the mold forming a hollow part. In order to form an even thickness throughout the part, the mold rotates at all times during the heating phase, and then continues to rotate during the cooling phase to avoid sagging or deformation. The process was applied to plastics in the 1950s but in the early years was little used because it was a slow process restricted to a small number of plastics. Over time, improvements in process control and developments with plastic powders have resulted in increased use.

713:

these steps. In the heating stage, the heat taken from the hot gas is absorbed both by the mold and the polymer material. The rig for rotational molding usually has a relatively small wall thickness and is manufactured from metals with a high thermal conductivity (aluminum, steel). As a rule, the mold transfers much more heat than plastic can absorb; therefore, the mold temperature must vary linearly. The rotational velocity in rotational molding is rather low (4 to 20 rpm). As a result, in the first stages of the heating cycle, the charged material remains as a powder layer at the bottom of the mold. The most convenient way of changing the cycle is by applying PU sheets in hot rolled forms.

553:

140:. Aluminum molds are usually much thicker than equivalent steel molds, as it is a softer metal. This thickness does not much affect cycle times because aluminum's thermal conductivity is many times greater than steel's. Owing to the need to develop a model prior to casting, cast molds tend to have additional costs associated with the manufacturing of the tooling, whereas fabricated steel or aluminum molds, particularly when used for less complex parts, are less expensive. However, some molds contain both aluminum and steel. This allows for variable thicknesses in the walls of the product. While this process is not as precise as

542:

89:. The cooling method consisted of placing the mold into cold water. This process of rotational molding led to the creation of other plastic toys. As demand for and popularity of this process increased, it was used to create other products such as road cones, marine buoys, and car armrests. This popularity led to the development of larger machinery. A new system of heating was also created, going from the original direct gas jets to the current indirect high velocity air system. In Europe during the 1960s the Engel process was developed. This allowed large hollow containers to be manufactured in

171:

257:

563:

265:

245:

typically occur, as opposed to other processes such as injection molding, where parts can be made in a few seconds. The process does have distinct advantages. Manufacturing large, hollow parts such as oil tanks is much easier by rotational molding than any other method. Rotational molds are much cheaper than other types of mold. Very little material is wasted using this process, and excess material can often be reused, making it a very economically and environmentally viable manufacturing process.

228:

249:

1467:

579:

29:

1473:

236:

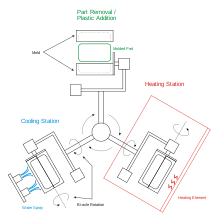

be in the heating chamber while another is in the cooling chamber and the third in the loading/reloading area. The fixed-arm carousel works well when identical cycle times are used for each arm. The independent-arm carousel machine is available with three or four arms that can move independently. This allows for different-size molds, with different cycle times and thickness needs.

588:

219:

mounted on the same corner, so that a four-arm machine has two pivot points. These machines are very useful for companies that have long cooling cycles or require a lot of time to demold parts, compared to the cook time. It is much easier to schedule maintenance work or try to run a new mold without interrupting production on the other arms of the machine.

626:

to move properly throughout the mold. Otherwise webbing may occur. A desirable parallel wall scenario would have a gap at least three times the nominal wall thickness, with five times the nominal wall thickness being optimal. Sharp corners for parallel walls must also be considered. With angles of less than 45° bridging, webbing, and voids may occur.

284:

is critical: too long and the polymer will degrade, reducing impact strength. If the mold spends too little time in the oven, the polymer melt may be incomplete. The polymer grains will not have time to fully melt and coalesce on the mold wall, resulting in large bubbles in the polymer. This impairs the mechanical properties of the finished product.

596:

705:

that it is not possible to make sharp threads that would be possible with injection molding. Some products based on polyethylene can be put in the mold before it is charged with the main material. This can help to avoid holes that otherwise would appear in some areas. This could also be achieved using molds with movable sections.

309:. This pressure delays the separation of the part from the mold wall due to shrinkage during the cooling phase, aiding cooling of the part. The main drawback to this is the danger to the operator of explosion of a pressurized part. This has prevented adoption of mold pressurization on a large scale by rotomolding manufacturers.

534:

and vegetables storage and playground slides. The process is also used to make highly specialised products, including UN-approved containers for the transportation of nuclear fissile materials, anti-piracy ship protectors, seals for inflatable oxygen masks and lightweight components for the aerospace industry.

179:

mold 45 degrees above or below horizontal in the other direction. Newer machines use forced hot air to heat the mold. These machines are best for large parts that have a large length-to-width ratio. Because of the smaller heating chambers, there is a saving in heating costs compared to biaxial machines.

672:

Rotational molding offers design advantages over other molding processes. With proper design, parts assembled from several pieces can be molded as one part, eliminating high fabrication costs. The process also has inherent design strengths, such as consistent wall thickness and strong outside corners

708:

Another limitation lies in the molds themselves. Unlike other processes in which only the product needs to be cooled before being removed, with rotational molding the entire mold must be cooled. While water-cooling processes are possible, there is still a large down time of the mold, increasing both

704:

Rotation-molded parts are subject to restrictions that are different from those of other plastic processes. As it is a low-pressure process, sometimes designers face hard-to-reach areas in the mold. Good-quality powder may help overcome some situations, but usually the designers have to keep in mind

658:

Wall thickness is important for corner radii as well. Large outside radii are preferable to small radii. Large inside radii are also preferable to small inside radii. This allows for a more even flow of material and a more even wall thickness. However, an outside corner is generally stronger than an

625:

Rotational molding excels at producing hollow parts. However, care must be taken when this is done. When the depth of the recess is greater than the width there may be problems with even heating and cooling. Additionally, enough room must be left between the parallel walls to allow for the melt-flow

156:

Normally all rotation molding systems include molds, oven, cooling chamber and mold spindles. The molds are used to create the part, and are typically made of aluminium. The quality and finish of the product is directly related to the quality of the mold being used. The oven is used to heat the part

533:

Products that can be manufactured using rotational molding include storage tanks, furniture, road signs and bollards, planters, pet houses, toys, bins and refuse containers, doll parts, road cones, footballs, helmets, canoes, rowing boats, tornado shelters, kayak hulls, underground cellars for vine

300:

Until recently, the process largely relied on both trial and error and the experience of the operator to determine when the part should be removed from the oven and when it was cool enough to be removed from the mold. Technology has improved in recent years, allowing the air temperature in the mold

287:

Cooling the mold, usually by fan. This stage of the cycle can be quite lengthy. The polymer must be cooled so that it solidifies and can be handled safely by the operator. This typically takes tens of minutes. The part will shrink on cooling, coming away from the mold, and facilitating easy removal

283:

Heating the mold in an oven while it rotates, until all the polymer has melted and adhered to the mold wall. The hollow part should be rotated through two or more axes, rotating at different speeds, in order to avoid the accumulation of polymer powder. The length of time the mold spends in the oven

235:

This is one of the most common biaxial machines in the industry. It can have up to four arms and six stations and comes in a wide range of sizes. The machine comes in two different models, fixed and independent. A fixed-arm carousel consists of three fixed arms that must move together. One arm will

209:

Most shuttle machines have two arms that move the molds back and forth between the heating chamber and cooling station. The arms are independent of each other and they turn the molds biaxially. In some cases, the shuttle machine has only one arm. This machine moves the mold in a linear direction in

178:

This is a specialized machine designed mainly to produce long, narrow parts. Some are of the clamshell type, having one arm, but there are also shuttle-type rock and roll machines, with two arms. Each arm rotates or rolls the mold 360 degrees in one direction and at the same time tips and rocks the

80:

Plastics were introduced to the rotational molding process in the early 1950s. One of the first applications was to manufacture doll heads. The machinery was made of an E Blue box-oven machine, inspired by a

General Motors rear axle, powered by an external electric motor and heated by floor-mounted

218:

The swing-arm machine can have up to four arms, with a biaxial movement. Each arm is independent from each other as it is not necessary to operate all arms at the same time. Each arm is mounted on a corner of the oven and swings in and out of the oven. On some swing-arm machines, a pair of arms is

712:

The stages of heating and cooling involve transfer of heat first from the hot medium to the polymer material and next from it to the cooling environment. In both cases, the process of heat transfer occurs in an unsteady regime; therefore, its kinetics attracts the greatest interest in considering

676:

The ability to add prefinished pieces to the mold alone is a large advantage. Metal threads, internal pipes and structures, and even different colored plastics can all be added to the mold prior to the addition of plastic pellets. However, care must be taken to ensure that minimal shrinkage while

654:

For the designer, while variable thicknesses are possible, a process called stop rotation is required. This process is limited in that only one side of the mold may be thicker than the others. After the mold is rotated and all the surfaces are sufficiently coated with the melt-flow, the rotation

200:

The loading and unloading area is at the front of the machine between the heating and cooling areas. These machines vary in size between small to medium compared to other rotational machines. Vertical rotational molding machines are energy-efficient, owing to the compactness of their heating and

187:

This is a single-arm rotational molding machine. The arm is usually supported by other arms on both ends. The clamshell machine heats and cools the mold in the same chamber. It takes up less space than equivalent shuttle and swing arm rotational molders. It is low in cost compared to the size of

695:

Another cost advantage with rotational molding is the minimal amount of material wasted in production. There are no sprues or runners (as in injection molding), and no off-cuts or pinch-off scrap (as in blow molding). What material is wasted, as scrap or from failed part testing, can usually be

72:

and other hollow vessels, the main purpose of which was to create consistency in wall thickness and density. In a U.S. patent in 1905, F.A. Voelke described a method including a polymer for the production of articles using paraffin wax. Development led to G.S. Baker's and G.W. Perks' process of

646:

One benefit of rotational molding is the ability to experiment, particularly with wall thicknesses. Cost is entirely dependent on wall thickness, with thicker walls being costlier and more time-consuming to produce. While the wall can have nearly any thickness, designers must remember that the

304:

Much current research is into reducing the cycle time, as well as improving part quality. The most promising area is in mold pressurization. It is well known that applying a small amount of pressure internally to the mold at the correct point in the heating phase accelerates coalescence of the

691:

Due to the uniform thicknesses achieved, large stretched sections are nonexistent, which makes large thin panels possible (although warping may occur). Also, there is little flow of plastic (stretching) but rather a placing of the material within the part. These thin walls also limit cost and

244:

The rotational molding process is a high-temperature, low-pressure plastic-forming process that uses heat and biaxial rotation (i.e., angular rotation on two axes) to produce hollow, one-piece parts. Critics of the process point to its long cycle times—only one or two cycles an hour can

687:

Another advantage lies in the molds themselves. Since they require less tooling, they can be manufactured and put into production much more quickly than other molding processes. This is especially true for complex parts, which may require large amounts of tooling for other molding processes.

617:

Another consideration is in the draft angles. These are required to remove the piece from the mold. On the outside walls, a draft angle of 1° may work (assuming no rough surface or holes). On inside walls, such as the inside of a boat hull, a draft angle of 5° may be required. This is due to

621:

Another consideration is of structural support ribs. While solid ribs may be desirable and achievable in injection molding and other processes, a hollow rib is the best solution in rotational molding. A solid rib may be achieved byinserting a finished piece in the mold, but this adds cost.

73:

producing hollow chocolate Easter eggs in 1910. Rotational molding had developed further when R.J. Powell made mention of the commonly used ratio of 4:1 between major and minor axes of rotation at slow rotation speeds. His patent covered this process for molding hollow objects from

332:

Semi-permanent coatings: the coating, if applied correctly, will last for multiple releases before requiring to be reapplied or touched up. This type of coating is most prevalent in today's rotational molding industry. The active chemistry involved in these coatings is typically a

50:

Rotocasting (also known as rotacasting), by comparison, uses self-curing or UV-curable resins (as opposed to thermoplastics) in an unheated mould, but shares slow rotational speeds in common with rotational molding. This kind of rotocasting should not be confused with

124:

Rotational molding machines are made in a wide range of sizes. They normally consist of molds, an oven, a cooling chamber, and mold spindles. The spindles are mounted on a rotating axis, which provides a uniform coating of the plastic inside each mold.

747:

Because there is no pressure to push the plastic into the mold, the chosen plastic must be able to flow easily through the cavities of the mold. The part's design must also take into account the flow characteristics of the particular plastic

688:

Rotational molding is also the process of choice for short runs and rush deliveries. The molds can be swapped quickly or different colors can be used without purging the mold. With other processes, purging may be required to swap colors.

321:(MRA) will allow the material to be removed quickly and effectively. Mold releases can reduce cycle times, defects, and browning of finished product. There are a number of mold release types available; they can be categorized as follows:

651:, meaning they require different times in the heating chamber and cooling chamber. Ideally, the part will be tested to use the minimum thickness required for the application. This minimum will then be established as a nominal thickness.

210:

and out of heating and cooling chambers. It is low in cost for the size of product produced and the footprint is kept to a minimum compared to other types of machines. It is also available in smaller scale for schools and prototyping.

96:

In 1976, the

Association of Rotational Molders (ARM) was founded in Chicago as a worldwide trade association. The main objective of this association is to increase awareness of the rotational molding technology and process.

157:

while also rotating the part to form it as desired. The cooling chamber is where the part is placed until it cools, and the spindles are mounted to rotate and provide a uniform coat of plastic inside each mold.

67:

documented the first use of a rotating mechanism producing “two centrifugal motions at right angles to each other” by means of beveled gearing, and heat. This rotational molding process was used to create

647:

thicker the wall, the more material and time will be required, increasing costs. In some cases, the plastics may degrade owing to extended periods at high temperature. Different materials have different

288:

of the part. The cooling rate must be kept within a certain range. Very rapid cooling (for example, water spray) would result in cooling and shrinking at an uncontrolled rate, producing a warped part.

112:, were introduced to rotational molding. This has led to new uses for this process, such as the creation of fuel tanks and industrial moldings. The research that has been done since the late 1980s at

638:, will require larger radii than other materials. The stiffness of the set material may be a factor. More structural and strengthening measures may be required when a flimsy material is used.

2074:

975:

128:

Molds (or tooling) are either fabricated from welded sheet steel or cast. The fabrication method is often driven by part size and complexity; most intricate parts are likely made with

518:

Designers can select the best material for their application, including materials that meet U.S. Food and Drug

Administration (FDA) requirements. Additives for weather resistance,

673:

that are virtually stress-free. For additional strength, reinforcing ribs can be designed into the part. Along with being designed into the part, they can be added to the mold.

684:

with products such as plastic bottles and cylindrical containers. This substitution is efficient on only a smaller scale, as blow-molding's efficiency depends on large runs.

1037:

325:

Sacrificial coatings: the coating of MRA has to be applied each time because most of the MRA comes off on the molded part when it releases from the tool.

1798:

709:

financial and environmental costs. Some plastics will degrade with the long heating cycles or in the process of turning them into a powder to be melted.

201:

cooling chambers. These machines have the same (or similar) capabilities as the horizontal carousel multi-arm machines, but take up much less space.

979:

116:

has led to the development of more precise monitoring and control of the cooling processes based on their development of the “Rotolog system”.

77:

in the 1920s. These early methods using different materials directed the advances in the way rotational molding is used today with plastics.

740:

of the melted plastic and deterioration of the material's properties. For this reason, the chosen plastic must have a sufficient number of

725:

Owing to high temperatures within the mold, the plastic must have a high resistance to permanent change in properties caused by heat (high

677:

cooling will not damage the part. This shrinking allows for mild undercuts and negates the need for ejection mechanisms (for most pieces).

344:(PTFE) coating, which is applied to the mold. Permanent coatings avoid the need for operator application, but may become damaged by misuse.

1791:

811:

492:

Recently it has become possible to use natural materials in the molding process. Through the use of real sands and stone chip,

93:. The cooling method consisted of turning off the burners and allowing the plastic to harden while still rocking in the mold.

1674:

1125:

1045:

1244:

2133:

2084:

2053:

530:

angles, or fine surface detail can be part of the design. Designs can also be multi-wall, either hollow or foam filled.

1784:

1291:

1025:

1232:

1218:

1147:

2175:

52:

20:

248:

1776:

1316:

423:

362:

2069:

2048:

1945:

1699:

113:

2123:

2043:

2116:

2038:

1854:

1451:

1249:

815:

2180:

1381:

1356:

1264:

2156:

1890:

1689:

1514:

1331:

1321:

366:

1960:

1950:

1812:

1499:

1446:

1336:

523:

358:

354:

144:, it does provide the designer with more options. The aluminum addition to the steel provides more

90:

1014:

1550:

1441:

1426:

1406:

791:

341:

1965:

1843:

1598:

1326:

1284:

552:

305:

polymer particles during the melting, producing a part with fewer bubbles in less time than at

129:

721:

Owing to the nature of the process, materials selection must take into account the following:

2145:

1849:

1494:

841:

1865:

1860:

1833:

1751:

1175:

648:

306:

81:

gas burners. The mold was made of electroformed nickel-copper and the plastic was a liquid

8:

1995:

1756:

1679:

1593:

1545:

541:

527:

1179:

522:, or static elimination can be incorporated. Inserts, graphics, threads, handles, minor

2010:

1928:

1669:

1613:

1573:

1555:

1504:

1456:

1436:

1191:

1166:

Revyako, M (2010), "Certain

Problems of Heat and Mass Transfer in Rotational Molding",

398:

370:

318:

82:

1001:

2140:

2106:

2026:

1838:

1660:

1578:

1277:

1228:

1214:

1195:

1143:

1121:

726:

141:

1026:

http://www.saywell.co.uk/wp-content/uploads/2011/09/TF100-15C_Rotational-Molding.pdf

819:

761: – Method of utilizing centrifugal force to produce castings from a rubber mold

2031:

1726:

1628:

1603:

1535:

1401:

1396:

1341:

1183:

192:

and for high quality models. More than one mold can be attached to the single arm.

74:

69:

1806:

1895:

1881:

1746:

1633:

1623:

1391:

1137:

519:

133:

634:

Another consideration is the melt-flow of materials. Certain materials, such as

1924:

1736:

1638:

1509:

1187:

662:

2169:

2111:

1918:

1704:

1694:

1684:

1588:

1489:

1411:

1361:

655:

stops and the melt-flow is allowed to pool at the bottom of the mold cavity.

444:

434:

408:

393:

378:

264:

145:

101:

64:

32:

A three-motor powered (tri-power) rotational-molding or spin-casting machine

1731:

1721:

1583:

1530:

1431:

1376:

1351:

976:"High specification Ibc's and drums for all applications from Francis Ward"

758:

681:

469:

454:

388:

334:

188:

products made. It is available in smaller scales for schools interested in

1977:

1466:

1914:

1886:

1821:

1741:

1540:

1421:

1416:

741:

464:

189:

414:

These materials are also occasionally used (not in order of most used):

353:

More than 80% of all the material used is from the polyethylene family:

1990:

1618:

1608:

1038:"Putting The Right Spin On Rotational-Molding Designs | Machine Design"

568:

504:

496:

composite can be created which is 80% natural non-processed material.

170:

151:

148:, causing the melt-flow to stay in a fluid state for a longer period.

28:

2079:

1985:

1955:

1825:

1386:

1371:

1346:

737:

562:

493:

480:

459:

374:

326:

301:

to be monitored and removing much of the guesswork from the process.

105:

86:

1259:

2000:

578:

474:

418:

227:

137:

1472:

2128:

2005:

1906:

1808:

1300:

951:"Storm Shelters Tornado Shelter Underground Shelters Granger ISS"

500:

449:

277:

272:

The rotational molding process consists of four distinct phases:

256:

1015:

http://www.rotomolding.org/About/WhatIsRotomolding/Default.aspx

733:

429:

195:

1254:

635:

587:

439:

403:

109:

1002:"Security bulwark to prevent unauthorised boarding of ships"

950:

680:

Rotational molding can be used as a feasible alternative to

546:

1366:

1269:

663:

Process: advantages, limitations, and material requirements

1265:

British

Plastics Federation - Rotational Moulding Overview

744:

molecules to prevent such degradation in its liquid state.

629:

260:

Unloading a molded polyethylene tank in a shuttle machine

40:

510:

Chocolate is rotationally molded to form hollow treats.

174:

A rock and roll rotational molding machine built in 2009

595:

1095:

1093:

1091:

1064:

933:

931:

903:

901:

888:

886:

1136:

Todd, Robert H.; Allen, Dell K.; Alting, Leo (1994),

1088:

1052:

928:

898:

883:

871:

732:The molten plastic will come into contact with the

612:

384:Order of materials most commonly used by industry:

152:

Standard setup and equipment for rotational molding

1168:Journal of Engineering Physics & Thermophysics

924:. Intermediate Technology Publication. p. 8.

772:

2167:

1159:Manufacturing Processes for Design Professionals

1135:

865:

132:tooling. Molds are typically manufactured from

1260:Association of Rotational Moulders Australasia

736:inside the mold. This can potentially lead to

160:

16:Making hollow plastic objects in a heated mold

1792:

1285:

231:A carousel machine with four independent arms

340:Permanent coatings: most often some form of

196:Vertical or up & over rotational machine

19:For the large-scale industrial process, see

919:

329:are typical MRA compounds in this category.

63:In 1855 a patent taken out by R. Peters in

1799:

1785:

1292:

1278:

369:(HDPE), and regrind. Other compounds are

1156:

716:

607:

594:

586:

577:

561:

551:

540:

263:

255:

226:

169:

165:

119:

27:

1165:

1139:Manufacturing Processes Reference Guide

630:Material limitations and considerations

280:(usually in powder form) into the mold.

2168:

1382:Polyethylene terephthalate (PET, PETE)

1225:Practical Guide to Rotational Moulding

805:

803:

801:

792:"Rotational Molding Industry Overview"

312:

295:

1780:

1322:Cross-linked polyethylene (PEX, XLPE)

1317:Acrylonitrile butadiene styrene (ABS)

1273:

1115:

1099:

1082:

1070:

1058:

937:

907:

892:

877:

778:

618:shrinkage and possible part warping.

239:

2134:List of environmental health hazards

2054:List of environmental health hazards

810:Ward, Noel Mansfield (Winter 1997).

809:

487:

213:

182:

100:In the 1980s, new plastics, such as

1245:Rotational Moulding Technical Guide

798:

222:

13:

1939:Miscellaneous additives incl. PHCs

1203:

812:"A History of Rotational Moulding"

572:molded into a liquid storage tank.

247:

204:

14:

2192:

1255:Association of Rotational Molders

1250:Rotational Molding process videos

1238:

922:Small Scale Recycling of Plastics

641:

1471:

1465:

1357:Polybutylene terephthalate (PBT)

1332:Poly(methyl methacrylate) (PMMA)

1227:, Rapra Technology Ltd. (2003).

842:"Rotational Molding Information"

613:Designing for rotational molding

21:Centrifugal casting (industrial)

1337:Poly(ethyl methacrylate) (PEMA)

1211:Rotational Moulding of Plastics

1209:Crawford, R, Throne, James L.,

1120:, Hanser Gardner Publications,

1109:

1076:

1030:

1019:

1008:

994:

968:

943:

424:Acrylonitrile butadiene styrene

363:linear low-density polyethylene

276:Loading a measured quantity of

1700:Category:Plastics applications

1447:Styrene maleic anhydride (SMA)

1442:Polyvinylidene chloride (PVDC)

1427:Polytetrafluoroethylene (PTFE)

1213:, William Andrew Inc. (2002).

913:

859:

834:

784:

699:

1:

1407:Poly(p-phenylene oxide) (PPO)

866:Todd, Allen & Alting 1994

765:

667:

599:Edon roto moulded rowing boat

2124:Persistent organic pollutant

2085:Toxic Substances Control Act

2044:Persistent organic pollutant

1327:Ethylene vinyl acetate (EVA)

1299:

348:

7:

2117:Great Pacific garbage patch

2039:Great Pacific garbage patch

1452:Styrene-acrylonitrile (SAN)

1367:Polyetheretherketone (PEEK)

816:Plastics Historical Society

752:

566:A blind brass threaded hex

545:Plastic grain bins made by

513:

161:Rotational molding machines

10:

2197:

2080:Japan Toxic Substances Law

1875:Miscellaneous plasticizers

591:Rotational Molded Flamingo

503:is used to produce hollow

479:Various foods (especially

268:Rotational molding process

252:Rotational Molding Process

114:Queen's University Belfast

58:

18:

2154:

2099:

2075:European REACH regulation

2070:California Proposition 65

2062:

2019:

1976:

1938:

1905:

1874:

1820:

1813:polyhalogenated compounds

1769:

1714:

1690:High-performance plastics

1659:

1652:

1564:

1523:

1515:High-performance plastics

1480:

1463:

1307:

1188:10.1007/s10891-010-0434-z

1142:, Industrial Press Inc.,

367:high-density polyethylene

1500:Fibre-reinforced plastic

1437:Polyvinyl chloride (PVC)

1223:Crawford, R, Kearns, M,

794:. Roto World (magazine).

547:Buffer Valley Industries

526:, flat surfaces without

359:low-density polyethylene

355:crosslinked polyethylene

91:low-density polyethylene

2176:Casting (manufacturing)

1551:Biodegradable additives

342:polytetrafluoroethylene

1966:Perfluorooctanoic acid

1402:Polyphenyl ether (PPE)

1397:Polyoxymethylene (POM)

1342:Polyacrylic acid (PAA)

1161:, Thames & Hudson.

600:

592:

582:

573:

557:

549:

499:Rotational molding of

269:

261:

253:

232:

175:

33:

2146:Biodegradable plastic

1495:Thermosetting polymer

1392:Polylactic acid (PLA)

1116:Beall, Glenn (1998),

846:RotationalMolding.com

717:Material requirements

608:Design considerations

598:

590:

581:

565:

555:

544:

267:

259:

251:

230:

173:

166:Rock and roll machine

120:Equipment and tooling

31:

2157:Identification codes

1757:Foam food containers

1680:Engineering plastics

1157:Thompson, R (2007),

920:John Vogler (1984).

649:thermal conductivity

307:atmospheric pressure

291:Removal of the part.

1996:Endocrine disruptor

1594:Compression molding

1546:Polymer stabilizers

1180:2010JEPT...83.1089R

868:, pp. 265–266.

822:on October 15, 2006

313:Mold release agents

296:Recent improvements

53:centrifugal casting

2011:Polymer fume fever

1670:Commodity plastics

1644:Rotational molding

1614:Fiberglass molding

1574:Injection moulding

1556:Filler (materials)

1505:Corrugated plastic

1457:Tritan copolyester

1412:Polypropylene (PP)

1362:Polycarbonate (PC)

1118:Rotational Molding

1048:on March 25, 2009.

982:on August 20, 2014

955:www.grangeriss.com

601:

593:

583:

574:

558:

550:

399:Polyvinyl chloride

371:polyvinyl chloride

319:mold release agent

270:

262:

254:

240:Production process

233:

176:

83:polyvinyl chloride

37:Rotational molding

34:

2181:Molding processes

2163:

2162:

2141:Plastic recycling

2107:Plastic pollution

2093:

2092:

2027:Plastic pollution

1807:Health issues of

1765:

1764:

1661:Plastics industry

1579:Plastic extrusion

1432:Polyurethane (PU)

1422:Polysulfone (PES)

1377:Polyethylene (PE)

1352:Polybutylene (PB)

1127:978-1-56990-260-8

1073:, pp. 75–77.

1042:machinedesign.com

727:thermal stability

692:production time.

605:

604:

520:flame retardation

488:Natural materials

214:Swing arm machine

183:Clamshell machine

142:injection molding

2188:

2032:Rubber pollution

1882:Organophosphates

1801:

1794:

1787:

1778:

1777:

1657:

1656:

1629:Filament winding

1604:Transfer molding

1531:Polymer additive

1475:

1469:

1417:Polystyrene (PS)

1294:

1287:

1280:

1271:

1270:

1199:

1162:

1153:

1131:

1103:

1097:

1086:

1080:

1074:

1068:

1062:

1056:

1050:

1049:

1044:. Archived from

1034:

1028:

1023:

1017:

1012:

1006:

1005:

998:

992:

991:

989:

987:

978:. Archived from

972:

966:

965:

963:

961:

947:

941:

935:

926:

925:

917:

911:

905:

896:

890:

881:

875:

869:

863:

857:

856:

854:

852:

838:

832:

831:

829:

827:

818:. Archived from

807:

796:

795:

788:

782:

776:

537:

536:

223:Carousel machine

75:plaster of Paris

70:artillery shells

2196:

2195:

2191:

2190:

2189:

2187:

2186:

2185:

2166:

2165:

2164:

2159:

2150:

2095:

2094:

2089:

2058:

2015:

1972:

1934:

1901:

1870:

1816:

1805:

1771:

1761:

1710:

1648:

1634:Solvent bonding

1624:Plastic welding

1566:

1560:

1519:

1482:

1476:

1470:

1461:

1372:Polyester (PEs)

1309:

1303:

1298:

1241:

1206:

1204:Further reading

1150:

1128:

1112:

1107:

1106:

1098:

1089:

1081:

1077:

1069:

1065:

1057:

1053:

1036:

1035:

1031:

1024:

1020:

1013:

1009:

1000:

999:

995:

985:

983:

974:

973:

969:

959:

957:

949:

948:

944:

936:

929:

918:

914:

906:

899:

891:

884:

876:

872:

864:

860:

850:

848:

840:

839:

835:

825:

823:

808:

799:

790:

789:

785:

777:

773:

768:

755:

719:

702:

670:

665:

659:inside corner.

644:

632:

615:

610:

556:Mold in graphic

516:

490:

351:

315:

298:

242:

225:

216:

207:

205:Shuttle machine

198:

185:

168:

163:

154:

134:stainless steel

122:

61:

24:

17:

12:

11:

5:

2194:

2184:

2183:

2178:

2161:

2160:

2155:

2152:

2151:

2149:

2148:

2143:

2138:

2137:

2136:

2131:

2126:

2121:

2120:

2119:

2103:

2101:

2097:

2096:

2091:

2090:

2088:

2087:

2082:

2077:

2072:

2066:

2064:

2060:

2059:

2057:

2056:

2051:

2046:

2041:

2036:

2035:

2034:

2023:

2021:

2017:

2016:

2014:

2013:

2008:

2003:

1998:

1993:

1988:

1982:

1980:

1974:

1973:

1971:

1970:

1969:

1968:

1958:

1953:

1948:

1942:

1940:

1936:

1935:

1933:

1932:

1925:Vinyl chloride

1922:

1919:Polycarbonates

1911:

1909:

1903:

1902:

1900:

1899:

1893:

1884:

1878:

1876:

1872:

1871:

1869:

1868:

1863:

1858:

1852:

1847:

1841:

1836:

1830:

1828:

1818:

1817:

1804:

1803:

1796:

1789:

1781:

1775:

1773:

1767:

1766:

1763:

1762:

1760:

1759:

1754:

1749:

1744:

1739:

1734:

1732:Packaging film

1729:

1724:

1718:

1716:

1715:Specific goods

1712:

1711:

1709:

1708:

1702:

1697:

1692:

1687:

1682:

1677:

1672:

1666:

1664:

1654:

1650:

1649:

1647:

1646:

1641:

1639:Vacuum forming

1636:

1631:

1626:

1621:

1616:

1611:

1606:

1601:

1596:

1591:

1586:

1581:

1576:

1570:

1568:

1562:

1561:

1559:

1558:

1553:

1548:

1543:

1538:

1533:

1527:

1525:

1521:

1520:

1518:

1517:

1512:

1510:Polymeric foam

1507:

1502:

1497:

1492:

1486:

1484:

1478:

1477:

1464:

1462:

1460:

1459:

1454:

1449:

1444:

1439:

1434:

1429:

1424:

1419:

1414:

1409:

1404:

1399:

1394:

1389:

1387:Polyimide (PI)

1384:

1379:

1374:

1369:

1364:

1359:

1354:

1349:

1347:Polyamide (PA)

1344:

1339:

1334:

1329:

1324:

1319:

1313:

1311:

1305:

1304:

1297:

1296:

1289:

1282:

1274:

1268:

1267:

1262:

1257:

1252:

1247:

1240:

1239:External links

1237:

1236:

1235:

1221:

1205:

1202:

1201:

1200:

1163:

1154:

1148:

1133:

1126:

1111:

1108:

1105:

1104:

1087:

1075:

1063:

1051:

1029:

1018:

1007:

993:

967:

942:

927:

912:

910:, p. 155.

897:

895:, p. 152.

882:

880:, p. 154.

870:

858:

833:

797:

783:

770:

769:

767:

764:

763:

762:

754:

751:

750:

749:

745:

730:

718:

715:

701:

698:

669:

666:

664:

661:

643:

642:Wall thickness

640:

631:

628:

614:

611:

609:

606:

603:

602:

584:

575:

559:

515:

512:

489:

486:

485:

484:

477:

472:

467:

462:

457:

452:

447:

442:

437:

432:

427:

421:

412:

411:

406:

401:

396:

391:

377:, nylons, and

350:

347:

346:

345:

338:

330:

314:

311:

297:

294:

293:

292:

289:

285:

281:

241:

238:

224:

221:

215:

212:

206:

203:

197:

194:

184:

181:

167:

164:

162:

159:

153:

150:

121:

118:

60:

57:

15:

9:

6:

4:

3:

2:

2193:

2182:

2179:

2177:

2174:

2173:

2171:

2158:

2153:

2147:

2144:

2142:

2139:

2135:

2132:

2130:

2127:

2125:

2122:

2118:

2115:

2114:

2113:

2112:Garbage patch

2110:

2109:

2108:

2105:

2104:

2102:

2098:

2086:

2083:

2081:

2078:

2076:

2073:

2071:

2068:

2067:

2065:

2061:

2055:

2052:

2050:

2047:

2045:

2042:

2040:

2037:

2033:

2030:

2029:

2028:

2025:

2024:

2022:

2018:

2012:

2009:

2007:

2004:

2002:

1999:

1997:

1994:

1992:

1989:

1987:

1984:

1983:

1981:

1979:

1978:Health issues

1975:

1967:

1964:

1963:

1962:

1959:

1957:

1954:

1952:

1949:

1947:

1944:

1943:

1941:

1937:

1930:

1926:

1923:

1920:

1916:

1913:

1912:

1910:

1908:

1904:

1897:

1894:

1892:

1888:

1885:

1883:

1880:

1879:

1877:

1873:

1867:

1864:

1862:

1859:

1856:

1853:

1851:

1848:

1845:

1842:

1840:

1837:

1835:

1832:

1831:

1829:

1827:

1823:

1819:

1814:

1810:

1802:

1797:

1795:

1790:

1788:

1783:

1782:

1779:

1774:

1768:

1758:

1755:

1753:

1752:Shopping bags

1750:

1748:

1745:

1743:

1740:

1738:

1735:

1733:

1730:

1728:

1725:

1723:

1720:

1719:

1717:

1713:

1707:(Agriculture)

1706:

1705:Plasticulture

1703:

1701:

1698:

1696:

1693:

1691:

1688:

1686:

1685:Geosynthetics

1683:

1681:

1678:

1676:

1673:

1671:

1668:

1667:

1665:

1662:

1658:

1655:

1651:

1645:

1642:

1640:

1637:

1635:

1632:

1630:

1627:

1625:

1622:

1620:

1617:

1615:

1612:

1610:

1607:

1605:

1602:

1600:

1597:

1595:

1592:

1590:

1589:Thermoforming

1587:

1585:

1582:

1580:

1577:

1575:

1572:

1571:

1569:

1563:

1557:

1554:

1552:

1549:

1547:

1544:

1542:

1539:

1537:

1534:

1532:

1529:

1528:

1526:

1522:

1516:

1513:

1511:

1508:

1506:

1503:

1501:

1498:

1496:

1493:

1491:

1490:Thermoplastic

1488:

1487:

1485:

1479:

1474:

1468:

1458:

1455:

1453:

1450:

1448:

1445:

1443:

1440:

1438:

1435:

1433:

1430:

1428:

1425:

1423:

1420:

1418:

1415:

1413:

1410:

1408:

1405:

1403:

1400:

1398:

1395:

1393:

1390:

1388:

1385:

1383:

1380:

1378:

1375:

1373:

1370:

1368:

1365:

1363:

1360:

1358:

1355:

1353:

1350:

1348:

1345:

1343:

1340:

1338:

1335:

1333:

1330:

1328:

1325:

1323:

1320:

1318:

1315:

1314:

1312:

1306:

1302:

1295:

1290:

1288:

1283:

1281:

1276:

1275:

1272:

1266:

1263:

1261:

1258:

1256:

1253:

1251:

1248:

1246:

1243:

1242:

1234:

1233:1-85957-387-8

1230:

1226:

1222:

1220:

1219:1-884207-85-5

1216:

1212:

1208:

1207:

1197:

1193:

1189:

1185:

1181:

1177:

1173:

1169:

1164:

1160:

1155:

1151:

1149:0-8311-3049-0

1145:

1141:

1140:

1134:

1129:

1123:

1119:

1114:

1113:

1102:, p. 70.

1101:

1096:

1094:

1092:

1085:, p. 71.

1084:

1079:

1072:

1067:

1061:, p. 69.

1060:

1055:

1047:

1043:

1039:

1033:

1027:

1022:

1016:

1011:

1003:

997:

981:

977:

971:

956:

952:

946:

940:, p. 18.

939:

934:

932:

923:

916:

909:

904:

902:

894:

889:

887:

879:

874:

867:

862:

847:

843:

837:

821:

817:

813:

806:

804:

802:

793:

787:

780:

775:

771:

760:

757:

756:

746:

743:

739:

735:

731:

728:

724:

723:

722:

714:

710:

706:

697:

693:

689:

685:

683:

678:

674:

660:

656:

652:

650:

639:

637:

627:

623:

619:

597:

589:

585:

580:

576:

571:

570:

564:

560:

554:

548:

543:

539:

538:

535:

531:

529:

525:

521:

511:

508:

506:

502:

497:

495:

482:

478:

476:

473:

471:

468:

466:

463:

461:

458:

456:

453:

451:

448:

446:

445:Fluorocarbons

443:

441:

438:

436:

433:

431:

428:

425:

422:

420:

417:

416:

415:

410:

409:Polycarbonate

407:

405:

402:

400:

397:

395:

394:Polypropylene

392:

390:

387:

386:

385:

382:

380:

379:polypropylene

376:

372:

368:

364:

360:

356:

343:

339:

336:

331:

328:

324:

323:

322:

320:

310:

308:

302:

290:

286:

282:

279:

275:

274:

273:

266:

258:

250:

246:

237:

229:

220:

211:

202:

193:

191:

180:

172:

158:

149:

147:

146:heat capacity

143:

139:

135:

131:

126:

117:

115:

111:

107:

103:

102:polycarbonate

98:

94:

92:

88:

84:

78:

76:

71:

66:

56:

54:

48:

46:

42:

38:

30:

26:

22:

1822:Plasticizers

1770:Environment

1722:Blister pack

1675:Construction

1643:

1584:Blow molding

1224:

1210:

1171:

1167:

1158:

1138:

1117:

1110:Bibliography

1078:

1066:

1054:

1046:the original

1041:

1032:

1021:

1010:

996:

984:. Retrieved

980:the original

970:

960:February 25,

958:. Retrieved

954:

945:

921:

915:

873:

861:

849:. Retrieved

845:

836:

824:. Retrieved

820:the original

786:

781:, p. 6.

774:

759:Spin casting

720:

711:

707:

703:

694:

690:

686:

682:blow molding

679:

675:

671:

657:

653:

645:

633:

624:

620:

616:

567:

532:

517:

509:

498:

491:

470:Polyurethane

455:Polybutylene

413:

389:Polyethylene

383:

352:

335:polysiloxane

316:

303:

299:

271:

243:

234:

217:

208:

199:

186:

177:

155:

127:

123:

99:

95:

79:

62:

49:

44:

36:

35:

25:

2063:Regulations

1915:Bisphenol A

1599:Calendering

1541:Plasticizer

1481:Mechanical

1174:(5): 1089,

826:December 3,

742:antioxidant

700:Limitations

465:Polystyrene

190:prototyping

2170:Categories

1991:Carcinogen

1956:Organotins

1826:Phthalates

1772:and health

1619:Pultrusion

1609:Laminating

1567:processing

1100:Beall 1998

1083:Beall 1998

1071:Beall 1998

1059:Beall 1998

986:August 19,

938:Beall 1998

908:Beall 1998

893:Beall 1998

878:Beall 1998

851:August 23,

779:Beall 1998

766:References

696:recycled.

668:Advantages

505:statuettes

375:plastisols

2020:Pollution

1986:Teratogen

1917:(BPA, in

1565:Plastics

1536:Colorants

1524:Additives

1308:Chemical

1196:119972566

738:oxidation

524:undercuts

494:sandstone

481:chocolate

460:Polyester

365:(LLDPE),

349:Materials

327:Silicones

106:polyester

87:plastisol

2001:Diabetes

1907:Monomers

1887:Adipates

1809:plastics

1663:segments

1653:Products

1301:Plastics

753:See also

514:Products

475:Silicone

419:Aluminum

361:(LDPE),

138:aluminum

45:moulding

2129:Dioxins

2049:Dioxins

2006:Obesity

1747:Cutlery

1737:Bottles

1176:Bibcode

748:chosen.

501:plaster

450:Ionomer

435:Acrylic

357:(PEX),

317:A good

278:polymer

65:Britain

59:History

1846:(BBzP)

1815:(PHCs)

1727:Chairs

1695:Nurdle

1231:

1217:

1194:

1146:

1124:

734:oxygen

569:insert

430:Acetal

373:(PVC)

108:, and

85:(PVC)

2100:Waste

1946:PBDEs

1857:(DOP)

1483:types

1310:types

1192:S2CID

636:nylon

528:draft

440:Epoxy

426:(ABS)

404:Nylon

110:nylon

1961:PFCs

1951:PCBs

1927:(in

1891:DEHA

1866:DINP

1861:DIDP

1855:DEHP

1850:DIHP

1834:DIBP

1811:and

1742:Bags

1229:ISBN

1215:ISBN

1144:ISBN

1122:ISBN

988:2014

962:2018

853:2020

828:2009

130:cast

1929:PVC

1896:DOA

1844:BBP

1839:DBP

1184:doi

136:or

41:BrE

2172::

1824::

1190:,

1182:,

1172:83

1170:,

1090:^

1040:.

953:.

930:^

900:^

885:^

844:.

814:.

800:^

729:).

507:.

381:.

104:,

55:.

43::

1931:)

1921:)

1898:)

1889:(

1800:e

1793:t

1786:v

1293:e

1286:t

1279:v

1198:.

1186::

1178::

1152:.

1132:}

1130:.

1004:.

990:.

964:.

855:.

830:.

483:)

337:.

39:(

23:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.