401:(NBR, HNBR, HSN, Buna-N): a common material for o-rings because of its good mechanical properties, its resistance to lubricants and greases, and its relatively low cost. The physical and chemical resistance properties of NBR materials are determined by the acrylonitrile (ACN) content of the base polymer: low content ensures good flexibility at low temperatures, but offers limited resistance to oils and fuels. As the ACN content increases, the low temperature flexibility reduces and the resistance to oils and fuels improves. Physical and chemical resistance properties of NBR materials are also affected by the cure system of the polymer. Peroxide-cured materials have improved physical properties, chemical resistance and thermal properties, as compared to sulfur-donor-cured materials. Standard grades of NBR are typically resistant to mineral oil-based lubricants and greases, many grades of hydraulic fluids, aliphatic hydrocarbons, silicone oils and greases and water to about 176 °F (80 °C). NBR is generally not resistant to aromatic and chlorinated hydrocarbons, fuels with a high aromatic content, polar solvents, glycol-based brake fluids and non-flammable hydraulic fluids (HFD). NBR also has low resistance to ozone, weathering and aging. HNBR has considerable improvement of the resistance to heat, ozone and aging, and gives it good mechanical properties.

395:(FKM): noted for their very high resistance to heat and a wide variety of chemicals. Other key benefits include excellent resistance to aging and ozone, very low gas permeability and the fact that the materials are self-extinguishing. Standard FKM materials have excellent resistance to mineral oils and greases, aliphatic, aromatic and chlorinated hydrocarbons, fuels, non-flammable hydraulic fluids (HFD) and many organic solvents and chemicals. Generally not resistant to hot water, steam, polar solvents, glycol-based brake fluids and low molecular weight organic acids. In addition to the standard FKM materials, a number of specialty materials with different monomer compositions and fluorine content (65% to 71%) are available that offer improved chemical or temperature resistance and/or better low temperature performance.

450:(SiR): noted for their ability to be used over a wide temperature range and for excellent resistance to ozone, weathering and aging. Compared with most other sealing elastomers, the physical properties of silicones are poor. Generally, silicone materials are physiologically harmless so they are commonly used by the food and drug industries. Standard silicones are resistant to water up to 212 °F (100 °C), aliphatic engine and transmission oils and animal and plant oils and fats. Silicones are generally not resistant to fuels, aromatic mineral oils, steam (short term to 248 °F (120 °C) is possible), silicone oils and greases, acids or alkalis. Fluorosilicone elastomers are far more resistant to oils and fuels. The temperature range of applications is somewhat more restricted.

692:, the cold O-ring, once compressed, will take longer than normal to return to its original shape. O-rings (and all other seals) work by producing positive pressure against a surface, thereby preventing leaks. On the night before the launch, exceedingly low air temperatures were recorded. Due to this, NASA technicians performed an inspection; the ambient temperature was within launch parameters, and the launch sequence was allowed to proceed. However, the temperature of the rubber O-rings remained significantly lower than that of the surrounding air. During his investigation of the launch footage, Feynman observed a small out-gassing event from the

145:... kneads or works the material of the ring to keep it alive and pliable without deleterious effects of scuffing which are caused by purely static sliding of rubber upon a surface. By this slight turning or kneading action, the life of the ring is prolonged." His application filed in 1937 says that it "is a continuation-in-part of my copending application Serial No. 704,463 for Hydraulic brakes, filed December 29, 1933, now U. S. Patent No. 2,115,383 granted April 26, 1938".

4287:

488:: Polyurethanes differ from classic elastomers in that they have much better mechanical properties. In particular they have a high resistance to abrasion, wear and extrusion, a high tensile strength and excellent tear resistance. Polyurethanes are generally resistant to aging and ozone, mineral oils and greases, silicone oils and greases, nonflammable hydraulic fluids HFA & HFB, water up to 122 °F (50 °C) and aliphatic hydrocarbons.

547:

177:

555:

installation, they seal with 4 contact surfaces—2 small contact surfaces on the top and bottom. This contrasts with the standard O-ring's comparatively larger single contact surfaces top and bottom. X-rings are most commonly used in reciprocating applications, where they provide reduced running and breakout friction and reduced risk of spiraling when compared to O-rings.

571:), especially in low volumes. The physical sealing performance of square rings in static applications is superior to that of O-rings, however in dynamic applications it is inferior to that of O-rings. Square rings are usually used only in dynamic applications as energizers in cap seal assemblies. Square rings can also be more difficult to install than O-rings.

701:

with the material, cure date, and batch information. O-rings can, if needed, be recalled off the shelf. Furthermore, O-rings and other seals are routinely batch-tested for quality control by the manufacturers, and often undergo quality assurance testing several more times by the distributor and ultimate end-users.

625:

Spiral failure – Found on long-stroke piston seals and – to a lesser degree – on rod seals. The seal gets "hung up" at one point on its diameter (against the cylinder wall) and slides and rolls at the same time. This twists the O-ring as the sealed device is cycled and finally causes a

602:

There are O-ring materials which can tolerate temperatures as low as −330 °F (−200 °C) or as high as 480 °F (250 °C). At the low end, nearly all engineering materials become rigid and fail to seal; at the high end, the materials often burn or decompose. Chemical attack can degrade

558:

There are also rings with a square profile, commonly called square-cuts, lathe cuts, tabular cut or Square rings. When O-rings were selling at a premium because of the novelty, lack of efficient manufacturing processes and high labor content, Square rings were introduced as an economical substitution

304:

O-rings come in a variety of sizes. Society of

Automotive Engineers (SAE) Aerospace Standard 568 (AS568) specifies the inside diameters, cross-sections, tolerances, and size identification codes (dash numbers) for O-rings used in sealing applications and for straight thread tube fitting boss gaskets.

218:

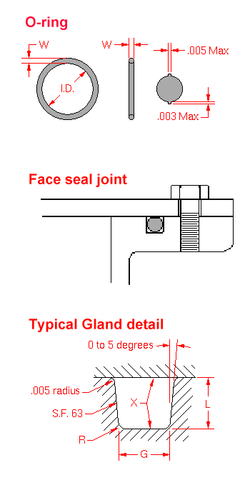

The seal is designed to have a point contact between the O-ring and sealing faces. This allows a high local stress, able to contain high pressure, without exceeding the yield stress of the O-ring body. The flexible nature of O-ring materials accommodates imperfections in the mounting parts. But it is

214:

being contained does not exceed the contact stress of the O-ring, leaking cannot occur. The pressure of the contained fluid transfers through the essentially incompressible O-ring material, and the contact stress rises with increasing pressure. For this reason, an O-ring can easily seal high pressure

193:

diameter (thickness). In the US the most common standard inch sizes are per SAE AS568C specification (e.g. AS568-214). ISO 3601-1:2012 contains the most commonly used standard sizes, both inch and metric, worldwide. The UK also has standards sizes known as BS sizes, typically ranging from BS001 to

700:

Since the accident, rubber production companies have enacted changes. Many O-rings now come with batch and cure date coding, as is done in medicine production, to precisely track and control distribution. For aerospace and military applications, O-rings are usually individually packaged and labeled

614:

Elastomers are sensitive to ionizing radiation. In typical applications, O-rings are well-protected from less-penetrating radiation such as ultraviolet and soft X-rays, but more-penetrating radiation such as neutrons may cause rapid deterioration. In such environments, soft metal seals are used.

704:

As for the boosters themselves, NASA and Morton-Thiokol redesigned them with a new joint design, which now incorporated three O-rings instead of two, with the joints themselves having onboard heaters that can be turned on when temperatures drop below 50 °F (10 °C). No O-ring issues have

137:. In his previously filed application in 1933, resulting in Patent 2115383, he opens by saying, "This invention relates to new and useful improvements in hydraulic brakes and more particularly to an improved seal for the pistons of power conveying cylinders." He describes "a circular section ring

312:

The World's

Largest O-ring was produced in a successful Guinness World Record attempt by Trelleborg Sealing Solutions Tewkesbury partnered with a group of 20 students from Tewkesbury School. The O-ring once finished and placed around the Medieval Tewkesbury Abbey had a 364 m (1,194 ft)

554:

Although the O-ring was originally so named because of its circular cross section, there are now variations in cross-section design. The shape can have different profiles, such as an x-shaped profile, commonly called the X-ring, Q-ring, or by the trademarked name Quad Ring. When squeezed upon

223:

and becomes increasingly inflexible and glassy. Surface finish is also especially important in dynamic applications. A surface finish that is too rough will abrade the surface of the O-ring, and a surface that is too smooth will not allow the seal to be adequately lubricated by a fluid film.

308:

Metric O-rings are usually defined by the internal dimension x the cross section. Typical part number for a metric O-ring - ID x CS 2x1N70 = defines this O-ring as 2mm id with 1mm cross section made from

Nitrile rubber which is 70Sh. BS O-rings are defined by a standard reference.

382:

oils and greases, many polar solvents and many diluted acids and chemicals. Special formulations are excellent for use with glycol-based brake fluids. Unsuitable for use with mineral oil products: lubricants, oils, or fuels. Peroxide-cured compounds are suitable for higher

81:

solid such that it is impermeable to the fluid or gas, and (3) the O-ring material is resistant to degradation by the fluid or gas. The wide range of potential liquids and gases that need to be sealed has necessitated the development of a wide range of O-ring materials.

322:

180:

O-ring mounting for an ultra-high vacuum application. Pressure distribution within the cross-section of the O-ring. The orange lines are hard surfaces, which apply high pressure. The fluid in the seams has lower pressure. The soft O-ring bridges the pressure over the

27:

629:

Explosive decompression – An O-ring embolism, also called gas expansion rupture, occurs when high pressure gas becomes trapped inside the elastomeric seal element. This expansion causes blisters and ruptures on the surface of the

696:

at the joint between two segments in the moments immediately preceding the disaster. This was blamed on a failed O-ring seal. The escaping high-temperature gas impinged upon the external tank, and the entire vehicle was destroyed as a result.

950:

559:

for O-rings. The square ring is typically manufactured by molding an elastomer sleeve which is then lathe-cut. This style of seal is sometimes less expensive to manufacture with certain materials and molding technologies (

1015:

969:

85:

O-rings are one of the most common seals used in machine design because they are inexpensive, easy to make, reliable and have simple mounting requirements. They have been tested to seal up to 5,000

3613:

305:

British

Standard (BS) which are imperial sizes or metric sizes. Typical dimensions of an O-ring are internal dimension (id), outer dimension (od) and thickness / cross section (cs)

77:

pistons. Static applications of O-rings may include fluid or gas sealing applications in which: (1) the O-ring is compressed resulting in zero clearance, (2) the O-ring material is

236:

applications, the permeability of the material renders the point contacts unusable. Instead, higher mounting forces are used and the ring fills the whole groove. Also, round

69:

The O-ring may be used in static applications or in dynamic applications where there is relative motion between the parts and the O-ring. Dynamic examples include rotating

599:

O-ring materials may be subjected to high or low temperatures, chemical attack, vibration, abrasion, and movement. Elastomers are selected according to the situation.

507:

202:

Successful O-ring joint design requires a rigid mechanical mounting that applies a predictable deformation to the O-ring. This introduces a calculated mechanical

813:

1325:

93:) of pressure. The maximum recommended pressure of an O-ring seal depends on the seal hardness, material, cross-sectional diameter, and radial clearance.

3125:

607:

gas at very low concentrations, unless protected. Swelling by contact with a low viscosity fluid causes an increase in dimensions, and also lowers the

3120:

126:

3342:

920:

3130:

2625:

2003:

611:

of the rubber. Other failures can be caused by using the wrong size of ring for a specific recess, which may cause extrusion of the rubber.

1089:

2847:

441:

219:

still important to maintain good surface finish of those mating parts, especially at low temperatures where the seal rubber reaches its

3817:

1298:

3922:

3842:

3633:

3628:

3474:

164:

as a critical war-related item and gave the right to manufacture to other organizations. Christensen received a lump sum payment of

1152:

3640:

1318:

153:

1994:

1250:

292:

In some high-temperature applications, O-rings may need to be mounted in a tangentially compressed state, to compensate for the

4173:

2363:

2535:

1893:

777:

657:

on

January 28, 1986. A crucial factor was cold weather prior to the launch. This was famously demonstrated on television by

313:

circumference, an approximately 116 m (381 ft) inner diameter, and a cross section of 7.2 mm (0.28 in).

4242:

4043:

3566:

2949:

2540:

2510:

731:

3887:

3217:

3014:

1311:

743:

737:

129:, the inventor of the O-ring, received the patent. The US patent for the O-ring was filed in 1937 by a then 72-year-old

2338:

1832:

1196:

693:

658:

3414:

2438:

688:, it loses its elasticity and becomes brittle. More importantly, when an O-ring is cooled near (but not beyond) its T

650:

644:

3978:

3150:

2994:

820:

375:

168:

75,000 for his efforts. Litigation resulted in a $ 100,000 payment to his heirs in 1971, 19 years after his death.

378:(EPDM): good resistance to hot water and steam, detergents, caustic potash solutions, sodium hydroxide solutions,

884:

710:

4073:

4068:

3827:

3775:

1510:

1043:

1749:

3867:

3197:

2710:

2358:

1807:

363:

152:(trams). Despite his legal efforts, the patents were passed from company to company until they ended up at

1391:

681:

220:

141:... made of solid rubber or rubber composition", and explains, "this sliding or partial rolling of the ring

603:

the material, start brittle cracks or cause it to swell. For example, NBR seals can crack when exposed to

4212:

3690:

1987:

215:

as long as it does not fail mechanically. The most common failure is extrusion through the mating parts.

62:, designed to be seated in a groove and compressed during assembly between two or more parts, forming a

3872:

3780:

3730:

3489:

2822:

2817:

2216:

1334:

945:

4138:

4083:

3862:

3847:

3105:

2525:

2021:

1943:

1857:

1822:

1802:

1754:

1662:

386:

4186:

4093:

3882:

3857:

3069:

3064:

1938:

1779:

1488:

453:

190:

185:

O-rings are available in various metric and inch standard sizes. Sizes are specified by the inside

59:

3740:

3282:

3272:

3267:

2842:

2827:

2767:

2201:

2196:

2156:

1713:

467:

435:

329:

O-ring selection is based on chemical compatibility, application temperature, sealing pressure,

4316:

4290:

4058:

4048:

3177:

2595:

2176:

1980:

1535:

1093:

924:

20:

3479:

2989:

2211:

2181:

2074:

2064:

2025:

2017:

1652:

1493:

1068:

86:

4237:

4143:

3877:

3852:

3695:

3536:

3287:

2974:

2777:

2650:

2433:

1647:

1419:

622:

Installation damage – This is caused by improper installation of the O-ring.

244:

and the partial pressure of gases only at the seal, their gradients will be steep near the

1222:

8:

4311:

4078:

1797:

1695:

1425:

844:

787:

665:, when he placed a small O-ring into ice-cold water, and subsequently showed its loss of

579:

560:

240:

are used to save the ring from excessive deformation. Because the ring is subject to the

110:

4023:

3958:

2298:

1718:

1515:

626:

series of deep spiral cuts (typically at a 45-degree angle) on the surface of the seal.

404:

148:

Soon after migrating to the United States in 1891, he patented an air brake system for

74:

1236:

2852:

1520:

1460:

1411:

1254:

575:

568:

429:

251:

245:

134:

106:

63:

3586:

3327:

2655:

1972:

1812:

1769:

1728:

1677:

1642:

1563:

1550:

608:

564:

351:

340:

293:

241:

203:

114:

906:

585:

Automotive cylinder heads are typically sealed by flat gaskets faced with copper.

4196:

3917:

3822:

3576:

3504:

3499:

3494:

2979:

2942:

2937:

2932:

2927:

2922:

2917:

2912:

1923:

1634:

1483:

1440:

1069:"MDC Vacuum Products-Vacuum Components, Chambers, Valves, Flanges & Fittings"

792:

662:

447:

392:

379:

369:

269:

1275:

1010:

964:

3484:

3232:

3044:

2907:

2897:

2892:

2887:

2882:

2877:

2872:

2867:

2862:

2231:

2221:

1789:

1759:

1614:

1381:

1128:

782:

772:

762:

677:

460:

410:

398:

1030:

873:. S.A.E. Annual Meeting. Hamilton Standard Prop. Div. of United Aircraft Corp.

4305:

4272:

4247:

4232:

4168:

4163:

4158:

4153:

4148:

3993:

3938:

3907:

3897:

3760:

3750:

3720:

3715:

3665:

3645:

3623:

3608:

3561:

3526:

3469:

3464:

3454:

3332:

3277:

3252:

3247:

3227:

3100:

2640:

2079:

2049:

1961:

1852:

1845:

1667:

1599:

1594:

1558:

1475:

1415:

1376:

1366:

1303:

90:

1153:"Trelleborg Sets Guinness World Record for the Largest O-Ring Ever Produced"

125:

The first patent for the O-ring is dated May 12, 1896, as a

Swedish patent.

4133:

4103:

3963:

3307:

3302:

3165:

3160:

3155:

3074:

3019:

2969:

2902:

2857:

2832:

2762:

2757:

2752:

2747:

2742:

2700:

2665:

2575:

2570:

2398:

2206:

1578:

1573:

1540:

1445:

1435:

1371:

1355:

477:

423:

357:

237:

157:

4108:

3805:

3800:

3795:

3379:

3296:

2268:

1956:

1840:

1657:

1609:

1568:

1525:

1455:

1044:"Nor-Cal Products, Inc. - NW Stainless Steel Centering Rings with O-ring"

1013:, Christensen, Niels A., "Hydraulic brake", issued 1938-04-26

757:

330:

248:

and shallow in the bulk (opposite to the gradient of the contact stress (

1251:"John Crane seals measure up to API standards: News from John Crane EAA"

4098:

4003:

3710:

3685:

3449:

3404:

3140:

2797:

2610:

2503:

2498:

2493:

2453:

2428:

2303:

2059:

1928:

1888:

1867:

1862:

1764:

1672:

1604:

1530:

1470:

1401:

989:

495:

78:

1166:

4267:

4262:

4257:

4252:

4227:

4217:

4178:

4128:

4123:

4118:

4113:

4018:

4013:

4008:

3998:

3988:

3973:

3953:

3948:

3943:

3892:

3837:

3832:

3812:

3790:

3770:

3725:

3705:

3660:

3655:

3650:

3618:

3581:

3571:

3556:

3551:

3546:

3531:

3516:

3511:

3439:

3434:

3429:

3409:

3399:

3394:

3389:

3374:

3369:

3317:

3312:

3292:

3262:

3237:

3222:

3192:

3145:

3135:

3115:

3110:

3095:

3090:

3004:

2725:

2720:

2615:

2261:

2256:

2251:

2246:

2241:

2149:

2144:

2139:

2134:

1883:

1624:

1619:

1406:

1386:

666:

485:

481:

344:

334:

165:

102:

55:

1047:

649:

The failure of an O-ring seal was determined to be the cause of the

591:

Elastomers or soft metals that solidify in place are used as seals.

3902:

3680:

3384:

3212:

3049:

3039:

3024:

2999:

2984:

2959:

2954:

2837:

2812:

2807:

2792:

2787:

2782:

2772:

2737:

2732:

2715:

2695:

2690:

2685:

2680:

2675:

2670:

2660:

2645:

2635:

2630:

2620:

2605:

2600:

2590:

2585:

2580:

2565:

2560:

2555:

2550:

2545:

2530:

2515:

2488:

2483:

2478:

2473:

2468:

2463:

2458:

2448:

2443:

2423:

2418:

2408:

2403:

2393:

2388:

2378:

2373:

2368:

2343:

2333:

2226:

2129:

2124:

2119:

2114:

2109:

2104:

2099:

2094:

2089:

1906:

1902:

1774:

1505:

1430:

1396:

1167:"O-ring Design, O-ring Design Guide, O-ring Seal Design -Mykin Inc"

417:

207:

186:

734:

Inside diameters, cross-sections, tolerances and designation codes

588:

Knife edges pressed into copper gaskets are used for high vacuum.

4191:

3983:

3968:

3765:

3755:

3745:

3521:

3337:

3182:

3170:

2328:

2323:

2318:

2313:

2308:

2293:

2288:

2283:

2278:

2273:

2236:

2191:

2186:

2171:

2166:

2161:

1933:

1817:

1114:

967:, Christensen, Niels A., "Packing", issued 1939-11-21

281:

130:

1129:"AS568: Aerospace Size Standard for O-Rings - SAE International"

546:

4053:

4038:

4033:

4028:

3700:

3675:

3603:

3459:

3444:

3424:

3419:

3364:

3357:

3352:

3347:

3242:

3207:

3054:

2705:

2084:

1744:

1723:

1500:

1450:

767:

277:

273:

265:

261:

233:

161:

47:

19:

This article is about the mechanical seal. For other uses, see

4088:

4063:

3785:

3670:

3541:

3322:

3187:

3059:

3034:

3029:

3009:

2383:

2353:

2348:

2069:

2054:

2044:

2039:

604:

211:

51:

491:

Thermoplastic etheresterelastomers (TEEEs) copolyesters

3735:

3598:

3591:

3257:

3202:

2802:

2413:

1898:

574:

Similar devices with a non-round cross-sections are called

257:

149:

70:

321:

268:

O-rings. Also, vacuum systems that have to be immersed in

4222:

3912:

2964:

1345:

725:

673:

176:

26:

676:, which was specified by the shuttle motor contractor,

473:

Thermoplastic polyolefin (TPO) LDPE, HDPE, LLDPE, ULDPE

514:

Air, 200 to 300 °F (93 to 149 °C) – Silicone

194:

BS932. Several other size specifications also exist.

2002:

944:

634:

618:There are a few common reasons for O-ring failure:

526:

Hydraulic Oil (Petroleum Base, Industrial) – Buna-N

871:O-Ring Seals in the Design of Hydraulic Mechanisms

206:at the O-ring contacting surfaces. As long as the

948:, Niels A. Christensen, issued 1939-11-21

923:. Inventors.about.com. 2010-06-15. Archived from

16:Mechanical, toroid gasket that seals an interface

4303:

1253:. Processingtalk.com. 2005-12-09. Archived from

1215:

287:

887:. Parker O-Ring & Engineered Seals Division

1333:

1191:

1189:

1187:

1185:

1183:

1988:

1319:

885:"Frequently Asked O-ring Technical Questions"

160:, the US government commandeered the O-ring

1180:

1092:. Glossary.oilfield.slb.com. Archived from

1009:

963:

740:Housing dimensions for general applications

1995:

1981:

1326:

1312:

819:. EPM, Inc. - The Seal Man. Archived from

1392:Crankcase ventilation system (PCV valve)

811:

545:

320:

175:

25:

529:Hydraulic Oils (Synthetic Base) – Viton

197:

4304:

726:ISO 3601 Fluid power systems — O-rings

709:, and they did not play a role in the

672:The material of the failed O-ring was

227:

1976:

1307:

1115:"DHCAE Tools GMBH: OpenFOAM-solution"

868:

778:O-ring theory of economic development

680:. When an O-ring is cooled below its

1299:O-ring basics from C. Otto Gehrckens

984:

982:

980:

746:Anti-extrusion rings (back-up rings)

171:

921:"O-Ring - Who Invented the O-Ring?"

669:before an investigative committee.

13:

14:

4328:

1292:

977:

645:Space Shuttle Challenger disaster

550:O-ring and other sealing profiles

4286:

4285:

814:"The Seal Man's O-Ring Handbook"

594:

578:, packings or gaskets. See also

523:Gasoline – Buna-N or Viton (FKM)

376:Ethylene propylene diene monomer

96:

1494:Overhead valve (pushrod) layout

1268:

1243:

1229:

1159:

1145:

1121:

1107:

1082:

1061:

1036:

1023:

1003:

503:Thermoplastic Vulcanizate (TPV)

494:Thermoplastic polyamide (PEBA)

256:) High-vacuum systems below 10

957:

938:

913:

899:

877:

862:

837:

805:

541:

30:Typical O-ring and application

1:

799:

500:Melt Processible Rubber (MPR)

364:Chlorosulfonated polyethylene

288:High temperature applications

1276:"What is O-Ring Shelf Life?"

1203:. Dichtomatik Americas. 2012

869:Pearl, D.R. (January 1947).

720:

682:glass transition temperature

520:Chlorine Water – Viton (FKM)

221:glass transition temperature

7:

750:

316:

101:O-rings can be produced by

10:

4335:

1335:Internal combustion engine

642:

120:

18:

4281:

4205:

3931:

3083:

2032:

2014:

1952:

1916:

1876:

1831:

1803:Diesel particulate filter

1788:

1755:Idle air control actuator

1737:

1704:

1696:Engine control unit (ECU)

1686:

1633:

1587:

1549:

1469:

1354:

1341:

387:Ethylene propylene rubber

1868:Viscous fan (fan clutch)

1780:Throttle position sensor

1489:Overhead camshaft layout

1223:"Chemical Compatibility"

812:Whitlock, Jerry (2004).

454:Styrene-butadiene rubber

299:

1407:Core plug (freeze plug)

1225:. The O-Ring Store LLC.

468:Thermoplastic elastomer

436:Polytetrafluoroethylene

551:

508:Chemical Compatibility

326:

182:

31:

1031:U.S. patent 5,516,122

946:US patent 2180795

549:

324:

284:at low temperatures.

252:Vacuum flange#KF.2FQF

179:

29:

1648:Compression ignition

1020:, applied 1933-12-29

992:. Uh.edu. 2004-08-01

974:, applied 1937-10-02

694:Solid Rocket Booster

198:Typical applications

1798:Catalytic converter

1237:"X-ring simulation"

788:Polymer degradation

561:compression molding

535:Motor Oils – Buna-N

411:Polyacrylate rubber

228:Vacuum applications

2008:by standard number

1924:Knocking / pinging

1516:Combustion chamber

661:physics professor

552:

430:Polysulfide rubber

405:Perfluoroelastomer

327:

325:Some small O-rings

183:

75:hydraulic cylinder

66:at the interface.

54:; it is a loop of

50:in the shape of a

46:, is a mechanical

38:, also known as a

32:

4299:

4298:

2022:ISO romanizations

1970:

1969:

1939:Stratified charge

1706:Electrical system

1688:Engine management

1521:Compression ratio

1461:Starter ring gear

1360:rotating assembly

990:"No. 555: O-Ring"

569:injection molding

416:Polychloroprene (

372:rubber (ECH, ECO)

341:Synthetic rubbers

337:, size and cost.

280:becomes hard and

276:O-rings, because

172:Theory and design

135:Niels Christensen

133:-born machinist,

107:injection molding

4324:

4289:

4288:

2009:

1997:

1990:

1983:

1974:

1973:

1813:Exhaust manifold

1678:Spark plug wires

1564:Boost controller

1551:Forced induction

1328:

1321:

1314:

1305:

1304:

1287:

1286:

1284:

1283:

1272:

1266:

1265:

1263:

1262:

1247:

1241:

1240:

1233:

1227:

1226:

1219:

1213:

1212:

1210:

1208:

1201:O-ring elastomer

1193:

1178:

1177:

1175:

1174:

1163:

1157:

1156:

1149:

1143:

1142:

1140:

1139:

1125:

1119:

1118:

1111:

1105:

1104:

1102:

1101:

1086:

1080:

1079:

1077:

1076:

1071:. Mdc-vacuum.com

1065:

1059:

1058:

1056:

1055:

1046:. Archived from

1040:

1034:

1033:

1027:

1021:

1019:

1018:

1014:

1007:

1001:

1000:

998:

997:

986:

975:

973:

972:

968:

961:

955:

954:

953:

949:

942:

936:

935:

933:

932:

917:

911:

910:

903:

897:

896:

894:

892:

881:

875:

874:

866:

860:

859:

857:

855:

841:

835:

834:

832:

831:

825:

818:

809:

609:tensile strength

565:transfer molding

352:Butadiene rubber

294:Gow-Joule effect

242:ambient pressure

144:

140:

115:transfer molding

111:pressure molding

4334:

4333:

4327:

4326:

4325:

4323:

4322:

4321:

4302:

4301:

4300:

4295:

4277:

4201:

3927:

3079:

2028:

2010:

2007:

2001:

1971:

1966:

1948:

1944:Top dead centre

1912:

1872:

1827:

1784:

1733:

1707:

1700:

1689:

1682:

1629:

1583:

1545:

1501:Tappet / lifter

1484:Flathead layout

1474:

1465:

1359:

1350:

1337:

1332:

1295:

1290:

1281:

1279:

1278:. Oringsusa.com

1274:

1273:

1269:

1260:

1258:

1249:

1248:

1244:

1235:

1234:

1230:

1221:

1220:

1216:

1206:

1204:

1195:

1194:

1181:

1172:

1170:

1165:

1164:

1160:

1151:

1150:

1146:

1137:

1135:

1127:

1126:

1122:

1113:

1112:

1108:

1099:

1097:

1088:

1087:

1083:

1074:

1072:

1067:

1066:

1062:

1053:

1051:

1042:

1041:

1037:

1029:

1028:

1024:

1016:

1008:

1004:

995:

993:

988:

987:

978:

970:

962:

958:

951:

943:

939:

930:

928:

919:

918:

914:

905:

904:

900:

890:

888:

883:

882:

878:

867:

863:

853:

851:

849:Gallagher Seals

843:

842:

838:

829:

827:

823:

816:

810:

806:

802:

797:

793:Obturating ring

753:

744:ISO 3601-4:2008

738:ISO 3601-2:2016

732:ISO 3601-1:2012

728:

723:

705:occurred since

691:

687:

663:Richard Feynman

647:

641:

597:

544:

470:(TPE) styrenics

448:Silicone rubber

393:Fluoroelastomer

370:Epichlorohydrin

319:

302:

290:

270:liquid nitrogen

230:

200:

174:

142:

138:

123:

99:

24:

17:

12:

11:

5:

4332:

4331:

4320:

4319:

4314:

4297:

4296:

4294:

4293:

4282:

4279:

4278:

4276:

4275:

4270:

4265:

4260:

4255:

4250:

4245:

4240:

4235:

4230:

4225:

4220:

4215:

4209:

4207:

4203:

4202:

4200:

4199:

4194:

4189:

4184:

4181:

4176:

4171:

4166:

4161:

4156:

4151:

4146:

4141:

4136:

4131:

4126:

4121:

4116:

4111:

4106:

4101:

4096:

4091:

4086:

4081:

4076:

4071:

4066:

4061:

4056:

4051:

4046:

4041:

4036:

4031:

4026:

4021:

4016:

4011:

4006:

4001:

3996:

3991:

3986:

3981:

3976:

3971:

3966:

3961:

3956:

3951:

3946:

3941:

3935:

3933:

3929:

3928:

3926:

3925:

3920:

3915:

3910:

3905:

3900:

3895:

3890:

3885:

3880:

3875:

3870:

3865:

3860:

3855:

3850:

3845:

3840:

3835:

3830:

3825:

3820:

3815:

3810:

3809:

3808:

3803:

3793:

3788:

3783:

3778:

3773:

3768:

3763:

3758:

3753:

3748:

3743:

3738:

3733:

3728:

3723:

3718:

3713:

3708:

3703:

3698:

3693:

3688:

3683:

3678:

3673:

3668:

3663:

3658:

3653:

3648:

3643:

3638:

3637:

3636:

3626:

3621:

3616:

3611:

3606:

3601:

3596:

3595:

3594:

3589:

3579:

3574:

3569:

3564:

3559:

3554:

3549:

3544:

3539:

3534:

3529:

3524:

3519:

3514:

3509:

3508:

3507:

3502:

3497:

3492:

3487:

3482:

3477:

3472:

3467:

3457:

3452:

3447:

3442:

3437:

3432:

3427:

3422:

3417:

3412:

3407:

3402:

3397:

3392:

3387:

3382:

3377:

3372:

3367:

3362:

3361:

3360:

3355:

3345:

3340:

3335:

3330:

3325:

3320:

3315:

3310:

3305:

3300:

3290:

3285:

3280:

3275:

3270:

3265:

3260:

3255:

3250:

3245:

3240:

3235:

3230:

3225:

3220:

3215:

3210:

3205:

3200:

3195:

3190:

3185:

3180:

3175:

3174:

3173:

3168:

3163:

3158:

3153:

3143:

3138:

3133:

3128:

3123:

3118:

3113:

3108:

3103:

3098:

3093:

3087:

3085:

3081:

3080:

3078:

3077:

3072:

3067:

3062:

3057:

3052:

3047:

3042:

3037:

3032:

3027:

3022:

3017:

3012:

3007:

3002:

2997:

2992:

2987:

2982:

2977:

2972:

2967:

2962:

2957:

2952:

2947:

2946:

2945:

2940:

2935:

2930:

2925:

2920:

2915:

2910:

2905:

2900:

2895:

2890:

2885:

2880:

2875:

2870:

2865:

2855:

2850:

2845:

2840:

2835:

2830:

2825:

2820:

2815:

2810:

2805:

2800:

2795:

2790:

2785:

2780:

2775:

2770:

2765:

2760:

2755:

2750:

2745:

2740:

2735:

2730:

2729:

2728:

2718:

2713:

2708:

2703:

2698:

2693:

2688:

2683:

2678:

2673:

2668:

2663:

2658:

2653:

2648:

2643:

2638:

2633:

2628:

2623:

2618:

2613:

2608:

2603:

2598:

2593:

2588:

2583:

2578:

2573:

2568:

2563:

2558:

2553:

2548:

2543:

2538:

2533:

2528:

2523:

2518:

2513:

2508:

2507:

2506:

2501:

2496:

2486:

2481:

2476:

2471:

2466:

2461:

2456:

2451:

2446:

2441:

2436:

2431:

2426:

2421:

2416:

2411:

2406:

2401:

2396:

2391:

2386:

2381:

2376:

2371:

2366:

2361:

2356:

2351:

2346:

2341:

2336:

2331:

2326:

2321:

2316:

2311:

2306:

2301:

2296:

2291:

2286:

2281:

2276:

2271:

2266:

2265:

2264:

2259:

2254:

2249:

2244:

2234:

2229:

2224:

2219:

2214:

2209:

2204:

2199:

2194:

2189:

2184:

2179:

2174:

2169:

2164:

2159:

2154:

2153:

2152:

2147:

2142:

2137:

2132:

2127:

2122:

2117:

2112:

2107:

2102:

2097:

2092:

2082:

2077:

2072:

2067:

2062:

2057:

2052:

2047:

2042:

2036:

2034:

2030:

2029:

2015:

2012:

2011:

2000:

1999:

1992:

1985:

1977:

1968:

1967:

1965:

1964:

1959:

1953:

1950:

1949:

1947:

1946:

1941:

1936:

1931:

1926:

1920:

1918:

1914:

1913:

1911:

1910:

1896:

1891:

1886:

1880:

1878:

1874:

1873:

1871:

1870:

1865:

1860:

1855:

1849:

1848:

1843:

1837:

1835:

1833:Cooling system

1829:

1828:

1826:

1825:

1820:

1815:

1810:

1805:

1800:

1794:

1792:

1790:Exhaust system

1786:

1785:

1783:

1782:

1777:

1772:

1767:

1762:

1760:Inlet manifold

1757:

1752:

1747:

1741:

1739:

1735:

1734:

1732:

1731:

1726:

1721:

1716:

1710:

1708:

1705:

1702:

1701:

1699:

1698:

1692:

1690:

1687:

1684:

1683:

1681:

1680:

1675:

1670:

1665:

1660:

1655:

1650:

1645:

1639:

1637:

1631:

1630:

1628:

1627:

1622:

1617:

1615:Fuel injection

1612:

1607:

1602:

1597:

1591:

1589:

1585:

1584:

1582:

1581:

1576:

1571:

1566:

1561:

1555:

1553:

1547:

1546:

1544:

1543:

1538:

1533:

1528:

1523:

1518:

1513:

1508:

1503:

1497:

1496:

1491:

1486:

1480:

1478:

1467:

1466:

1464:

1463:

1458:

1453:

1448:

1443:

1438:

1433:

1428:

1423:

1409:

1404:

1399:

1394:

1389:

1384:

1382:Connecting rod

1379:

1374:

1369:

1363:

1361:

1352:

1351:

1342:

1339:

1338:

1331:

1330:

1323:

1316:

1308:

1302:

1301:

1294:

1293:External links

1291:

1289:

1288:

1267:

1242:

1228:

1214:

1197:"Type details"

1179:

1158:

1144:

1120:

1106:

1081:

1060:

1035:

1022:

1002:

976:

956:

937:

912:

907:"Factory Tour"

898:

876:

861:

836:

803:

801:

798:

796:

795:

790:

785:

783:Ozone cracking

780:

775:

773:Labyrinth seal

770:

765:

763:Diaphragm seal

760:

754:

752:

749:

748:

747:

741:

735:

727:

724:

722:

719:

711:Space Shuttle

689:

685:

678:Morton-Thiokol

651:Space Shuttle

643:Main article:

640:

635:Space Shuttle

633:

632:

631:

627:

623:

596:

593:

543:

540:

537:

536:

533:

530:

527:

524:

521:

518:

515:

505:

504:

501:

498:

492:

489:

476:Thermoplastic

474:

471:

461:Thermoplastics

458:

457:

451:

445:

439:

433:

427:

421:

414:

408:

402:

399:Nitrile rubber

396:

390:

384:

373:

367:

361:

355:

333:requirements,

318:

315:

301:

298:

289:

286:

229:

226:

199:

196:

173:

170:

127:J. O. Lundberg

122:

119:

98:

95:

15:

9:

6:

4:

3:

2:

4330:

4329:

4318:

4317:ISO standards

4315:

4313:

4310:

4309:

4307:

4292:

4284:

4283:

4280:

4274:

4271:

4269:

4266:

4264:

4261:

4259:

4256:

4254:

4251:

4249:

4246:

4244:

4241:

4239:

4236:

4234:

4231:

4229:

4226:

4224:

4221:

4219:

4216:

4214:

4211:

4210:

4208:

4204:

4198:

4195:

4193:

4190:

4188:

4185:

4182:

4180:

4177:

4175:

4172:

4170:

4167:

4165:

4162:

4160:

4157:

4155:

4152:

4150:

4147:

4145:

4142:

4140:

4137:

4135:

4132:

4130:

4127:

4125:

4122:

4120:

4117:

4115:

4112:

4110:

4107:

4105:

4102:

4100:

4097:

4095:

4092:

4090:

4087:

4085:

4082:

4080:

4077:

4075:

4072:

4070:

4067:

4065:

4062:

4060:

4057:

4055:

4052:

4050:

4047:

4045:

4042:

4040:

4037:

4035:

4032:

4030:

4027:

4025:

4022:

4020:

4017:

4015:

4012:

4010:

4007:

4005:

4002:

4000:

3997:

3995:

3992:

3990:

3987:

3985:

3982:

3980:

3977:

3975:

3972:

3970:

3967:

3965:

3962:

3960:

3957:

3955:

3952:

3950:

3947:

3945:

3942:

3940:

3937:

3936:

3934:

3930:

3924:

3921:

3919:

3916:

3914:

3911:

3909:

3906:

3904:

3901:

3899:

3896:

3894:

3891:

3889:

3886:

3884:

3881:

3879:

3876:

3874:

3871:

3869:

3866:

3864:

3861:

3859:

3856:

3854:

3851:

3849:

3846:

3844:

3841:

3839:

3836:

3834:

3831:

3829:

3826:

3824:

3821:

3819:

3816:

3814:

3811:

3807:

3804:

3802:

3799:

3798:

3797:

3794:

3792:

3789:

3787:

3784:

3782:

3779:

3777:

3774:

3772:

3769:

3767:

3764:

3762:

3759:

3757:

3754:

3752:

3749:

3747:

3744:

3742:

3739:

3737:

3734:

3732:

3729:

3727:

3724:

3722:

3719:

3717:

3714:

3712:

3709:

3707:

3704:

3702:

3699:

3697:

3694:

3692:

3689:

3687:

3684:

3682:

3679:

3677:

3674:

3672:

3669:

3667:

3664:

3662:

3659:

3657:

3654:

3652:

3649:

3647:

3644:

3642:

3639:

3635:

3632:

3631:

3630:

3627:

3625:

3622:

3620:

3617:

3615:

3612:

3610:

3607:

3605:

3602:

3600:

3597:

3593:

3590:

3588:

3585:

3584:

3583:

3580:

3578:

3575:

3573:

3570:

3568:

3565:

3563:

3560:

3558:

3555:

3553:

3550:

3548:

3545:

3543:

3540:

3538:

3535:

3533:

3530:

3528:

3525:

3523:

3520:

3518:

3515:

3513:

3510:

3506:

3503:

3501:

3498:

3496:

3493:

3491:

3488:

3486:

3483:

3481:

3478:

3476:

3473:

3471:

3468:

3466:

3463:

3462:

3461:

3458:

3456:

3453:

3451:

3448:

3446:

3443:

3441:

3438:

3436:

3433:

3431:

3428:

3426:

3423:

3421:

3418:

3416:

3413:

3411:

3408:

3406:

3403:

3401:

3398:

3396:

3393:

3391:

3388:

3386:

3383:

3381:

3378:

3376:

3373:

3371:

3368:

3366:

3363:

3359:

3356:

3354:

3351:

3350:

3349:

3346:

3344:

3341:

3339:

3336:

3334:

3331:

3329:

3326:

3324:

3321:

3319:

3316:

3314:

3311:

3309:

3306:

3304:

3301:

3298:

3294:

3291:

3289:

3286:

3284:

3281:

3279:

3276:

3274:

3271:

3269:

3266:

3264:

3261:

3259:

3256:

3254:

3251:

3249:

3246:

3244:

3241:

3239:

3236:

3234:

3231:

3229:

3226:

3224:

3221:

3219:

3216:

3214:

3211:

3209:

3206:

3204:

3201:

3199:

3196:

3194:

3191:

3189:

3186:

3184:

3181:

3179:

3176:

3172:

3169:

3167:

3164:

3162:

3159:

3157:

3154:

3152:

3149:

3148:

3147:

3144:

3142:

3139:

3137:

3134:

3132:

3129:

3127:

3124:

3122:

3119:

3117:

3114:

3112:

3109:

3107:

3104:

3102:

3099:

3097:

3094:

3092:

3089:

3088:

3086:

3082:

3076:

3073:

3071:

3068:

3066:

3063:

3061:

3058:

3056:

3053:

3051:

3048:

3046:

3043:

3041:

3038:

3036:

3033:

3031:

3028:

3026:

3023:

3021:

3018:

3016:

3013:

3011:

3008:

3006:

3003:

3001:

2998:

2996:

2993:

2991:

2988:

2986:

2983:

2981:

2978:

2976:

2973:

2971:

2968:

2966:

2963:

2961:

2958:

2956:

2953:

2951:

2948:

2944:

2941:

2939:

2936:

2934:

2931:

2929:

2926:

2924:

2921:

2919:

2916:

2914:

2911:

2909:

2906:

2904:

2901:

2899:

2896:

2894:

2891:

2889:

2886:

2884:

2881:

2879:

2876:

2874:

2871:

2869:

2866:

2864:

2861:

2860:

2859:

2856:

2854:

2851:

2849:

2846:

2844:

2841:

2839:

2836:

2834:

2831:

2829:

2826:

2824:

2821:

2819:

2816:

2814:

2811:

2809:

2806:

2804:

2801:

2799:

2796:

2794:

2791:

2789:

2786:

2784:

2781:

2779:

2776:

2774:

2771:

2769:

2766:

2764:

2761:

2759:

2756:

2754:

2751:

2749:

2746:

2744:

2741:

2739:

2736:

2734:

2731:

2727:

2724:

2723:

2722:

2719:

2717:

2714:

2712:

2709:

2707:

2704:

2702:

2699:

2697:

2694:

2692:

2689:

2687:

2684:

2682:

2679:

2677:

2674:

2672:

2669:

2667:

2664:

2662:

2659:

2657:

2654:

2652:

2649:

2647:

2644:

2642:

2639:

2637:

2634:

2632:

2629:

2627:

2624:

2622:

2619:

2617:

2614:

2612:

2609:

2607:

2604:

2602:

2599:

2597:

2594:

2592:

2589:

2587:

2584:

2582:

2579:

2577:

2574:

2572:

2569:

2567:

2564:

2562:

2559:

2557:

2554:

2552:

2549:

2547:

2544:

2542:

2539:

2537:

2534:

2532:

2529:

2527:

2524:

2522:

2519:

2517:

2514:

2512:

2509:

2505:

2502:

2500:

2497:

2495:

2492:

2491:

2490:

2487:

2485:

2482:

2480:

2477:

2475:

2472:

2470:

2467:

2465:

2462:

2460:

2457:

2455:

2452:

2450:

2447:

2445:

2442:

2440:

2437:

2435:

2432:

2430:

2427:

2425:

2422:

2420:

2417:

2415:

2412:

2410:

2407:

2405:

2402:

2400:

2397:

2395:

2392:

2390:

2387:

2385:

2382:

2380:

2377:

2375:

2372:

2370:

2367:

2365:

2362:

2360:

2357:

2355:

2352:

2350:

2347:

2345:

2342:

2340:

2337:

2335:

2332:

2330:

2327:

2325:

2322:

2320:

2317:

2315:

2312:

2310:

2307:

2305:

2302:

2300:

2297:

2295:

2292:

2290:

2287:

2285:

2282:

2280:

2277:

2275:

2272:

2270:

2267:

2263:

2260:

2258:

2255:

2253:

2250:

2248:

2245:

2243:

2240:

2239:

2238:

2235:

2233:

2230:

2228:

2225:

2223:

2220:

2218:

2215:

2213:

2210:

2208:

2205:

2203:

2200:

2198:

2195:

2193:

2190:

2188:

2185:

2183:

2180:

2178:

2175:

2173:

2170:

2168:

2165:

2163:

2160:

2158:

2155:

2151:

2148:

2146:

2143:

2141:

2138:

2136:

2133:

2131:

2128:

2126:

2123:

2121:

2118:

2116:

2113:

2111:

2108:

2106:

2103:

2101:

2098:

2096:

2093:

2091:

2088:

2087:

2086:

2083:

2081:

2078:

2076:

2073:

2071:

2068:

2066:

2063:

2061:

2058:

2056:

2053:

2051:

2048:

2046:

2043:

2041:

2038:

2037:

2035:

2031:

2027:

2026:IEC standards

2023:

2019:

2018:ISO standards

2013:

2005:

1998:

1993:

1991:

1986:

1984:

1979:

1978:

1975:

1963:

1960:

1958:

1955:

1954:

1951:

1945:

1942:

1940:

1937:

1935:

1932:

1930:

1927:

1925:

1922:

1921:

1919:

1915:

1908:

1904:

1900:

1897:

1895:

1892:

1890:

1887:

1885:

1882:

1881:

1879:

1875:

1869:

1866:

1864:

1861:

1859:

1856:

1854:

1851:

1850:

1847:

1846:Water cooling

1844:

1842:

1839:

1838:

1836:

1834:

1830:

1824:

1823:Oxygen sensor

1821:

1819:

1816:

1814:

1811:

1809:

1806:

1804:

1801:

1799:

1796:

1795:

1793:

1791:

1787:

1781:

1778:

1776:

1773:

1771:

1768:

1766:

1763:

1761:

1758:

1756:

1753:

1751:

1748:

1746:

1743:

1742:

1740:

1738:Intake system

1736:

1730:

1729:Starter motor

1727:

1725:

1722:

1720:

1717:

1715:

1712:

1711:

1709:

1703:

1697:

1694:

1693:

1691:

1685:

1679:

1676:

1674:

1671:

1669:

1668:Ignition coil

1666:

1664:

1661:

1659:

1656:

1654:

1651:

1649:

1646:

1644:

1641:

1640:

1638:

1636:

1632:

1626:

1623:

1621:

1618:

1616:

1613:

1611:

1608:

1606:

1603:

1601:

1600:Petrol engine

1598:

1596:

1595:Diesel engine

1593:

1592:

1590:

1586:

1580:

1577:

1575:

1572:

1570:

1567:

1565:

1562:

1560:

1559:Blowoff valve

1557:

1556:

1554:

1552:

1548:

1542:

1539:

1537:

1534:

1532:

1529:

1527:

1524:

1522:

1519:

1517:

1514:

1512:

1509:

1507:

1504:

1502:

1499:

1498:

1495:

1492:

1490:

1487:

1485:

1482:

1481:

1479:

1477:

1476:Cylinder head

1472:

1468:

1462:

1459:

1457:

1454:

1452:

1449:

1447:

1444:

1442:

1439:

1437:

1434:

1432:

1429:

1427:

1424:

1421:

1417:

1413:

1410:

1408:

1405:

1403:

1400:

1398:

1395:

1393:

1390:

1388:

1385:

1383:

1380:

1378:

1375:

1373:

1370:

1368:

1367:Balance shaft

1365:

1364:

1362:

1357:

1353:

1349:

1347:

1340:

1336:

1329:

1324:

1322:

1317:

1315:

1310:

1309:

1306:

1300:

1297:

1296:

1277:

1271:

1257:on 2009-02-24

1256:

1252:

1246:

1238:

1232:

1224:

1218:

1202:

1198:

1192:

1190:

1188:

1186:

1184:

1168:

1162:

1154:

1148:

1134:

1130:

1124:

1116:

1110:

1096:on 2011-06-07

1095:

1091:

1085:

1070:

1064:

1050:on 2007-09-21

1049:

1045:

1039:

1032:

1026:

1012:

1006:

991:

985:

983:

981:

966:

960:

947:

941:

927:on 2009-03-15

926:

922:

916:

908:

902:

886:

880:

872:

865:

850:

846:

845:"GFS O-Rings"

840:

826:on 2019-08-10

822:

815:

808:

804:

794:

791:

789:

786:

784:

781:

779:

776:

774:

771:

769:

766:

764:

761:

759:

756:

755:

745:

742:

739:

736:

733:

730:

729:

718:

716:

714:

708:

702:

698:

695:

683:

679:

675:

670:

668:

664:

660:

656:

654:

646:

638:

628:

624:

621:

620:

619:

616:

612:

610:

606:

600:

595:Failure modes

592:

589:

586:

583:

581:

577:

572:

570:

566:

562:

556:

548:

539:

534:

531:

528:

525:

522:

519:

516:

513:

512:

511:

509:

502:

499:

497:

493:

490:

487:

483:

479:

475:

472:

469:

466:

465:

464:

462:

455:

452:

449:

446:

443:

440:

437:

434:

431:

428:

425:

422:

419:

415:

412:

409:

406:

403:

400:

397:

394:

391:

388:

385:

383:temperatures.

381:

377:

374:

371:

368:

365:

362:

359:

356:

353:

350:

349:

348:

346:

342:

338:

336:

332:

323:

314:

310:

306:

297:

295:

285:

283:

279:

275:

271:

267:

263:

259:

255:

253:

247:

243:

239:

238:back-up rings

235:

225:

222:

216:

213:

209:

205:

195:

192:

191:cross section

188:

178:

169:

167:

163:

159:

155:

151:

146:

136:

132:

128:

118:

116:

112:

108:

104:

97:Manufacturing

94:

92:

88:

83:

80:

76:

72:

67:

65:

61:

60:cross-section

58:with a round

57:

53:

49:

45:

41:

37:

28:

22:

4144:27000 series

2520:

1853:Electric fan

1653:Coil-on-plug

1579:Turbocharger

1574:Supercharger

1446:Main bearing

1436:Firing order

1426:Displacement

1372:Block heater

1356:Engine block

1344:Part of the

1343:

1280:. Retrieved

1270:

1259:. Retrieved

1255:the original

1245:

1231:

1217:

1205:. Retrieved

1200:

1171:. Retrieved

1161:

1147:

1136:. Retrieved

1132:

1123:

1109:

1098:. Retrieved

1094:the original

1084:

1073:. Retrieved

1063:

1052:. Retrieved

1048:the original

1038:

1025:

1005:

994:. Retrieved

959:

940:

929:. Retrieved

925:the original

915:

901:

889:. Retrieved

879:

870:

864:

852:. Retrieved

848:

839:

828:. Retrieved

821:the original

807:

712:

706:

703:

699:

671:

652:

648:

636:

617:

613:

601:

598:

590:

587:

584:

573:

557:

553:

538:

532:Water – EPDM

506:

478:polyurethane

459:

424:Polyisoprene

358:Butyl rubber

339:

328:

311:

307:

303:

291:

249:

231:

217:

201:

184:

158:World War II

154:Westinghouse

147:

124:

100:

84:

68:

43:

39:

35:

33:

3932:20000–29999

3084:10000–19999

1877:Lubrication

1841:Air cooling

1658:Distributor

1610:Fuel filter

1588:Fuel system

1569:Intercooler

1536:Timing belt

1526:Head gasket

1456:Piston ring

1169:. Mykin.com

1133:www.sae.org

891:December 7,

758:Cooper Ring

667:flexibility

542:Other seals

517:Beer - EPDM

331:lubrication

73:shafts and

44:toric joint

4312:Seal rings

4306:Categories

3711:16949 (TS)

3308:11941 (TR)

2006:standards

1929:Power band

1889:Oil filter

1863:Thermostat

1808:EGT sensor

1770:MAF sensor

1765:MAP sensor

1750:Air filter

1714:Alternator

1673:Spark plug

1605:Carburetor

1531:Rocker arm

1471:Valvetrain

1402:Crankshaft

1346:Automobile

1282:2011-03-25

1261:2011-03-25

1173:2011-03-25

1138:2018-02-20

1100:2011-03-25

1075:2011-03-25

1054:2008-01-25

996:2011-03-25

931:2011-03-25

830:2018-12-08

800:References

707:Challenger

653:Challenger

637:Challenger

496:Polyamides

345:Thermosets

156:. During

150:streetcars

79:vulcanized

3666:15926 WIP

3030:9592/9593

2955:9000/9001

2843:8805/8806

1663:Glow plug

1625:Fuel tank

1620:Fuel pump

1387:Crankcase

721:Standards

717:of 2003.

486:polyester

482:polyether

442:Sanifluor

335:durometer

103:extrusion

89:(34

56:elastomer

4291:Category

2016:List of

1962:Category

1907:Dry sump

1903:Wet sump

1894:Oil pump

1858:Radiator

1775:Throttle

1635:Ignition

1506:Camshaft

1431:Flywheel

1412:Cylinder

1397:Crankpin

1090:"O-ring"

854:4 August

751:See also

715:disaster

713:Columbia

655:disaster

639:disaster

418:neoprene

380:silicone

317:Material

208:pressure

189:and the

187:diameter

4192:29199-2

4064:23094-2

4059:23094-1

4049:23090-3

3918:19794-5

3913:19775-1

3701:16612-2

3691:16355-1

3380:13406-2

3338:12234-2

3106:10118-3

1934:Redline

1818:Muffler

1719:Battery

1643:Magneto

1207:9 April

1011:2115383

965:2180795

659:Caltech

580:washers

282:brittle

210:of the

121:History

40:packing

4206:30000+

3045:9797-1

2853:8820-5

2798:8501-1

2354:1073-2

2349:1073-1

2033:1–9999

1957:Portal

1745:Airbox

1724:Dynamo

1451:Piston

1441:Stroke

1420:layout

1348:series

1017:

971:

952:

768:Gasket

480:(TPU)

444:(FEPM)

438:(PTFE)

420:) (CR)

407:(FFKM)

278:rubber

274:indium

266:nickel

262:copper

234:vacuum

204:stress

181:seams.

162:patent

143:

139:

131:Danish

48:gasket

36:O-ring

4273:80000

4268:56000

4263:55000

4258:50001

4253:45001

4248:42010

4243:40500

4238:39075

4233:38500

4228:37001

4223:32000

4218:31000

4213:30170

4197:29500

4187:29148

4183:29110

4179:28000

4174:27729

4169:27006

4164:27005

4159:27002

4154:27001

4149:27000

4139:26324

4134:26300

4129:26262

4124:26000

4119:25964

4114:25178

4109:24728

4104:24707

4099:24617

4094:24613

4089:24517

4084:23941

4079:23360

4074:23271

4069:23270

4054:23092

4044:23009

4039:23008

4034:23003

4029:23000

4024:22537

4019:22395

4014:22301

4009:22300

4004:22275

3999:22000

3994:21827

3989:21500

3984:21122

3979:21047

3974:21001

3969:21000

3964:20830

3959:20802

3954:20400

3949:20121

3944:20022

3939:20000

3923:19831

3908:19770

3903:19757

3898:19752

3893:19600

3888:19510

3883:19509

3878:19508

3873:19507

3868:19506

3863:19505

3858:19503

3853:19502

3848:19501

3843:19500

3838:19439

3833:19407

3828:19136

3823:19125

3818:19115

3813:19114

3796:19092

3791:19011

3786:19005

3781:18916

3776:18629

3771:18245

3766:18181

3761:18014

3756:18004

3751:17799

3746:17506

3741:17442

3736:17369

3731:17203

3726:17100

3721:17025

3716:17024

3706:16750

3696:16485

3686:16262

3681:16023

3676:15938

3671:15930

3661:15926

3656:15924

3651:15919

3646:15897

3641:15707

3629:15706

3624:15693

3619:15686

3614:15511

3609:15504

3604:15438

3599:15445

3582:15444

3577:15408

3572:15398

3567:15291

3562:15288

3557:15189

3552:15022

3547:14971

3542:14882

3537:14764

3532:14698

3527:14651

3522:14649

3517:14644

3512:14617

3460:14496

3455:14443

3450:14396

3445:14289

3440:14224

3435:14031

3430:14000

3425:13818

3420:13816

3415:13616

3410:13584

3405:13568

3400:13567

3395:13490

3390:13485

3385:13450

3375:13399

3370:13250

3365:13216

3348:13211

3343:12620

3333:12207

3328:12182

3323:12052

3318:12006

3313:11992

3303:11941

3293:11940

3288:11898

3283:11889

3278:11801

3273:11785

3268:11784

3263:11783

3258:11544

3253:11404

3248:11179

3243:11172

3238:11170

3233:11073

3228:10967

3223:10962

3218:10957

3213:10861

3208:10746

3203:10664

3198:10646

3193:10628

3188:10589

3183:10585

3178:10383

3146:10303

3141:10279

3136:10218

3131:10206

3126:10179

3121:10165

3116:10161

3111:10160

3101:10116

3096:10007

3091:10006

1917:Other

1541:Valve

1511:Chest

824:(PDF)

817:(PDF)

630:seal.

605:ozone

576:seals

456:(SBR)

432:(PSR)

413:(ACM)

389:(EPR)

366:(CSM)

360:(IIR)

300:Sizes

212:fluid

52:torus

42:or a

21:Oring

3171:-238

3075:9995

3070:9985

3065:9984

3060:9945

3055:9899

3050:9897

3040:9660

3035:9594

3025:9564

3020:9529

3015:9506

3010:9496

3005:9407

3000:9362

2995:9314

2990:9293

2985:9241

2980:9227

2975:9141

2970:9126

2965:9075

2960:9036

2950:8879

2903:-8-I

2858:8859

2848:8807

2838:8691

2833:8652

2828:8651

2823:8632

2818:8613

2813:8601

2808:8583

2803:8571

2793:8373

2788:8217

2783:8178

2778:8093

2773:8000

2768:7942

2763:7816

2758:7813

2753:7812

2748:7811

2743:7810

2738:7736

2733:7637

2721:7498

2716:7200

2711:7185

2706:7098

2701:7064

2696:7027

2691:7010

2686:7002

2681:7001

2676:6943

2671:6709

2666:6523

2661:6438

2656:6429

2651:6425

2646:6385

2641:6373

2636:6346

2631:6344

2626:6166

2621:5964

2616:5807

2611:5800

2606:5776

2601:5775

2596:5725

2591:5428

2586:5427

2581:5426

2576:5218

2571:4909

2566:4217

2561:4165

2556:4157

2551:4031

2546:3977

2541:3950

2536:3901

2531:3864

2526:3602

2521:3601

2516:3307

2511:3297

2489:3166

2484:3103

2479:3029

2474:2921

2469:2852

2464:2848

2459:2788

2454:2720

2449:2711

2444:2709

2439:2533

2434:2281

2429:2240

2424:2146

2419:2145

2414:2108

2409:2047

2404:2033

2399:2022

2394:2015

2389:2014

2384:1989

2379:1745

2374:1629

2369:1538

2364:1413

2359:1155

2344:1007

2339:1004

2334:1000

2157:68-1

1899:Sump

1416:bank

1377:Bore

1209:2013

893:2018

856:2021

426:(IR)

354:(BR)

272:use

260:use

258:Torr

250:See

246:seal

166:US$

71:pump

64:seal

3505:-20

3500:-17

3495:-14

3490:-12

3485:-11

3480:-10

3166:-28

3161:-22

3156:-21

3151:-11

2943:-16

2938:-15

2933:-14

2928:-13

2923:-12

2918:-11

2913:-10

2329:999

2324:965

2319:898

2314:860

2309:843

2304:838

2299:764

2294:732

2289:704

2284:690

2279:668

2274:657

2269:646

2237:639

2232:519

2227:518

2222:500

2217:361

2212:306

2207:302

2202:262

2197:261

2192:259

2187:233

2182:228

2177:226

2172:217

2167:216

2162:128

2150:-13

2145:-12

2140:-11

2135:-10

2004:ISO

1884:Oil

1473:and

1358:and

674:FKM

264:or

232:In

113:or

91:MPa

87:psi

34:An

4308::

3806:-2

3801:-1

3634:-2

3592:-9

3587:-3

3475:-6

3470:-3

3465:-2

3358:-2

3353:-1

3297:-2

2908:-9

2898:-8

2893:-7

2888:-6

2883:-5

2878:-4

2873:-3

2868:-2

2863:-1

2726:-1

2504:-3

2499:-2

2494:-1

2262:-6

2257:-5

2252:-3

2247:-2

2242:-1

2130:-9

2125:-8

2120:-7

2115:-6

2110:-5

2105:-4

2100:-3

2095:-1

2090:-0

2085:31

2080:17

2075:16

2024:–

2020:–

1905:,

1418:,

1199:.

1182:^

1131:.

979:^

847:.

582:.

567:,

563:,

510::

484:,

463::

347::

343:-

296:.

117:.

109:,

105:,

3299:)

3295:(

2070:9

2065:7

2060:6

2055:4

2050:3

2045:2

2040:1

1996:e

1989:t

1982:v

1909:)

1901:(

1422:)

1414:(

1327:e

1320:t

1313:v

1285:.

1264:.

1239:.

1211:.

1176:.

1155:.

1141:.

1117:.

1103:.

1078:.

1057:.

999:.

934:.

909:.

895:.

858:.

833:.

690:g

686:g

684:T

254:.

23:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.