237:

enough to remove larger defects (typically 80 or 100 grit, but sometimes higher if the surface is already quite smooth), and progresses through a series of sandpaper grades that gradually remove the sanding scratches created by the previous sanding steps. A typical sanding schedule prior to wood finishing might involve sanding wood along the grain with the following grades of sandpaper, 80, 100, 120, 150 and finishing with 180 and sometimes 220 grit. The precise sanding schedule is a matter of trial and error because the appearance of a sanded surface depends on the wood you are sanding and the finish that will subsequently be applied to the wood. According to

Nagyszalanczy, coarse grained woods with large pores such as oak hide sanding scratches better than fine grained wood and hence with such species it may be possible to use 180 or even 150 grit sandpaper as the final step in the sanding schedule. Conversely, sanding scratches are more easily seen in finer grained, harder woods and also end-grain, and hence, they require finer sandpaper (220 grit) during the final sanding stage. The sandpaper selected for the final sanding stage affects the colour of stained wood, and therefore when staining is part of finishing avoid sanding the wood to a very smooth finish. On the other hand, according to Nagyszalanczy if you are using an oil-based finish, it is desirable to sand the wood using higher grit sandpaper (400 grit) because oil tends to highlight sanding scratches.

218:

269:

249:

241:

340:. Bleaches are also occasionally used to reduce the difference in colour between lighter sapwood and heartwood and also colour variation within heartwood. Such bleaching make it easier to achieve a uniformly coloured wood when the wood is subsequently coloured with pigmented stains and dyes (see below). Furthermore, the natural colours of wood fade when wood is exposed to sunlight, and more permanent colours can be created by bleaching wood to remove its natural colour and then re-colouring the wood using artificial, light-fast, stains.

544:

592:

628:

568:

122:

604:

257:

229:

616:

556:

640:

580:

520:

3719:

1147:

1126:

315:

307:

299:

508:

532:

25:

3729:

3739:

286:

to burn the wood. The transfer of heat from the iron to the wood will cause compressed fibres in the dent to recover their original dimensions. As a result the dent will diminish in size or even disappear completely, although removal of large dents may require a number of wetting and heating cycles. The wood in the recovered dent should then be dried and sanded smooth to match the surrounding wood.

1122:

spray guns in an enclosed environment or spray cabin. The material then can enter an oven or be sanded again depending on the manufacturer’s setup. The material can also be recycled through the line to apply another coat of finish or continue in a system that adds successive coats depending on the layout of the production line. The systems typically used one of two approaches to production.

156:

they can be adequately coated and are able to resist wear and cracking. Careful attention should also be given to the design and strength of wooden joints to ensure they do not open-up in service and crack the overlying finish. Care should also be taken to eliminate recesses in furniture, which are difficult to finish with some systems, especially UV-cured finishes.

323:

may alter the scratch pattern created by sanding. Both these effects will influence the way in which the wood colours when stains are used to finish the wood. To overcome this problem it may be necessary to locally stain and touch-up areas previously covered by glue to ensure that the finish on such areas matches that of the surrounding wood.

1160:

mobile carts used in the towline approach can be designed with top platens that rotate either manually or automatically. The rotating top platens allow the operator to have easy access to all sides of the wood item throughout the various wood finishing processes such as sanding, painting and sealing.

322:

Glue smears and droplets are sometimes present around the joints of furniture. They can be removed using a combination of scraping, scrubbing and sanding. These approaches remove surface glue, but not the glue beneath the wood surface. Sub-surface glue will reduce the absorption of stain by wood, and

285:

Removing dents from wood surfaces is quite straightforward as pointed out by

Flexner. Add a few droplets of demineralized water to the dent and let it soak in. Then put a clean cloth over the dent and place the tip of a hot iron on the cloth that lies immediately above the dent, taking great care not

146:

Finishing is the final step of the manufacturing process that gives wood surfaces desirable characteristics, including enhanced appearance and increased resistance to moisture and other environmental agents. Finishing can also make wood easier to clean and keep it sanitized, sealing pores that can be

331:

Wood surfaces are occasionally affected by various organic and inorganic stains. Sometimes such stains enhance the colour and appearance of wood. For example, oak wood affected by the beef-steak fungus has a deep rich, attractive, brown colour and there is no reason to remove the stain from the wood

1142:

that moves the items overhead or above the floor space. The conveyor itself can be ceiling mounted, wall mounted or supported by floor mounts. A simple overhead conveyor system can be designed to move wood products through several wood finishing processes in a continuous loop. The hangline approach

213:

Sanding is carried out before finishing to remove defects from the wood surface that will affect the appearance and performance of finishes that are subsequently applied to the wood. These defects include cutter marks and burns, scratches and indentations, small glue spots and raised grain. Sanding

200:

Wood’s moisture content affects the staining of wood. Changes in wood moisture content can result in swelling and shrinkage of wood which can stress and crack coatings. Both problems can be avoided by storing wood indoors in an environment where it can equilibriate to a recommended moisture content

196:

Planning for wood finishing also involves being aware of how the finishing process influences the result. Careful handling of the wood is needed to avoid dents, scratches and soiling with dirt. Wood should be marked for cutting using pencil rather than ink; however, avoid hard or soft pencil. HB is

168:

or within heartwood may require a preliminary staining step to reduce colour variation. Alternatively, the wood can be bleached to remove the natural colour of the wood and then stained to the desired colour. Woods that are coarse textured such as oaks and other ring-porous hardwoods may need to be

155:

Finishing of wood requires careful planning to ensure that the finished piece looks attractive, performs well in service and meets safety and environmental requirements. Planning for finishing begins with the design of furniture. Care should be taken to ensure that edges of furniture are rounded so

368:

or pigmented finishes. These finishes are available in a wide variety of colours, many of which are not part of the natural colour palette of wood, for example, blues and greens. Pigmented stains tend to highlight the grain (and also sanding scratches), whereas dyes do not have this effect and are

281:

Larger defects that interfere with wood finishing include dent, gouges, splits and glue spots and smears. These defects should also be removed before finishing, otherwise they will affect the quality of the finished furniture or object. However, it is difficult to eliminate large defects from wood

264:

Sanding is very good at removing defects at wood surfaces, but it creates a surface that contains minute scratches in the form of microscopic valleys and ridges, and also slivers of wood cell wall material that are attached to the underlying wood. These sanding ridges and slivers of wood swell and

1159:

The towline approach to automating wood finishing uses mobile carts that are propelled by conveyors mounted in or on the floor. This approach is useful for moving large, awkward shaped wood products that are difficult or impossible to lift or hang overhead, such as four-legged wood furniture. The

363:

Wood can be stained to change its colour or left unstained before application of lacquer, or other types of top-coats. Staining should enhance the appearance of wood by reducing colour variation between and within sapwood and heartwood. It also provides a way of giving bland looking woods such as

289:

Gouges and holes in wood are more difficult to repair than dents because wood fibres have been cut, torn and removed from the wood. Larger gouges and splits are best repaired by patching the void with a piece of wood that matches the colour and grain orientation of the wood under repair. Patching

159:

Planning for wood finishing also involves thinking about the properties of the wood being finished, as these can greatly affect the appearance and performance of finishes, and also the type of finishing system that will give the wood the desired characteristics. For example, woods that show great

1121:

products implement automated flatline finish systems. These systems consist of a series of processing stations that may include sanding, dust removal, staining, sealer and topcoat applications. As the name suggests, the primary part shapes are flat. Liquid wood finishes are applied via automated

236:

The key to preparing a defect free surface is to develop a sanding schedule that will quickly eliminate defects and leave the surface smooth enough so that tiny scratches produced by sanding cannot be seen when the wood is finished. A sanding schedule usually begins with sandpaper that is coarse

294:

and waxes) are produced commercially and are coloured to match different wood species. Successful filling of voids in wood requires the filler to precisely match the colour and grain pattern of the wood around the void, which is difficult to achieve in practice. Furthermore, filled voids do not

265:

spring-up, respectively, when sanded wood is finished with water-based finishes, creating a rough fuzzy surface. This defect is known as grain raising. It can be eliminated by wetting the surface with water, leaving the wood to dry and then lightly sanding the wood to remove the ‘raised grain’.

147:

breeding grounds for bacteria. Finishing can also influence other wood properties, for example tonal qualities of musical instruments and hardness of flooring. In addition, finishing provides a way of giving low-value woods the appearance of ones that are expensive and difficult to obtain.

495:

Clear finishes are intended to make wood look good and meet the demands to be placed on the finish. Choosing a clear finish for wood involves trade-offs between appearance, protection, durability, safety, requirements for cleaning, and ease of application. The following table compares the

295:

behave like wood during subsequent finishing steps, and they age differently to wood. Hence, repairs to wood using fillers may noticeable. Therefore filling is best used with opaque finishes rather than semitransparent finishes, which allow the grain of the wood to be seen.

377:. Staining of wood is difficult to control because some parts of the wood absorb more stain than others, which leads to problems such as blotchiness and streaking. For this reason, as pointed out by Flexner, many people prefer to omit the staining step when finishing wood.

204:

Finally, consideration needs to be given to whether the finished wood will come into contact with food, in which case a food-safe finish should be used, local environmental regulations governing the use of finishes, and recycling of finished wood at the end of its life.

1291:

Bongova, M.; Urgela, Stanislav (1999-01-01). "Surface coating influence on elastic properties of spruce wood by means of holographic vibration mode visualization". 11th Slovak-Czech-Polish

Optical Conference on Wave and Quantum Aspects of Contemporary Optics.

169:

filled before they are finished to ensure the coating can bridge the pores and resist cracking. The pores in ring-porous woods more readily absorb pigmented stain, and advantage can be taken of this to highlight the wood's grain. Some tropical woods, such as

1669:

197:

recommend for face work and 2H for joint work. Care should be taken to avoid squeeze-out of glue from joints because the glue will reduce absorption of stain and finish. Any excess glue should be carefully removed to avoid further damage to the wood.

500:

as a finish and as a way to manipulate the wood's ability to absorb other finishes. The alcohol evaporates almost immediately to yield a finish that will attach to virtually any surface, even glass, and virtually any other finish can be used over it.

369:

more transparent. Wood can also be coloured by exposing it to chemicals that react with the wood to form coloured compounds. Chemical staining of wood is rarely carried out because it is easier to colour wood using dye or pigmented stain, however,

1891:

496:

characteristics of different clear finishes. 'Rubbing qualities' indicates the ease with which a finish can be manipulated to deliver the finish desired. Shellac should be considered in two different ways. It is used thinned with

1497:

Wood

Finishing, Plain and Decorative: Methods, Materials, and Tools for Natural, Stained, Varnished, Waxed, Oiled, Enameled, and Painted Finishes. Antiqued, Stippled, Streaked and Rough Glazed Finishes. Stain Making

290:

wood requires skill, but when done properly it is possible to create a repair that is very difficult to see. An alternative to patching is filling (sometimes known as stopping). Numerous coloured fillers (

905:

Moderate. Applied in thin coats with cloth or brush, excess is wiped off. First coat is typically thinned down. Partial cure is necessary as very long finishing schedule for sufficient amount of coats.

1822:

Marra, G.G. 1943. An analysis of the factors responsible for raised grain on the wood of oak following sanding and staining. Transactions of the

American Society of Mechanical Engineers 65:177–185.

193:), contain extractives such as quinones, which retard the curing of unsaturated polyester and UV-cured acrylate coatings, and so other finishing systems should be used with these species.

1917:

Evans, Philip D.; Palmer, Gareth; Chowdhury, Mohammed (2007-03-22). "Bleaching treatments for blue-stained lodgepole pine affected by the mountain pine beetle

Dendroctonus ponderosae".

757:

Clogs spray equipment. Quick solvent flash time makes brushing difficult. Ox or badger/skunk hair brush recommended. Easy to pad, however French Polish is difficult

1998:

214:

should not be used to eliminate larger defects such as gouges, and various forms of discolouration. Other techniques are used to remove these defects (see below).

3612:

1002:

Easy. Applied with brush, roller or sprayer. Fast drying demands care in application technique to avoid bubbles and streaks. Sanding required between coats.

1872:

Uzunovic, A., Byrne, T., Gignac, M, Yang, D-Q. (2008). Wood discolourations & their prevention with an emphasis on bluestain. FPInnovations (Forintek)

336:. On the other hand some fungal stains and those caused by the reaction of iron with wood can disfigure wood. These stains can be removed from wood using

1605:

Kumar, R. N.; Al-Mahdi, Haider Osma; Scherzer, T.; Sonntag, J. von (2002-06-26). "Influence of Wood

Extracts on the Uv Curing of Acrylate Coatings".

799:

344:

1545:

Sandermann, Wilhelm; Dietrichs, Hans-Hermann; Puth, Martin (1960-02-01). "Über die

Trocknungsinhibierung von Lackanstrichen auf Handelshölzern".

918:

966:

Moderate. Applied in coats with brush, roller or sprayer. Medium curing times, sanding required between coats. Easy when thinned and wiped on.

1456:

709:

3602:

1980:

467:

or other materials, depending on the shine desired. Often, a final coat of wax is applied over the finish to add a degree of protection.

1143:

to automated wood finishing also allows the option of moving items up to warmer air at the ceiling level to speed up drying process.

351:. The former is particularly effective at removing the natural colour of wood before it is recoloured with pigmented stains or dyes.

697:

Easy. Applied with cloth or brush and worked into wood, excess left to cure before buffing with a cloth for desired level of sheen.

902:

Relatively safe when fully cured. Pure tung oil contains no metallic dryers. Many products labeled tung oil are oil/varnish blends

1715:"Case study project: The use of low-VOC/HAP coatings at wood furniture manufacturing facilities. Report for March 1995 March 1999"

1650:"A Note on the Effect of Wood Moisture Content and Clear Coating on the Color of Veneer Panels Stained with Solvent-Borne Stain"

2094:

1263:

1232:

89:

1813:

Nakamura, G-I, Takachio, H. 1961. An experiment on the roughness and stability of sanded surface. Mokuzai

Gakkaishi 7:41–45.

1800:

1700:

1502:

1480:

1831:

Koehler, A. 1932. Some observations on raised grain. Transactions of the

American Society of Mechanical Engineers 54:27–30.

61:

3587:

1994:

1278:

Jaić, Milan, and Tanja Palija. "The impact of the top coating on the mechanical properties of lacquered wood surfaces."

1008:

Excellent. It finishes hard and can be buffed to a gloss. Use a release agent. A thick finish can leave a plastic feel.

3768:

1370:

1065:

Easy. Applied in thin coats with cloth or brush, excess wiped off. Too many applications can result in sticky build up

567:

473:

is a finishing method of applying many thin coats of shellac using a rubbing pad, yielding a very fine glossy finish.

68:

3763:

3732:

3617:

2059:

2045:

1901:

1852:

1794:

1694:

1529:

1432:

108:

1129:

In this hangline approach, wood items being finished are moved through various finishing stages on a conveyor system

3592:

1686:

Finishes & Finishing Techniques: Professional Secrets for Simple and Beautiful Finishes from Fine Woodworking

42:

1741:

Parikka-Alhola, Katriina (2008-12-01). "Promoting environmentally sound furniture by green public procurement".

1150:

In this towline method, mobile carts move large furniture through various finishing stages on a conveyor system.

1071:

Dries hard. can be buffed to a matte finish or to a gloss. Often top coated with paste wax for extra protection

373:

is a chemical staining method that is still occasionally used to darken woods such as oak that contain a lot of

75:

3597:

46:

543:

424:

Once the wood surface is prepared and stained, the finish is applied. It usually consists of several coats of

364:

poplar, the appearance of prized furniture woods such as ebony, mahogany or walnut. Wood can be stained using

3607:

3317:

2335:

591:

217:

3742:

2944:

1138:

In the hangline approach, wood items being finished are hung by carriers or hangers that are attached to a

57:

972:

Cures hard. Easy to rub out with steel wool or synthetic pads to reduce sheen, or buffed to a high gloss.

1059:

Fairly durable, but may require periodic reapplication for heavy use areas such as tables and worktops.

845:

Moderate. Requires spray equipment. Used in professional shops only. No sanding required between coats.

730:

Difficult. Solvents thin wax causing it to penetrate deeper. Sanding creates heat. Scraping recommended

700:

Difficult. Solvents thin wax causing it to penetrate deeper. Sanding creates heat. Scraping recommended

2794:

997:

787:

Moderate. Available in cans, large scale requires spray equipment. No sanding required between coats.

3622:

3541:

2760:

2087:

627:

615:

1338:

332:

prior to finishing. The same applies to spalted wood whose attractive appearance is again caused by

1449:

603:

2974:

2122:

2117:

1095:

Easy pour-on application for flat surfaces, difficult to apply evenly on more complicated shapes

35:

1714:

3699:

2780:

2750:

2745:

2451:

769:

555:

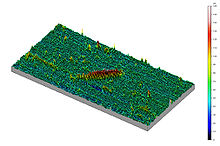

1976:

1255:

1249:

639:

2765:

2614:

2476:

2388:

1325:

936:

Moderate. Brush, roll or spray. Brushing needs good technique to avoid bubbles and streaks.

82:

3773:

3722:

3627:

3511:

3402:

2896:

2576:

2556:

2496:

2080:

1297:

1083:

Thick, high-gloss, and transparent. Some formulations can cloud or yellow with UV exposure

487:

in the wood and cause it to change colours. The resulting product is known as "fumed oak".

186:

875:

Easy. Applied in thin coats with cloth or brush, excess wiped off. Cure time can be long.

8:

3352:

3347:

2881:

2866:

2846:

2841:

2717:

2599:

519:

348:

268:

1301:

579:

3410:

2920:

2856:

2481:

2436:

2208:

2168:

1942:

1630:

1570:

1313:

857:

248:

240:

3704:

3561:

3392:

3372:

2959:

2702:

2426:

2268:

2055:

2041:

1934:

1897:

1848:

1790:

1690:

1649:

1622:

1562:

1525:

1518:

1428:

1366:

1317:

1259:

1228:

507:

497:

1946:

1634:

1574:

3362:

3337:

3312:

3282:

2939:

2521:

2416:

2183:

1926:

1754:

1750:

1661:

1614:

1554:

1305:

1189:

531:

1053:

Enhances natural figure like a drying oil, but more protective and faster drying.

3694:

3307:

3243:

3017:

2737:

2707:

2667:

2581:

2283:

1842:

1784:

1684:

1589:

1495:

1474:

1422:

1139:

1118:

165:

161:

1966:

Anon (1948). Bleaching wood. US Forest Products Laboratory Report FPL-0165, 9pp.

1665:

121:

3673:

3663:

3531:

3327:

3322:

3287:

3238:

3213:

3203:

3193:

3007:

2770:

2466:

2288:

2273:

2258:

2158:

476:

370:

126:

1930:

1030:

generally sprayed, equipment must be cleaned of any mixed product immediately

343:

The bleaches used to remove unwanted fungal stains from wood include two-part

3757:

3643:

3536:

3506:

3208:

3178:

3173:

3163:

3110:

2964:

2949:

2911:

2861:

2851:

2604:

2561:

2318:

2243:

2193:

2153:

2148:

1938:

1626:

1566:

1068:

Difficult. All saturated wood needs to be removed (planing/sanding/scraping)

909:

Difficult. All saturated wood needs to be removed (planing/sanding/scraping)

878:

Difficult. All saturated wood needs to be removed (planing/sanding/scraping)

470:

390:

256:

228:

201:(6 to 8%) that is similar to that of the intended end use of the furniture.

3456:

3451:

3387:

3342:

3332:

3297:

3228:

3223:

3183:

3155:

3090:

3075:

3012:

2984:

2928:

2924:

2916:

2586:

2566:

2303:

2278:

2263:

2223:

2188:

464:

402:

398:

3678:

3668:

3556:

3382:

3367:

3233:

3218:

3168:

3115:

3080:

3022:

2969:

2901:

2642:

2358:

2308:

2103:

1618:

1179:

1174:

1062:

Relatively safe once VOCs have evaporated, uses petroleum based solvents

410:

352:

2019:

143:

where typically it represents between 5 and 30% of manufacturing costs.

3566:

3521:

3302:

3248:

3198:

3188:

3140:

3130:

3085:

3027:

2992:

2932:

2687:

2677:

2672:

2536:

2491:

2340:

2253:

2218:

1558:

1184:

1169:

1146:

1125:

1046:

1042:

817:

Moderate. Requires spray equipment. No sanding required between coats.

456:

433:

414:

406:

291:

2052:

Understanding Wood Finishing: How to Select and Apply the Right Finish

1424:

Understanding Wood Finishing: How to Select and Apply the Right Finish

1309:

990:

Excellent protection. Newer products (2009) also UV stable when noted

784:

Uses toxic solvents. Good protection is needed, especially if painted

3501:

3471:

3466:

3357:

3292:

3135:

3120:

3095:

2906:

2886:

2831:

2821:

2755:

2727:

2662:

2298:

2233:

2178:

2173:

2163:

480:

452:

386:

140:

721:

Moderate durability once cured. May require periodic reapplication.

24:

3481:

3461:

3105:

3070:

2806:

2682:

2609:

2551:

2516:

2511:

2408:

2327:

2238:

2203:

2198:

963:

Relatively safe once VOCs evaporate, uses petroleum based solvents

933:

Relatively safe once VOCs evaporate, uses petroleum based solvents

887:

727:

Easy. Applied in very thin coats with cloth, pad, roller or brush.

333:

314:

306:

298:

178:

170:

1786:

The Wood Sanding Book: A Guide to Abrasives, Machines, and Methods

924:

Not as transparent as lacquer, yellowish/orange tint, pops grain.

823:

Excellent general furniture finish, harder than standard lacquer.

479:

is a traditional process for darkening and enriching the color of

3658:

3653:

3546:

3516:

3476:

3420:

3274:

3253:

3145:

3100:

3065:

3060:

3055:

3050:

3032:

3002:

2997:

2871:

2775:

2712:

2657:

2546:

2501:

2456:

2378:

2368:

2353:

2248:

2228:

1995:"Difference between lacquer and varnish? : Finishing Advice"

978:

948:

739:

484:

441:

437:

429:

405:. Imperfections or nail holes on the surface may be filled using

1893:

Three-dimensional structure of wood: An Ultrastructural Approach

3648:

3377:

3125:

2876:

2826:

2722:

2692:

2632:

2506:

2431:

2393:

2346:

2213:

2131:

1108:

accentuates visual properties due to differences in wood grain.

460:

418:

394:

374:

337:

2072:

1722:

National Service Center for Environmental Publications (NSCEP)

3526:

3435:

3430:

3415:

2836:

2627:

2620:

2591:

2571:

2541:

2526:

2486:

2471:

2461:

2446:

2441:

2421:

2398:

2373:

2293:

1077:

745:

From virtually clear (super blond) to a rich orange (garnet)

445:

355:

is particularly effective at removing iron stains from wood.

252:

Scanning Electron Microscopy of 180 grit aluminum oxide paper

244:

Scanning Electron Microscopy of 120 grit aluminum oxide paper

1604:

1098:

Cleanable with acetone when liquid. Irreversible once cured

754:

Safe when solvent evaporates, used as food and pill coating

272:

Profilometry image of Yellow birch after sanding and wetting

3425:

2954:

2891:

2816:

2697:

2652:

2647:

2383:

2127:

957:

Excellent protection against many substances, tough finish

872:

Relatively safe once cured, metallic driers are poisonous.

136:

3551:

3042:

2811:

2637:

2531:

2363:

679:

490:

425:

365:

2020:"A Guide on Choosing the Best Teak Oil Finish for Wood"

1544:

1212:. Nashville: Production Publishing Company. p. 3.

1021:

Stronger protection than regular polyurethane varnish

912:

Cures hard and matte, can be buffed to a satin sheen.

3613:

International Federation of Building and Wood Workers

1916:

703:

Matte to satin finish, can to be buffed to a sheen.

1112:

927:Good protection, also available with UV resistance

811:Meets UK and European standards for "general use".

49:. Unsourced material may be challenged and removed.

1517:

839:Meets UK and European standards for "severe use".

808:Good general protection against wet and dry heat.

448:, and each coat is typically followed by sanding.

326:

135:refers to the process of refining or protecting a

16:Process of refining or protecting a wooden surface

1101:flexibility makes sanding difficult but possible

733:matte to satin finish, can be buffed to a sheen.

380:

3755:

1683:Press, Taunton; Woodworking, Fine (1999-01-01).

1682:

1227:. Madison: Forest Products Society. p. 11.

1024:Durable once cured, generally less than an hour

942:Cures hard yet flexible, gloss or satin finish.

260:Profilometry image of Yellow birch after sanding

1036:Sands easily. Sanding not needed between coats

863:Yellow warm glow, pops grain, darkens with age

1740:

2088:

1847:. Sterling Publishing Company, Incorporated.

1782:

1290:

954:Slight ambering, comes in a variety of sheen

836:Excellent protection against many substances

1493:

1365:. Ramsbury, Marlborough: The Crowood Press.

1027:low or free of VOCs, nonreactive when cured

893:Warm glow, pops grain, lighter than linseed

814:Uses toxic solvents. Spray booth is needed.

748:Fair against water, poor solvent protection

1889:

1647:

1254:. New York: Van Nostrand Reinhold. p.

685:Dull, even sheen unless buffed or polished

2095:

2081:

960:Durable after approx. 7 day curing period

718:Moderate protection and water resistance.

694:Safe when solvents in paste wax evaporate

421:, or any of a number of other techniques.

276:

1896:. Springer Science & Business Media.

1607:Journal of Macromolecular Science, Part A

1450:"Wood Finishing with UV-Curable Coatings"

996:Safer than oil-based polyurethane, fewer

833:Transparent, all sheens from 5% to Gloss

139:surface, especially in the production of

125:A worker sprays a urethane finish onto a

109:Learn how and when to remove this message

3603:Building and Wood Workers' International

1494:Vanderwalker, Fred Norman (1940-01-01).

1360:

1145:

1124:

842:Uses toxic solvents, including toluene.

413:. Often, the wood's color is changed by

313:

305:

297:

267:

255:

247:

239:

227:

216:

120:

1840:

1447:

1420:

1363:Wood Finishing: Step-by-step techniques

805:Transparent, all sheens from 5% to 90%

483:. Ammonia fumes react with the natural

3756:

1997:. UKworkshop.co.uk. 19 February 2010.

1648:Evans, Philip D.; Cullis, Ian (2010).

1587:

1472:

1448:Iseghem, Lawrence C. Van (June 2006).

1247:

1207:

1056:Low, but more than pure oil finishes.

993:Durable after a two-day curing period

829:Conversion varnish or Acid-Cat Lacquer

724:Safe when low VOC solvents evaporate.

491:Comparison of different clear finishes

150:

2076:

1962:

1960:

1958:

1956:

1868:

1866:

1864:

1778:

1776:

1774:

1772:

1770:

1768:

1766:

1764:

1515:

1476:Coloring, Finishing and Painting Wood

1416:

1414:

1412:

1410:

1408:

1406:

1404:

1402:

1005:Can be stripped using paint removers

969:Can be stripped using paint removers

939:Can be stripped using paint removers

573:2:1 ratio of beeswax and carnauba wax

3738:

1783:Nagyszalanczy, Sandor (1997-01-01).

1591:Chemistry in the utilization of wood

1588:Farmer, Robert Harvey (1967-06-01).

1473:Newell, Adnah Clifton (1940-01-01).

1400:

1398:

1396:

1394:

1392:

1390:

1388:

1386:

1384:

1382:

1356:

1354:

1352:

1350:

1348:

1133:

760:Completely reversible using alcohol

47:adding citations to reliable sources

18:

3728:

3588:American Association of Woodturners

1520:The Complete Guide to Wood Finishes

1222:

1154:

232:Pore distribution in southern beech

13:

1953:

1876:Special Publication SP-50, 51 pp.

1861:

1841:Hayward, Charles H. (1974-09-01).

1761:

1225:Building an industrial wood finish

389:either by hand, typically using a

14:

3785:

3618:National Wood Carvers Association

2065:

1379:

1345:

358:

318:Macro photo of 320 grit sandpaper

310:Macro photo of 220 grit sandpaper

302:Macro photo of 120 grit sandpaper

3737:

3727:

3718:

3717:

3593:Architectural Woodwork Institute

1983:from the original on 2010-02-10.

1803:from the original on 2017-10-22.

1703:from the original on 2017-10-22.

1672:from the original on 2016-10-23.

1505:from the original on 2017-10-22.

1483:from the original on 2017-10-22.

1462:from the original on 2015-09-10.

1113:Automated wood finishing methods

979:Polyurethane water-based varnish

790:Reversible with proper solvents

691:Requires frequent reapplication

638:

626:

614:

602:

590:

578:

566:

554:

542:

530:

518:

506:

23:

2102:

2012:

2001:from the original on 2016-08-10

1987:

1969:

1910:

1883:

1834:

1825:

1816:

1807:

1734:

1707:

1676:

1641:

1598:

1581:

1538:

1509:

1487:

327:Bleaching and removal of stains

34:needs additional citations for

3598:British Woodworking Federation

1890:Butterfield, B. (2012-12-06).

1755:10.1016/j.ecolecon.2008.05.004

1466:

1441:

1284:

1272:

1251:Wood finishing and refinishing

1241:

1216:

1201:

1049:, Teak oil, "Tung oil finish")

949:Polyurethane oil based varnish

896:Low, but has water resistance

381:Basic wood finishing procedure

1:

3608:Caricature Carvers of America

1516:Crump, Derrick (1992-01-01).

1501:. F. J. Drake & Company.

1195:

775:Transparent, satin and gloss

409:or pores may be filled using

1210:Furniture finishing textbook

820:Non-Reversible after 5 days

451:Finally, the surface may be

160:variation in colour between

7:

1919:Holz Als Roh- und Werkstoff

1666:10.13073/0015-7473-60.3.273

1547:Holz Als Roh- und Werkstoff

1421:Flexner, Bob (1999-01-01).

1280:Glasnik Sumarskog fakulteta

1163:

385:Wood finishing starts with

10:

3790:

1075:

1040:

1012:

998:volatile organic compounds

986:all sheens from 1% to 80%

976:

946:

916:

885:

855:

827:

797:

781:Soft and somewhat durable

767:

737:

707:

677:

208:

3769:Wood finishing techniques

3713:

3687:

3636:

3623:Society of Wood Engravers

3580:

3494:

3444:

3401:

3273:

3266:

3154:

3041:

2983:

2802:

2793:

2736:

2407:

2326:

2317:

2141:

2110:

2036:Michael Dresdner (1992).

1931:10.1007/s00107-007-0177-5

1086:High level of protection

3764:Wood finishing materials

1524:. Simon & Schuster.

549:Tung oil and linseed oil

1654:Forest Products Journal

1223:Cox, Robert M. (2003).

984:Transparent or paints,

597:Shellac and linseed oil

277:Removing larger defects

3700:Frameless construction

2781:Wood-plastic composite

2038:The Woodfinishing Book

1844:Staining and Polishing

1361:Hatchard, Den (1992).

1333:Cite journal requires

1151:

1130:

851:Excellent hard finish

793:Excellent soft finish

778:Reasonable protection

770:Nitrocellulose lacquer

715:Matte to Satin sheen.

319:

311:

303:

273:

261:

253:

245:

233:

225:

221:Large open ‘pores’ in

129:

1479:. Manual arts Press.

1248:Gibbia, S.W. (1981).

1208:Whaler, J.H. (1972).

1149:

1128:

1089:Flexible and durable

848:Difficult to reverse

621:Spar or yacht varnish

317:

309:

301:

271:

259:

251:

243:

231:

220:

124:

3628:Timber Framers Guild

2482:Australian Blackwood

2050:Bob Flexner (1994).

1743:Ecological Economics

1619:10.1081/MA-120004510

191:Pterocarpus soyauxii

43:improve this article

3348:Hammer-headed tenon

2867:Janka hardness test

1427:. Reader's Digest.

1302:1999SPIE.3820..103B

1014:2-Part polyurethane

667:Ease of application

349:sodium hypochlorite

151:Planning the finish

2209:Japanese carpentry

1977:"Fuming white oak"

1559:10.1007/BF02615619

1455:. RADTECH REPORT.

1152:

1131:

1117:Manufacturers who

1043:Oil-varnish blends

858:Boiled linseed oil

673:Rubbing qualities

320:

312:

304:

274:

262:

254:

246:

234:

226:

223:Eucalyptus sieberi

130:

3751:

3750:

3705:Green woodworking

3562:Wood preservation

3490:

3489:

3393:Tongue and groove

3373:Mortise and tenon

3262:

3261:

2960:Warrington hammer

2789:

2788:

2477:African Blackwood

2269:Segmented turning

2040:. Taunton Press.

1789:. Taunton Press.

1689:. Taunton Press.

1594:. Pergamon Press.

1310:10.1117/12.353047

1265:978-0-442-24708-9

1234:978-1-892529-30-5

1134:Hangline approach

1105:

1104:

498:denatured alcohol

347:and solutions of

119:

118:

111:

93:

3781:

3741:

3740:

3731:

3730:

3721:

3720:

3271:

3270:

2940:Thickness planer

2800:

2799:

2594:(lime, basswood)

2324:

2323:

2184:Chainsaw carving

2097:

2090:

2083:

2074:

2073:

2030:

2029:

2027:

2026:

2016:

2010:

2009:

2007:

2006:

1991:

1985:

1984:

1973:

1967:

1964:

1951:

1950:

1914:

1908:

1907:

1887:

1881:

1870:

1859:

1858:

1838:

1832:

1829:

1823:

1820:

1814:

1811:

1805:

1804:

1780:

1759:

1758:

1749:(1–2): 472–485.

1738:

1732:

1731:

1729:

1728:

1719:

1711:

1705:

1704:

1680:

1674:

1673:

1645:

1639:

1638:

1602:

1596:

1595:

1585:

1579:

1578:

1542:

1536:

1535:

1523:

1513:

1507:

1506:

1491:

1485:

1484:

1470:

1464:

1463:

1461:

1454:

1445:

1439:

1438:

1418:

1377:

1376:

1358:

1343:

1342:

1336:

1331:

1329:

1321:

1288:

1282:

1276:

1270:

1269:

1245:

1239:

1238:

1220:

1214:

1213:

1205:

1190:Xylotechnigraphy

1155:Towline approach

1092:Safe when cured

688:Low, short term

650:

649:

642:

630:

618:

606:

594:

582:

570:

558:

546:

534:

522:

510:

471:French polishing

455:or buffed using

183:Dalbergia retusa

114:

107:

103:

100:

94:

92:

58:"Wood finishing"

51:

27:

19:

3789:

3788:

3784:

3783:

3782:

3780:

3779:

3778:

3754:

3753:

3752:

3747:

3709:

3695:Frame and panel

3683:

3632:

3576:

3486:

3445:Surface piecing

3440:

3397:

3318:Crown of thorns

3258:

3244:Smoothing plane

3150:

3037:

2979:

2882:Milling machine

2785:

2746:Cross-laminated

2732:

2403:

2313:

2284:Spindle turning

2274:Shingle weaving

2244:Pallet crafting

2137:

2106:

2101:

2070:

2068:

2054:. Rodale Press

2033:

2024:

2022:

2018:

2017:

2013:

2004:

2002:

1993:

1992:

1988:

1975:

1974:

1970:

1965:

1954:

1915:

1911:

1904:

1888:

1884:

1880:SSN #1916–4238.

1871:

1862:

1855:

1839:

1835:

1830:

1826:

1821:

1817:

1812:

1808:

1797:

1781:

1762:

1739:

1735:

1726:

1724:

1717:

1713:

1712:

1708:

1697:

1681:

1677:

1646:

1642:

1603:

1599:

1586:

1582:

1543:

1539:

1532:

1514:

1510:

1492:

1488:

1471:

1467:

1459:

1452:

1446:

1442:

1435:

1419:

1380:

1373:

1359:

1346:

1334:

1332:

1323:

1322:

1289:

1285:

1277:

1273:

1266:

1246:

1242:

1235:

1221:

1217:

1206:

1202:

1198:

1166:

1157:

1140:conveyor system

1136:

1115:

800:Pre-Cat lacquer

646:

643:

634:

633:Acrylic varnish

631:

622:

619:

610:

607:

598:

595:

586:

583:

574:

571:

562:

559:

550:

547:

538:

535:

526:

523:

514:

511:

493:

383:

361:

345:peroxide bleach

329:

279:

211:

175:Dalbergia nigra

153:

115:

104:

98:

95:

52:

50:

40:

28:

17:

12:

11:

5:

3787:

3777:

3776:

3771:

3766:

3749:

3748:

3746:

3745:

3735:

3725:

3714:

3711:

3710:

3708:

3707:

3702:

3697:

3691:

3689:

3685:

3684:

3682:

3681:

3676:

3674:Quarter sawing

3671:

3666:

3664:Wood splitting

3661:

3656:

3651:

3646:

3640:

3638:

3634:

3633:

3631:

3630:

3625:

3620:

3615:

3610:

3605:

3600:

3595:

3590:

3584:

3582:

3578:

3577:

3575:

3574:

3572:Wood finishing

3569:

3564:

3559:

3554:

3549:

3544:

3539:

3534:

3532:Paint stripper

3529:

3524:

3519:

3514:

3509:

3504:

3498:

3496:

3492:

3491:

3488:

3487:

3485:

3484:

3479:

3474:

3469:

3464:

3459:

3454:

3448:

3446:

3442:

3441:

3439:

3438:

3433:

3428:

3423:

3418:

3413:

3407:

3405:

3399:

3398:

3396:

3395:

3390:

3385:

3380:

3375:

3370:

3365:

3360:

3355:

3350:

3345:

3340:

3335:

3330:

3325:

3320:

3315:

3310:

3305:

3300:

3295:

3290:

3285:

3279:

3277:

3268:

3264:

3263:

3260:

3259:

3257:

3256:

3251:

3246:

3241:

3239:Shoulder plane

3236:

3231:

3226:

3221:

3216:

3214:Moulding plane

3211:

3206:

3204:Japanese plane

3201:

3196:

3194:Grooving plane

3191:

3186:

3181:

3176:

3171:

3166:

3160:

3158:

3152:

3151:

3149:

3148:

3143:

3138:

3133:

3128:

3123:

3118:

3113:

3108:

3103:

3098:

3093:

3088:

3083:

3078:

3073:

3068:

3063:

3058:

3053:

3047:

3045:

3039:

3038:

3036:

3035:

3030:

3025:

3020:

3015:

3010:

3008:Flooring clamp

3005:

3000:

2995:

2989:

2987:

2981:

2980:

2978:

2977:

2972:

2967:

2965:Winding sticks

2962:

2957:

2952:

2947:

2945:Timber-framing

2942:

2937:

2909:

2904:

2899:

2894:

2889:

2884:

2879:

2874:

2869:

2864:

2859:

2854:

2849:

2844:

2839:

2834:

2829:

2824:

2819:

2814:

2809:

2803:

2797:

2791:

2790:

2787:

2786:

2784:

2783:

2778:

2773:

2771:Particle board

2768:

2763:

2758:

2753:

2751:Glue laminated

2748:

2742:

2740:

2734:

2733:

2731:

2730:

2725:

2720:

2715:

2710:

2705:

2700:

2695:

2690:

2685:

2680:

2675:

2670:

2665:

2660:

2655:

2650:

2645:

2640:

2635:

2630:

2625:

2607:

2602:

2597:

2589:

2584:

2579:

2574:

2569:

2564:

2559:

2554:

2549:

2544:

2539:

2534:

2529:

2524:

2519:

2514:

2509:

2504:

2499:

2494:

2489:

2484:

2479:

2474:

2469:

2464:

2459:

2454:

2449:

2444:

2439:

2434:

2429:

2424:

2419:

2413:

2411:

2405:

2404:

2402:

2401:

2396:

2391:

2386:

2381:

2376:

2371:

2366:

2361:

2356:

2351:

2332:

2330:

2321:

2315:

2314:

2312:

2311:

2306:

2301:

2296:

2291:

2289:Timber framing

2286:

2281:

2276:

2271:

2266:

2261:

2259:Relief carving

2256:

2251:

2246:

2241:

2236:

2231:

2226:

2221:

2216:

2211:

2206:

2201:

2196:

2191:

2186:

2181:

2176:

2171:

2166:

2161:

2159:Bush carpentry

2156:

2151:

2145:

2143:

2139:

2138:

2136:

2135:

2125:

2120:

2114:

2112:

2108:

2107:

2100:

2099:

2092:

2085:

2077:

2067:

2066:External links

2064:

2063:

2062:

2048:

2032:

2031:

2011:

1986:

1968:

1952:

1925:(6): 485–486.

1909:

1902:

1882:

1860:

1853:

1833:

1824:

1815:

1806:

1795:

1760:

1733:

1706:

1695:

1675:

1660:(3): 273–275.

1640:

1613:(7): 657–666.

1597:

1580:

1537:

1530:

1508:

1486:

1465:

1440:

1433:

1378:

1372:978-1852235826

1371:

1344:

1335:|journal=

1283:

1271:

1264:

1240:

1233:

1215:

1199:

1197:

1194:

1193:

1192:

1187:

1182:

1177:

1172:

1165:

1162:

1156:

1153:

1135:

1132:

1114:

1111:

1103:

1102:

1099:

1096:

1093:

1090:

1087:

1084:

1081:

1073:

1072:

1069:

1066:

1063:

1060:

1057:

1054:

1051:

1038:

1037:

1034:

1031:

1028:

1025:

1022:

1019:

1016:

1010:

1009:

1006:

1003:

1000:

994:

991:

988:

982:

974:

973:

970:

967:

964:

961:

958:

955:

952:

944:

943:

940:

937:

934:

931:

928:

925:

922:

914:

913:

910:

907:

903:

900:

897:

894:

891:

883:

882:

879:

876:

873:

870:

867:

864:

861:

853:

852:

849:

846:

843:

840:

837:

834:

831:

825:

824:

821:

818:

815:

812:

809:

806:

803:

795:

794:

791:

788:

785:

782:

779:

776:

773:

765:

764:

761:

758:

755:

752:

749:

746:

743:

735:

734:

731:

728:

725:

722:

719:

716:

713:

705:

704:

701:

698:

695:

692:

689:

686:

683:

675:

674:

671:

668:

665:

662:

659:

656:

653:

648:

647:

644:

637:

635:

632:

625:

623:

620:

613:

611:

608:

601:

599:

596:

589:

587:

584:

577:

575:

572:

565:

563:

561:Molten bee wax

560:

553:

551:

548:

541:

539:

536:

529:

527:

524:

517:

515:

512:

505:

492:

489:

477:Ammonia fuming

382:

379:

371:ammonia fuming

360:

359:Colouring wood

357:

328:

325:

278:

275:

210:

207:

187:African padauk

152:

149:

133:Wood finishing

117:

116:

31:

29:

22:

15:

9:

6:

4:

3:

2:

3786:

3775:

3772:

3770:

3767:

3765:

3762:

3761:

3759:

3744:

3736:

3734:

3726:

3724:

3716:

3715:

3712:

3706:

3703:

3701:

3698:

3696:

3693:

3692:

3690:

3686:

3680:

3677:

3675:

3672:

3670:

3667:

3665:

3662:

3660:

3657:

3655:

3652:

3650:

3647:

3645:

3644:Chainsaw mill

3642:

3641:

3639:

3635:

3629:

3626:

3624:

3621:

3619:

3616:

3614:

3611:

3609:

3606:

3604:

3601:

3599:

3596:

3594:

3591:

3589:

3586:

3585:

3583:

3581:Organizations

3579:

3573:

3570:

3568:

3565:

3563:

3560:

3558:

3555:

3553:

3550:

3548:

3545:

3543:

3540:

3538:

3537:Steam bending

3535:

3533:

3530:

3528:

3525:

3523:

3520:

3518:

3515:

3513:

3510:

3508:

3507:French polish

3505:

3503:

3500:

3499:

3497:

3493:

3483:

3480:

3478:

3475:

3473:

3470:

3468:

3465:

3463:

3460:

3458:

3455:

3453:

3450:

3449:

3447:

3443:

3437:

3434:

3432:

3429:

3427:

3424:

3422:

3419:

3417:

3414:

3412:

3409:

3408:

3406:

3404:

3400:

3394:

3391:

3389:

3386:

3384:

3381:

3379:

3378:Rabbet/Rebate

3376:

3374:

3371:

3369:

3366:

3364:

3363:Mason's mitre

3361:

3359:

3356:

3354:

3351:

3349:

3346:

3344:

3341:

3339:

3336:

3334:

3331:

3329:

3326:

3324:

3321:

3319:

3316:

3314:

3311:

3309:

3306:

3304:

3301:

3299:

3296:

3294:

3291:

3289:

3286:

3284:

3281:

3280:

3278:

3276:

3272:

3269:

3265:

3255:

3252:

3250:

3247:

3245:

3242:

3240:

3237:

3235:

3232:

3230:

3227:

3225:

3222:

3220:

3217:

3215:

3212:

3210:

3209:Jointer plane

3207:

3205:

3202:

3200:

3197:

3195:

3192:

3190:

3187:

3185:

3182:

3180:

3179:Compass plane

3177:

3175:

3174:Chamfer plane

3172:

3170:

3167:

3165:

3164:Bedrock plane

3162:

3161:

3159:

3157:

3153:

3147:

3144:

3142:

3139:

3137:

3134:

3132:

3129:

3127:

3124:

3122:

3119:

3117:

3114:

3112:

3109:

3107:

3104:

3102:

3099:

3097:

3094:

3092:

3089:

3087:

3084:

3082:

3079:

3077:

3074:

3072:

3069:

3067:

3064:

3062:

3059:

3057:

3054:

3052:

3049:

3048:

3046:

3044:

3040:

3034:

3031:

3029:

3026:

3024:

3021:

3019:

3016:

3014:

3011:

3009:

3006:

3004:

3001:

2999:

2996:

2994:

2991:

2990:

2988:

2986:

2982:

2976:

2973:

2971:

2968:

2966:

2963:

2961:

2958:

2956:

2953:

2951:

2950:Veneer hammer

2948:

2946:

2943:

2941:

2938:

2935:

2934:

2930:

2926:

2922:

2918:

2913:

2910:

2908:

2905:

2903:

2900:

2898:

2895:

2893:

2890:

2888:

2885:

2883:

2880:

2878:

2875:

2873:

2870:

2868:

2865:

2863:

2862:Impact driver

2860:

2858:

2855:

2853:

2850:

2848:

2845:

2843:

2840:

2838:

2835:

2833:

2830:

2828:

2825:

2823:

2820:

2818:

2815:

2813:

2810:

2808:

2805:

2804:

2801:

2798:

2796:

2792:

2782:

2779:

2777:

2774:

2772:

2769:

2767:

2764:

2762:

2759:

2757:

2754:

2752:

2749:

2747:

2744:

2743:

2741:

2739:

2735:

2729:

2726:

2724:

2721:

2719:

2716:

2714:

2711:

2709:

2706:

2704:

2701:

2699:

2696:

2694:

2691:

2689:

2686:

2684:

2681:

2679:

2678:Red Quebracho

2676:

2674:

2671:

2669:

2666:

2664:

2661:

2659:

2656:

2654:

2651:

2649:

2646:

2644:

2641:

2639:

2636:

2634:

2631:

2629:

2626:

2623:

2622:

2617:

2616:

2611:

2608:

2606:

2603:

2601:

2598:

2596:

2595:

2590:

2588:

2585:

2583:

2580:

2578:

2575:

2573:

2570:

2568:

2565:

2563:

2560:

2558:

2555:

2553:

2550:

2548:

2545:

2543:

2540:

2538:

2535:

2533:

2530:

2528:

2525:

2523:

2520:

2518:

2515:

2513:

2510:

2508:

2505:

2503:

2500:

2498:

2495:

2493:

2490:

2488:

2485:

2483:

2480:

2478:

2475:

2473:

2470:

2468:

2465:

2463:

2460:

2458:

2455:

2453:

2450:

2448:

2445:

2443:

2440:

2438:

2435:

2433:

2430:

2428:

2425:

2423:

2420:

2418:

2415:

2414:

2412:

2410:

2406:

2400:

2397:

2395:

2392:

2390:

2387:

2385:

2382:

2380:

2377:

2375:

2372:

2370:

2367:

2365:

2362:

2360:

2357:

2355:

2352:

2349:

2348:

2343:

2342:

2337:

2334:

2333:

2331:

2329:

2325:

2322:

2320:

2316:

2310:

2307:

2305:

2302:

2300:

2297:

2295:

2292:

2290:

2287:

2285:

2282:

2280:

2277:

2275:

2272:

2270:

2267:

2265:

2262:

2260:

2257:

2255:

2252:

2250:

2247:

2245:

2242:

2240:

2237:

2235:

2232:

2230:

2227:

2225:

2222:

2220:

2217:

2215:

2212:

2210:

2207:

2205:

2202:

2200:

2197:

2195:

2192:

2190:

2187:

2185:

2182:

2180:

2177:

2175:

2172:

2170:

2167:

2165:

2162:

2160:

2157:

2155:

2154:Bow and arrow

2152:

2150:

2149:Boat building

2147:

2146:

2144:

2140:

2133:

2129:

2126:

2124:

2121:

2119:

2116:

2115:

2113:

2109:

2105:

2098:

2093:

2091:

2086:

2084:

2079:

2078:

2075:

2071:

2061:

2060:0-87596-566-0

2057:

2053:

2049:

2047:

2046:1-56158-037-6

2043:

2039:

2035:

2034:

2021:

2015:

2000:

1996:

1990:

1982:

1978:

1972:

1963:

1961:

1959:

1957:

1948:

1944:

1940:

1936:

1932:

1928:

1924:

1921:(in German).

1920:

1913:

1905:

1903:9789401181464

1899:

1895:

1894:

1886:

1879:

1875:

1869:

1867:

1865:

1856:

1854:9780877490074

1850:

1846:

1845:

1837:

1828:

1819:

1810:

1802:

1798:

1796:9781561581757

1792:

1788:

1787:

1779:

1777:

1775:

1773:

1771:

1769:

1767:

1765:

1756:

1752:

1748:

1744:

1737:

1723:

1716:

1710:

1702:

1698:

1696:9781561582983

1692:

1688:

1687:

1679:

1671:

1667:

1663:

1659:

1655:

1651:

1644:

1636:

1632:

1628:

1624:

1620:

1616:

1612:

1608:

1601:

1593:

1592:

1584:

1576:

1572:

1568:

1564:

1560:

1556:

1552:

1549:(in German).

1548:

1541:

1533:

1531:9780671796693

1527:

1522:

1521:

1512:

1504:

1500:

1499:

1490:

1482:

1478:

1477:

1469:

1458:

1451:

1444:

1436:

1434:9780762101917

1430:

1426:

1425:

1417:

1415:

1413:

1411:

1409:

1407:

1405:

1403:

1401:

1399:

1397:

1395:

1393:

1391:

1389:

1387:

1385:

1383:

1374:

1368:

1364:

1357:

1355:

1353:

1351:

1349:

1340:

1327:

1319:

1315:

1311:

1307:

1303:

1299:

1295:

1287:

1281:

1275:

1267:

1261:

1257:

1253:

1252:

1244:

1236:

1230:

1226:

1219:

1211:

1204:

1200:

1191:

1188:

1186:

1183:

1181:

1178:

1176:

1173:

1171:

1168:

1167:

1161:

1148:

1144:

1141:

1127:

1123:

1120:

1110:

1109:

1100:

1097:

1094:

1091:

1088:

1085:

1082:

1080:

1079:

1074:

1070:

1067:

1064:

1061:

1058:

1055:

1052:

1050:

1048:

1044:

1039:

1035:

1033:Irreversible

1032:

1029:

1026:

1023:

1020:

1017:

1015:

1011:

1007:

1004:

1001:

999:

995:

992:

989:

987:

983:

981:

980:

975:

971:

968:

965:

962:

959:

956:

953:

951:

950:

945:

941:

938:

935:

932:

929:

926:

923:

921:

920:

919:Alkyd varnish

915:

911:

908:

904:

901:

898:

895:

892:

890:

889:

884:

880:

877:

874:

871:

868:

865:

862:

860:

859:

854:

850:

847:

844:

841:

838:

835:

832:

830:

826:

822:

819:

816:

813:

810:

807:

804:

802:

801:

796:

792:

789:

786:

783:

780:

777:

774:

772:

771:

766:

762:

759:

756:

753:

750:

747:

744:

742:

741:

736:

732:

729:

726:

723:

720:

717:

714:

712:

711:

706:

702:

699:

696:

693:

690:

687:

684:

682:

681:

676:

672:

670:Reversibility

669:

666:

663:

660:

657:

654:

652:

651:

645:Acrylic paint

641:

636:

629:

624:

617:

612:

609:Alkyd varnish

605:

600:

593:

588:

581:

576:

569:

564:

557:

552:

545:

540:

533:

528:

521:

516:

509:

504:

503:

502:

499:

488:

486:

482:

478:

474:

472:

468:

466:

462:

458:

454:

449:

447:

443:

439:

435:

431:

427:

422:

420:

416:

412:

408:

404:

400:

396:

392:

391:sanding block

388:

378:

376:

372:

367:

356:

354:

350:

346:

341:

339:

335:

324:

316:

308:

300:

296:

293:

287:

283:

270:

266:

258:

250:

242:

238:

230:

224:

219:

215:

206:

202:

198:

194:

192:

188:

184:

180:

176:

172:

167:

163:

157:

148:

144:

142:

138:

134:

128:

123:

113:

110:

102:

99:November 2012

91:

88:

84:

81:

77:

74:

70:

67:

63:

60: –

59:

55:

54:Find sources:

48:

44:

38:

37:

32:This article

30:

26:

21:

20:

3571:

3512:Heat bending

3457:Edge banding

3229:Router plane

3224:Rebate plane

3184:Finger plane

2915:

2619:

2613:

2593:

2587:Lignum vitae

2345:

2339:

2304:Wood carving

2279:Shipbuilding

2264:Root carving

2224:Log building

2189:Chip carving

2069:

2051:

2037:

2023:. Retrieved

2014:

2003:. Retrieved

1989:

1971:

1922:

1918:

1912:

1892:

1885:

1877:

1873:

1843:

1836:

1827:

1818:

1809:

1785:

1746:

1742:

1736:

1725:. Retrieved

1721:

1709:

1685:

1678:

1657:

1653:

1643:

1610:

1606:

1600:

1590:

1583:

1553:(2): 63–75.

1550:

1546:

1540:

1519:

1511:

1496:

1489:

1475:

1468:

1443:

1423:

1362:

1326:cite journal

1293:

1286:

1279:

1274:

1250:

1243:

1224:

1218:

1209:

1203:

1158:

1137:

1119:mass-produce

1116:

1107:

1106:

1076:

1041:

1018:Transparent

1013:

985:

977:

947:

917:

886:

881:Cures matte

856:

828:

798:

768:

738:

708:

678:

494:

475:

469:

465:rotten stone

450:

423:

384:

362:

342:

330:

321:

288:

284:

280:

263:

235:

222:

212:

203:

199:

195:

190:

182:

174:

158:

154:

145:

132:

131:

105:

96:

86:

79:

72:

65:

53:

41:Please help

36:verification

33:

3774:Woodworking

3733:WikiProject

3679:Rift sawing

3669:Flat sawing

3557:Wood drying

3234:Scrub plane

3219:Razee plane

3169:Block plane

3023:Mitre clamp

2970:Wood scribe

2921:Combination

2663:Purpleheart

2359:Douglas fir

2309:Woodturning

2142:Occupations

2104:Woodworking

1296:: 103–110.

1180:Distressing

1175:Refinishing

1078:Epoxy resin

710:Hardwax oil

525:Linseed oil

411:wood filler

353:Oxalic acid

3758:Categories

3688:Techniques

3637:Conversion

3567:Wood stain

3495:Treatments

3283:Birdsmouth

3249:Spokeshave

3199:Jack plane

3189:Fore plane

3028:Pipe clamp

2993:Band clamp

2917:Carpenters

2738:Engineered

2688:Rubberwood

2537:Eucalyptus

2341:Calocedrus

2254:Pyrography

2219:Kohlrosing

2025:2017-06-24

2005:2016-07-26

1727:2016-01-18

1196:References

1185:Danish oil

1170:Wood stain

1047:Danish oil

763:Excellent

751:Moderate.

661:Durability

658:Protection

655:Appearance

457:steel wool

434:drying oil

407:wood putty

282:surfaces.

69:newspapers

3477:Parquetry

3472:Oystering

3467:Marquetry

3308:Butterfly

2975:Workbench

2907:Sandpaper

2887:Mitre box

2832:Drawknife

2822:Burnisher

2807:Abrasives

2756:Hardboard

2417:Afromosia

2299:Whittling

2249:Parquetry

2234:Marquetry

2179:Certosina

2174:Carpentry

2164:Cabinetry

2111:Overviews

1939:0018-3768

1627:1060-1325

1567:0018-3768

1318:136371456

513:No finish

481:white oak

419:bleaching

393:or power

166:heartwood

141:furniture

3723:Category

3502:Adhesive

3482:Purfling

3462:Intarsia

3403:Profiles

3328:Dovetail

3267:Geometry

3106:Hand saw

3091:Crosscut

3076:Circular

3071:Chainsaw

3018:Holdfast

2683:Rosewood

2615:American

2610:Mahogany

2582:Jelutong

2552:Hornbeam

2517:Cocobolo

2512:Chestnut

2427:Andiroba

2239:Millwork

2204:Intarsia

2199:Fretwork

2194:Ébéniste

2123:Glossary

1999:Archived

1981:Archived

1947:40952556

1801:Archived

1701:Archived

1670:Archived

1635:94434204

1575:39882526

1503:Archived

1498:Formulas

1481:Archived

1457:Archived

1164:See also

930:Durable

888:Tung oil

537:Tung oil

453:polished

415:staining

399:scraping

179:cocobolo

171:rosewood

3743:Commons

3659:Whipsaw

3654:Sawmill

3547:Varnish

3542:Thermal

3517:Lacquer

3452:Binding

3421:Chamfer

3288:Biscuit

3254:Surform

3146:Whipsaw

3116:Keyhole

3101:Fretsaw

3081:Compass

3066:Bucksaw

3056:Bandsaw

3051:Backsaw

3033:Sawbuck

3003:F-clamp

2998:C-clamp

2872:Jointer

2776:Plywood

2728:Zebrano

2668:Ovankol

2633:Meranti

2621:African

2592:Linden

2547:Hickory

2502:Cedrela

2497:Camphor

2492:Bubinga

2487:Boxwood

2467:Bilinga

2452:Avodire

2369:Juniper

2354:Cypress

2229:Luthier

2118:History

1298:Bibcode

740:Shellac

585:Shellac

485:tannins

442:varnish

438:lacquer

430:shellac

403:planing

387:sanding

375:tannins

292:putties

209:Sanding

162:sapwood

83:scholar

3649:Hewing

3388:Splice

3343:Halved

3338:Groove

3333:Finger

3313:Coping

3298:Bridle

3275:Joints

3156:Planes

3141:Veneer

3131:Scroll

3126:Ripsaw

3111:Jigsaw

3086:Coping

2985:Clamps

2912:Square

2902:Shaper

2897:Router

2877:Mallet

2852:Gimlet

2827:Chisel

2723:Willow

2713:Walnut

2703:Totara

2693:Sapele

2658:Poplar

2643:Padauk

2605:Merbau

2577:Jarrah

2562:Imbuia

2557:Idigbo

2522:Cumaru

2507:Cherry

2432:Anigre

2394:Spruce

2347:Cedrus

2214:Khatam

2169:Caning

2132:lumber

2058:

2044:

1945:

1937:

1900:

1851:

1793:

1693:

1633:

1625:

1573:

1565:

1528:

1431:

1369:

1316:

1262:

1231:

1045:(i.e.

664:Safety

461:pumice

395:sander

338:bleach

185:) and

137:wooden

127:timber

85:

78:

71:

64:

56:

3527:Paint

3436:Ovolo

3431:Ogive

3416:Bevel

3383:Scarf

3368:Miter

3136:Table

3121:Miter

3096:Frame

3013:Gripe

2929:Speed

2925:Miter

2857:Gauge

2847:Float

2842:Fence

2837:Drill

2795:Tools

2718:Wenge

2708:Utile

2673:Ramin

2628:Maple

2600:Lovoa

2572:Iroko

2542:Hazel

2527:Ebony

2472:Birch

2462:Beech

2457:Balsa

2447:Aspen

2442:Apple

2422:Alder

2379:Kauri

2374:Larch

2336:Cedar

2319:Woods

2294:Treen

1943:S2CID

1718:(PDF)

1631:S2CID

1571:S2CID

1460:(PDF)

1453:(PDF)

1314:S2CID

446:paint

444:, or

401:, or

334:fungi

90:JSTOR

76:books

3426:Ogee

3411:Bead

3353:Knee

3323:Dado

3303:Butt

3043:Saws

2955:Vise

2892:Rasp

2817:Adze

2698:Teak

2653:Plum

2648:Pear

2409:Hard

2389:Rimu

2384:Pine

2328:Soft

2128:Wood

2056:ISBN

2042:ISBN

1935:ISSN

1898:ISBN

1849:ISBN

1791:ISBN

1691:ISBN

1623:ISSN

1563:ISSN

1526:ISBN

1429:ISBN

1367:ISBN

1339:help

1294:3820

1260:ISBN

1229:ISBN

899:Low

869:Low

866:Low

366:dyes

164:and

62:news

3552:Wax

3522:Oil

3358:Lap

3293:Box

3061:Bow

2933:Try

2812:Axe

2766:OSB

2761:MDF

2638:Oak

2567:Ipê

2532:Elm

2437:Ash

2399:Yew

2364:Fir

1927:doi

1751:doi

1662:doi

1615:doi

1555:doi

1306:doi

680:Wax

426:wax

177:),

45:by

3760::

2931:,

2927:,

2923:,

2919:,

2618:,

2344:,

1979:.

1955:^

1941:.

1933:.

1923:65

1863:^

1799:.

1763:^

1747:68

1745:.

1720:.

1699:.

1668:.

1658:60

1656:.

1652:.

1629:.

1621:.

1611:39

1609:.

1569:.

1561:.

1551:18

1381:^

1347:^

1330::

1328:}}

1324:{{

1312:.

1304:.

1258:.

463:,

459:,

440:,

436:,

432:,

428:,

417:,

397:,

2936:)

2914:(

2624:)

2612:(

2350:)

2338:(

2134:)

2130:(

2096:e

2089:t

2082:v

2028:.

2008:.

1949:.

1929::

1906:.

1878:I

1874:.

1857:.

1757:.

1753::

1730:.

1664::

1637:.

1617::

1577:.

1557::

1534:.

1437:.

1375:.

1341:)

1337:(

1320:.

1308::

1300::

1268:.

1256:9

1237:.

189:(

181:(

173:(

112:)

106:(

101:)

97:(

87:·

80:·

73:·

66:·

39:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.