106:

98:

17:

207:

PPAs, as any thermoplastic, are theoretically fully recyclable by remelting, and as a condensation polymer by depolymerization. Commercial recycling requires the cost of logistics and cleaning and processing to be lower than the cost of virgin polymer, which is not always the case. The PPA waste

177:

Polyphthalamide based resins are injection molded into parts that are used in a wide variety of applications. Automotive uses include fuel and coolant lines, pump wear rings, motor bobbin parts, fuel line connectors, water heater manifolds fuel modules, fuel cut-off valves, thermostat housing, air

66:

168:

While there have been large investigations into PA/polyolefin blends, little has been published about the properties of PPA/ polyolefin blends. This may be due to the relatively high processing temperatures needed for PPA based resins compared to the temperature stability of polyolefins.

148:

v amorphous polymers are described elsewhere in detail. Briefly, crystallinity helps with chemical resistance and mechanical properties above the glass transition temperature (but below the melting point). Amorphous polymers are good in warpage and transparency.

241:

Solvay under the brand Amodel. Initially commercialized by Amoco, today this brand is owned by Solvay. According to

Nevicolor, all current Amodel grades are based on a single polymer, A1000 but there are grades based on 66/6T copolymer and others on 66/6T/6I

86:. PA6T homopolymer melts at 371 °C, which renders it intractable. To make usable polymers, it is necessary to lower the melting point, which can be achieved practically using either a longer diamine (with 9-12 carbon atoms) or by copolymerizing 6I.

194:

connectors, LED mounts and cable/wire protection. Other applications for PPA based resins include gas pipes and supply lines for the oil industry (due to their ability to withstand high pressures), Medical applications such as tubing for

164:

The addition of aliphatic polyamides to PPAs (PPA/PA blend) lowers the melting point and glass transition temperature, which potentially makes these polyphthalamide blends easier to process when compared to higher melting/softening PPAs.

61:

PPA based resins are molded into parts to replace metals in applications requiring high temperature resistance such as automotive powertrain components, the housing for high temperature electrical connectors and many other uses.

155:

Formulations with specific properties have been developed. For example, resins with ability to bond directly to elastomers to give plastic-rubber composites, and with approval for direct contact with drinking water and food.

208:

that produces energy can be recovered at incineration plants. The best recovery options depend on many conditions such as local legislation, plastic part design, access to sorting facilities, and recycling costs.

112:

If more than 55% of the acid part of a PPA is made out of IPA, then the copolymer is amorphous. Molar masses for PPAs made with direct polycondensation techniques range between 12,000 and 16,000 g/mol.

58:(IPA) acids. The substitution of aliphatic diacids by aromatic diacids in the polymer backbone increases the melting point, glass transition temperature, chemical resistance and stiffness.

169:

PPA/PA/polyolefin blends exhibit a good balance of ductility, strength, stiffness, impact, and thermal performance, indicating that these types of materials should have commercial utility.

144:

The glass transition temperature of PPA increases as the amount of TPA increases. If more than 55% of the acid part of a PPA is made out of IPA, then the copolymer is amorphous. The

199:, in personal care, for toothbrush bristles as well as hairbrushes. PPAs are also used in sports equipment, valve bodies for showers, bushings and bearing pads in aircraft engines

304:

Cousin, Thibault; Galy, Jocelyne; Dupuy, Jérôme (2012). "Molecular modelling of polyphthalamides thermal properties: Comparison between modelling and experimental results".

777:

519:

152:

Like aliphatic nylons, PPAs can be (in fact are almost invariably) modified with reinforcing agents such as glass fibers, tougheners and/or stabilizers.

50:) family defined as when 55% or more moles of the carboxylic acid portion of the repeating unit in the polymer chain is composed of a combination of

145:

620:

229:

EMS under the brand

Grivory. GV grades are based on PA66/6I/6T. HT1 grades on 6T/6I, HT2 grades on 6T/66 and HT3/HT3-CO on copolymers of 10T

494:

220:

BASF under the brand

Ultramid Advanced N (PA9T), Ultramid Advanced T1000 (PA6T/6I), Ultramid Advanced T2000 (PA6T/66), Ultramid T KR (PA6T/6).

664:

382:

594:

648:

365:

340:

717:

784:

761:

564:"Characterization and properties of polyphthalamide/polyamide blends and polyphthalamide/polyamide/polyolefin blends"

550:

439:

464:

413:

105:

97:

809:

383:"High Performance Polyamides Fulfill Demanding Requirements for Automotive Thermal Management Components"

831:

863:

753:

183:

745:

692:

563:

649:"PPAssion for perfection The Ultramid® Advanced portfolio: We provide the PPA you need..."

8:

858:

89:

Three copolymers have found commercial success: PA 6T/66, PA 6T/"DT" and PA6T/6I (with

83:

757:

746:

361:

336:

51:

235:

Kuraray under the brand

Genestar with 9T copolymer (used two isomers of C9 diamine).

575:

313:

271:

267:

217:

Arkema under the brand Rilsan HT polymers based on decanediamine, presumably 10T/X.

90:

55:

317:

275:

39:

551:

http://www.vestamid.com/product/vestamid/en/products-services/pages/default.aspx

852:

36:

258:

Care should be taken not to confuse this with 'PP&A', which stands for

232:

Evonik under the brand

Vestamid HT 'plus' with 6T/X and 10T/X polymers.

579:

65:

263:

259:

196:

187:

43:

595:"DuPont's Zytel HTN selected for use in USB Type-C 3.1 connectors"

182:

headlights. In electronics, the high melting point of PPA allows

79:

16:

191:

47:

520:"Practical Guide to High Performance Engineering Plastics"

109:

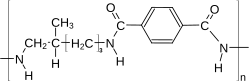

Polyphthalamide TPA/methylpentanediamine (DT) repeat unit

101:

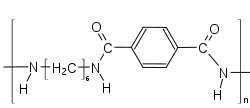

Polyphthalamide TPA/hexamethylenediamine (6T) repeat unit

223:

DuPont under the brand Zytel HTN with 6T/66 and 6T/MPDMT.

179:

748:

Practical Guide to High

Performance Engineering Plastics

186:

parts molded from PPA to be assembled using a lead-free

380:

128:

higher strength and stiffness at elevated temperatures

121:

Compared to aliphatic polyamides, PPAs offer improved

226:

DSM under the brand ForTii with copolymers of PA 4T.

850:

333:Handbook of plastics, elastomers, and composites

545:

543:

381:Glass; Walter; Kozielski, Gary; Martens, Marv.

303:

540:

270:- all of which are used to make fibres. See

659:

657:

299:

297:

295:

293:

489:

487:

485:

408:

406:

159:

69:Formulated PPA granules ready for molding

665:"HPPA Genestar PA9T - Auto applications"

238:Mitsui under the brand Arlen with 6T/66

64:

15:

783:. Nevicolor. p. 13. Archived from

654:

592:

290:

211:

851:

482:

403:

330:

146:properties of semicrystalline polymers

593:Zistler, Andrew (December 11, 2015).

561:

355:

202:

13:

140:sensitivity to moisture absorption

14:

875:

190:process. PPAs are also used for

20:Repeating unit of polyphthalamide

104:

96:

824:

802:

770:

752:. SmithersRapra. 2011. p.

738:

710:

685:

641:

613:

586:

555:

512:

335:. McGraw-Hill. pp. 51–52.

172:

457:

432:

374:

360:. Munich: Hanser. p. 71.

349:

324:

281:

252:

1:

356:Kohan, Melvin I, ed. (1995).

318:10.1016/j.polymer.2012.05.051

276:10.1016/j.jhazmat.2019.02.067

246:

116:

178:coolers, coolant pumps, and

131:creep and fatigue resistance

73:

7:

621:"Introduction to Rilsan HT"

331:Harper, Charles A. (2002).

10:

880:

33:High Performance Polyamide

287:ASTM standard D 5336 -15a

832:"Amodel A1133 datasheet"

358:Nylon Plastics Handbook

810:"Technical data sheet"

160:Polyphthalamide blends

70:

21:

778:"Amodel design guide"

568:J Vinyl Addit Technol

184:surface mount devices

137:dimensional stability

68:

19:

562:Desio, G.P. (1996).

212:Commercial suppliers

549:Evonik Industries,

125:chemical resistance

718:"Vestamid HT Plus"

418:www.emsgrivory.com

71:

22:

599:connectortips.com

580:10.1002/vnl.10131

367:978-1-56990-189-2

342:978-0-07-138476-6

268:acrylate polymers

35:) is a subset of

871:

844:

843:

841:

839:

828:

822:

821:

819:

817:

806:

800:

799:

797:

795:

789:

782:

774:

768:

767:

751:

742:

736:

735:

733:

731:

722:

714:

708:

707:

705:

703:

689:

683:

682:

680:

678:

669:

661:

652:

651:

645:

639:

638:

636:

634:

625:

617:

611:

610:

608:

606:

590:

584:

583:

559:

553:

547:

538:

537:

535:

533:

524:

516:

510:

509:

507:

505:

491:

480:

479:

477:

475:

461:

455:

454:

452:

450:

436:

430:

429:

427:

425:

410:

401:

400:

398:

396:

387:

378:

372:

371:

353:

347:

346:

328:

322:

321:

301:

288:

285:

279:

256:

203:Lifecycle impact

108:

100:

91:Isophthalic acid

40:synthetic resins

879:

878:

874:

873:

872:

870:

869:

868:

849:

848:

847:

837:

835:

830:

829:

825:

815:

813:

808:

807:

803:

793:

791:

787:

780:

776:

775:

771:

764:

744:

743:

739:

729:

727:

720:

716:

715:

711:

701:

699:

693:"Stanyl ForTii"

691:

690:

686:

676:

674:

667:

663:

662:

655:

647:

646:

642:

632:

630:

623:

619:

618:

614:

604:

602:

591:

587:

560:

556:

548:

541:

531:

529:

522:

518:

517:

513:

503:

501:

493:

492:

483:

473:

471:

463:

462:

458:

448:

446:

438:

437:

433:

423:

421:

412:

411:

404:

394:

392:

385:

379:

375:

368:

354:

350:

343:

329:

325:

312:(15): 3203–10.

302:

291:

286:

282:

257:

253:

249:

214:

205:

175:

162:

119:

76:

25:Polyphthalamide

12:

11:

5:

877:

867:

866:

864:Thermoplastics

861:

846:

845:

823:

801:

790:on 25 May 2015

769:

762:

737:

709:

684:

653:

640:

612:

585:

574:(3): 229–234.

554:

539:

511:

481:

456:

431:

402:

373:

366:

348:

341:

323:

289:

280:

250:

248:

245:

244:

243:

239:

236:

233:

230:

227:

224:

221:

218:

213:

210:

204:

201:

174:

171:

161:

158:

142:

141:

138:

135:

132:

129:

126:

118:

115:

75:

72:

9:

6:

4:

3:

2:

876:

865:

862:

860:

857:

856:

854:

833:

827:

811:

805:

786:

779:

773:

765:

763:9781847355775

759:

755:

750:

749:

741:

726:

719:

713:

698:

694:

688:

673:

666:

660:

658:

650:

644:

629:

622:

616:

600:

596:

589:

581:

577:

573:

569:

565:

558:

552:

546:

544:

528:

527:SmithersRapra

521:

515:

500:

496:

490:

488:

486:

470:

466:

460:

445:

441:

435:

419:

415:

409:

407:

391:

384:

377:

369:

363:

359:

352:

344:

338:

334:

327:

319:

315:

311:

307:

300:

298:

296:

294:

284:

277:

273:

269:

265:

261:

255:

251:

240:

237:

234:

231:

228:

225:

222:

219:

216:

215:

209:

200:

198:

193:

189:

185:

181:

170:

166:

157:

153:

150:

147:

139:

136:

133:

130:

127:

124:

123:

122:

114:

110:

107:

102:

99:

94:

92:

87:

85:

81:

67:

63:

59:

57:

53:

49:

45:

41:

38:

37:thermoplastic

34:

30:

26:

18:

836:. Retrieved

826:

814:. Retrieved

804:

792:. Retrieved

785:the original

772:

747:

740:

728:. Retrieved

724:

712:

700:. Retrieved

696:

687:

675:. Retrieved

671:

643:

631:. Retrieved

627:

615:

603:. Retrieved

598:

588:

571:

567:

557:

530:. Retrieved

526:

514:

502:. Retrieved

498:

472:. Retrieved

468:

465:"Grivory HT"

459:

447:. Retrieved

443:

440:"Amodel PPA"

434:

422:. Retrieved

420:. EMS Chimie

417:

414:"Grivory HT"

393:. Retrieved

389:

376:

357:

351:

332:

326:

309:

305:

283:

254:

206:

176:

173:Applications

167:

163:

154:

151:

143:

120:

111:

103:

95:

88:

82:in PPAs are

77:

60:

52:terephthalic

32:

28:

24:

23:

495:"Zytel HTN"

469:EMS Grivory

56:isophthalic

859:Polyamides

853:Categories

601:. EE World

247:References

242:copolymer.

117:Properties

54:(TPA) and

264:polyamide

260:polyester

197:catheters

188:soldering

84:aliphatic

74:Structure

44:polyamide

730:26 March

702:26 March

677:26 March

633:26 March

605:26 March

532:26 March

504:26 March

474:26 March

449:26 March

395:26 March

80:diamines

672:Kuraray

306:Polymer

134:warpage

42:in the

838:25 May

834:. IDES

816:25 May

812:. IDES

794:24 Jan

760:

725:Evonik

628:Arkema

499:DuPont

444:Solvay

424:25 May

390:DuPont

364:

339:

27:(aka.

788:(PDF)

781:(PDF)

721:(PDF)

668:(PDF)

624:(PDF)

523:(PDF)

386:(PDF)

192:USB-C

48:nylon

840:2015

818:2015

796:2022

758:ISBN

732:2016

704:2016

679:2016

635:2016

607:2016

534:2016

506:2016

476:2016

451:2016

426:2015

397:2016

362:ISBN

337:ISBN

266:and

78:The

697:DSM

576:doi

314:doi

272:doi

180:LED

93:).

29:PPA

855::

756:.

754:50

723:.

695:.

670:.

656:^

626:.

597:.

570:.

566:.

542:^

525:.

497:.

484:^

467:.

442:.

416:.

405:^

388:.

310:53

308:.

292:^

262:,

31:,

842:.

820:.

798:.

766:.

734:.

706:.

681:.

637:.

609:.

582:.

578::

572:2

536:.

508:.

478:.

453:.

428:.

399:.

370:.

345:.

320:.

316::

278:.

274::

46:(

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.