440:) one repair company estimates that the process, if there are no unexpected problems, takes about 80 minutes. On a forum where professional repair people discuss reflowing of laptop computer graphics chips, different contributors cite success rates (no failure within 6 months) of between 60 and 90% for reflowing with professional equipment and techniques, in equipment whose value does not justify complete reballing. Reflowing can be done non-professionally in a domestic oven or with a heat gun. While such methods can cure some problems, the outcome is likely to be less successful than is possible with accurate thermal profiling achieved by an experienced technician using professional equipment.

233:

25:

189:

122:

443:

Reballing involves dismantling, heating the chip until it can be removed from the board, typically with a hot-air gun and vacuum pickup tool, removing the device, removing solder remaining on the device and board, putting new solder balls in place, replacing the original device if there was a poor

363:

High quality demands or specific designs of SMDs require the precise application of solder paste before positioning and soldering the unit. The surface tension of the molten solder, which is on the board's solder pads, tends to pull the device into precise alignment with the pads if not initially

465:

Chips are at risk of being damaged by the repeated heating and cooling of reballing, and manufacturers' warranties sometimes do not cover this case. Removing solder with solder wick subjects devices to thermal stress fewer times than using a flowing solder bath. In a test twenty devices were

308:

The rework may involve several components, which must be worked on one by one without damage to surrounding parts or the PCB itself. All parts not being worked on are protected from heat and damage. Thermal stress on the electronic assembly is kept as low as possible to prevent unnecessary

474:

Properly carried out rework restores the functionality of the reworked assembly, and its subsequent lifetime should not significantly be affected. Consequently, where the cost of reworking is less than the value of the assembly, it is widely used in all sectors of the electronic industry.

347:

is usually the first step, followed by removing the SMD while the solder is molten. The pad array on the conductor board should then be cleaned of old solder. It is quite easy to remove these residues by heating them to melting temperature. A soldering iron or hot air gun can be used with

412:

between adjacent pads. Bad connections produced during assembly can be detected and the assembly reworked (or scrapped). Imperfect connections of devices which are not themselves faulty, which work for a time and then fail, often triggered by thermal expansion and contraction at

359:

Finally the newly placed SMD is soldered onto the board. Reliable solder joints are facilitated by use of a solder profile which preheats the board, heats all the connections between the unit and the PCB to the melting temperature of the solder used, then properly cools them.

399:

and rework, as they have many small, closely spaced pads on their underside which are connected to matching pads on the PCB. Connecting pins are not accessible from the top for testing, and cannot be desoldered without heating the whole device to the melting point of solder.

432:, and reassembling, a process which is hoped will repair the bad connection without the need to remove and replace the component. This may or not resolve the problem; and there is a chance that the reflowed board will fail again after some time. For typical devices (

373:

332:

324:

294:

381:

355:

The precise placement of the new unit onto the prepared pad array requires skillful use of a highly accurate vision-alignment system with high resolution and magnification. The smaller the pitch and size of the components, the more precise working must be.

420:

Assemblies which fail because of bad BGA connections can be repaired either by reflowing, or by removing the device and cleaning it of solder, reballing, and replacing. Devices can be recovered from scrapped assemblies for reuse in the same way.

475:

Manufacturer and service providers of communications-technologies, entertainment- and consumer-devices, industrial commodities, automobiles, medical technology, aerospace and other high power electronics rework when necessary.

407:

are glued to the pads on its underside; during assembly the balled package is placed on the PCB and heated to melt the solder and, all being well, to connect each pad on the device to its mate on the PCB without any extraneous

428:, involves dismantling the equipment to remove the faulty circuit board, pre-heating the whole board in an oven, heating the non-functioning component further to melt the solder, then cooling, following a carefully determined

160:(SMD). Mass processing techniques are not applicable to single device repair or replacement, and specialized manual techniques by expert personnel using appropriate equipment are required to replace defective components;

466:

reballed, some several times. Two failed to function, but were restored to full functionality after reballing again. One was subjected to 17 thermal cycles without failing.

601:

444:

connection, or using a new one, and heating the device or board to solder it in place. The new balls can be placed via several methods, including:

559:

172:

or hot air station is used to heat devices and melt solder, and specialised tools are used to pick up and position often tiny components. A

89:

61:

254:

42:

68:

616:

581:

280:

108:

262:

75:

320:. Where this precaution is not necessary, tin-lead solder melts at a lower temperature and is easier to work with.

258:

57:

46:

533:

396:

218:

Components damaged due to liquid ingress, leading to corrosion, weak solder joints or physical damage.

206:

Solder bridges—unwanted drops of solder that connect points that should be isolated from each other.

243:

247:

35:

82:

414:

344:

157:

142:

340:

154:

8:

392:

161:

570:

462:

For the PS3 and Xbox mentioned above, the time is about 120 minutes if all goes well.

196:

Rework is practiced in many kinds of manufacturing when defective products are found.

489:

429:

349:

425:

313:

301:

455:

Using a BGA "preform" with embedded balls corresponding to the device pattern, or

404:

388:

297:

165:

176:

is a place to do this work—the tools and supplies for this work, typically on a

317:

610:

508:

433:

215:

Components broken due to natural wear, physical stress or excessive current.

484:

424:

Reflowing as a rework technique, similar to the manufacturing process of

409:

169:

146:

130:

592:

309:

contractions of the board which might cause immediate or future damage.

582:

Repair VGA card by re-flowing solder on the board (using domestic oven)

168:(BGA) devices particularly require expertise and appropriate tools. A

602:

Permanent

Elastomeric/Semi-Elastomeric Ball Grid Array (BGA) Stencils

177:

150:

16:

Refinishing operation of an electronic printed circuit board assembly

232:

24:

437:

449:

203:

Poor solder joints because of faulty assembly or thermal cycling.

343:

with a hot-air gun to melt all solder joints between it and the

316:, both on manufactured assemblies and in rework, to avoid the

312:

In the 21st century, almost all soldering is carried out with

560:

Rework

Analysis of PS3 YLOD & Xbox RROD: Reflow vs Reball

571:

badcaps.net forum: Laptop reflowing improving reliability?

513:

Lean Supply

Solutions - Innovative Supply Chain Solutions

372:

331:

323:

293:

188:

121:

380:

49:. Unsourced material may be challenged and removed.

509:"Product Rework | Rework Process in Manufacturing"

534:"Reduce Manufacturing Rework: Five Steps to Take"

458:Using semiautomated or fully automated machinery.

608:

452:for both the balls and the solder paste or flux,

555:

553:

593:Sparkfun tutorials: Reflow skillet, July 2006

180:. Other kinds of rework require other tools.

327:Dispensed solder paste on the pads of a QFPs

550:

403:After fabrication of the BGA package, tiny

261:. Unsourced material may be challenged and

367:

281:Learn how and when to remove this message

212:Engineering parts changes, upgrades, etc.

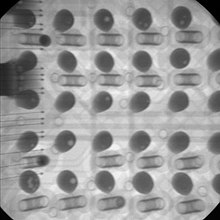

192:X-ray picture of inadequate solder joints

109:Learn how and when to remove this message

379:

371:

330:

322:

318:health and environmental hazards of lead

292:

187:

120:

609:

384:Good solder joints between BGA and PCB

199:For electronics, defects may include:

531:

183:

376:X-ray picture of good solder joints.

259:adding citations to reliable sources

226:

47:adding citations to reliable sources

18:

13:

145:(PCB) assembly, usually involving

14:

628:

141:) is the repair or refinish of a

231:

23:

34:needs additional citations for

586:

575:

564:

525:

501:

364:positioned totally correctly.

335:Mask and spheres for reballing

1:

495:

7:

478:

10:

633:

469:

222:

125:Electronic assembly (PCBA)

617:Electronics manufacturing

58:"Rework" electronics

397:difficulties for testing

368:Reflowing and reballing

417:, are not infrequent.

395:(CSA) present special

385:

377:

336:

328:

305:

193:

126:

415:operating temperature

383:

375:

334:

326:

296:

191:

158:electronic components

143:printed circuit board

124:

255:improve this section

43:improve this article

393:chip scale packages

162:area array packages

532:Rasmussen, Patty.

386:

378:

337:

329:

306:

209:Faulty components.

194:

184:Reasons for rework

127:

490:Thermal profiling

350:desoldering braid

339:Heating a single

291:

290:

283:

119:

118:

111:

93:

624:

595:

590:

584:

579:

573:

568:

562:

557:

548:

547:

545:

544:

529:

523:

522:

520:

519:

505:

426:reflow soldering

389:Ball grid arrays

314:lead-free solder

302:lead free solder

286:

279:

275:

272:

266:

235:

227:

114:

107:

103:

100:

94:

92:

51:

27:

19:

632:

631:

627:

626:

625:

623:

622:

621:

607:

606:

598:

591:

587:

580:

576:

569:

565:

558:

551:

542:

540:

530:

526:

517:

515:

507:

506:

502:

498:

481:

472:

430:thermal profile

410:solder bridging

405:balls of solder

370:

298:Thermal profile

287:

276:

270:

267:

252:

236:

225:

186:

166:ball grid array

155:surface-mounted

115:

104:

98:

95:

52:

50:

40:

28:

17:

12:

11:

5:

630:

620:

619:

605:

604:

597:

596:

585:

574:

563:

549:

538:news.ewmfg.com

524:

499:

497:

494:

493:

492:

487:

480:

477:

471:

468:

460:

459:

456:

453:

369:

366:

289:

288:

239:

237:

230:

224:

221:

220:

219:

216:

213:

210:

207:

204:

185:

182:

174:rework station

117:

116:

31:

29:

22:

15:

9:

6:

4:

3:

2:

629:

618:

615:

614:

612:

603:

600:

599:

594:

589:

583:

578:

572:

567:

561:

556:

554:

539:

535:

528:

514:

510:

504:

500:

491:

488:

486:

483:

482:

476:

467:

463:

457:

454:

451:

447:

446:

445:

441:

439:

435:

434:PlayStation 3

431:

427:

422:

418:

416:

411:

406:

401:

398:

394:

390:

382:

374:

365:

361:

357:

353:

351:

346:

342:

333:

325:

321:

319:

315:

310:

303:

299:

295:

285:

282:

274:

264:

260:

256:

250:

249:

245:

240:This section

238:

234:

229:

228:

217:

214:

211:

208:

205:

202:

201:

200:

197:

190:

181:

179:

175:

171:

167:

163:

159:

156:

152:

148:

144:

140:

136:

132:

123:

113:

110:

102:

91:

88:

84:

81:

77:

74:

70:

67:

63:

60: –

59:

55:

54:Find sources:

48:

44:

38:

37:

32:This article

30:

26:

21:

20:

588:

577:

566:

541:. Retrieved

537:

527:

516:. Retrieved

512:

503:

473:

464:

461:

442:

423:

419:

402:

387:

362:

358:

354:

338:

311:

307:

277:

268:

253:Please help

241:

198:

195:

173:

138:

134:

128:

105:

99:October 2010

96:

86:

79:

72:

65:

53:

41:Please help

36:verification

33:

485:Reflow oven

170:hot air gun

147:desoldering

131:electronics

543:2019-02-23

518:2020-06-02

496:References

391:(BGA) and

69:newspapers

271:July 2015

242:does not

178:workbench

151:soldering

611:Category

479:See also

448:Using a

438:Xbox 360

164:such as

470:Results

450:stencil

304:process

263:removed

248:sources

223:Process

149:and re-

139:re-work

83:scholar

135:rework

85:

78:

71:

64:

56:

300:of a

90:JSTOR

76:books

436:and

246:any

244:cite

137:(or

62:news

345:PCB

341:SMD

257:by

153:of

129:In

45:by

613::

552:^

536:.

511:.

352:.

133:,

546:.

521:.

284:)

278:(

273:)

269:(

265:.

251:.

112:)

106:(

101:)

97:(

87:·

80:·

73:·

66:·

39:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.