374:

403:

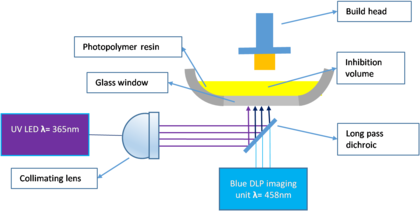

faster. This method allows us to speed up the process up to 200 cm/hr. Moreover, by controlling the intensity of each pixel in the setup topographical patterning can be created in a single exposure with no stage translation. A mixture of photo initiators and photo inhibitors is used in the setup. The absorbance spectra of two material is orthogonal this allows to control the process with the two orthogonal light sources. As the material is generated layer by layer the tray is gradually lifted and the photo inhibitors will not allow adhesion near the window.

255:

348:

270:

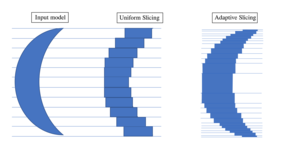

post-processing time decreases. The benefits of adaptive slicing depend on the proportion of the surface-to-volume ratio of the part. Efficient computation of adaptive layers is possible by analyzing the model surface over the full layer height. Several implementations are available as an open source software.

424:

parts) before print, can lead to 2.44x increase in speed over conventional printing method. Moreover, when the object needs to be iterated to find the optimal design it is not efficient to reprint the whole object over and over again: One solution is to print the main constant structure only once and

369:

methods. The process follows by placing silicone rubber particles in a liquid medium with photo-initiator agents. Then the acoustic mask is used to generate the desired pressure sound field to put the particle in the correct order. The next step is applying the UV light to solidify the final product.

337:

Printing methodologies. Each printing methods has its own pros and cons. For example, DLP-based methods have an advantage of manufacturing the entire layer at once. However, DLP idle time is longer due to the adhesion force. SLA based method uses two or more lasers that intersect at specific points

402:

Due to the mentioned effects, the printing speed with SLA methods is limited to a few millimeters to several centimeters per hour. To address this problem a system of two light sources is used, one for polymerization and one for inhibiting the polymerization to avoid adhesion and as a result print

360:

Interesting features of sound waves have encouraged scientists to use it in additive manufacturing. Sound waves can form pressure fields that shape the material in the desired form in a contact-free setup. The fact that it can be applied over a large area at the same time makes it a good candidate

411:

Another way to address the adhesion problem is to create a dead layer which prohibits the curing process. One method to create this dead layer is to use fluorinated oil flow. This liquid is omniphobic which means that it repels all the materials and will not stick to anything. The reason to use a

242:

The less support material used, the faster the build time and finishing time for removing supports. By minimizing the support volume, less material is deposited so, in general, manufacturing time decreases. This factor influences processes that use external support structures, such as SLA,

269:

Error caused by the staircase effect can be measured using several metrics, all of which refer to the difference between model surface and actual printed surface. By adaptively computing the height distribution of layers, this error can be minimized: The quality of surface increases while

333:

Hardware and maintenance issues. After a part is printed, typical cleanup procedures required to ensure that operations continue with the same quality. Depending on the used material's type, parameters of lasers need to be tuned for avoiding the unnecessary over-curing or

229:. Determining the optimal part orientation is a common software solution for all additive manufacturing processes. This can lead to a significant improvement in many key factors that affect the total print time. The following factors heavily depend on part orientation:

127:

3D printing speed refers to only the build stage, a subcomponent of the entire 3D printing process. However, the entire process spans from pre-processing to post-processing stages. The time required for printing a completed part from a data file

317:. Since a product's interior can be filled using many different structures, design optimization through additive manufacturing is necessary. Finding the best way to fill in a product interior given certain constraints is a challenging problem.

364:

The process starts by designing an acoustic hologram. An acoustic hologram is a mask that will direct the sound field to form the desired pattern. It can be fabricated in an additive fabrication combined with etching and

249:

The orientation of a part determines which faces are subjected to the staircase effect -- an artifact of layering. By maximizing the surface quality, the required time to finish the surface to the desired tolerance

206:

Additive manufacturing technologies usually imply a trade off between the printing speed and quality. Improvements in speed of the entire 3D printing process can be grouped in the following two categories.

326:

Tool path planning. Since the speed of the printing tool can change the size of the layer, the physical and mechanical properties of the process need to be taken into account during the tool path planning.

329:

Post-processing. The removed support material can still leave burrs or residue that can be polished by using other methods like sanding the part by hand, bead blasting, traditional machining, or acetone

51:), where the unit of time is measured in Seconds, and the unit of manufactured material is typically measured in units of either kg, mm or cm, depending on the type of additive manufacturing technique.

320:

Part orientation. Theoretically, there are infinitely many orientations. Depending on the purpose of the part, there may not be an optimal orientation when trying to optimize multiple criteria at once.

143:, which spans the preparation process of both part and printer. This is required before the actual printing starts. It is calculated as the sum of the time required for the following processes:

49:

289:

Temperature: including an additional laser to melt the filament before going to the extruder. This prevents unnecessary printhead heating, thereby lowering printhead cooling time.

338:

to cure the material -- point by point curing -- however, it presents challenges in both planning and implementation. Layer-less methods have more complicated path planning.

236:

Build speed is slower for z-direction than x-y directions. By minimizing height, the number of layers will be decreased. Hence, both manufacturing and idle time decrease.

175:, which is the actual print time after the prepared data are transferred to the printer for manufacturing. It can be considered as the sum of the following periods:

412:

flow instead of a static layer is to create a larger force against the adhesion force and also help with the cooling of the cured layer (curing generates heat).

215:

Since the actual printing process is directly influenced by how the model is sliced, oriented, and filled, optimizing them results in shorter print time.

282:

Modified printheads: using different types of printheads for different printing processes. For instance, having an additional knifed feeder to prevent

351:

1. Homogeneous material 2. The structured ultrasound field is applied 3. UV light is applied to cure the resulting shape of the previous step

278:

Increasing the speed of printing through hardware can take the following forms, many of which are used by leading 3D printing companies.

609:

Alexander, Paul; Allen, Seth; Dutta, Debasish (1998-04-01). "Part orientation and build cost determination in layered manufacturing".

890:

de Beer, Martin P.; van der Laan, Harry L.; Cole, Megan A.; Whelan, Riley J.; Burns, Mark A.; Scott, Timothy F. (January 2019).

976:

664:

181:

Idle time, non-productive time such as z-axis movement, cooling time, leveling, non-manufacturing movement of printhead

647:

Wasserfall, Florens; Hendrich, Norman; Zhang, Jianwei (2017-08-20). "Adaptive slicing for the FDM process revisited".

425:

reprint only the small changing parts with high resolution. These smaller parts are mounted onto the main structure.

22:

1011:

310:

Depending on the technology used, there are some challenges that could limit the speed of the 3D printing:

295:

Gel

Dispensing Printing technology, which extrudes a gel material immediately hardened by UV-LED curing

189:, which is the final stage, taking place post part manufacturing. It includes the following processes:

91:

454:

757:

512:

955:

Mueller, Stefanie; Mohr, Tobias; Guenther, Kerstin; Frohnhofen, Johannes; Baudisch, Patrick (2014).

323:

Slicing. Two main challenges with the slicing are the staircase effect and the containment problem.

825:

366:

240:

A total volume of support material and total contact area of the part with the support structure.

298:

Adding more printheads which collaborative using path planning to increase the printing speed.

292:

Minimizing adhesion force within the dead layer of

Digital Light Projector based technologies.

892:"Rapid, continuous additive manufacturing by volumetric polymerization inhibition patterning"

1006:

903:

837:

704:

283:

149:

Entering the parameters (e.g. layer thickness, material type) within the printer's software

824:

Melde, Kai; Choi, Eunjin; Wu, Zhiguang; Palagi, Stefano; Qiu, Tian; Fischer, Peer (2018).

8:

907:

841:

708:

373:

982:

932:

891:

869:

803:

769:

733:

693:"Rapid, large-volume, thermally controlled 3D printing using a mobile liquid interface"

692:

670:

588:

314:

956:

622:

407:

Rapid, large-volume, thermally controlled 3D printing, using a mobile liquid interface

972:

937:

919:

861:

853:

807:

795:

738:

720:

660:

626:

580:

434:

222:

129:

78:

873:

986:

964:

927:

911:

845:

787:

779:

728:

712:

674:

652:

618:

592:

572:

415:

264:

485:

783:

563:

Oropallo, William; Piegl, Les A. (2015-06-12). "Ten challenges in 3D printing".

656:

576:

178:

Manufacturing time, when the part and support materials are being manufactured

1000:

923:

857:

799:

724:

630:

584:

540:

968:

716:

941:

915:

865:

849:

742:

961:

Proceedings of the SIGCHI Conference on Human

Factors in Computing Systems

791:

301:

Using special types of materials for specific manufacturing technologies.

133:

55:

347:

254:

19:

measures the amount of manufactured material over a given time period (

649:

2017 13th IEEE Conference on

Automation Science and Engineering (CASE)

226:

963:. Chi '14. Toronto, Ontario, Canada: ACM Press. pp. 3827–3834.

774:

691:

Walker, David A.; Hedrick, James L.; Mirkin, Chad A. (2019-10-18).

221:

Changing the orientation of a part can be done through either the

54:

The following table compares the speeds of commercially relevant

416:

Fast 3D printing by integrating construction kit building blocks

398:

Rapid continuous additive manufacturing by inhibition patterning

377:

Rapid

Continuous additive manufacturing by inhibition patterning

826:"Acoustic Fabrication via the Assembly and Fusion of Particles"

136:) is calculated as the sum of time for the following stages:

195:

Refining the surface for obtaining the desired surface quality

954:

889:

455:"How to Make Resin 3D Printing 8x Faster and 9x More Precise"

486:"5 Fastest 3D Printers - High Speed 3D Printing (Feb. 2020)"

421:

513:"3D Printing Speed : How long does 3d Printing take"

646:

758:"Fast Desktop-Scale Extrusion Additive Manufacturing"

161:

Warming up and loading of support and build materials

25:

690:

608:

390:

Adhesion of cured material to the projection window

146:

Positioning and orienting of the part to be printed

43:

823:

998:

158:Generation of the tool path plan by the software

420:Dividing an Object into smaller blocks (e.g.

234:The height of the part in the build direction.

562:

44:{\displaystyle {\text{amount}}/{\text{time}}}

534:

532:

167:Diagnostics, cleaning or additional testing

686:

684:

642:

640:

604:

602:

558:

556:

554:

386:The speed of SLA processes is limited by:

931:

773:

756:Go, Jamison; Hart, A. John (2017-12-01).

732:

381:

529:

372:

346:

273:

253:

210:

681:

637:

599:

551:

507:

505:

483:

355:

999:

755:

247:The quality of the total surface area.

885:

883:

819:

817:

538:

502:

479:

477:

475:

152:Generation of the support structure

13:

880:

814:

14:

1023:

472:

164:The setting of the x-y and z axes

539:Flynt, Joseph (April 10, 2019).

393:Disturbance of the resin surface

948:

749:

447:

155:Generation of slices (slicing)

1:

623:10.1016/s0010-4485(97)00083-3

541:"Fastest 3D Printers in 2019"

440:

305:

258:Uniform and adaptive slicing

7:

784:10.1016/j.addma.2017.10.016

428:

342:

201:

10:

1028:

657:10.1109/coase.2017.8256074

565:Engineering with Computers

118:2800 cm³/hr to 4000 cm/hr

577:10.1007/s00366-015-0407-0

187:The post-processing stage

651:. IEEE. pp. 49–54.

361:for rapid fabrication.

141:The pre-processing stage

72:Maximum speed (claimed)

969:10.1145/2556288.2557005

717:10.1126/science.aax1562

916:10.1126/sciadv.aau8723

850:10.1002/adma.201704507

762:Additive Manufacturing

484:Armando (2019-08-14).

382:Improved SLA processes

378:

352:

259:

45:

1012:3D printing processes

611:Computer-Aided Design

376:

350:

274:Hardware improvements

257:

211:Software improvements

192:Removing the supports

46:

356:Acoustic fabrication

219:Optimal Orientation.

23:

908:2019SciA....5.8723D

842:2018AdM....3004507M

709:2019Sci...366..360W

62:

830:Advanced Materials

379:

353:

315:Shape optimization

260:

61:

41:

978:978-1-4503-2473-1

703:(6463): 360–364.

666:978-1-5090-6781-7

435:Rapid prototyping

125:

124:

115:Multi Jet Fusion

39:

29:

17:3D printing speed

1019:

991:

990:

952:

946:

945:

935:

896:Science Advances

887:

878:

877:

821:

812:

811:

777:

753:

747:

746:

736:

688:

679:

678:

644:

635:

634:

606:

597:

596:

560:

549:

548:

536:

527:

526:

524:

523:

509:

500:

499:

497:

496:

481:

470:

469:

467:

466:

451:

63:

60:

50:

48:

47:

42:

40:

37:

35:

30:

27:

1027:

1026:

1022:

1021:

1020:

1018:

1017:

1016:

997:

996:

995:

994:

979:

953:

949:

902:(1): eaau8723.

888:

881:

822:

815:

754:

750:

689:

682:

667:

645:

638:

607:

600:

561:

552:

537:

530:

521:

519:

511:

510:

503:

494:

492:

482:

473:

464:

462:

453:

452:

448:

443:

431:

418:

384:

358:

345:

308:

276:

213:

204:

173:The build stage

36:

31:

26:

24:

21:

20:

12:

11:

5:

1025:

1015:

1014:

1009:

993:

992:

977:

957:"FaBrickation"

947:

879:

836:(3): 1704507.

813:

748:

680:

665:

636:

617:(5): 343–356.

598:

571:(1): 135–148.

550:

528:

501:

471:

445:

444:

442:

439:

438:

437:

430:

427:

417:

414:

395:

394:

391:

383:

380:

357:

354:

344:

341:

340:

339:

335:

331:

327:

324:

321:

318:

307:

304:

303:

302:

299:

296:

293:

290:

287:

275:

272:

252:

251:

244:

237:

212:

209:

203:

200:

199:

198:

197:

196:

193:

184:

183:

182:

179:

170:

169:

168:

165:

162:

159:

156:

153:

150:

147:

123:

122:

119:

116:

112:

111:

108:

105:

101:

100:

97:

94:

88:

87:

84:

81:

74:

73:

70:

67:

58:technologies.

34:

9:

6:

4:

3:

2:

1024:

1013:

1010:

1008:

1005:

1004:

1002:

988:

984:

980:

974:

970:

966:

962:

958:

951:

943:

939:

934:

929:

925:

921:

917:

913:

909:

905:

901:

897:

893:

886:

884:

875:

871:

867:

863:

859:

855:

851:

847:

843:

839:

835:

831:

827:

820:

818:

809:

805:

801:

797:

793:

792:1721.1/128535

789:

785:

781:

776:

771:

767:

763:

759:

752:

744:

740:

735:

730:

726:

722:

718:

714:

710:

706:

702:

698:

694:

687:

685:

676:

672:

668:

662:

658:

654:

650:

643:

641:

632:

628:

624:

620:

616:

612:

605:

603:

594:

590:

586:

582:

578:

574:

570:

566:

559:

557:

555:

546:

542:

535:

533:

518:

514:

508:

506:

491:

487:

480:

478:

476:

460:

456:

450:

446:

436:

433:

432:

426:

423:

413:

409:

408:

404:

400:

399:

392:

389:

388:

387:

375:

371:

368:

362:

349:

336:

332:

328:

325:

322:

319:

316:

313:

312:

311:

300:

297:

294:

291:

288:

285:

281:

280:

279:

271:

268:

266:

256:

248:

245:

241:

238:

235:

232:

231:

230:

228:

224:

220:

216:

208:

194:

191:

190:

188:

185:

180:

177:

176:

174:

171:

166:

163:

160:

157:

154:

151:

148:

145:

144:

142:

139:

138:

137:

135:

131:

120:

117:

114:

113:

109:

106:

103:

102:

98:

95:

93:

90:

89:

85:

82:

80:

76:

75:

71:

69:Normal speed

68:

65:

64:

59:

57:

52:

32:

18:

960:

950:

899:

895:

833:

829:

765:

761:

751:

700:

696:

648:

614:

610:

568:

564:

544:

520:. Retrieved

516:

493:. Retrieved

489:

463:. Retrieved

461:. 2018-09-21

458:

449:

419:

410:

406:

405:

401:

397:

396:

385:

363:

359:

309:

277:

262:

261:

246:

239:

233:

218:

217:

214:

205:

186:

172:

140:

126:

121:4500 cm/hr

96:50-150 mm/h

83:20-36 mm/h.

53:

16:

15:

1007:3D printing

768:: 276–284.

367:nanoimprint

107:48 mm/sec

99:500 mm/sec

86:720 mm/sec

66:Technology

56:3D printing

1001:Categories

775:1709.05918

522:2020-02-05

495:2020-02-05

465:2020-02-05

441:References

334:sintering.

330:finishing.

306:Challenges

250:decreases.

225:or on the

110:60 mm/sec

924:2375-2548

858:1521-4095

808:115574095

800:2214-8604

725:0036-8075

631:0010-4485

585:0177-0667

545:3dinsider

490:AllThat3D

286:slipping.

263:Adaptive

227:CAD model

942:30746465

874:36229060

866:29205522

743:31624211

517:Sculpteo

429:See also

343:Research

284:filament

223:STL file

202:Speed up

987:6772574

933:6357759

904:Bibcode

838:Bibcode

734:6933944

705:Bibcode

697:Science

675:1784826

593:7264133

459:Zortrax

265:Slicing

985:

975:

940:

930:

922:

872:

864:

856:

806:

798:

741:

731:

723:

673:

663:

629:

591:

583:

28:amount

983:S2CID

870:S2CID

804:S2CID

770:arXiv

671:S2CID

589:S2CID

973:ISBN

938:PMID

920:ISSN

862:PMID

854:ISSN

796:ISSN

739:PMID

721:ISSN

661:ISBN

627:ISSN

581:ISSN

422:Lego

243:FDM.

134:.obj

104:SLS

77:DLP/

38:time

965:doi

928:PMC

912:doi

846:doi

788:hdl

780:doi

729:PMC

713:doi

701:366

653:doi

619:doi

573:doi

132:or

130:stl

92:FDM

79:SLA

1003::

981:.

971:.

959:.

936:.

926:.

918:.

910:.

898:.

894:.

882:^

868:.

860:.

852:.

844:.

834:30

832:.

828:.

816:^

802:.

794:.

786:.

778:.

766:18

764:.

760:.

737:.

727:.

719:.

711:.

699:.

695:.

683:^

669:.

659:.

639:^

625:.

615:30

613:.

601:^

587:.

579:.

569:32

567:.

553:^

543:.

531:^

515:.

504:^

488:.

474:^

457:.

128:(.

989:.

967::

944:.

914::

906::

900:5

876:.

848::

840::

810:.

790::

782::

772::

745:.

715::

707::

677:.

655::

633:.

621::

595:.

575::

547:.

525:.

498:.

468:.

267:.

33:/

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.