130:

138:

33:

223:

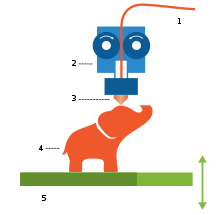

smaller and lighter motor due to the short distance to the nozzle. One typical disadvantage of direct-drive extruders is the added mass to the hotend, compared to a typical Bowden extruder, which may cause more vibrations so that the direct-drive printhead has to move slower, which can affect print speed. Another typical disadvantage is more complex maintenance due to tight packaging of many components in the hotend.

222:

With a direct-drive extruder, the motor pushing the filament is installed by the hotend and pushes the filament directly into the nozzle. Direct-drive designs have several advantages, and typically give better extrusion, faster retraction, are able to print more types of filaments, and can use a

206:

One disadvantage is that because Bowden extruders push filament through a long and curved tube, more friction must be overcome compared with direct drive extruders. To partially mitigate these friction forces, the tube is made of

195:

Bowden type extruders are easier to swap since they are outside the print head. They also have less chance of tangling the filament while it unwinds from the spool. Additionally, they reduce the

268:

203:. This allows for faster changes in print head movement direction, increased print speed, increased accuracy, and decreased instances of artifacting or ghosting along the x and y axes.

214:

Another disadvantage is that the feeding distance is relatively long, and thus the resistance is high, meaning the stepping motor of extrusion is required to have a higher torque.

314:

142:

133:

On a Bowden design, the feeding mechanism (here indicated with two roller wheels) often sits relatively far away from the hot end part of the extruder.

211:, which has a low coefficient of friction. Flexible filaments do not print well because the filament flexes inside the tube and clogs up the machine.

258:

309:

97:

69:

50:

76:

355:

304:

17:

83:

116:

65:

54:

337:

158:

90:

232:

208:

173:

43:

182:

360:

180:. An alternative type of extruder which is also widely used in filament 3D printers is the

154:

8:

289:

239:

device for manufacturing new filament from plastic pellets or recycled filament

236:

349:

263:

200:

259:"Extruders 101: A crash course on an essential component of your 3D printer"

129:

167:

137:

338:

Direct-drive extruder vs. Bowden extruder - Guide - 3DJake

International

172:

is a type of extruder that pushes filament through a long and flexible

162:

32:

177:

199:

of the extrusion carriage because it doesn't have to hold a

196:

305:"Comparing Bowden Extruders And Direct Drive Extruders"

165:. There are several types of 3D printer extruders. A

57:. Unsourced material may be challenged and removed.

347:

145:mechanism, an alternative to a Bowden extruder.

187:, which sits closer to the extruder hot end.

117:Learn how and when to remove this message

333:

331:

217:

136:

128:

14:

348:

256:

328:

55:adding citations to reliable sources

26:

24:

190:

25:

372:

31:

317:from the original on 2021-05-19

271:from the original on 2021-01-27

157:feeding mechanism used in many

42:needs additional citations for

297:

282:

250:

13:

1:

257:Landry, Taylor (2016-03-15).

243:

7:

290:"3d Printer for Miniatures"

226:

66:"Extruder" 3D printing

10:

377:

356:Fused filament fabrication

159:fused filament fabrication

294:Friday, 19 November 2021

233:Lyman filament extruder

146:

134:

218:Direct-drive extruder

176:(Teflon) tube to the

143:direct drive extruder

140:

132:

51:improve this article

151:3D printer extruder

18:3D printer extruder

147:

135:

127:

126:

119:

101:

16:(Redirected from

368:

340:

335:

326:

325:

323:

322:

301:

295:

293:

286:

280:

279:

277:

276:

254:

122:

115:

111:

108:

102:

100:

59:

35:

27:

21:

376:

375:

371:

370:

369:

367:

366:

365:

346:

345:

344:

343:

336:

329:

320:

318:

303:

302:

298:

292:. 25 June 2021.

288:

287:

283:

274:

272:

255:

251:

246:

229:

220:

193:

191:Bowden extruder

123:

112:

106:

103:

60:

58:

48:

36:

23:

22:

15:

12:

11:

5:

374:

364:

363:

358:

342:

341:

327:

296:

281:

248:

247:

245:

242:

241:

240:

228:

225:

219:

216:

192:

189:

125:

124:

39:

37:

30:

9:

6:

4:

3:

2:

373:

362:

359:

357:

354:

353:

351:

339:

334:

332:

316:

312:

311:

306:

300:

291:

285:

270:

266:

265:

264:MatterHackers

260:

253:

249:

238:

234:

231:

230:

224:

215:

212:

210:

204:

202:

201:stepper motor

198:

188:

186:

184:

179:

175:

171:

169:

164:

160:

156:

152:

144:

139:

131:

121:

118:

110:

99:

96:

92:

89:

85:

82:

78:

75:

71:

68: –

67:

63:

62:Find sources:

56:

52:

46:

45:

40:This article

38:

34:

29:

28:

19:

319:. Retrieved

308:

299:

284:

273:. Retrieved

262:

252:

221:

213:

205:

194:

183:direct-drive

181:

166:

150:

148:

141:Figure of a

113:

104:

94:

87:

80:

73:

61:

49:Please help

44:verification

41:

361:3D printing

163:3D printers

350:Categories

321:2021-05-19

275:2021-05-19

244:References

77:newspapers

315:Archived

269:Archived

227:See also

185:extruder

170:extruder

155:filament

107:May 2021

310:Raise3D

178:hot end

91:scholar

168:Bowden

161:(FFF)

93:

86:

79:

72:

64:

153:is a

98:JSTOR

84:books

235:, a

209:PTFE

197:mass

174:PTFE

70:news

237:DIY

53:by

352::

330:^

313:.

307:.

267:.

261:.

149:A

324:.

278:.

120:)

114:(

109:)

105:(

95:·

88:·

81:·

74:·

47:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.