1721:. Compared with methods used for mass production, the etching time is long. Heat and agitation can be applied to the bath to speed the etching rate. In bubble etching, air is passed through the etchant bath to agitate the solution and speed up etching. Splash etching uses a motor-driven paddle to splash boards with etchant; the process has become commercially obsolete since it is not as fast as spray etching. In spray etching, the etchant solution is distributed over the boards by nozzles, and recirculated by pumps. Adjustment of the nozzle pattern, flow rate, temperature, and etchant composition gives predictable control of etching rates and high production rates. As more copper is consumed from the boards, the etchant becomes saturated and less effective; different etchants have different capacities for copper, with some as high as 150 grams of copper per liter of solution. In commercial use, etchants can be regenerated to restore their activity, and the dissolved copper recovered and sold. Small-scale etching requires attention to disposal of used etchant, which is corrosive and toxic due to its metal content. The etchant removes copper on all surfaces not protected by the resist. "Undercut" occurs when etchant attacks the thin edge of copper under the resist; this can reduce conductor widths and cause open-circuits. Careful control of etch time is required to prevent undercut. Where metallic plating is used as a resist, it can "overhang" which can cause short-circuits between adjacent traces when closely spaced. Overhang can be removed by wire-brushing the board after etching.

1802:

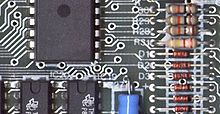

2430:, where short traces were important. In cordwood construction, axial-leaded components were mounted between two parallel planes. The name comes from the way axial-lead components (capacitors, resistors, coils, and diodes) are stacked in parallel rows and columns, like a stack of firewood. The components were either soldered together with jumper wire or they were connected to other components by thin nickel ribbon welded at right angles onto the component leads. To avoid shorting together different interconnection layers, thin insulating cards were placed between them. Perforations or holes in the cards allowed component leads to project through to the next interconnection layer. One disadvantage of this system was that special

609:

2434:-leaded components had to be used to allow reliable interconnecting welds to be made. Differential thermal expansion of the component could put pressure on the leads of the components and the PCB traces and cause mechanical damage (as was seen in several modules on the Apollo program). Additionally, components located in the interior are difficult to replace. Some versions of cordwood construction used soldered single-sided PCBs as the interconnection method (as pictured), allowing the use of normal-leaded components at the cost of being difficult to remove the boards or replace any component that is not at the edge.

1394:

2031:). A photo-sensitive coating is applied to the surface of the PWB, then exposed to light through the solder mask image film, and finally developed where the unexposed areas are washed away. Dry film solder mask is similar to the dry film used to image the PWB for plating or etching. After being laminated to the PWB surface it is imaged and developed as LPI. Once but no longer commonly used, because of its low accuracy and resolution, is to screen print epoxy ink. In addition to repelling solder, solder resist also provides protection from the environment to the copper that would otherwise be exposed.

2328:. Improper handling techniques might transmit an accumulated static charge through the board, damaging or destroying components. The damage might not immediately affect function but might lead to early failure later on, cause intermittent operating faults, or cause a narrowing of the range of environmental and electrical conditions under which the board functions properly. Even bare boards are sometimes static sensitive: traces have become so fine that it is possible to blow a trace (or change its characteristics) with a static discharge. This is especially true on non-traditional PCBs such as

672:

smaller and component placement on both sides of the board became more common than with through-hole mounting, allowing much smaller PCB assemblies with much higher circuit densities. Surface mounting lends itself well to a high degree of automation, reducing labor costs and greatly increasing production rates compared with through-hole circuit boards. Components can be supplied mounted on carrier tapes. Surface mount components can be about one-quarter to one-tenth of the size and weight of through-hole components, and passive components much cheaper. However, prices of semiconductor

378:

multi-layer HDI PCBs the interconnection of several vias stacked on top of each other (stacked vías, instead of one deep buried via) can be made stronger, thus enhancing reliability in all conditions. The most common applications for HDI technology are computer and mobile phone components as well as medical equipment and military communication equipment. A 4-layer HDI microvia PCB is equivalent in quality to an 8-layer through-hole PCB, so HDI technology can reduce costs. HDI PCBs are often made using build-up film such as ajinomoto build-up film, which is also used in the production of

61:

1684:

1692:

1700:

2196:

be desired to take advantage of the size, weight, and cost reductions obtainable by using some available surface-mount devices. Another reason to use both methods is that through-hole mounting can provide needed strength for components likely to endure physical stress (such as connectors that are frequently mated and demated or that connect to cables expected to impart substantial stress to the PCB-and-connector interface), while components that are expected to go untouched will take up less space using surface-mount techniques.

2016:

235:

597:

1773:

2473:

572:

6769:

584:

2399:

6779:

2615:

2346:

1343:

391:

6789:

2008:

1912:. The de-smear process ensures that a good connection is made to the copper layers when the hole is plated through. On high reliability boards a process called etch-back is performed chemically with a potassium permanganate based etchant or plasma etching. The etch-back removes resin and the glass fibers so that the copper layers extend into the hole and as the hole is plated become integral with the deposited copper.

4283:

1139:

2407:

69:

2121:

620:"Through hole" components are mounted by their wire leads passing through the board and soldered to traces on the other side. "Surface mount" components are attached by their leads to copper traces on the same side of the board. A board may use both methods for mounting components. PCBs with only through-hole mounted components are now uncommon. Surface mounting is used for

1027:(IMS), clad with thermally conductive thin dielectric - used for parts requiring significant cooling - power switches, LEDs. Consists of usually single, sometimes double layer thin circuit board based on e.g. FR-4, laminated on aluminum sheet metal, commonly 0.8, 1, 1.5, 2 or 3 mm thick. The thicker laminates sometimes also come with thicker copper metalization.

4003:

1733:

the board in the unmasked areas; copper may be plated to any desired weight. Tin-lead or other surface platings are then applied. The mask is stripped away and a brief etching step removes the now-exposed bare original copper laminate from the board, isolating the individual traces. Some single-sided boards which have plated-through holes are made in this way.

2546:

replaces it. This shift is economically efficient from a manufacturer's point of view but is also materially wasteful, as a circuit board with hundreds of functional components may be discarded and replaced due to the failure of one minor and inexpensive part, such as a resistor or capacitor. This practice is a significant contributor to the problem of

1729:

which removes the unexposed film). The exposed areas are sensitized in a chemical bath, usually containing palladium and similar to that used for through hole plating which makes the exposed area capable of bonding metal ions. The laminate is then plated with copper in the sensitized areas. When the mask is stripped, the PCB is finished.

652:

leads (such as resistors, capacitors, and diodes) is done by bending the leads 90 degrees in the same direction, inserting the part in the board (often bending leads located on the back of the board in opposite directions to improve the part's mechanical strength), soldering the leads, and trimming off the ends. Leads may be

2943:

2195:

Often, through-hole and surface-mount construction must be combined in a single assembly because some required components are available only in surface-mount packages, while others are available only in through-hole packages. Or, even if all components are available in through-hole packages, it might

554:

In multi-layer boards, the layers of material are laminated together in an alternating sandwich: copper, substrate, copper, substrate, copper, etc.; each plane of copper is etched, and any internal vias (that will not extend to both outer surfaces of the finished multilayer board) are plated-through,

542:

A printed circuit board can have multiple layers of copper which almost always are arranged in pairs. The number of layers and the interconnection designed between them (vias, PTHs) provide a general estimate of the board complexity. Using more layers allow for more routing options and better control

2266:

In boundary scan testing, test circuits integrated into various ICs on the board form temporary connections between the PCB traces to test that the ICs are mounted correctly. Boundary scan testing requires that all the ICs to be tested use a standard test configuration procedure, the most common one

2155:

on the surfaces of the PCB; solder paste, which was previously applied to the pads, holds the components in place temporarily; if surface-mount components are applied to both sides of the board, the bottom-side components are glued to the board. In both through hole and surface mount, the components

1788:

Multi-layer printed circuit boards have trace layers inside the board. This is achieved by laminating a stack of materials in a press by applying pressure and heat for a period of time. This results in an inseparable one piece product. For example, a four-layer PCB can be fabricated by starting from

1567:

uses a photomask and developer to selectively remove a UV-sensitive photoresist coating and thus create a photoresist mask that will protect the copper below it. Direct imaging techniques are sometimes used for high-resolution requirements. Experiments have been made with thermal resist. A laser may

1310:

1/2 oz/ft foil is not widely used as a finished copper weight, but is used for outer layers when plating for through holes will increase the finished copper weight Some PCB manufacturers refer to 1 oz/ft copper foil as having a thickness of 35 μm (may also be referred to as 35 μ,

309:

Even as circuit boards became available, the point-to-point chassis construction method remained in common use in industry (such as TV and hi-fi sets) into at least the late 1960s. Printed circuit boards were introduced to reduce the size, weight, and cost of parts of the circuitry. In 1960, a small

1545:

The first step is to replicate the pattern in the fabricator's CAM system on a protective mask on the copper foil PCB layers. Subsequent etching removes the unwanted copper unprotected by the mask. (Alternatively, a conductive ink can be ink-jetted on a blank (non-conductive) board. This technique

1536:

The panel is eventually broken into individual PCBs along perforations or grooves in the panel through milling or cutting. For milled panels a common distance between the individual boards is 2–3 mm. Today depaneling is often done by lasers which cut the board with no contact. Laser depaneling

305:

Motorola was an early leader in bringing the process into consumer electronics, announcing in August 1952 the adoption of "plated circuits" in home radios after six years of research and a $ 1M investment. Motorola soon began using its trademarked term for the process, PLAcir, in its consumer radio

1994:

under the influence of an electric field. Silver also grows conducting surface paths in the presence of halide and other ions, making it a poor choice for electronics use. Tin will grow "whiskers" due to tension in the plated surface. Tin-lead or solder plating also grows whiskers, only reduced by

1732:

Semi-additive is the most common process: The unpatterned board has a thin layer of copper already on it. A reverse mask is then applied (Unlike a subtractive process mask, this mask exposes those parts of the substrate that will eventually become the traces). Additional copper is then plated onto

1521:

or similar patterns for even copper distribution over the whole panel in order to avoid bending. The assemblers often mount components on panels rather than single PCBs because this is efficient. Panelization may also be necessary for boards with components placed near an edge of the board because

1211:

copper per ft (35 μm) is the most common thickness; 2 oz (70 μm) and 0.5 oz (17.5 μm) thickness is often an option. Less common are 12 and 105 μm, 9 μm is sometimes available on some substrates. Flexible substrates typically have thinner metalization. Metal-core boards for

941:, frequency dependence introduces phase distortion in wideband applications; as flat a dielectric constant vs frequency characteristics as is achievable is important here. The impedance of transmission lines decreases with frequency, therefore faster edges of signals reflect more than slower ones.

651:

inserted through holes on one side of the board and soldered onto copper traces on the other side. Boards may be single-sided, with an unplated component side, or more compact double-sided boards, with components soldered on both sides. Horizontal installation of through-hole parts with two axial

564:

160:

PCBs can be single-sided (one copper layer), double-sided (two copper layers on both sides of one substrate layer), or multi-layer (outer and inner layers of copper, alternating with layers of substrate). Multi-layer PCBs allow for much higher component density, because circuit traces on the inner

958:

Moisture absorption occurs when the material is exposed to high humidity or water. Both the resin and the reinforcement may absorb water; water also may be soaked by capillary forces through voids in the materials and along the reinforcement. Epoxies of the FR-4 materials are not too susceptible,

671:

emerged in the 1960s, gained momentum in the early 1980s, and became widely used by the mid-1990s. Components were mechanically redesigned to have small metal tabs or end caps that could be soldered directly onto the PCB surface, instead of wire leads to pass through holes. Components became much

543:

of signal integrity, but are also time-consuming and costly to manufacture. Likewise, selection of the vias for the board also allow fine tuning of the board size, escaping of signals off complex ICs, routing, and long term reliability, but are tightly coupled with production complexity and cost.

156:

software is available to do much of the work of layout. Mass-producing circuits with PCBs is cheaper and faster than with other wiring methods, as components are mounted and wired in one operation. Large numbers of PCBs can be fabricated at the same time, and the layout has to be done only once.

1728:

onto a bare substrate using a complex process. The advantage of the additive method is that less material is needed and less waste is produced. In the full additive process the bare laminate is covered with a photosensitive film which is imaged (exposed to light through a mask and then developed

967:

and cyanate esters, on the other side, suffer from high water absorption. Absorbed water can lead to significant degradation of key parameters; it impairs tracking resistance, breakdown voltage, and dielectric parameters. Relative dielectric constant of water is about 73, compared to about 4 for

377:

HDI (High

Density Interconnect) technology allows for a denser design on the PCB and thus potentially smaller PCBs with more traces and components in a given area. As a result, the paths between components can be shorter. HDIs use blind/buried vias, or a combination that includes microvias. With

925:

the thermal expansion of the resin roughly matches copper and glass, above it gets significantly higher. As the reinforcement and copper confine the board along the plane, virtually all volume expansion projects to the thickness and stresses the plated-through holes. Repeated soldering or other

866:

The reinforcement type defines two major classes of materials: woven and non-woven. Woven reinforcements are cheaper, but the high dielectric constant of glass may not be favorable for many higher-frequency applications. The spatially nonhomogeneous structure also introduces local variations in

546:

One of the simplest boards to produce is the two-layer board. It has copper on both sides that are referred to as external layers; multi layer boards sandwich additional internal layers of copper and insulation. After two-layer PCBs, the next step up is the four-layer. The four layer board adds

198:

connectors, wire connector lugs on screw terminals, or other methods. Circuits were large, bulky, heavy, and relatively fragile (even discounting the breakable glass envelopes of the vacuum tubes that were often included in the circuits), and production was labor-intensive, so the products were

2545:

Manufacturers may not support component-level repair of printed circuit boards because of the relatively low cost to replace compared with the time and cost of troubleshooting to a component level. In board-level repair, the technician identifies the board (PCA) on which the fault resides and

2508:

Since it was quite easy to stack interconnections (wires) inside the embedding matrix, the approach allowed designers to forget completely about the routing of wires (usually a time-consuming operation of PCB design): Anywhere the designer needs a connection, the machine will draw a wire in a

1792:

The inner layers are given a complete machine inspection before lamination because mistakes cannot be corrected afterwards. Automatic optical inspection (AOI) machines compare an image of the board with the digital image generated from the original design data. Automated

Optical Shaping (AOS)

950:

Loss tangent determines how much of the electromagnetic energy from the signals in the conductors is absorbed in the board material. This factor is important for high frequencies. Low-loss materials are more expensive. Choosing unnecessarily low-loss material is a common engineering error in

2465:

850:

With decreasing size of board features and increasing frequencies, small nonhomogeneities like uneven distribution of fiberglass or other filler, thickness variations, and bubbles in the resin matrix, and the associated local variations in the dielectric constant, are gaining importance.

664:

on layers immediately below the top layer on multi-layer boards, since the holes must pass through all layers to the opposite side. Once surface-mounting came into use, small-sized SMD components were used where possible, with through-hole mounting only of components unsuitably large for

2962:

434:

which is coated onto the PCB, then exposed to light projected in the pattern of the artwork. The resist material protects the copper from dissolution into the etching solution. The etched board is then cleaned. A PCB design can be mass-reproduced in a way similar to the way

2528:

thanks to the versatility of their layers, especially the copper layer. PCB layers have been used to fabricate sensors, such as capacitive pressure sensors and accelerometers, actuators such as microvalves and microheaters, as well as platforms of sensors and actuators for

1716:

Subtractive methods remove copper from an entirely copper-coated board to leave only the desired copper pattern. The simplest method, used for small-scale production and often by hobbyists, is immersion etching, in which the board is submerged in etching solution such as

4001:, Burr, Robert P.; Morino, Ronald & Keogh, Raymond J., "Multi-wire electrical interconnecting member having a multi-wire matrix of insulated wires mechanically terminated thereon", published 1979-11-27, assigned to Kollmorgen Technologies Corp.

185:

on a chassis. Typically, the chassis was a sheet metal frame or pan, sometimes with a wooden bottom. Components were attached to the chassis, usually by insulators when the connecting point on the chassis was metal, and then their leads were connected directly or with

352:

From the 1980s onward, small surface mount parts have been used increasingly instead of through-hole components; this has led to smaller boards for a given functionality and lower production costs, but with some additional difficulty in servicing faulty boards.

696:, determined by its width, thickness, and length, must be sufficiently low for the current the conductor will carry. Power and ground traces may need to be wider than signal traces. In a multi-layer board one entire layer may be mostly solid copper to act as a

2798:

2492:. The purpose of a breakout board is to "break out" the leads of a component on separate terminals so that manual connections to them can be made easily. Breakout boards are especially used for surface-mount components or any components with fine lead pitch.

257:

for use in World War II. Such fuzes required an electronic circuit that could withstand being fired from a gun, and could be produced in quantity. The

Centralab Division of Globe Union submitted a proposal which met the requirements: a ceramic plate would be

1397:

A PCB as a design on a computer (left) and realized as a board assembly populated with components (right). The board is double sided, with through-hole plating, green solder resist and a white legend. Both surface mount and through-hole components have been

840:(woven glass and epoxy), CEM-1 (cotton paper and epoxy), CEM-2 (cotton paper and epoxy), CEM-3 (non-woven glass and epoxy), CEM-4 (woven glass and epoxy), CEM-5 (woven glass and polyester). Thermal expansion is an important consideration especially with

2504:

Multiwire is a patented technique of interconnection which uses machine-routed insulated wires embedded in a non-conducting matrix (often plastic resin). It was used during the 1980s and 1990s. As of 2010, Multiwire was still available through

Hitachi.

266:, with ceramic disc capacitors and subminiature vacuum tubes soldered in place. The technique proved viable, and the resulting patent on the process, which was classified by the U.S. Army, was assigned to Globe Union. It was not until 1984 that the

2027:). The solder mask is what gives PCBs their characteristic green color, although it is also available in several other colors, such as red, blue, purple, yellow, black and white. One of the most common solder resists used today is called "LPI" (

1833:

Holes may be made conductive, by electroplating or inserting hollow metal eyelets, to connect board layers. Some conductive holes are intended for the insertion of through-hole-component leads. Others used to connect board layers, are called

373:

have meant that there are several new techniques in PCB creation. 3D printed electronics (PEs) can be utilized to print items layer by layer and subsequently the item can be printed with a liquid ink that contains electronic functionalities.

2764:

867:

electrical parameters, due to different resin/glass ratio at different areas of the weave pattern. Nonwoven reinforcements, or materials with low or no reinforcement, are more expensive but more suitable for some RF/analog applications.

2495:

Advanced PCBs may contain components embedded in the substrate, such as capacitors and integrated circuits, to reduce the amount of space taken up by components on the surface of the PCB while improving electrical characteristics.

863:) and a reinforcement (usually a woven, sometimes nonwoven, glass fibers, sometimes even paper), and in some cases a filler is added to the resin (e.g. ceramics; titanate ceramics can be used to increase the dielectric constant).

1870:

drilling, laser drilling, or by pre-drilling the individual sheets of the PCB before lamination, to produce holes that connect only some of the copper layers, rather than passing through the entire board. These holes are called

202:

Development of the methods used in modern printed circuit boards started early in the 20th century. In 1903, a German inventor, Albert Hanson, described flat foil conductors laminated to an insulating board, in multiple layers.

1817:. Coated tungsten carbide is used because board materials are abrasive. High-speed-steel bits would dull quickly, tearing the copper and ruining the board. Drilling is done by computer-controlled drilling machines, using a

761:

resin under pressure and heat to form an integral final piece of uniform thickness. They can be up to 4 by 8 feet (1.2 by 2.4 m) in width and length. Varying cloth weaves (threads per inch or cm), cloth thickness, and

356:

In the 1990s the use of multilayer surface boards became more frequent. As a result, size was further minimized and both flexible and rigid PCBs were incorporated in different devices. In 1995 PCB manufacturers began using

1763:

are done after the holes are drilled, then copper is electroplated to build up the thickness, the boards are screened, and plated with tin/lead. The tin/lead becomes the resist leaving the bare copper to be etched away.

2096:. A short is a connection between two points that should not be connected. An open is a missing connection between points that should be connected. For high-volume production, a fixture such as a "bed of nails" in a

2191:

packages. All through-hole components can be hand soldered, making them favored for prototyping where size, weight, and the use of the exact components that would be used in high volume production are not concerns.

1789:

a two-sided copper-clad laminate, etch the circuitry on both sides, then laminate to the top and bottom pre-preg and copper foil. It is then drilled, plated, and etched again to get traces on top and bottom layers.

4190:

1. “You Are HereDEQ Pollutants and

Toxicants Environmental Lead (Pb).” DEQ - How Does Lead Affect Our Environment?, Agency: Environmental Quality, www.michigan.gov/deq/0,4561,7-135-3307_29693_30031-90418--,00.html.

161:

layers would otherwise take up surface space between components. The rise in popularity of multilayer PCBs with more than two, and especially with more than four, copper planes was concurrent with the adoption of

2100:

makes contact with copper lands on the board. The fixture or adapter is a significant fixed cost and this method is only economical for high-volume or high-value production. For small or medium volume production

344:

techniques, this concept evolved into the standard printed circuit board fabrication process in use today. Soldering could be done automatically by passing the board over a ripple, or wave, of molten solder in a

2275:

test architecture provides a means to test interconnects between integrated circuits on a board without using physical test probes, by using circuitry in the ICs to employ the IC pins themselves as test probes.

414:

or other purposes. The tracks function as wires fixed in place, and are insulated from each other by air and the board substrate material. The surface of a PCB may have a coating that protects the copper from

2960:, Cole, Jr., Herbert S.; Sitnik-Nieters, Theresa A. & Wojnarowski, Robert J. et al., "Reworkable high density interconnect structure incorporating a release layer", issued 18 July 1995

2513:(which is worse when wires run parallel to each other—which almost never happens in Multiwire), though the cost is too high to compete with cheaper PCB technologies when large quantities are needed.

591:

used for making holes in printed circuit boards. While tungsten-carbide bits are very hard, they eventually wear out or break. Drilling is a considerable part of the cost of a through-hole printed circuit

1013:. Low water absorption (up to about 0.15%), good insulation properties, good arc resistance. Very common. Several grades with somewhat different properties are available. Typically rated to 130 °C.

2107:

testers are used where test probes are moved over the board by an XY drive to make contact with the copper lands. There is no need for a fixture and hence the fixed costs are much lower. The CAM system

1223:. Common thicknesses are 1/2 oz/ft (150 g/m), 1 oz/ft (300 g/m), 2 oz/ft (600 g/m), and 3 oz/ft (900 g/m). These work out to thicknesses of 17.05 μm (0.67

2305:, which is applied by dipping or spraying after the components have been soldered. The coat prevents corrosion and leakage currents or shorting due to condensation. The earliest conformal coats were

1442:

signal ground while providing DC power to the circuits mounted on the PCB. Signal interconnections are traced on signal planes. Signal planes can be on the outer as well as inner layers. For optimal

1204:

is a layer exceeding three ounces of copper per ft, or approximately 0.0042 inches (4.2 mils, 105 μm) thick. Heavy copper layers are used for high current or to help dissipate heat.

1106:, ("Teflon") - expensive, low dielectric loss, for high frequency applications, very low moisture absorption (0.01%), mechanically soft. Difficult to laminate, rarely used in multilayer applications.

4230:

2772:

2599:

Safety

Standard UL 796 covers component safety requirements for printed wiring boards for use as components in devices or appliances. Testing analyzes characteristics such as flammability, maximum

1382:

sheet, usually at two or four times the true size. Starting from the schematic diagram the component pin pads were laid out on the mylar and then traces were routed to connect the pads. Rub-on

1580:

uses a two or three-axis mechanical milling system to mill away the copper foil from the substrate. A PCB milling machine (referred to as a 'PCB Prototyper') operates in a similar way to a

1386:

of common component footprints increased efficiency. Traces were made with self-adhesive tape. Pre-printed non-reproducing grids on the mylar assisted in layout. The finished photomask was

1846:

When vias with a diameter smaller than 76.2 micrometers are required, drilling with mechanical bits is impossible because of high rates of wear and breakage. In this case, the vias may be

951:

high-frequency digital design; it increases the cost of the boards without a corresponding benefit. Signal degradation by loss tangent and dielectric constant can be easily assessed by an

2309:; modern conformal coats are usually dips of dilute solutions of silicone rubber, polyurethane, acrylic, or epoxy. Another technique for applying a conformal coating is for plastic to be

2255:

To facilitate these tests, PCBs may be designed with extra pads to make temporary connections. Sometimes these pads must be isolated with resistors. The in-circuit test may also exercise

3984:

3232:

2740:

1668:

Laser-printed resist: Laser-print onto toner transfer paper, heat-transfer with an iron or modified laminator onto bare laminate, soak in water bath, touch up with a marker, then etch.

1793:

machines can then add missing copper or remove excess copper using a laser, reducing the number of PCBs that have to be discarded. PCB tracks can have a width of just 10 micrometers.

1594:

laser plotter. The laser raster-scans the PCB and ablates (vaporizes) the paint where no resist is wanted. (Note: laser copper ablation is rarely used and is considered experimental.)

2596:

in electrical equipment. PCBs sold in such countries must therefore use lead-free manufacturing processes and lead-free solder, and attached components must themselves be compliant.

1067:

FR-1, like FR-2, typically specified to 105 °C, some grades rated to 130 °C. Room-temperature punchable. Similar to cardboard. Poor moisture resistance. Low arc resistance.

2280:

tool vendors provide various types of stimuli and sophisticated algorithms, not only to detect the failing nets, but also to isolate the faults to specific nets, devices, and pins.

665:

surface-mounting due to power requirements or mechanical limitations, or subject to mechanical stress which might damage the PCB (e.g. by lifting the copper off the board surface).

944:

Dielectric breakdown voltage determines the maximum voltage gradient the material can be subjected to before suffering a breakdown (conduction, or arcing, through the dielectric).

824:

There are quite a few different dielectrics that can be chosen to provide different insulating values depending on the requirements of the circuit. Some of these dielectrics are

4129:

1990:(ECM) is the growth of conductive metal filaments on or in a printed circuit board (PCB) under the influence of a DC voltage bias. Silver, zinc, and aluminum are known to grow

1109:

PTFE, ceramic filled - expensive, low dielectric loss, for high frequency applications. Varying ceramics/PTFE ratio allows adjusting dielectric constant and thermal expansion.

732:

of the printed circuit board conductors become significant circuit elements, usually undesired; conversely, they can be used as a deliberate part of the circuit design, as in

2175:

for SMT components or through-hole parts, but skilled technicians are able to hand-solder very tiny parts (for instance 0201 packages which are 0.02 in. by 0.01 in.) under a

976:, the same effect responsible for "popcorning" damage on wet packaging of electronic parts. Careful baking of the substrates may be required to dry them prior to soldering.

2873:

274:

for early key contributions to the development of printed components and conductors on a common insulating substrate. Rubinstein was honored in 1984 by his alma mater, the

1902:

of the high temperature decomposition products of bonding agent in the laminate system. Before the holes can be plated through, this smear must be removed by a chemical

2112:

the electrical tester to apply a voltage to each contact point as required and to check that this voltage appears on the appropriate contact points and only on these.

1452:

is determined using dielectric layer thickness, routing copper thickness and trace-width. Trace separation is also taken into account in case of differential signals.

744:, obviating the need for additional discrete components. High density interconnects (HDI) PCBs have tracks or vias with a width or diameter of under 152 micrometers.

278:, for his innovations in the technology of printed electronic circuits and the fabrication of capacitors. This invention also represents a step in the development of

1879:

when they connect two or more internal copper layers and no outer layers. Laser drilling machines can drill thousands of holes per second and can use either UV or CO

2509:

straight line from one location/pin to another. This led to very short design times (no complex algorithms to use even for high density designs) as well as reduced

349:

machine. However, the wires and holes are inefficient since drilling holes is expensive and consumes drill bits and the protruding wires are cut off and discarded.

423:

between traces or undesired electrical contact with stray bare wires. For its function in helping to prevent solder shorts, the coating is called solder resist or

1957:

1949:

290:

In 1948, the USA released the invention for commercial use. Printed circuits did not become commonplace in consumer electronics until the mid-1950s, after the

907:

903:

131:

onto or between sheet layers of a non-conductive substrate. Electrical components may be fixed to conductive pads on the outer layers, generally by means of

1737:

made consumer radio sets in the late 1960s using additive boards. The (semi-)additive process is commonly used for multi-layer boards as it facilitates the

3304:

676:(SMDs) are determined more by the chip itself than the package, with little price advantage over larger packages, and some wire-ended components, such as

534:

was used for this purpose, but today other, finer quality printing methods are usually used. Normally the legend does not affect the function of a PCBA.

215:

obtained a patent to flame-spray metal onto a board through a patterned mask. Charles Ducas in 1925 patented a method of electroplating circuit patterns.

2445:. The cordwood method of construction was used only rarely once PCBs became widespread, mainly in aerospace or other extremely high-density electronics.

926:

exposition to higher temperatures can cause failure of the plating, especially with thicker boards; thick boards therefore require a matrix with a high T

4261:

4177:

555:

before the layers are laminated together. Only the outer layers need be coated; the inner copper layers are protected by the adjacent substrate layers.

152:, both once popular but now rarely used. PCBs require additional design effort to lay out the circuit, but manufacturing and assembly can be automated.

3287:

3047:

1354:, and component information. The fabrication data is read into the CAM (Computer Aided Manufacturing) software. CAM performs the following functions:

1124:, a high-temperature polymer. Expensive, high-performance. Higher water absorption (0.4%). Can be used from cryogenic temperatures to over 260 °C.

999:. Common in consumer electronics with single-sided boards. Electrical properties inferior to FR-4. Poor arc resistance. Generally rated to 105 °C.

547:

significantly more routing options in the internal layers as compared to the two layer board, and often some portion of the internal layers is used as

2765:"Global Single Sided Printed Circuit Board Market - Growth, Future Prospects and Competitive Analysis and Forecast 2018 - 2023 - The Industry Herald"

310:

consumer radio receiver might be built with all its circuitry on one circuit board, but a TV set would probably contain one or more circuit boards.

267:

2938:, Abramson, Moe & Danko, Stanislaus F., "Process of assembling electrical circuits", published 1956-07-31, assigned to

2714:

660:

machine. Through-hole manufacture adds to board cost by requiring many holes to be drilled accurately, and it limits the available routing area for

3862:"A Triple Objective Function with a Chebychev Dynamic Pick-and-place Point Specification Approach to Optimise the Surface Mount Placement Machine"

1192:

Copper thickness of PCBs can be specified directly or as the weight of copper per area (in ounce per square foot) which is easier to measure. One

246:

invented the printed circuit as part of a radio set while working in the UK around 1936. In 1941 a multi-layer printed circuit was used in German

4315:

1085:

G-11, woven glass and epoxy - high resistance to solvents, high flexural strength retention at high temperatures. Typically rated to 170 °C.

3580:

1995:

reducing the percentage of tin. Reflow to melt solder or tin plate to relieve surface stress lowers whisker incidence. Another coating issue is

3247:

2313:

onto the PCB in a vacuum chamber. The chief disadvantage of conformal coatings is that servicing of the board is rendered extremely difficult.

1506:

5365:

2559:

2441:, this method allowed the highest possible component packing density; because of this, it was used by a number of computer vendors including

6833:

3743:

3732:

Publication IPC-TR-476A, "Electrochemical

Migration: Electrically Induced Failures in Printed Wiring Assemblies," Northbrook, IL, May 1997.

3644:

1522:

otherwise the board could not be mounted during assembly. Most assembly shops require a free area of at least 10 mm around the board.

212:

123:

layers: each of the conductive layers is designed with a pattern of traces, planes and other features (similar to wires on a flat surface)

1647:

Print onto transparent film and use as photo mask along with photo-sensitized boards, then etch. (Alternatively, use a film photoplotter.)

1112:

RF-35, fiberglass-reinforced ceramics-filled PTFE. Relatively less expensive, good mechanical properties, good high-frequency properties.

1920:

Proper plating or surface finish selection can be critical to process yield, the amount of rework, field failure rate, and reliability.

5812:

5597:

2051:, switch settings, test points and other indications helpful in assembling, testing, servicing, and sometimes using the circuit board.

1801:

1082:, woven glass and epoxy - high insulation resistance, low moisture absorption, very high bond strength. Typically rated to 130 °C.

5189:

4125:

3273:

1054:

785:, etc.) and therefore the characteristics of the laminate produced. Important characteristics are the level to which the laminate is

5635:

3945:

1972:

using ENIG. Another coating consideration is rapid diffusion of coating metal into tin solder. Tin forms intermetallics such as Cu

1493:

Several small printed circuit boards can be grouped together for processing as a panel. A panel consisting of a design duplicated

165:. However, multilayer PCBs make repair, analysis, and field modification of circuits much more difficult and usually impractical.

5537:

4830:

4287:

2884:

847:

FR-4 is by far the most common material used today. The board stock with unetched copper on it is called "copper-clad laminate".

551:

or power plane, to achieve better signal integrity, higher signaling frequencies, lower EMI, and better power supply decoupling.

2160:; once cooled and solidified, the solder holds the components in place permanently and electrically connects them to the board.

1584:, receiving commands from the host software that control the position of the milling head in the x, y, and (if relevant) z axis.

6522:

6494:

5640:

3716:

2363:

1474:

294:

process was developed by the United States Army. At around the same time in the UK work along similar lines was carried out by

3799:

3616:

1051:, in this form common in small form-factor consumer electronics or for flexible interconnects. Resistant to high temperatures.

6547:

4109:

3928:

3783:

3681:

3351:

3031:

3021:

2997:

499:). In informal usage, the term "printed circuit board" most commonly means "printed circuit assembly" (with components). The

207:

experimented with chemical methods of plating conductors onto linen paper in 1904. Arthur Berry in 1913 patented a print-and-

1937:(BGA) using tin-lead solder balls for connections losing their balls on bare copper traces or using lead-free solder paste.

947:

Tracking resistance determines how the material resists high voltage electrical discharges creeping over the board surface.

317:, and a PCB had holes drilled for each wire of each component. The component leads were then inserted through the holes and

135:, which both electrically connects and mechanically fastens the components to the board. Another manufacturing process adds

6398:

5472:

4747:

2666:

410:, pads for connections, vias to pass connections between layers of copper, and features such as solid conductive areas for

3060:

1600:, in which the copper may be removed directly by a CNC laser. Like PCB milling above, this is used mainly for prototyping.

479:. However, the term "printed wiring board" has fallen into disuse. A PCB populated with electronic components is called a

6552:

5831:

4528:

4308:

3823:

Ayob, M.; Kendall, G. (2008). "A Survey of

Surface Mount Device Placement Machine Optimisation: Machine Classification".

2939:

2861:

1364:

Compensation for deviations in the manufacturing processes (e.g. scaling to compensate for distortions during lamination)

306:

advertisements. Hallicrafters released its first "foto-etch" printed circuit product, a clock-radio, on 1 November 1952.

275:

1477:. Electronic design automation tools usually create clearances and connections in power and ground planes automatically.

6823:

6064:

5585:

5484:

1941:

4223:

3630:

2796:, Schoop, Max Ulrich, "Process and mechanism for the production of electric heaters", published 1918-02-19

6704:

6532:

6069:

5519:

5358:

4511:

4407:

3717:"Solder Joint Reliability of Gold Surface Finishes (ENIG, ENEPIG and DIG) for PWB Assembled with Lead Free SAC Alloy"

3502:

3475:

3448:

3403:

3257:

3092:

2385:

2028:

1953:

1212:

high power devices commonly use thicker copper; 35 μm is usual but also 140 and 400 μm can be encountered.

1179:

430:

The pattern to be etched into each copper layer of a PCB is called the "artwork". The etching is usually done using

4152:"The Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment Regulations 2012"

3744:"Reliability Issues of No-Clean Flux Technology with Lead-free Solder Alloy for High Density Printed Circuit Boards"

3598:

1886:

The hole walls for boards with two or more layers can be made conductive and then electroplated with copper to form

859:

The circuitboard substrates are usually dielectric composite materials. The composites contain a matrix (usually an

6792:

5893:

4651:

4378:

2067:

Ink jet printing is increasingly used. Ink jet can print variable data, unique to each PWB unit, such as text or a

937:. This constant is also dependent on frequency, usually decreasing with frequency. As this constant determines the

1930:

is applied, and then any exposed copper is coated with solder, nickel/gold, or some other anti-corrosion coating.

6828:

6818:

6813:

6180:

5531:

5467:

4699:

4498:

3168:

2633:

17:

3308:

6471:

6433:

6097:

5805:

4301:

2824:

2367:

1984:

Cu that dissolve into the Tin liquidus or solidus (at 50 °C), stripping surface coating or leaving voids.

1610:

1604:

1346:

A board designed in 1967; the sweeping curves in the traces are evidence of freehand design using adhesive tape

168:

The world market for bare PCBs exceeded $ 60.2 billion in 2014 and is estimated to reach $ 79 billion by 2024.

2857:

2690:

2199:

1760:

6613:

6590:

6320:

6310:

5657:

5525:

4250:

4185:

6694:

6282:

6190:

6102:

5878:

5863:

5351:

4730:

4482:

3108:

2215:

1443:

1410:

1073:

FR-5, woven fiberglass and epoxy, high strength at higher temperatures, typically specified to 170 °C.

914:

871:

810:

153:

4018:

6782:

6517:

6022:

5774:

5669:

4534:

4471:

2976:

Ostmann, Andreas; Schein, Friedrich-Leonhard; Dietterle, Michael; Kunz, Marc; Lang, Klaus-Dieter (2018).

182:

149:

6754:

6403:

5689:

5647:

5194:

4741:

2131:

In assembly the bare board is populated (or "stuffed") with electronic components to form a functional

1854:. Laser-drilled vias typically have an inferior surface finish inside the hole. These holes are called

1713:

after the subtractive method of the process, though there are also additive and semi-additive methods.

1709:

733:

3998:

3197:

2957:

2935:

2793:

1674:

and resist, non-washable marker, some other methods. Labor-intensive, only suitable for single boards.

6772:

6699:

6674:

6537:

6185:

5798:

5590:

5575:

5501:

5461:

4948:

4662:

4505:

4390:

3135:

Sood, B. and Pecht, M. 2011. Printed

Circuit Board Laminates. Wiley Encyclopedia of Composites. 1–11.

2534:

2230:

1149:

1024:

996:

411:

328:. In 1949, Moe Abramson and Stanislaus F. Danko of the United States Army Signal Corps developed the

299:

282:

technology, as not only wiring but also passive components were fabricated on the ceramic substrate.

271:

3837:

1033:- can be a standalone copper-clad foil or can be laminated to a thin stiffener, e.g. 50-130 μm

6623:

6456:

6049:

5918:

5602:

5507:

5495:

4957:

4815:

4667:

4523:

2442:

2144:

1945:

818:

778:

721:

709:

668:

608:

453:

162:

3048:"Advances in Optical Communications: Making optical printed circuit boards on an industrial scale"

1393:

6684:

6618:

6509:

6325:

5992:

5652:

5430:

5425:

4968:

4688:

4487:

3147:"A SURVEY AND TUTORIAL OF DIELECTRIC MATERIALS USED IN THE MANUFACTURE OF PRINTED CIRCUIT BOARDS"

2419:

2356:

2317:

2136:

1784:, visible as a bright copper-colored band running between the top and bottom layers of the board.

828:(Teflon), FR-4, FR-1, CEM-1 or CEM-3. Well known pre-preg materials used in the PCB industry are

825:

644:

322:

120:

3753:

3747:

3661:

2524:

Printed circuit boards have been used as an alternative to their typical use for electronic and

2222:

guidelines for PCB component placement, soldering, and inspection are commonly used to maintain

1446:

performance high frequency signals are routed in internal layers between power or ground planes.

336:. The patent they obtained in 1956 was assigned to the U.S. Army. With the development of board

144:

Printed circuit boards are used in nearly all electronic products. Alternatives to PCBs include

6749:

6580:

6461:

6228:

6218:

6213:

5746:

5543:

5137:

4704:

4569:

4545:

3861:

3832:

2569:

2525:

2168:

1505:

combines several different designs onto a single panel. The outer tooling strip often includes

1161:

921:

then exerts mechanical overload on the board components - e.g. the joints and the vias. Below T

637:

1621:

The method chosen depends on the number of boards to be produced and the required resolution.

1420:

Card dimensions and template are decided based on required circuitry and enclosure of the PCB.

332:

process in which component leads were inserted into a copper foil interconnection pattern and

6719:

6689:

6679:

6575:

6489:

6365:

6305:

6272:

6262:

6152:

6117:

6107:

6044:

5913:

5888:

5883:

5758:

5712:

5580:

5478:

5206:

5158:

4979:

4795:

4710:

4477:

3697:

2600:

2485:

2167:

techniques used to attach components to a PCB. High volume production is usually done with a

1933:

It is important to use solder compatible with both the PCB and the parts used. An example is

1351:

1118:, a ceramic. Hard, brittle, very expensive, very high performance, good thermal conductivity.

917:

the resin in the composite softens and significantly increases thermal expansion; exceeding T

693:

519:. "Card" is another widely used informal term for a "printed circuit assembly". For example,

116:

3895:

6479:

6451:

6423:

6418:

6247:

6223:

6175:

6160:

6142:

6132:

6127:

6089:

6039:

6034:

5951:

5897:

5684:

5679:

5662:

5382:

5280:

5024:

4919:

4693:

4586:

4440:

4401:

4332:

4324:

3333:

2325:

2289:

2097:

2048:

1991:

1569:

1402:

Modern PCBs are designed with dedicated layout software, generally in the following steps:

1048:

1030:

673:

444:

104:

60:

38:

1683:

968:

common circuit board materials. Absorbed moisture can also vaporize on heating, as during

181:

Before the development of printed circuit boards, electrical and electronic circuits were

8:

6744:

6669:

6585:

6570:

6335:

6122:

6079:

6074:

5971:

5961:

5933:

5731:

5674:

5513:

5435:

5410:

5374:

5000:

4908:

4800:

4636:

4613:

4151:

4037:"Printed Circuit Boards: The Layers' Functions for Electronic and Biomedical Engineering"

3702:

Printed Wiring Board

Project Report – Table of Contents, Design for the Environment (DfE)

2184:

2058:

1752:

1691:

1518:

1439:

1057:, a polyimide-fluoropolymer composite foil. Copper layer can delaminate during soldering.

934:

887:

844:(BGA) and naked die technologies, and glass fiber offers the best dimensional stability.

836:(woven glass and epoxy), FR-5 (woven glass and epoxy), FR-6 (matte glass and polyester),

790:

677:

531:

382:

packages. Some PCBs have optical waveguides, similar to optical fibers built on the PCB.

31:

3960:

777:

material, and the cloth to resin ratio determine the laminate's type designation (FR-4,

80:

to the other surface, and some electronic components mounted using through-hole mounting

6709:

6608:

6484:

6441:

6350:

6292:

6277:

6267:

6059:

5858:

5751:

5736:

5617:

5455:

5420:

5305:

5165:

4873:

4840:

4656:

4540:

4518:

4101:

4069:

4036:

3357:

3003:

2620:

2438:

2310:

2260:

2147:(SMT), the component is placed on the PCB so that the pins line up with the conductive

1898:

For multi-layer boards, those with three layers or more, drilling typically produces a

1748:

1703:

The two processing methods used to produce a double-sided PWB with plated-through holes

1671:

1430:

Layer stack of the PCB is decided, with one to tens of layers depending on complexity.

648:

629:

314:

279:

247:

195:

108:

3332:

Lienig, J.; Scheible, J. (2020). "§1.3.3: Physical Design of Printed Circuit Boards".

3123:

IPC-D-275: Design Standard for Rigid Printed Boards and Rigid Printed Board Assemblies

2841:

2741:"Global Printed Circuit Board (PCB) Market to Witness a CAGR of 3.1% during 2018-2024"

2516:

Corrections can be made to a Multiwire board layout more easily than to a PCB layout.

2259:

test features of some components. In-circuit test systems may also be used to program

870:

The substrates are characterized by several key parameters, chiefly thermomechanical (

636:, and capacitors. Through-hole mounting may be used for some large components such as

6729:

6659:

6638:

6600:

6408:

6375:

6355:

6054:

5966:

5840:

5707:

5300:

5221:

5112:

5064:

4893:

4820:

4782:

4105:

4092:

Brown, Mark; Rawtani, Jawahar; Patil, Dinesh (2004). "Appendix B - Troubleshooting".

4074:

3924:

3779:

3729:

3677:

3498:

3471:

3444:

3399:

3361:

3347:

3253:

3198:"Using Metal Core Printed Circuit Board (MCPCB) as a Solution for Thermal Management"

3088:

3027:

2993:

2820:

2603:, electrical tracking, heat deflection, and direct support of live electrical parts.

2593:

2329:

2302:

2234:

2211:

1835:

1781:

1742:

1699:

1614:

1590:

involves spraying black paint onto copper clad laminate, then placing the board into

1514:

1464:

1406:

895:

883:

770:

characteristics. Available standard laminate thickness are listed in ANSI/IPC-D-275.

741:

705:

680:

small-signal switch diodes, are actually significantly cheaper than SMD equivalents.

500:

136:

77:

3552:

3007:

6562:

6446:

6413:

6208:

6137:

6026:

6012:

6007:

5956:

5943:

5868:

5821:

5440:

5016:

4963:

4790:

4429:

4097:

4064:

4054:

3876:

3842:

3669:

3375:

3339:

2985:

2187:

may be used for delicate parts. Some SMT parts cannot be soldered by hand, such as

1814:

1734:

1463:

Components are placed. Thermal considerations and geometry are taken into account.

1387:

875:

802:

124:

4825:

3806:

3566:

1537:

reduces stress on the fragile circuits, improving the yield of defect-free units.

1438:

are decided. A power plane is the counterpart to a ground plane and behaves as an

1370:

Output of the digital tools (copper patterns, drill files, inspection, and others)

398:

A basic PCB consists of a flat sheet of insulating material and a layer of copper

222:'s 1936–1947 Electronic Circuit Making Equipment (ECME) that sprayed metal onto a

141:, drilled holes that allow electrical interconnections between conductive layers.

6633:

6527:

6499:

6393:

6345:

6330:

6315:

6170:

6165:

6112:

6002:

5976:

5928:

5873:

5630:

5625:

5607:

5570:

5565:

5490:

5450:

5293:

5226:

5079:

4810:

4720:

4564:

3946:"History of Electronic Packaging at APL: From the VT Fuze to the NEAR Spacecraft"

3538:

3492:

3465:

3438:

3393:

3146:

3082:

2248:

2241:

2223:

2188:

2015:

1934:

1777:

1756:

1718:

1155:

899:

841:

798:

737:

295:

4451:

3081:

Buschow, K.H., ed. (2001). "Electronic Packaging:Solder Mounting Technologies".

2925:"Topics & Trends of TV Trade." Television Digest 8:44 (1 November 1952), 10.

6739:

6643:

6542:

6388:

6360:

5560:

5268:

5049:

5039:

4805:

4608:

3880:

3846:

2977:

2573:

2468:

A breakout board can allow interconnection between two incompatible connectors.

2411:

2321:

2180:

1965:

1908:

1847:

1725:

1695:

PCBs in process of having copper pattern plated (note the blue dry film resist)

1563:

1547:

1510:

1449:

1079:

992:

938:

879:

837:

806:

786:

782:

657:

613:

520:

461:

346:

259:

254:

4184:. Department of Environmental Quality, State of Michigan. 2019. Archived from

3343:

2989:

2480:'s pins to be accessed easily while still allowing the card to be hot-swapped.

1325:

H/0 or H/H – denotes 0.5 oz/ft copper on one or both sides, respectively.

234:

6807:

6628:

5923:

5741:

5724:

5719:

5330:

5153:

5069:

4888:

4715:

4683:

4041:

3662:"Appendix F Sample Fabrication Sequence for a Standard Printed Circuit Board"

3631:"GTW5-UVF20 series Laser drilling machine Laser processing machines MELLASER"

2916:"Travel and Play with Motorola" LIFE magazine advertisement, 24 May 1954, 14.

2639:

2530:

2256:

2072:

1822:

1319:

1/0 – denotes 1 oz/ft copper one side, with no copper on the other side.

1246:

1228:

1224:

440:

420:

333:

219:

204:

3169:"Method for the Manufacture of an Aluminum Substrate PCB and its Advantages"

1328:

2/0 or 2/2 – denotes 2 oz/ft copper on one or both sides, respectively.

76:

computer board, a printed circuit board, showing the conductive traces, the

6724:

6383:

5211:

5199:

5087:

5054:

4883:

4868:

4435:

4078:

3218:

2103:

1961:

1470:

1431:

1383:

973:

891:

697:

661:

596:

576:

548:

457:

399:

157:

PCBs can also be made manually in small quantities, with reduced benefits.

2206:

After the board has been populated it may be tested in a variety of ways:

1772:

1707:

The process by which copper traces are applied to the surface is known as

1231:), 68.2 μm (2.68 thou), and 102.3 μm (4.02 thou), respectively.

1070:

FR-3, cotton paper impregnated with epoxy. Typically rated to 105 °C.

6714:

6340:

6252:

5253:

4995:

4944:

4850:

4835:

4618:

4580:

4200:

2907:"New Process Perfected for Radio Wiring." Chicago Tribune, 1 August 1952.

2472:

2418:

Cordwood construction can save significant space and was often used with

2284:

2172:

2024:

1969:

1927:

1576:

1555:

1481:

1435:

1197:

1010:

952:

860:

729:

431:

424:

370:

253:

Around 1943 the USA began to use the technology on a large scale to make

243:

73:

45:

4293:

4251:"Analog, RF and EMC Considerations in Printed Wiring Board (PWB) Design"

3666:

Linkages: Manufacturing Trends in Electronics Interconnection Technology

3490:

2061:

epoxy ink was the established method, resulting in the alternative name.

1999:, the transformation of tin to a powdery allotrope at low temperature.

571:

467:

When a PCB has no components installed, it is less ambiguously called a

44:"PC board" redirects here. For the mainboard of personal computers, see

6734:

6664:

6257:

5997:

5853:

5779:

5445:

5390:

5325:

5315:

5248:

5122:

5092:

5059:

5034:

5029:

5006:

4878:

4858:

4736:

4598:

4575:

4461:

4363:

4358:

4353:

4059:

2628:

2563:

2370: in this section. Unsourced material may be challenged and removed.

2176:

2125:

1687:

PCB copper electroplating line in the process of pattern plating copper

1531:

1453:

1390:

reproduced onto a photoresist coating on the blank copper-clad boards.

1006:

964:

767:

725:

717:

621:

601:

583:

527:

456:

is the most common insulating substrate. Another substrate material is

436:

337:

128:

112:

5343:

4094:

Practical Troubleshooting of Electrical Equipment and Control Circuits

2398:

2135:(PCA), sometimes called a "printed circuit board assembly" (PCBA). In

6239:

6200:

5405:

5288:

5132:

5127:

5117:

5044:

4924:

4758:

4753:

4678:

4603:

2510:

2454:

2164:

2157:

2139:, the component leads are inserted in holes surrounded by conductive

2023:

Areas that should not be soldered may be covered with solder resist (

1968:, placed along one edge of some boards, are often nickel-plated then

1890:. These holes electrically connect the conducting layers of the PCB.

1810:

1457:

1424:

1375:

1121:

1044:

969:

758:

713:

701:

653:

588:

512:

416:

379:

226:

plastic board. The ECME could produce three radio boards per minute.

191:

187:

145:

132:

2345:

2064:

Liquid photo imaging is a more accurate method than screen printing.

2047:) is often printed on one or both sides of the PCB. It contains the

218:

Predating the printed circuit invention, and similar in spirit, was

6300:

5790:

5400:

5395:

5310:

5258:

5238:

5216:

5102:

5097:

4985:

4974:

4903:

4673:

3673:

2982:

2018 7th Electronic System-Integration Technology Conference (ESTC)

2645:

2614:

2427:

2068:

1996:

1342:

1016:

757:

Laminates are manufactured by curing layers of cloth or paper with

633:

358:

263:

223:

3518:

390:

5170:

5107:

4929:

4914:

4768:

4725:

4373:

3440:

Printed circuit boards: design, fabrication, assembly and testing

2589:

2547:

2477:

2464:

2244:, where physical measurements (for example, voltage) can be done.

2007:

1875:

when they connect an internal copper layer to an outer layer, or

1738:

1581:

1115:

575:

Through-hole devices mounted on the circuit board of a mid-1980s

341:

208:

51:"Panelization" redirects here. For the page layout strategy, see

3144:

2251:, just checking if the PCB does what it had been designed to do.

563:

5243:

4934:

4898:

4863:

4423:

4395:

4368:

4343:

4282:

2978:"High Density Interconnect Processes for Panel Level Packaging"

2577:

2431:

2324:

during transport. When handling these boards, the user must be

1312:

1040:

1036:

960:

766:

percentage are used to achieve the desired final thickness and

689:

526:

A PCB may be printed with a legend identifying the components,

403:

318:

101:

68:

5320:

5231:

4990:

4763:

4556:

4418:

4413:

3896:"SMTA TechScan Compendium: 0201 Design, Assembly and Process"

3553:"Printing of 3d structures by laser-induced forward transfer"

2667:"What Is a Printed Circuit Board (PCB)? - Technical Articles"

2581:

2426:, missile guidance, and telemetry systems) and in high-speed

2219:

1851:

1379:

1216:

1208:

1193:

774:

763:

625:

4224:"PCB Fabrication Data - Design to Fabrication Data Transfer"

2406:

1350:

Manufacturing starts from the fabrication data generated by

720:

with carefully controlled dimensions to assure a consistent

361:

technology to produce High-Density Interconnect (HDI) PCBs.

321:

to the copper PCB traces. This method of assembly is called

5263:

4646:

4592:

4493:

4446:

4384:

4257:

4050:

3233:"Pyralux® Flexible Circuit Materials - DuPont - DuPont USA"

2880:

2585:

2423:

2277:

2272:

2268:

1825:

that describes the location and size of each drilled hole.

1103:

1002:

988:

833:

829:

450:

402:, laminated to the substrate. Chemical etching divides the

262:

with metallic paint for conductors and carbon material for

52:

3491:

Riley, Frank; Electronic Packaging and Production (2013).

2975:

2120:

1923:

PCBs may be plated with solder, tin, or gold over nickel.

1215:

In the US, copper foil thickness is specified in units of

2306:

1632:

Silk screen printing – Used for PCBs with bigger features

1591:

1219:

per square foot (oz/ft), commonly referred to simply as

832:(phenolic cotton paper), FR-3 (cotton paper and epoxy),

616:: the component side (left) and the printed side (right)

268:

Institute of Electrical and Electronics Engineers (IEEE)

3274:"A High Performance, Economical RF/Microwave Substrate"

3219:"Applications | UBE Heat Resistant Polyimide Materials"

1958:

electroless nickel electroless palladium immersion gold

1559:

uses etch-resistant inks to create the protective mask.

3617:"Laser drilling machines GTW5 series (English) Videos"

2422:

in applications where space was at a premium (such as

1926:

After PCBs are etched and then rinsed with water, the

1759:. For PTH (plated-through holes), additional steps of

1635:

Photoengraving – Used when finer features are required

3335:

Fundamentals of Layout Design for Electronic Circuits

724:. In radio-frequency and fast switching circuits the

3581:"Laser drilling high-density printed circuit boards"

2610:

2301:

PCBs intended for extreme environments often have a

1613:

to remove a metal from a substrate submerged into a

1374:

Initially PCBs were designed manually by creating a

3645:"Considerations for Selecting a PCB Surface Finish"

3567:"System producing a conductive path on a substrate"

2866:

2715:"World PCB Production in 2014 Estimated at $ 60.2B"

1858:and can have diameters as small as 10 micrometers.

995:or phenolic cotton paper, paper impregnated with a

821:(how much the thickness changes with temperature).

4035:Perdigones, Francisco; Quero, José Manuel (2022).

3395:Complete PCB Design Using OrCad Capture and Layout

3145:By Lee W. Ritchey, Speeding Edge (November 1999).

2171:and bulk wave soldering for through-hole parts or

2019:A PCB with green solder mask and yellow silkscreen

688:Each trace consists of a flat, narrow part of the

27:Board to support and connect electronic components

4182:Pollutants and Toxicants: Environmental Lead (Pb)

4091:

3084:Encyclopedia of Materials: Science and Technology

1568:be used instead of a photomask. This is known as

6805:

3749:38th International Symposium on Microelectronics

3741:

3599:"Non-Traditional Methods For Making Small Holes"

2320:sensitive, and therefore they must be placed in

2084:Boards with no components installed are usually

1322:1/1 – denotes 1 oz/ft copper on both sides.

406:into separate conducting lines called tracks or

313:Originally, every electronic component had wire

4034:

3997:

3305:"Printed Circuit Board Design Flow Methodology"

2484:A minimal PCB for a single component, used for

2287:and replace failed components, a task known as

2011:A PCB with red solder mask and white silkscreen

1809:Holes through a PCB are typically drilled with

1776:Cut through a SDRAM-module, a multi-layer PCB (

1460:or dual stripline can be used to route signals.

600:Surface mount components, including resistors,

394:An example of hand-drawn etched traces on a PCB

3698:"Production Methods and Materials 3.1 General"

3421:Liquid Photoresists for Thermal Direct Imaging

3331:

3327:

3325:

2846:. Washington DC: National Bureau of Standards.

2642:- solder-free circuit board manufacture method

5830:Note: This template roughly follows the 2012

5806:

5359:

4309:

4126:"EURLex – 02011L0065-20140129 – EN – EUR-Lex"

3714:

3467:Printed Circuit Boards: Design and Technology

3432:

3430:

2934:

2560:Restriction of Hazardous Substances Directive

2143:; the holes keep the components in place. In

2054:There are three methods to print the legend:

933:The materials used determine the substrate's

3778:. McGraw–Hill Professional. pp. 45–19.

3742:Zhan, S.; Azarian, M. H.; Pecht, M. (2005).

2002:

1741:-through of the holes to produce conductive

3859:

3822:

3470:. Tata McGraw-Hill Education. p. 298.

3322:

3061:6 Reasons Why Choose Printed Circuit Boards

2817:Electronic materials and processes handbook

2296:

2283:When boards fail the test, technicians may

1200:is 1.344 mils or 34 micrometers thickness.

854:

238:Proximity fuze Mark 53 production line 1944

211:method in the UK, and in the United States

5813:

5799:

5366:

5352:

4316:

4302:

3427:

3419:Taff, Itshak; Benron, Hai (October 1999).

3418:

3412:

2810:

2808:

1484:, a drill file, and a pick-and-place file.

4323:

4221:

4068:

4058:

3836:

3805:. Coates Circuit Products. Archived from

2386:Learn how and when to remove this message

2088:for "shorts" and "opens". This is called

1180:Learn how and when to remove this message

503:preferred term for an assembled board is

4016:

3869:European Journal of Operational Research

3825:European Journal of Operational Research

3463:

3436:

2839:

2471:

2463:

2405:

2397:

2335:

2119:

2014:

2006:

1861:

1800:

1771:

1698:

1690:

1682:

1392:

1341:

683:

607:

595:

582:

570:

562:

389:

285:

233:

127:from one or more sheet layers of copper

67:

59:

5538:Application-specific integrated circuit

5373:

4248:

4178:"How Does Lead Affect Our Environment?"

3391:

3080:

3074:

2805:

14:

6806:

6523:Knowledge representation and reasoning

3943:

3901:. Surface Mount Technology Association

3773:

3668:. National Academy of Sciences. 2005.

3245:

2874:"IEEE CLEDO BRUNETTI AWARD RECIPIENTS"

2814:

2792:

2537:(PCR), and fuel cells, to name a few.

2034:

1915:

1480:Fabrication data consists of a set of

6548:Philosophy of artificial intelligence

5794:

5347:

4297:

2691:"Printed Circuit Board – An Overview"

692:foil that remains after etching. Its

558:

64:Printed circuit board of a DVD player

5874:Energy consumption (Green computing)

5820:

5473:Three-dimensional integrated circuit

4748:Three-dimensional integrated circuit

3800:"liquid photoimageable solder masks"

3443:. Tata-McGraw Hill. pp. 373–8.

3195:

3166:

3109:"Why Use High Density Interconnect?"

2840:Brunetti, Cledo (22 November 1948).

2738:

2584:), legislation restricts the use of

2368:adding citations to reliable sources

2339:

1540:

1423:The positions of the components and

1154:In particular, it has problems with

1132:

979:

700:for shielding and power return. For

647:, mounting electronic components by

6834:Printed circuit board manufacturing

6553:Distributed artificial intelligence

5832:ACM Computing Classification System

4529:Programmable unijunction transistor

4222:Tavernier, Karel (September 2015).

2940:Secretary of the United States Army

2499:

2267:being the Joint Test Action Group (

2226:in this stage of PCB manufacturing.

1724:In additive methods the pattern is

1546:is also used in the manufacture of

1128:

530:, or identifying text. Originally,

24:

6065:Integrated development environment

5485:Erasable programmable logic device

4430:Multi-gate field-effect transistor

4215:

3953:Johns Hopkins APL Technical Digest

3893:

3752:. pp. 367–375. Archived from

3715:Milad, George; Gudeczauskas, Don.

3704:. Environmental Protection Agency.

2819:. McGraw-Hill. pp. 7.3, 7.4.

2459:

2410:Cordwood construction was used in

2079:

1942:organic solderability preservative

1063:Less-often encountered materials:

963:has very low absorption of 0.01%.