97:

17:

48:, on which the fibers have been straightened and aligned. The main cylinder of the card will have one or two doffers that comb and remove the fiber. The doffer is set with pins that hold the fiber, which is then removed by a comb or knife and fed into the next stage of production. Doffers are also used in

112:

A breakthrough was made with the ring doffer, where the surface was covered by alternating continuous rings of clothing about an inch wide, separated by spacing rings of some material like leather. The idea seems to have originated with Louis Martin in Europe in 1803, and may have been used by Arnold

128:

filed a patent for a doffer made of a set of parallel wheels with rims about four inches wide, separated by an inch or slightly more. By setting the wheels at a slight angle, the whole surface of the main cylinder would be cleared by them. This doffer would feed a system of rollers that could feed

87:

shortly after 1785. Before the surface of the carding cylinder reaches the doffer it passes a "fancy roller", which brushes and raises the fibers on the cylinder so they can be transferred to the doffer more easily. In a wool mill a doffer would move relatively slowly compared to the surface of the

137:

The most common arrangement today uses a tape doffer completely wrapped in fillet clothing, producing a web the width of the card, which is then split into strips using an array of endless tapes. These tapes used to be made of leather, but today are usually of synthetic material.

104:

At first, the card clothing for wool mills was made in the form of sheets, and when attached to the cylinder and to all the rollers including the last doffer there were gaps of about an inch between the sheets. This made it impossible to make endless

109:. Even when it became possible to wrap the doffer with fillet clothing with no gaps, sheets with gaps continued to be used because a continuous woolen sliver was too difficult to manage through the subsequent steps.

125:

129:

the fiber onto spools or into machines that would immediately twist it into a thread. However, the ring doffer was relatively inefficient.

121:

patented the idea in 1825. With this design, it became possible to produce continuous lengths of slubbing to feed into the next stage.

106:

67:

holding spun fiber and replace them with empty bobbins or pirns. In modern mills, a machine called a doffer may do this task.

270:

59:(meaning something that takes off, as in "doff your hat") is also used for mill workers whose job it is to remove full

320:

79:

for inventing the doffer, which was incorporated in his machine, but others consider that it was invented by

20:

Breaker card showing the doffing cylinder with its longer fancy card and the doffing knife below, at

118:

88:

carding cylinder, picking up the fiber. The fiber would then be removed from the doffer by a comb.

287:

260:

96:

8:

238:

16:

266:

76:

80:

84:

100:

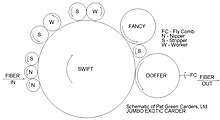

Diagram showing name, location, and rotation of rollers used on a cottage carder

314:

49:

114:

41:

21:

288:"Specification of a Patent for a Doffer for Wool Carding Machines"

45:

124:

Various inventors proposed improvements. Thus, in

October 1835

60:

56:

292:

Mechanics' Magazine, and

Journal of the Mechanics' Institute

64:

217:

215:

176:

200:

152:

212:

188:

164:

312:

44:to remove fiber from the main cylinder of a

237:

158:

262:The Wool Textile Industry in Great Britain

285:

206:

95:

15:

258:

221:

194:

182:

170:

52:and other machinery that handle fiber.

313:

91:

13:

14:

332:

132:

75:Some people have given credit to

286:Parkhurst, Stephen R. (1836).

259:Jenkins, John Geraint (1972).

70:

1:

141:

83:. The design was refined by

7:

10:

337:

265:. Routledge and K. Paul.

119:Haverhill, Massachusetts

40:is a component used in

101:

55:Confusingly, the word

25:

24:in Derbyshire, England

113:Pawtucket in 1812 in

99:

19:

321:Industrial machinery

126:Stephen R. Parkhurst

117:. Ezekial Hale of

92:Design improvements

102:

26:

272:978-0-7100-6979-5

239:"Doff and Doffer"

185:, pp. 79–80.

77:Richard Arkwright

36:or commonly just

328:

306:

304:

303:

282:

280:

279:

255:

253:

252:

243:

225:

219:

210:

204:

198:

192:

186:

180:

174:

168:

162:

156:

81:James Hargreaves

30:doffing cylinder

336:

335:

331:

330:

329:

327:

326:

325:

311:

310:

309:

301:

299:

277:

275:

273:

250:

248:

241:

228:

220:

213:

205:

201:

193:

189:

181:

177:

169:

165:

159:Doff and Doffer

157:

153:

144:

135:

94:

85:Samuel Crompton

73:

12:

11:

5:

334:

324:

323:

308:

307:

283:

271:

256:

246:Nonwoven Tools

234:

233:

232:

227:

226:

224:, pp. 82.

211:

207:Parkhurst 1836

199:

197:, pp. 80.

187:

175:

163:

150:

149:

148:

143:

140:

134:

133:Modern doffers

131:

93:

90:

72:

69:

50:cotton pickers

34:doffing roller

32:, also called

9:

6:

4:

3:

2:

333:

322:

319:

318:

316:

298:. D. K. Minor

297:

293:

289:

284:

274:

268:

264:

263:

257:

247:

240:

236:

235:

230:

229:

223:

218:

216:

209:, p. 81.

208:

203:

196:

191:

184:

179:

173:, p. 79.

172:

167:

160:

155:

151:

146:

145:

139:

130:

127:

122:

120:

116:

110:

108:

98:

89:

86:

82:

78:

68:

66:

62:

58:

53:

51:

47:

43:

42:textile mills

39:

35:

31:

23:

18:

300:. Retrieved

295:

291:

276:. Retrieved

261:

249:. Retrieved

245:

222:Jenkins 1972

202:

195:Jenkins 1972

190:

183:Jenkins 1972

178:

171:Jenkins 1972

166:

154:

136:

123:

115:Rhode Island

111:

103:

74:

54:

37:

33:

29:

27:

71:Early years

22:Masson Mill

302:2012-06-29

278:2012-06-29

251:2012-06-28

142:References

147:Citations

107:slubbings

315:Category

231:Sources

61:bobbins

269:

57:doffer

38:doffer

242:(PDF)

65:pirns

267:ISBN

46:card

63:or

317::

294:.

290:.

244:.

214:^

28:A

305:.

296:8

281:.

254:.

161:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.