125:

200:

260:

of nanometers, comparable to or smaller than the lamellar crystal thickness or the radius of gyration, nucleation and growth can be dramatically affected. As an example, when a polymer crystallizes in a confined ultrathin layer, the isotropic spherulitic organization of lamellar crystals is hampered and confinement can produce unique lamellar crystal orientations. Sometimes the chain alignment is parallel to the layer plane and the crystals are organized as ‘‘on-edge’’ lamellae. In other cases, "in-plane" lamellae with chain orientation perpendicular to the layers are observed.

48:

243:

occur via solvent evaporation, induces interaction between molecular chains and a possible crystallization as in the crystallization from the melt. Crystallization from solution may result in the highest degree of polymer crystallinity. For example, highly linear polyethylene can form platelet-like single crystals with a thickness on the order 10–20 nm when crystallized from a dilute solution. The crystal shape can be more complex for other polymers, including hollow pyramids, spirals and multilayer dendritic structures.

629:

stress or shearing. Evidence suggests that cavitation also impacts the onset of yielding. The voids are associated with the breaking of the amorphous phase. The strength of the crystalline phase determines the importance of cavitation in yielding. If the crystalline structures are weak, they deform easily resulting in yielding. Semi-crystalline polymers with strong crystalline regions resist deformation and cavitation, the formation of voids in the amorphous phase, drives yielding.

84:

92:

61:

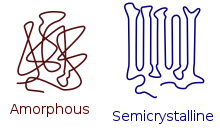

typical size of the order 1 micrometer. Although it would be energetically favorable for the polymer chains to align parallel, such alignment is hindered by the entanglement. Therefore, within the ordered regions, the polymer chains are both aligned and folded. Those regions are therefore neither crystalline nor amorphous and are classified as semicrystalline. Examples of semi-crystalline polymers are linear

191:

quasi-spherical aggregates called spherulites. Spherulites have a size between about 1 and 100 micrometers and form a large variety of colored patterns (see, e.g. front images) when observed between crossed polarizers in an optical microscope, which often include the "maltese cross" pattern and other polarization phenomena caused by molecular alignment within the individual lamellae of a spherulite.

149:

279:

polymerization happens in the crystalline lattice without the aid of solvents or reagents, it comes under the domain of green chemistry. Also, the topochemical polymerizations are mostly atom economical reactions. The product can be obtained without any further purifications. It can achieve unique products which cannot be synthesized through conventional methods.

617:

load. When a tensile stress is applied the semi-crystalline polymer first deforms elastically. While the crystalline regions remain unaffected by the applied stress, the molecular chains of the amorphous phase stretch. Then yielding, which signifies the onset of plastic deformation of the crystalline regions, occurs.

613:

and more thermally stable, but also more brittle material, whereas the amorphous regions provide certain elasticity and impact resistance. Another characteristic feature of semicrystalline polymers is strong anisotropy of their mechanical properties along the direction of molecular alignment and perpendicular to it.

625:

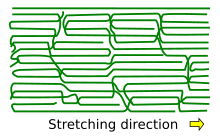

significantly following neck propagation. Mechanical anisotropy increases and the elastic modulus varies along different directions, with a high modulus observed in the draw direction. Drawn semi-crystalline polymers are the strongest polymeric materials due to the stress-induced ordering of the molecular chains.

596:

Below their glass transition temperature, amorphous polymers are usually hard and brittle because of the low mobility of their molecules. Increasing the temperature induces molecular motion resulting in the typical rubber-elastic properties. A constant force applied to a polymer at temperatures above

553:

Infrared absorption or reflection spectra from crystalline polymers contain additional peaks which are absent in amorphous materials with the same composition. These signals may originate from deformation vibrations of the regular arrangement of molecular chains. From the analysis of these bands, the

620:

The molecular mechanism for semi-crystalline yielding involves the deformation of crystalline regions of the material via dislocation motion. Dislocations result in coarse or fine slips in the polymer and lead to crystalline fragmentation and yielding. Fine slip is defined as a small amount of slip

612:

Relatively strong intermolecular forces in semicrystalline polymers prevent softening even above the glass transition temperature. Their elastic modulus changes significantly only at high (melting) temperature. It also depends on the degree of crystallinity: higher crystallinity results in a harder

287:

The fraction of the ordered molecules in polymer is characterized by the degree of crystallinity, which typically ranges between 10% and 80%. Higher values are only achieved in materials having small molecules, which are usually brittle, or in samples stored for long time at temperatures just under

259:

When polymers crystallize from an isotropic, bulk of melt or concentrated solution, the crystalline lamellae (10 to 20 nm in thickness) are typically organized into a spherulitic morphology as illustrated above. However, when polymer chains are confined in a space with dimensions of a few tens

246:

A very different process is precipitation; it uses a solvent which dissolves individual monomers but not the resulting polymer. When a certain degree of polymerization is reached, the polymerized and partially crystallized product precipitates out of the solution. The rate of crystallization can be

242:

Polymers can also be crystallized from a solution or upon evaporation of a solvent. This process depends on the degree of dilution: in dilute solutions, the molecular chains have no connection with each other and exist as a separate polymer coils in the solution. Increase in concentration which can

640:

materials meaning that under applied stress, their deformation increases with time (creep). The elastic properties of plastics are therefore distinguished according to the time scale of the testing to short-time behavior (such as tensile test which lasts minutes), shock loading, the behavior under

632:

As done in crystalline materials, particles can be added to semi-crystalline polymers to change the mechanical properties. In crystalline materials the addition of particles works to impede dislocation motion and strengthen the material. However, for many semi-crystalline polymers particle fillers

139:

Apart from the thermal mechanism, nucleation is strongly affected by impurities, dyes, plasticizers, fillers and other additives in the polymer. This is also referred to as heterogeneous nucleation. This effect is poorly understood and irregular, so that the same additive can promote nucleation in

616:

Above the glass transition temperature amorphous chains in a semi-crystalline polymer are ductile and are able to deform plastically. Crystalline regions of the polymer are linked by the amorphous regions. Tie molecules prevent the amorphous and crystalline phases from separating under an applied

544:

Regular arrangement of atoms and molecules produce sharp diffraction peaks whereas amorphous regions result in broad halos. The diffraction pattern of polymers usually contains a combination of both. Degree of crystallinity can be estimated by integrating the relative intensities of the peaks and

190:

and is suppressed at the top and bottom of the lamellae by the amorphous folded parts at those surfaces. In the case of a strong gradient, the growth has a unidirectional, dendritic character. However, if temperature distribution is isotropic and static then lamellae grow radially and form larger

222:

which partially aligns its molecules. Such alignment can be considered as crystallization and it affects the material properties. For example, the strength of the fiber is greatly increased in the longitudinal direction, and optical properties show large anisotropy along and perpendicular to the

60:

Polymers are composed of long molecular chains which form irregular, entangled coils in the melt. Some polymers retain such a disordered structure upon freezing and readily convert into amorphous solids. In other polymers, the chains rearrange upon freezing and form partly ordered regions with a

628:

Other defects, such as voids, occur in the semi-crystalline polymer under tensile stress and can drive the formation of the neck. The voids can be observed via small angle x-ray scattering. Unlike crazes these voids do not transfer stresses. Notably, cavitation is not observed under compressive

624:

After yielding, a neck is formed in the amorphous region and propagates down the sample length. During necking, the disordered chains align along the tensile direction, forming an ordered structure that demonstrates strengthening due to the molecular reorientation. The flow stress now increases

278:

topochemical polymerisation are generally crystalline. In many cases, the monomer to polymer transition occurs with the retention of crystallinity. Often one can determine the crystal structure of such polymers and the mechanism of polymerisation via single crystal X-ray diffraction. Since the

38:

is estimated by different analytical methods and it typically ranges between 10 and 80%, with crystallized polymers often called "semi-crystalline". The properties of semi-crystalline polymers are determined not only by the degree of crystallinity, but also by the size and orientation of the

649:

Crystalline polymers are usually opaque because of light scattering on the numerous boundaries between the crystalline and amorphous regions. The density of such boundaries is lower in polymers with very low crystallinity (amorphous polymer) or very high degree of crystalline polymers,

633:

weaken the material. It has been suggested that for particles to have a toughening effect in polymers the interparticle matrix ligament thickness must be smaller than a certain threshold. Crystalline polymers polypropylene and polyethylene display particle strengthening.

135:

starts with small, nanometer-sized areas where as a result of heat motion some chains or their segments occur parallel. Those seeds can either dissociate, if thermal motion destroys the molecular order, or grow further, if the grain size exceeds a certain critical value.

223:

fiber axis. Such anisotropy is more enhanced in presence of rod-like fillers such as carbon nanotubes, compared to spherical fillers. Polymer strength is increased not only by extrusion, but also by blow molding, which is used in the production of plastic tanks and

654:

polypropylene, which has crystallinity ~50%, is opaque. Crystallinity also affects dyeing of polymers: crystalline polymers are more difficult to stain than amorphous ones because the dye molecules penetrate through amorphous regions with greater ease.

579:. Polymers can crystallize through a variety of different regimes and unlike simple molecules, the polymer crystal lamellae have two very different surfaces. The two most prominent theories in polymer crystallization kinetics are the

99:

Whether or not polymers can crystallize depends on their molecular structure – presence of straight chains with regularly spaced side groups facilitates crystallization. For example, crystallization occurs much easier in

263:

The unique crystal orientation of confined polymers imparts anisotropic properties. In one example the large, in-plane polymer crystals reduce the gas permeability of nanolayered films by almost 2 orders of magnitude.

291:

Most methods of evaluating the degree of crystallinity assume a mixture of perfect crystalline and totally disordered areas; the transition areas are expected to amount to several percent. These methods include

172:. Higher temperatures destroy the molecular arrangement and below the glass transition temperature, the movement of molecular chains is frozen. Nevertheless, secondary crystallization can proceed even below T

1316:

515:

Crystalline areas are generally more densely packed than amorphous areas. This results in a higher density, up to 15% depending on the material. For example, polyamide 6 (nylon) has crystalline density

1496:

Bartczak, Z., Argon A.S., Weinberg, M. Toughness mechanism in semi-crystalline polymer blends: II. High-density polyethylene toughened with calcium carbonate filler particles. Polymer, 1999. 2347-2365.

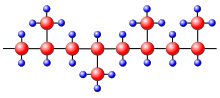

571:

The methods used to determine the degree of crystallinity can be incorporated over time to measure the kinetics of crystallization. The most basic model for polymer crystallization kinetics comes from

140:

one polymer, but not in another. Many of the good nucleating agents are metal salts of organic acids, which themselves are crystalline at the solidification temperature of the polymer solidification.

621:

occurring on a large number of planes. Conversely, coarse slip is a large amount of slip on few planes. The yield stress is determined by the creation of dislocations and their resistance to motion.

34:

can crystallize upon cooling from melting, mechanical stretching or solvent evaporation. Crystallization affects optical, mechanical, thermal and chemical properties of the polymer. The degree of

1069:

Wang, Haopeng; Jong K. Keum; Anne

Hiltner; Eric Baer; Benny Freeman; Artur Rozanski; Andrzej Galeski (6 February 2009). "Confined Crystallization of Polyethylene Oxide in Nanolayer Assemblies".

176:, in the time scale of months and years. This process affects mechanical properties of the polymers and decreases their volume because of a more compact packing of aligned polymer chains.

965:

Patil, N; Balzano, L; Portale, G; Rastogi, S (July 2010). "A Study on the Chain−Particle

Interaction and Aspect Ratio of Nanoparticles on Structure Development of a Linear Polymer".

562:

crystalline and amorphous areas differ by the mobility of protons. The latter can be monitored through the line shape of NMR signals and used to estimate the degree of crystallinity.

952:

183:. The interaction strength depends on the distance between the parallel chain segments and it determines the mechanical and thermal properties of the polymer.

1269:

Kory, Max J.; Wörle, Michael; Weber, Thomas; Payamyar, Payam; van de Poll, Stan W.; Dshemuchadse, Julia; Trapp, Nils; Schlüter, A. Dieter (September 2014).

315:

In addition to the above integral methods, the distribution of crystalline and amorphous regions can be visualized with microscopic techniques, such as

742:

1469:

Pawlak, A., Galeski A,. Rozanski, A. Cavitation during deformation of semicrystalline polymers. Progress in

Polymer Science. (2014). 921-958

1031:

J. Lehmann (1966). "The observation of the crystallization of high polymer substances from the solution by nuclear magnetic resonance".

22:

is a process associated with partial alignment of their molecular chains. These chains fold together and form ordered regions called

156:

Crystal growth is achieved by the further addition of folded polymer chain segments and only occurs for temperatures below the

1571:

1544:

1517:

828:

782:

752:

650:

consequentially, the transparency is higher. For example, atactic polypropylene is usually amorphous and transparent while

536:

and compared with that released upon melting of the standard sample of the same material with known crystallization degree.

312:(NMR). The measured value depends on the method used, which is therefore quoted together with the degree of crystallinity.

1478:

Bowden, P.B., Young, R.J. Deformation

Mechanisms in Crystalline Polymers. Journal of Materials Science. (1974), 2034-2051.

1446:

1424:

1387:

1016:

941:

916:

896:

863:

533:

297:

1607:

320:

1330:

Luo, Liang; Wilhelm, Christopher; Sun, Aiwu; Grey, Clare P.; Lauher, Joseph W.; Goroff, Nancy S. (18 June 2008).

104:

than in the atactic polypropylene form. Atactic polymers crystallize when the side groups are very small, as in

1332:"Poly(diiododiacetylene): Preparation, Isolation, and Full Characterization of a Very Simple Poly(diacetylene)"

1120:

Hema, Kuntrapakam; Ravi, Arthi; Raju, Cijil; Pathan, Javed R.; Rai, Rishika; Sureshan, Kana M. (2021-03-29).

1271:"Gram-scale synthesis of two-dimensional polymer crystals and their structure analysis by X-ray diffraction"

955:

in the IWF Knowledge and Media gGmbH (videos and articles on the dendritic crystallization of polypropylene)

669:

165:

27:

524:= 1.08 g/cm). However, moisture which is often present in the sample does affect this type of measurement.

128:

Lamellae form during crystallization from the melt. The arrow shows the direction of temperature gradient.

124:

1592:

268:

1597:

609:. Heat resistance is usually given for amorphous polymers just below the glass transition temperature.

532:

Additional energy is released upon melting a semicrystalline polymer. This energy can be measured with

412:

395:

316:

309:

248:

227:

bottles. Some polymers which do not crystallize from the melt, can be partially aligned by stretching.

224:

66:

1438:

Plastics in engineering applications: properties, processing and practical use of polymeric materials.

572:

477:

1121:

493:

429:

199:

70:

664:

231:

1534:

1507:

1436:

1377:

1224:"Single-Crystal-to-Single-Crystal (SCSC) Linear Polymerization of a Desymmetrized Anthraphane"

931:

886:

1561:

1414:

1223:

1176:

1008:

855:

818:

305:

772:

1078:

974:

700:

187:

47:

8:

606:

180:

23:

16:

Partial alignment of polymer molecular chains, resulting in "semi-crystalline" structures

1177:"Spontaneous Single-Crystal-to-Single-Crystal Evolution of Two Cross-Laminated Polymers"

1082:

978:

704:

288:

the melting point. The latter procedure is costly and is applied only in special cases.

186:

The growth of the crystalline regions preferably occurs in the direction of the largest

1251:

1204:

1157:

1102:

1048:

716:

152:

Schematic model of a spherulite. Black arrows indicate direction of molecular alignment

1602:

1567:

1540:

1513:

1442:

1420:

1383:

1359:

1351:

1298:

1290:

1243:

1196:

1161:

1149:

1141:

1094:

1012:

990:

937:

912:

892:

859:

824:

778:

748:

301:

208:

207:

The above mechanism considered crystallization from the melt, which is important for

1255:

1208:

1052:

1343:

1282:

1235:

1188:

1133:

1086:

1040:

982:

720:

708:

378:

1457:

Courtney, T. H. "Mechanical

Behavior of Materials". Waveland Press (2005), 392-396

247:

monitored by a technique which selectively probes the dissolved fraction, such as

1487:

Courtney, T. H.. Mechanical

Behavior of Materials. Waveland Press (2005), 392-396

1106:

637:

602:

580:

1317:"Topochemical polymerizations for the solid-state synthesis of organic polymers"

1122:"Topochemical polymerizations for the solid-state synthesis of organic polymers"

575:. The crystallization process of polymers does not always obey simple chemical

219:

770:

51:

The arrangement of molecular chains in amorphous and semicrystalline polymers.

1586:

1355:

1331:

1294:

1270:

1145:

994:

688:

576:

447:

157:

77:

35:

1090:

218:

In this process, the polymer is forced through, e.g., a nozzle that creates

1363:

1302:

1247:

1239:

1200:

1192:

1153:

1098:

740:

62:

230:

Some elastomers which are amorphous in the unstrained state undergo rapid

203:

The arrangement of the molecule chains upon crystallization by stretching.

83:

854:

Georg Menges, Edmund

Haberstroh, Walter Michaeli, Ernst Schmachtenberg:

91:

1286:

1137:

1044:

641:

long-term and static loading, as well as the vibration-induced stress.

132:

1347:

986:

1068:

712:

651:

212:

105:

101:

74:

1401:

Fundamentals of

Polymer Science An Introductory Text, Second Edition

816:

1532:

328:

Degree of crystallinity (D, %) and densities of crystalline (ρ

211:

of plastic components. Another type of crystallization occurs upon

113:

1398:

293:

31:

1222:

Servalli, Marco; Trapp, Nils; Schlüter, A. Dieter (2018-10-09).

1559:

109:

148:

361:

108:

and don't crystallize in case of large substituents like in

771:

Linda C. Sawyer; David T. Grubb; Gregory F. Meyers (2008).

964:

885:

GW Becker, Ludwig

Bottenbruch, Rudolf Binsack, D. Braun:

586:

820:

Polymeric materials: structure, properties, applications

1376:

Gottfried W. Ehrenstein, Gabriela Riedel, Pia

Trawiel:

1268:

741:

Charles E. Carraher; Raymond Benedict Seymour (2003).

566:

1221:

1175:

Athiyarath, Vignesh; Sureshan, Kana M. (2019-01-08).

1505:

591:

26:, which compose larger spheroidal structures named

1465:

1463:

1174:

1119:

1399:Paul C. Painter; Michael M. Coleman (1997). "8".

1329:

1584:

691:(1952). "Morphology of crystallizing polymers".

237:

194:

1509:Introduction to Materials Science for Engineers

1460:

907:Wilbrand Woebcken, Klaus Stöckhert, HBP Gupta:

817:G. W. Ehrenstein; Richard P. Theriault (2001).

143:

55:

1536:Polymer chemistry: properties and applications

1533:Andrew J. Peacock; Allison R. Calhoun (2006).

267:

687:

179:The chains interact via various types of the

42:

1007:Michael Thielen, Klaus Hartwig, Peter Gust:

1563:Chemical principles of textile conservation

1370:

254:

1560:Ágnes Tímár-Balázsy; Dinah Eastop (1998).

1030:

1026:

1024:

926:

924:

282:

1379:Practice of thermal analysis of plastics.

605:deformation, i.e., the polymer begins to

554:degree of crystallinity can be estimated.

87:The structure of isotactic polypropylene.

1441:(in German) Vieweg+Teubner Verlag, 2008

1336:Journal of the American Chemical Society

933:Materials science and materials testing.

881:

879:

877:

875:

873:

871:

850:

848:

846:

844:

842:

840:

198:

147:

123:

90:

82:

46:

1407:

1181:Angewandte Chemie International Edition

1064:

1062:

1021:

1001:

921:

901:

888:Engineering Thermoplastics. Polyamides.

95:The structure of atactic polypropylene.

1585:

1429:

812:

810:

808:

806:

804:

802:

800:

798:

796:

794:

587:Properties of semicrystalline polymers

1566:. Butterworth-Heinemann. p. 11.

868:

837:

766:

764:

681:

644:

583:and Lauritzen-Hoffman Growth Theory.

1059:

744:Seymour/Carraher's polymer chemistry

736:

734:

732:

730:

1539:. Hanser Verlag. pp. 286–287.

1512:. Prentice Hall. pp. 168–169.

791:

567:Kinetics of polymer crystallization

520:= 1.24 g/cm and amorphous density ρ

13:

946:

761:

14:

1619:

1419:(in German) Hanser Verlag, 2006,

911:(in German) Hanser Verlag, 1998,

823:. Hanser Verlag. pp. 67–78.

727:

592:Thermal and mechanical properties

534:differential scanning calorimetry

298:differential scanning calorimetry

215:used in making fibers and films.

1009:Blow molding of plastic articles

891:(in German) Hanser Verlag, 1998

559:Nuclear magnetic resonance (NMR)

321:transmission electron microscopy

1553:

1526:

1499:

1490:

1481:

1472:

1451:

1392:

1323:

1309:

1262:

1215:

1168:

1113:

958:

936:Vieweg + Teubner Verlag, 2007,

1228:Chemistry - A European Journal

1:

1506:James F. Shackelford (2009).

1033:Colloid & Polymer Science

747:. CRC Press. pp. 43–45.

675:

238:Crystallization from solution

195:Crystallization by stretching

119:

670:Modeling of polymer crystals

166:glass transition temperature

144:Crystal growth from the melt

56:Solidification from the melt

7:

658:

269:Topochemical polymerization

20:Crystallization of polymers

10:

1624:

856:Plastics Materials Science

550:Infrared spectroscopy (IR)

413:Polybutylene terephthalate

396:Polyethylene terephthalate

317:polarized light microscopy

310:nuclear magnetic resonance

249:nuclear magnetic resonance

67:polyethylene terephthalate

43:Crystallization mechanisms

573:Hoffman nucleation theory

478:High-density polyethylene

1126:Chemical Society Reviews

494:Low-density polyethylene

255:Confined crystallization

1608:Liquid-solid separation

1091:10.1126/science.1164601

777:. Springer. p. 5.

430:Polytetrafluoroethylene

283:Degree of crystallinity

71:polytetrafluoroethylene

1240:10.1002/chem.201802513

1193:10.1002/anie.201812094

909:Plastics Encyclopedia.

665:Liquid-crystal polymer

204:

153:

129:

96:

88:

52:

1382:Hanser Verlag, 2003,

1011:Hanser Verlag, 2006,

858:Hanser Verlag, 2002,

463:atactic polypropylene

306:infrared spectroscopy

202:

151:

127:

94:

86:

50:

930:Wolfgang Weissbach:

512:Density measurements

188:temperature gradient

181:van der Waals forces

1234:(56): 15003–15012.

1083:2009Sci...323..757W

979:2010MaMol..43.6749P

705:1952Natur.169..913K

337:

158:melting temperature

1593:Chemical processes

1287:10.1038/nchem.2007

1138:10.1039/D0CS00840K

1045:10.1007/BF01553085

774:Polymer microscopy

645:Optical properties

336:, g/cm) polymers.

332:) and amorphous (ρ

327:

205:

154:

130:

97:

89:

53:

39:molecular chains.

1598:Phase transitions

1573:978-0-7506-2620-0

1546:978-1-56990-397-1

1519:978-0-13-601260-3

1413:Joachim Nentwig:

1348:10.1021/ja8011403

1342:(24): 7702–7709.

1077:(5915): 757–760.

987:10.1021/ma100636v

973:(16): 6749–6759.

830:978-1-56990-310-0

784:978-0-387-72627-4

754:978-0-8247-0806-1

699:(4309): 913–914.

541:X-ray diffraction

508:

507:

302:X-ray diffraction

234:upon stretching.

209:injection molding

1615:

1578:

1577:

1557:

1551:

1550:

1530:

1524:

1523:

1503:

1497:

1494:

1488:

1485:

1479:

1476:

1470:

1467:

1458:

1455:

1449:

1433:

1427:

1411:

1405:

1404:

1396:

1390:

1374:

1368:

1367:

1327:

1321:

1320:

1313:

1307:

1306:

1275:Nature Chemistry

1266:

1260:

1259:

1219:

1213:

1212:

1172:

1166:

1165:

1132:(6): 4062–4099.

1117:

1111:

1110:

1066:

1057:

1056:

1028:

1019:

1005:

999:

998:

962:

956:

950:

944:

928:

919:

905:

899:

883:

866:

852:

835:

834:

814:

789:

788:

768:

759:

758:

738:

725:

724:

713:10.1038/169913a0

685:

379:Polyoxymethylene

338:

326:

274:Polymers formed

1623:

1622:

1618:

1617:

1616:

1614:

1613:

1612:

1583:

1582:

1581:

1574:

1558:

1554:

1547:

1531:

1527:

1520:

1504:

1500:

1495:

1491:

1486:

1482:

1477:

1473:

1468:

1461:

1456:

1452:

1435:Martin Bonnet:

1434:

1430:

1412:

1408:

1397:

1393:

1375:

1371:

1328:

1324:

1315:

1314:

1310:

1267:

1263:

1220:

1216:

1173:

1169:

1118:

1114:

1067:

1060:

1029:

1022:

1006:

1002:

963:

959:

951:

947:

929:

922:

906:

902:

884:

869:

853:

838:

831:

815:

792:

785:

769:

762:

755:

739:

728:

686:

682:

678:

661:

647:

600:

594:

589:

581:Avrami equation

569:

523:

519:

509:

356:

350:

335:

331:

285:

272:

257:

240:

232:crystallization

197:

175:

171:

163:

146:

122:

58:

45:

17:

12:

11:

5:

1621:

1611:

1610:

1605:

1600:

1595:

1580:

1579:

1572:

1552:

1545:

1525:

1518:

1498:

1489:

1480:

1471:

1459:

1450:

1428:

1406:

1391:

1369:

1322:

1308:

1281:(9): 779–784.

1261:

1214:

1187:(2): 612–617.

1167:

1112:

1058:

1039:(2): 167–168.

1020:

1000:

967:Macromolecules

957:

945:

920:

900:

867:

836:

829:

790:

783:

760:

753:

726:

679:

677:

674:

673:

672:

667:

660:

657:

646:

643:

598:

593:

590:

588:

585:

577:rate equations

568:

565:

564:

563:

560:

556:

555:

551:

547:

546:

542:

538:

537:

530:

526:

525:

521:

517:

513:

506:

505:

502:

499:

496:

490:

489:

486:

483:

480:

474:

473:

470:

467:

464:

460:

459:

456:

453:

450:

443:

442:

439:

436:

433:

426:

425:

422:

419:

416:

409:

408:

405:

402:

399:

392:

391:

388:

385:

382:

375:

374:

371:

368:

365:

364:(PA66 and PA6)

358:

357:

354:

351:

348:

345:

342:

333:

329:

325:

284:

281:

271:

266:

256:

253:

239:

236:

220:tensile stress

196:

193:

173:

169:

164:and above the

161:

145:

142:

121:

118:

57:

54:

44:

41:

15:

9:

6:

4:

3:

2:

1620:

1609:

1606:

1604:

1601:

1599:

1596:

1594:

1591:

1590:

1588:

1575:

1569:

1565:

1564:

1556:

1548:

1542:

1538:

1537:

1529:

1521:

1515:

1511:

1510:

1502:

1493:

1484:

1475:

1466:

1464:

1454:

1448:

1447:3-8348-0349-9

1444:

1440:

1439:

1432:

1426:

1425:3-446-40390-6

1422:

1418:

1417:

1416:Plastic films

1410:

1402:

1395:

1389:

1388:3-446-22340-1

1385:

1381:

1380:

1373:

1365:

1361:

1357:

1353:

1349:

1345:

1341:

1337:

1333:

1326:

1318:

1312:

1304:

1300:

1296:

1292:

1288:

1284:

1280:

1276:

1272:

1265:

1257:

1253:

1249:

1245:

1241:

1237:

1233:

1229:

1225:

1218:

1210:

1206:

1202:

1198:

1194:

1190:

1186:

1182:

1178:

1171:

1163:

1159:

1155:

1151:

1147:

1143:

1139:

1135:

1131:

1127:

1123:

1116:

1108:

1104:

1100:

1096:

1092:

1088:

1084:

1080:

1076:

1072:

1065:

1063:

1054:

1050:

1046:

1042:

1038:

1034:

1027:

1025:

1018:

1017:3-446-22671-0

1014:

1010:

1004:

996:

992:

988:

984:

980:

976:

972:

968:

961:

954:

949:

943:

942:3-8348-0295-6

939:

935:

934:

927:

925:

918:

917:3-446-17969-0

914:

910:

904:

898:

897:3-446-16486-3

894:

890:

889:

882:

880:

878:

876:

874:

872:

865:

864:3-446-21257-4

861:

857:

851:

849:

847:

845:

843:

841:

832:

826:

822:

821:

813:

811:

809:

807:

805:

803:

801:

799:

797:

795:

786:

780:

776:

775:

767:

765:

756:

750:

746:

745:

737:

735:

733:

731:

722:

718:

714:

710:

706:

702:

698:

694:

690:

689:Andrew Keller

684:

680:

671:

668:

666:

663:

662:

656:

653:

642:

639:

636:Plastics are

634:

630:

626:

622:

618:

614:

610:

608:

604:

601:results in a

584:

582:

578:

574:

561:

558:

557:

552:

549:

548:

543:

540:

539:

535:

531:

528:

527:

514:

511:

510:

503:

500:

497:

495:

492:

491:

487:

484:

481:

479:

476:

475:

471:

468:

465:

462:

461:

457:

454:

451:

449:

448:polypropylene

445:

444:

440:

437:

434:

431:

428:

427:

423:

420:

417:

414:

411:

410:

406:

403:

400:

397:

394:

393:

389:

386:

383:

380:

377:

376:

372:

369:

366:

363:

360:

359:

352:

346:

343:

340:

339:

324:

322:

318:

313:

311:

307:

303:

299:

296:measurement,

295:

289:

280:

277:

270:

265:

261:

252:

250:

244:

235:

233:

228:

226:

221:

216:

214:

210:

201:

192:

189:

184:

182:

177:

167:

159:

150:

141:

137:

134:

126:

117:

115:

111:

107:

103:

93:

85:

81:

79:

78:polypropylene

76:

72:

68:

64:

49:

40:

37:

36:crystallinity

33:

29:

25:

21:

1562:

1555:

1535:

1528:

1508:

1501:

1492:

1483:

1474:

1453:

1437:

1431:

1415:

1409:

1403:. CRC Press.

1400:

1394:

1378:

1372:

1339:

1335:

1325:

1311:

1278:

1274:

1264:

1231:

1227:

1217:

1184:

1180:

1170:

1129:

1125:

1115:

1074:

1070:

1036:

1032:

1003:

970:

966:

960:

948:

932:

908:

903:

887:

819:

773:

743:

696:

692:

683:

652:syndiotactic

648:

638:viscoelastic

635:

631:

627:

623:

619:

615:

611:

603:viscoelastic

595:

570:

314:

290:

286:

275:

273:

262:

258:

245:

241:

229:

217:

206:

185:

178:

155:

138:

131:

98:

63:polyethylene

59:

19:

18:

529:Calorimetry

28:spherulites

1587:Categories

676:References

446:isotactic

133:Nucleation

120:Nucleation

73:(PTFE) or

1356:0002-7863

1295:1755-4349

1162:231819465

1146:1460-4744

995:0024-9297

213:extrusion

114:silicones

106:polyvinyl

102:isotactic

75:isotactic

1603:Polymers

1364:18489101

1303:25143212

1256:51599257

1248:29984526

1209:53945431

1201:30461147

1154:33543741

1099:19197057

1053:96640893

953:Dendrite

659:See also

32:Polymers

24:lamellae

1079:Bibcode

1071:Science

975:Bibcode

721:4255757

701:Bibcode

341:Polymer

304:(XRD),

300:(DSC),

294:density

69:(PET),

1570:

1543:

1516:

1445:

1423:

1386:

1362:

1354:

1301:

1293:

1254:

1246:

1207:

1199:

1160:

1152:

1144:

1105:

1097:

1051:

1015:

993:

940:

915:

895:

862:

827:

781:

751:

719:

693:Nature

545:halos.

432:(PTFE)

110:rubber

80:(PP).

65:(PE),

1252:S2CID

1205:S2CID

1158:S2CID

1107:19276

1103:S2CID

1049:S2CID

717:S2CID

607:creep

504:0.85

498:45–55

488:0.85

482:70–80

458:0.85

452:70–80

441:2.00

435:60–80

418:40–50

415:(PBT)

407:1.33

401:30–40

398:(PET)

390:1.28

384:70–80

381:(POM)

373:1.08

367:35–45

362:Nylon

1568:ISBN

1541:ISBN

1514:ISBN

1443:ISBN

1421:ISBN

1384:ISBN

1360:PMID

1352:ISSN

1299:PMID

1291:ISSN

1244:PMID

1197:PMID

1150:PMID

1142:ISSN

1095:PMID

1013:ISBN

991:ISSN

938:ISBN

913:ISBN

893:ISBN

860:ISBN

825:ISBN

779:ISBN

749:ISBN

455:0.95

438:2.35

404:1.50

387:1.54

370:1.24

319:and

308:and

1344:doi

1340:130

1283:doi

1236:doi

1189:doi

1134:doi

1087:doi

1075:323

1041:doi

1037:212

983:doi

709:doi

697:169

501:1.0

485:1.0

276:via

225:PET

112:or

1589::

1462:^

1358:.

1350:.

1338:.

1334:.

1297:.

1289:.

1277:.

1273:.

1250:.

1242:.

1232:24

1230:.

1226:.

1203:.

1195:.

1185:58

1183:.

1179:.

1156:.

1148:.

1140:.

1130:50

1128:.

1124:.

1101:.

1093:.

1085:.

1073:.

1061:^

1047:.

1035:.

1023:^

989:.

981:.

971:43

969:.

923:^

870:^

839:^

793:^

763:^

729:^

715:.

707:.

695:.

472:–

466:~0

424:–

323:.

251:.

116:.

30:.

1576:.

1549:.

1522:.

1366:.

1346::

1319:.

1305:.

1285::

1279:6

1258:.

1238::

1211:.

1191::

1164:.

1136::

1109:.

1089::

1081::

1055:.

1043::

997:.

985::

977::

833:.

787:.

757:.

723:.

711::

703::

599:g

597:T

522:a

518:c

516:ρ

469:–

421:–

355:a

353:ρ

349:c

347:ρ

344:D

334:a

330:c

174:g

170:g

168:T

162:m

160:T

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.