465:

131:

1375:

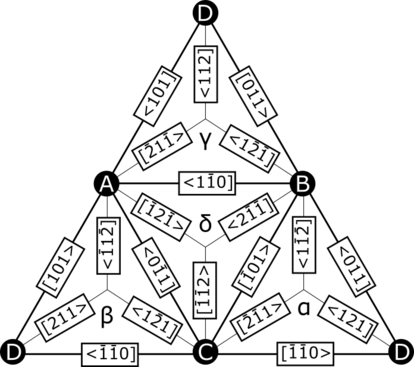

corresponding (Aα, Bβ,...) or a

Shockley partial otherwise (Aβ, Aγ,...). Vectors made from two Greek letters describe stair-rod dislocations. Using Thompson notation, Burgers vectors can be added to describe other dislocations and mechanisms. For example, two Shockley partial dislocations can be added to form a perfect dislocation: Aβ + βC = AC. It is necessary that the interior letters of a given operation match, but many can be added in sequence to describe more complex mechanisms.

460:{\displaystyle {\begin{aligned}|{\boldsymbol {b_{1}}}|^{2}>&|{\boldsymbol {b_{2}}}|^{2}+|{\boldsymbol {b_{3}}}|^{2}{\text{ (favorable, will decompose)}}\\|{\boldsymbol {b_{1}}}|^{2}<&|{\boldsymbol {b_{2}}}|^{2}+|{\boldsymbol {b_{3}}}|^{2}{\text{ (not favorable, will not decompose)}}\\|{\boldsymbol {b_{1}}}|^{2}=&|{\boldsymbol {b_{2}}}|^{2}+|{\boldsymbol {b_{3}}}|^{2}{\text{ (will remain in original state)}}\end{aligned}}}

1382:

1414:

1367:

1025:

36:

1275:

1401:

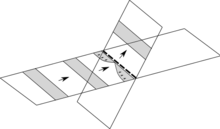

partials of each extended dislocation now form a stair-rod partial. This structure leads to reduced mobility of the dislocations as the core structure is non-planar (meaning it doesn’t cross along the face of the tetrahedron). This reduction of mobility transforms the Lomer-Cottrell dislocation into an obstacle for other dislocations, thus strengthening the material.

695:

1409:

When forming stacking faults, the partial dislocations reach an equilibrium when the repulsive energy between partial dislocations matches the attractive energy of the stacking fault. This means that higher stacking fault energy materials, i.e. those with high shear modulus and large

Burgers vectors,

1362:

For FCC crystals, Thompson tetrahedrons or

Thompson notation are an invented notation for more easily describing partial dislocations. In a given unit cell, mark point A at the origin, point B at a/2 , point C at a/2, and point D at a/2--these points form the vertices of a tetrahedron. Then, mark the

1400:

The Lomer-Cottrell dislocation forms via a more complex dislocation reaction. For example, consider two extended dislocations: DB = Dγ + γB and BC = Bδ + δC. When they meet, it is more energetically favorable to form a single dislocation, DC = DB + BC = Dγ + γB + Bδ + δC = Dγ + γδ + δC. The trailing

1433:

The more easily a dislocation can cross slip, the more freely the dislocation can move around obstacles–this makes work hardening more difficult. Thus, materials that allow easy cross slip (high stacking fault energy) will see less work hardening and strengthening from methods like solid-solution

1040:

1374:

Any combination of Roman letters describes a member of the {111} slip planes in an FCC crystal. A vector made from two Roman letters describes the

Burgers vector of a perfect dislocation. If the vector is made from a Roman letter and a Greek letter, then it is a Frank partial if the letters are

1020:{\displaystyle {\begin{aligned}|{\frac {a}{2}}{\sqrt {1^{2}+0^{2}+(-1)^{2}}}|^{2}>&|{\frac {a}{6}}{\sqrt {2^{2}+(-1)^{2}+(-1)^{2}}}|^{2}+|{\frac {a}{6}}{\sqrt {1^{2}+1^{2}+(-2)^{2}}}|^{2}\\{\frac {a^{2}}{2}}>&{\frac {a^{2}}{6}}+{\frac {a^{2}}{6}}\end{aligned}}}

550:

1429:

to reduce the distance between them, so partial dislocations with low stacking fault energies will inherently be more difficult to bring together and thus more difficult to cross slip. Conversely, high stacking fault energy materials will be easier to cross slip.

1425:, both partial dislocations need to change slip planes. The common Friedel-Escaig mechanism requires that the partial dislocations recombine at a point before cross slipping onto a different slip plane. Bringing the partials together entails applying sufficient

684:

1352:

1270:{\displaystyle {\begin{aligned}{\frac {a}{2}}(1)=&{\frac {a}{6}}(2)+{\frac {a}{6}}(1)\\{\frac {a}{2}}(0)=&{\frac {a}{6}}(-1)+{\frac {a}{6}}(1)\\{\frac {a}{2}}(-1)=&{\frac {a}{6}}(-1)+{\frac {a}{6}}(-2)\end{aligned}}}

1299:

1045:

700:

566:

493:

136:

488:

121:

A dislocation will decompose into partial dislocations if the energy state of the sum of the partials is less than the energy state of the original dislocation. This is summarized by

561:

1294:

1410:

will have smaller distance between partial dislocations. Conversely, low stacking fault energy materials will have large distances between partial dislocations.

1363:

center of the opposite faces for each point as α, β, γ, and δ, respectively. With this, the geometric representation of a

Thompson tetrahedron is complete.

1417:

Partial dislocations move freely, but in order to cross slip onto a different plane, they must first constrict to before slipping on a different plane.

54:

1385:

Unfolded

Thompson tetrahedrons contain information to quickly view Burgers vectors relative directions in an FCC structure.

545:{\displaystyle {\begin{aligned}{\boldsymbol {b_{1}}}\rightarrow {\boldsymbol {b_{2}}}+{\boldsymbol {b_{3}}}\end{aligned}}}

1524:

72:

482:. This pair of partial dislocations can enable dislocation motion by allowing an alternate path for atomic motion.

1395:

1288:

are sessile (immobile), but can move by diffusion of atoms. In FCC systems, Frank partials are given by:

1370:

Thompson tetrahedron drawn inside an FCC crystal and then rotated to more easily see faces and vertices.

679:{\displaystyle {\begin{aligned}{\frac {a}{2}}\rightarrow {\frac {a}{6}}+{\frac {a}{6}}\end{aligned}}}

1347:{\displaystyle {\begin{aligned}{\boldsymbol {b}}_{\text{frank}}=&{\frac {a}{3}}\end{aligned}}}

105:

is a dislocation that has dissociated into a pair of partial dislocations. The vector sum of the

50:

20:

8:

86:

24:

1378:

It is useful to summarize this information using an unfolded

Thompson tetrahedron.

479:

110:

106:

1518:

478:

generally refer to a pair of dislocations which can lead to the presence of

1426:

94:

16:

Decomposed form of dislocation that occurs within a crystalline material

1422:

1413:

1381:

1366:

98:

1034:

must add up to the original vector that is being decomposed:

555:

In FCC systems, an example of

Shockley decomposition is:

1297:

1043:

698:

564:

491:

134:

45:

may be too technical for most readers to understand

1346:

1269:

1019:

678:

544:

459:

1516:

1491:Mechanical Behavior of Materials, Second Edition

470:

1280:

1506:Introduction to Dislocations (Fifth Edition)

1484:

1482:

1404:

1503:

344: (not favorable, will not decompose)

73:Learn how and when to remove this message

57:, without removing the technical details.

1412:

1380:

1365:

116:

1479:

1357:

1304:

528:

513:

498:

426:

394:

358:

320:

288:

252:

214:

182:

146:

1517:

1470:

1389:

1466:

1464:

1462:

1460:

450: (will remain in original state)

55:make it understandable to non-experts

1488:

29:

1473:Imperfections in Crystalline Solids

109:of the partial dislocations is the

13:

1457:

1452:Mechanical Behaviors of Materials.

689:Which is energetically favorable:

14:

1536:

238: (favorable, will decompose)

19:For the syntactic operation, see

532:

517:

502:

430:

398:

362:

324:

292:

256:

218:

186:

150:

34:

1471:Cai, Wei; Nix, William (2016),

1504:Hull, D.; Bacon, D.J. (2011),

1497:

1444:

1337:

1329:

1260:

1251:

1235:

1226:

1208:

1199:

1182:

1176:

1160:

1151:

1133:

1127:

1110:

1104:

1088:

1082:

1064:

1058:

940:

927:

917:

875:

861:

848:

838:

826:

816:

787:

769:

756:

746:

704:

669:

653:

637:

611:

598:

595:

579:

508:

438:

420:

406:

388:

370:

352:

332:

314:

300:

282:

264:

246:

226:

208:

194:

176:

158:

140:

1:

1437:

476:Shockley partial dislocations

471:Shockley partial dislocations

113:of the extended dislocation.

664:

632:

622:

590:

23:. For the medical term, see

7:

10:

1541:

1450:Meyers and Chawla. (1999)

1393:

1286:Frank partial dislocations

1281:Frank partial dislocations

18:

1525:Crystallographic defects

1454:Prentice Hall, Inc. 217.

123:Frank's Energy Criterion

93:is a decomposed form of

1405:Mechanical implications

1396:Lomer–Cottrell junction

1418:

1386:

1371:

1348:

1271:

1030:The components of the

1021:

680:

546:

461:

1416:

1384:

1369:

1349:

1272:

1022:

681:

547:

462:

117:Reaction favorability

97:that occurs within a

1358:Thompson tetrahedron

1295:

1041:

696:

562:

489:

132:

103:extended dislocation

21:Dislocation (syntax)

1390:Lomer–Cottrell lock

91:partial dislocation

1493:, pp. 117–119

1489:Courtney, Thomas,

1475:, pp. 349–375

1419:

1387:

1372:

1344:

1342:

1267:

1265:

1017:

1015:

676:

674:

542:

540:

457:

455:

1335:

1327:

1311:

1249:

1224:

1197:

1174:

1149:

1125:

1102:

1080:

1056:

1032:Shockley Partials

1011:

991:

969:

936:

887:

857:

799:

765:

716:

667:

651:

635:

625:

609:

593:

577:

451:

345:

239:

87:materials science

83:

82:

75:

25:Joint dislocation

1532:

1509:

1508:

1501:

1495:

1494:

1486:

1477:

1476:

1468:

1455:

1448:

1353:

1351:

1350:

1345:

1343:

1336:

1333:

1328:

1320:

1313:

1312:

1309:

1307:

1276:

1274:

1273:

1268:

1266:

1250:

1242:

1225:

1217:

1198:

1190:

1175:

1167:

1150:

1142:

1126:

1118:

1103:

1095:

1081:

1073:

1057:

1049:

1026:

1024:

1023:

1018:

1016:

1012:

1007:

1006:

997:

992:

987:

986:

977:

970:

965:

964:

955:

949:

948:

943:

937:

935:

934:

913:

912:

900:

899:

890:

888:

880:

878:

870:

869:

864:

858:

856:

855:

834:

833:

812:

811:

802:

800:

792:

790:

778:

777:

772:

766:

764:

763:

742:

741:

729:

728:

719:

717:

709:

707:

685:

683:

682:

677:

675:

668:

660:

652:

644:

636:

628:

626:

618:

610:

602:

594:

586:

578:

570:

551:

549:

548:

543:

541:

537:

536:

535:

522:

521:

520:

507:

506:

505:

466:

464:

463:

458:

456:

452:

449:

447:

446:

441:

435:

434:

433:

423:

415:

414:

409:

403:

402:

401:

391:

379:

378:

373:

367:

366:

365:

355:

346:

343:

341:

340:

335:

329:

328:

327:

317:

309:

308:

303:

297:

296:

295:

285:

273:

272:

267:

261:

260:

259:

249:

240:

237:

235:

234:

229:

223:

222:

221:

211:

203:

202:

197:

191:

190:

189:

179:

167:

166:

161:

155:

154:

153:

143:

78:

71:

67:

64:

58:

38:

37:

30:

1540:

1539:

1535:

1534:

1533:

1531:

1530:

1529:

1515:

1514:

1513:

1512:

1502:

1498:

1487:

1480:

1469:

1458:

1449:

1445:

1440:

1434:strengthening.

1407:

1398:

1392:

1360:

1341:

1340:

1332:

1319:

1317:

1308:

1303:

1302:

1298:

1296:

1293:

1292:

1283:

1264:

1263:

1241:

1216:

1214:

1189:

1186:

1185:

1166:

1141:

1139:

1117:

1114:

1113:

1094:

1072:

1070:

1048:

1044:

1042:

1039:

1038:

1014:

1013:

1002:

998:

996:

982:

978:

976:

974:

960:

956:

954:

951:

950:

944:

939:

938:

930:

926:

908:

904:

895:

891:

889:

879:

874:

865:

860:

859:

851:

847:

829:

825:

807:

803:

801:

791:

786:

782:

773:

768:

767:

759:

755:

737:

733:

724:

720:

718:

708:

703:

699:

697:

694:

693:

673:

672:

659:

643:

627:

617:

601:

585:

569:

565:

563:

560:

559:

539:

538:

531:

527:

526:

516:

512:

511:

501:

497:

496:

492:

490:

487:

486:

480:stacking faults

473:

454:

453:

448:

442:

437:

436:

429:

425:

424:

419:

410:

405:

404:

397:

393:

392:

387:

383:

374:

369:

368:

361:

357:

356:

351:

348:

347:

342:

336:

331:

330:

323:

319:

318:

313:

304:

299:

298:

291:

287:

286:

281:

277:

268:

263:

262:

255:

251:

250:

245:

242:

241:

236:

230:

225:

224:

217:

213:

212:

207:

198:

193:

192:

185:

181:

180:

175:

171:

162:

157:

156:

149:

145:

144:

139:

135:

133:

130:

129:

119:

107:Burgers vectors

79:

68:

62:

59:

51:help improve it

48:

39:

35:

28:

17:

12:

11:

5:

1538:

1528:

1527:

1511:

1510:

1496:

1478:

1456:

1442:

1441:

1439:

1436:

1406:

1403:

1394:Main article:

1391:

1388:

1359:

1356:

1355:

1354:

1339:

1331:

1326:

1323:

1318:

1316:

1306:

1301:

1300:

1282:

1279:

1278:

1277:

1262:

1259:

1256:

1253:

1248:

1245:

1240:

1237:

1234:

1231:

1228:

1223:

1220:

1215:

1213:

1210:

1207:

1204:

1201:

1196:

1193:

1188:

1187:

1184:

1181:

1178:

1173:

1170:

1165:

1162:

1159:

1156:

1153:

1148:

1145:

1140:

1138:

1135:

1132:

1129:

1124:

1121:

1116:

1115:

1112:

1109:

1106:

1101:

1098:

1093:

1090:

1087:

1084:

1079:

1076:

1071:

1069:

1066:

1063:

1060:

1055:

1052:

1047:

1046:

1028:

1027:

1010:

1005:

1001:

995:

990:

985:

981:

975:

973:

968:

963:

959:

953:

952:

947:

942:

933:

929:

925:

922:

919:

916:

911:

907:

903:

898:

894:

886:

883:

877:

873:

868:

863:

854:

850:

846:

843:

840:

837:

832:

828:

824:

821:

818:

815:

810:

806:

798:

795:

789:

785:

783:

781:

776:

771:

762:

758:

754:

751:

748:

745:

740:

736:

732:

727:

723:

715:

712:

706:

702:

701:

687:

686:

671:

666:

663:

658:

655:

650:

647:

642:

639:

634:

631:

624:

621:

616:

613:

608:

605:

600:

597:

592:

589:

584:

581:

576:

573:

568:

567:

553:

552:

534:

530:

525:

519:

515:

510:

504:

500:

495:

494:

472:

469:

468:

467:

445:

440:

432:

428:

422:

418:

413:

408:

400:

396:

390:

386:

384:

382:

377:

372:

364:

360:

354:

350:

349:

339:

334:

326:

322:

316:

312:

307:

302:

294:

290:

284:

280:

278:

276:

271:

266:

258:

254:

248:

244:

243:

233:

228:

220:

216:

210:

206:

201:

196:

188:

184:

178:

174:

172:

170:

165:

160:

152:

148:

142:

138:

137:

118:

115:

111:Burgers vector

81:

80:

42:

40:

33:

15:

9:

6:

4:

3:

2:

1537:

1526:

1523:

1522:

1520:

1507:

1500:

1492:

1485:

1483:

1474:

1467:

1465:

1463:

1461:

1453:

1447:

1443:

1435:

1431:

1428:

1424:

1415:

1411:

1402:

1397:

1383:

1379:

1376:

1368:

1364:

1324:

1321:

1314:

1291:

1290:

1289:

1287:

1257:

1254:

1246:

1243:

1238:

1232:

1229:

1221:

1218:

1211:

1205:

1202:

1194:

1191:

1179:

1171:

1168:

1163:

1157:

1154:

1146:

1143:

1136:

1130:

1122:

1119:

1107:

1099:

1096:

1091:

1085:

1077:

1074:

1067:

1061:

1053:

1050:

1037:

1036:

1035:

1033:

1008:

1003:

999:

993:

988:

983:

979:

971:

966:

961:

957:

945:

931:

923:

920:

914:

909:

905:

901:

896:

892:

884:

881:

871:

866:

852:

844:

841:

835:

830:

822:

819:

813:

808:

804:

796:

793:

784:

779:

774:

760:

752:

749:

743:

738:

734:

730:

725:

721:

713:

710:

692:

691:

690:

661:

656:

648:

645:

640:

629:

619:

614:

606:

603:

587:

582:

574:

571:

558:

557:

556:

523:

485:

484:

483:

481:

477:

443:

416:

411:

385:

380:

375:

337:

310:

305:

279:

274:

269:

231:

204:

199:

173:

168:

163:

128:

127:

126:

124:

114:

112:

108:

104:

101:material. An

100:

96:

92:

88:

77:

74:

66:

56:

52:

46:

43:This article

41:

32:

31:

26:

22:

1505:

1499:

1490:

1472:

1451:

1446:

1432:

1427:shear stress

1421:In order to

1420:

1408:

1399:

1377:

1373:

1361:

1285:

1284:

1031:

1029:

688:

554:

475:

474:

122:

120:

102:

90:

84:

69:

60:

44:

99:crystalline

95:dislocation

1438:References

1423:cross slip

63:April 2021

1255:−

1230:−

1203:−

1155:−

921:−

842:−

820:−

750:−

665:¯

633:¯

623:¯

599:→

591:¯

509:→

1519:Category

49:Please

1334:1 1 1

1310:frank

972:>

780:>

275:<

169:>

89:, a

85:In

53:to

1521::

1481:^

1459:^

657:11

583:10

125::

1338:]

1330:[

1325:3

1322:a

1315:=

1305:b

1261:)

1258:2

1252:(

1247:6

1244:a

1239:+

1236:)

1233:1

1227:(

1222:6

1219:a

1212:=

1209:)

1206:1

1200:(

1195:2

1192:a

1183:)

1180:1

1177:(

1172:6

1169:a

1164:+

1161:)

1158:1

1152:(

1147:6

1144:a

1137:=

1134:)

1131:0

1128:(

1123:2

1120:a

1111:)

1108:1

1105:(

1100:6

1097:a

1092:+

1089:)

1086:2

1083:(

1078:6

1075:a

1068:=

1065:)

1062:1

1059:(

1054:2

1051:a

1009:6

1004:2

1000:a

994:+

989:6

984:2

980:a

967:2

962:2

958:a

946:2

941:|

932:2

928:)

924:2

918:(

915:+

910:2

906:1

902:+

897:2

893:1

885:6

882:a

876:|

872:+

867:2

862:|

853:2

849:)

845:1

839:(

836:+

831:2

827:)

823:1

817:(

814:+

809:2

805:2

797:6

794:a

788:|

775:2

770:|

761:2

757:)

753:1

747:(

744:+

739:2

735:0

731:+

726:2

722:1

714:2

711:a

705:|

670:]

662:2

654:[

649:6

646:a

641:+

638:]

630:1

620:1

615:2

612:[

607:6

604:a

596:]

588:1

580:[

575:2

572:a

533:3

529:b

524:+

518:2

514:b

503:1

499:b

444:2

439:|

431:3

427:b

421:|

417:+

412:2

407:|

399:2

395:b

389:|

381:=

376:2

371:|

363:1

359:b

353:|

338:2

333:|

325:3

321:b

315:|

311:+

306:2

301:|

293:2

289:b

283:|

270:2

265:|

257:1

253:b

247:|

232:2

227:|

219:3

215:b

209:|

205:+

200:2

195:|

187:2

183:b

177:|

164:2

159:|

151:1

147:b

141:|

76:)

70:(

65:)

61:(

47:.

27:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.