73:

Sonics & Materials Inc., was a lab manager at

Branson Instruments where thin plastic films were welded into bags and tubes using ultrasonic probes. He unintentionally moved the probe close to a plastic tape dispenser and observed that the halves of the dispenser welded together. He realized that the probe did not need to be manually moved around the part, but that the ultrasonic energy could travel through and around rigid plastics and weld an entire joint. He went on to develop the first ultrasonic press. The first application of this new technology was in the toy industry.

407:, and then welded together to create an airtight seal. The main obstacle to overcome in this process is the setting of the parameters. For example, if over-welding occurs, then the concentration of plastic in the weld zone may be too low and cause the seal to break. If it is under-welded, the seal is incomplete. Variations in the thicknesses of materials can cause variations in weld quality. Some other food items sealed using ultrasonic welding include candy bar wrappers, frozen food packages and beverage containers.

91:

138:

377:

20:

268:

162:

point contact between the parts, creating a joint. Ultrasonic welding of thermoplastics causes local melting of the plastic due to absorption of vibrational energy along the joint to be welded. In metals, welding occurs due to high-pressure dispersion of surface oxides and local motion of the materials. Although there is heating, it is not enough to melt the base materials.

395:, but cannot be subjected to high temperatures. One example is a butane lighter. This container weld must be able to withstand high pressure and stress and must be airtight to contain the butane. Another example is the packaging of ammunition and propellants. These packages must be able to withstand high pressure and stress to protect the consumer from the contents.

64:. In ultrasonic welding, there are no connective bolts, nails, soldering materials, or adhesives necessary to bind the materials together. When used to join metals, the temperature stays well below the melting point of the involved materials, preventing any unwanted properties which may arise from high temperature exposure of the metal.

360:. The process can also be highly automated, provides strict control over dimensional tolerances and does not interfere with the biocompatibility of parts. Therefore, it increases part quality and decreases production costs. Items such as arterial filters, anesthesia filters, blood filters, IV catheters, dialysis tubes,

327:

For automobiles, ultrasonic welding tends to be used to assemble large plastic and electrical components such as instrument panels, door panels, lamps, air ducts, steering wheels, upholstery and engine components. As plastics have continued to replace other materials in the design and manufacture of

248:

The applications of ultrasonic welding are extensive and are found in many industries including electrical and computer, automotive and aerospace, medical, and packaging. Whether two items can be ultrasonically welded is determined by their thickness. If they are too thick this process will not join

192:

Ultrasonic welding is typically used with small parts (e.g. cell phones, consumer electronics, disposable medical tools, toys, etc.) but it can be used on parts as large as a small automotive instrument cluster. Ultrasonics can also be used to weld metals, but are typically limited to small welds of

184:

A benefit of ultrasonic welding is that there is no drying time as with conventional adhesives or solvents, so the workpieces do not need to remain in a fixture for longer than it takes for the weld to cool. The welding can easily be automated, making clean and precise joints; the site of the weld

279:

In the electrical and computer industry ultrasonic welding is often used to join wired connections and to create connections in small, delicate circuits. Junctions of wire harnesses are often joined using ultrasonic welding. Wire harnesses are large groupings of wires used to distribute electrical

439:

Sub-harmonic vibrations, which can create annoying audible noise, may be caused in larger parts near the machine due to the ultrasonic welding frequency. This noise can be damped by clamping these large parts at one or more locations. Also, high-powered welders with frequencies of 15 kHz and

161:

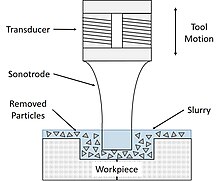

low-amplitude acoustic vibration is emitted. When welding plastics, the interface of the two parts is specially designed to concentrate the melting process. One of the materials usually has a spiked or rounded energy director which contacts the second plastic part. The ultrasonic energy melts the

431:

Hazards of ultrasonic welding include exposure to high temperatures and voltages. This equipment should be operated using the safety guidelines provided by the manufacturer to avoid injury. For instance, operators must never place hands or arms near the welding tip when the machine is activated.

169:

plastics, and metals. The understanding of ultrasonic welding has increased with research and testing. The invention of more sophisticated and inexpensive equipment and increased demand for plastic and electronic components has led to a growing knowledge of the fundamental process. However, many

72:

Practical application of ultrasonic welding for rigid plastics was completed in the 1960s. At this point only hard plastics could be welded. The patent for the ultrasonic method for welding rigid thermoplastic parts was awarded to Robert Soloff and

Seymour Linsley in 1965. Soloff, the founder of

300:

One of the areas in which ultrasonic welding is most used and where new research and experimentation is centered is microcircuits. This process is ideal for microcircuits since it creates reliable bonds without introducing impurities or thermal distortion into components. Semiconductor devices,

339:

is a difficult metal to weld using traditional techniques because of its high thermal conductivity. However, it is one of the easier materials to weld using ultrasonic welding because it is a softer metal and thus a solid-state weld is simple to achieve. Since aluminum is so widely used in the

398:

The food industry finds ultrasonic welding preferable to traditional joining techniques, because it is fast, sanitary and can produce hermetic seals. Milk and juice containers are examples of products often sealed using ultrasonic welding. The paper parts to be sealed are coated with plastic,

309:

are often connected by thin aluminum and gold wires using ultrasonic welding. It is also used for bonding wiring and ribbons as well as entire chips to microcircuits. An example of where microcircuits are used is in medical sensors used to monitor the human heart in bypass patients.

253:. It is fast and easily automated with weld times often below one second and there is no ventilation system required to remove heat or exhaust. This type of welding is often used to build assemblies that are too small, too complex, or too delicate for more common welding techniques.

296:

may also be assembled with ultrasonic welding. It is also often preferred in the assembly of storage media such as flash drives and computer disks because of the high volumes required. Ultrasonic welding of computer disks has been found to have cycle times of less than 300 ms.

435:

Ultrasonic welding machines require routine maintenance and inspection. Panel doors, housing covers and protective guards may need to be removed for maintenance. This should be done when the power to the equipment is off and only by the trained professional servicing the machine.

364:, cardiometry reservoirs, blood/gas filters, face masks and IV spike/filters can all be made using ultrasonic welding. Another important application in the medical industry for ultrasonic welding is textiles. Items like hospital gowns, sterile garments, masks,

313:

One difference between ultrasonic welding and traditional welding is the ability of ultrasonic welding to join dissimilar materials. The assembly of battery components is a good example of where this ability is utilized. When creating battery and

249:

them. This is the main obstacle in the welding of metals. However, wires, microcircuit connections, sheet metal, foils, ribbons and meshes are often joined using ultrasonic welding. Ultrasonic welding is a very popular technique for bonding

318:

components, thin gauge copper, nickel and aluminium connections, foil layers and metal meshes are often ultrasonically welded together. Multiple layers of foil or mesh can often be applied in a single weld eliminating steps and costs.

185:

is very clean and rarely requires any touch-up work. The low thermal impact on the materials involved enables a greater number of materials to be welded together. The process is a good automated alternative to glue, screws or

332:, low capital costs, and flexibility. Ultrasonic welding does not damage surface finish because the high-frequency vibrations prevent marks from being generated, which is a crucial consideration for many car manufacturers, .

432:

Also, operators should be provided with hearing protection and safety glasses. Operators should be informed of government agency regulations for the ultrasonic welding equipment and these regulations should be enforced.

193:

thin, malleable metals such as aluminum, copper, and nickel. Ultrasonics would not be used in welding the chassis of an automobile or in welding pieces of a bicycle together, due to the power levels required.

76:

The first car made entirely out of plastic was assembled using ultrasonic welding in 1969. The automotive industry has used it regularly since the 1980s, and it is now used for a multitude of applications.

423:

for the US Army's Close Combat

Assault Ration project without the use of binders. Dried food is pressed into a mold and welded for an hour, during which food particles become stuck together.

218:, an optional booster and a Horn. All three elements of the stack are specifically tuned to resonate at the same exact ultrasonic frequency (Typically 15, 20, 30, 35 or 40 kHz)

524:

Mostafavi, Shimaalsadat; Hesser, Daniel Frank; Markert, Bernd (December 2018). "Effect of process parameters on the interface temperature in ultrasonic aluminum wire bonding".

356:

In the medical industry ultrasonic welding is often used because it does not introduce contaminants or degradation into the weld and the machines can be specialized for use in

440:

20 kHz typically emit a potentially damaging high-pitched squeal in the range of human hearing. Shielding this radiating sound can be done using an acoustic enclosure.

328:

automobiles, the assembly and joining of plastic components has increasingly become a critical issue. Some of the advantages for ultrasonic welding are low cycle times,

149:

parts, ultrasonic welding equipment can be customized to fit the exact specifications of the parts being welded. The parts are sandwiched between a fixed shaped nest (

384:

Ultrasonic welding is often used in packaging applications. Many common items are either created or packaged using ultrasonic welding. Sealing containers, tubes and

391:

Ultrasonic welding is also applied in the packaging of dangerous materials, such as explosives, fireworks and other reactive chemicals. These items tend to require

368:

and textiles for clean rooms can be sealed and sewn using ultrasonic welding. This prevents contamination and dust production and reduces the risk of infection.

173:

Scientists from the

Institute of Materials Science and Engineering (WKK) of University of Kaiserslautern, with the support from the German Research Foundation (

1071:

510:

990:

1033:

748:

227:

Horn: Takes the shape of the part, also modifies the amplitude mechanically and applies the mechanical vibration to the parts to be welded.

335:

Ultrasonic welding is generally utilized in the aerospace industry when joining thin sheet gauge metals and other lightweight materials.

224:

Booster: Modifies the amplitude of the vibration mechanically. It is also used in standard systems to clamp the stack in the press.

627:

Materialwissenschaft und

Werkstofftechnik: Entwicklung, Fertigung, Prüfung, Eigenschaften und Anwendungen Technischer Werkstoffe

208:

A nest or anvil or fixture where the parts are placed and allowing the high frequency vibration to be directed to the interfaces

1064:

177:), have succeeded in proving that using ultrasonic welding processes can lead to highly durable bonds between light metals and

981:

232:

An electronic ultrasonic generator (US: Power supply) delivering a high power electric signal with frequency matching the

170:

aspects of ultrasonic welding still require more study, such as the relationship of weld quality to process parameters.

596:

344:, ultrasonic welding is becoming even more prevalent. It has been used in the bonding of the popular composite material

746:

Harras, B; Cole, K C; Vu-Khanh, T (February 1996). "Optimization of the

Ultrasonic Welding of PEEK-Carbon Composites".

1057:

1026:

963:

948:

933:

918:

903:

340:

aerospace industry, it follows that ultrasonic welding is an important manufacturing process. With the advent of new

348:. Numerous studies have been done to find the optimum parameters that will produce quality welds for this material.

833:

475:"Microstructure and lap shear strength of the weld interface in ultrasonic welding of Al alloy to stainless steel"

178:

174:

1384:

1209:

1019:

474:

1154:

1131:

1008:. (Topeka, KS: Peterson Publications, Inc.). Section: Assembly: pages 36–39, covers Crawford's article.

987:

1146:

563:"Close up on technology: Top 50 Update Who Was First In Hot Runners, Ultrasonic Welding, & PET?"

1389:

1121:

108:

be customized is presented as though an advantage, but later text seems to indicate that equipment

472:

1348:

1096:

622:

221:

Converter: Converts the electrical signal into a mechanical vibration using piezo electric effect

117:

1005:

1204:

1111:

48:

are locally applied to work pieces being held together under pressure to create a solid-state

1189:

1184:

1159:

1136:

1116:

504:

239:

A controller controlling the movement of the press and the delivery of the ultrasonic energy.

1255:

1199:

112:

be customized for each assembly, which is a disadvantage in general as it prevents re-use.

8:

1374:

1164:

449:

205:

A press, usually with a pneumatic or electric drive, to assemble two parts under pressure

1281:

1194:

1169:

1126:

1101:

765:

642:

541:

341:

35:

1323:

1318:

1001:

977:

959:

944:

929:

914:

899:

769:

646:

545:

490:

416:

365:

61:

473:

Hiromichi T. Fujii, Yuta Goto, Yutaka S. Sato, and

Hiroyuki Kokawa (February 2016).

1379:

1179:

1080:

757:

634:

533:

486:

623:"Ultrasonic spot welding of aluminum sheet/carbon fiber reinforced polymer–joints"

562:

1291:

994:

537:

420:

166:

1286:

1250:

761:

281:

271:

The thin aluminium wires around the edges of the Intel C8751H silicon die were

1368:

1265:

1260:

1224:

1174:

1106:

400:

392:

250:

212:

146:

137:

1245:

1214:

1042:

638:

404:

385:

345:

272:

262:

376:

1296:

1088:

289:

939:

Grewell, David A.; Benatar, Avraham; & Park, Joon B. (Eds), (2003).

201:

All ultrasonic welding systems are composed of the same basic elements:

165:

Ultrasonic welding can be used for both hard and soft plastics, such as

1343:

1338:

357:

329:

302:

285:

215:

39:

976:

Tres, Paul A., "Designing

Plastic Parts for Assembly", 6th ed., 2006,

1333:

1328:

1240:

315:

293:

233:

158:

154:

45:

42:

24:

19:

336:

186:

53:

1353:

1313:

694:

692:

361:

49:

1011:

415:"Sonic agglomeration", a combination of ultrasonic welding and

267:

57:

689:

306:

150:

943:. Cincinnati, Ohio: Hanser Gardner Publications, Inc.

523:

322:

256:

988:"Port Sealing: An Effective Heat Sealing Solution".

795:

The

Welding Institute, Ultrasonic Welding Technique

834:"Cooking (and Shrinking) the Modern Combat Ration"

745:

620:

1366:

911:Welding Handbook: Welding Science and Technology

855:Welding Handbook: Welding Science and Technology

621:Balle, F; Wagner, G; Eifler, D (November 2007).

956:Handbook of Plastics Joining: A Practical Guide

806:Handbook of Plastics Joining: A Practical Guide

784:Handbook of Plastics Joining: A Practical Guide

716:Handbook of Plastics Joining: A Practical Guide

211:An ultrasonic stack composed of a converter or

23:Ultrasonic welding of thin metallic foils. The

958:. Norwich, New York: Plastics Design Library.

157:(horn) connected to a transducer, and a ~20-70

104:on Customisability advantage; that equipment

1065:

1027:

818:

816:

814:

749:Journal of Reinforced Plastics and Composites

597:"Welding Still Ensures High-Strength Joints"

509:: CS1 maint: multiple names: authors list (

878:

876:

1072:

1058:

1034:

1020:

811:

660:

658:

656:

849:

847:

941:Plastics and Composites Welding Handbook

873:

375:

266:

136:

90:

60:, and especially for joining dissimilar

18:

653:

1367:

928:. Boca Raton, Florida: CRC Press LLC.

844:

710:

708:

557:

555:

1053:

1015:

594:

371:

145:For joining complex injection molded

926:New Developments in Advanced Welding

831:

590:

588:

586:

584:

84:

705:

552:

351:

323:Aerospace and automotive industries

13:

970:

595:Weber, Austin (30 November 2007).

526:Journal of Manufacturing Processes

257:Computer and electrical industries

14:

1401:

1000:. January/February 2013 Edition.

909:American Welding Society (2001).

894:American Welding Society (1997).

581:

1041:

954:Plastics Design Library (1997).

896:Jefferson’s Welding Encyclopedia

868:Jefferson's Welding Encyclopedia

700:Jefferson's Welding Encyclopedia

675:Jefferson's Welding Encyclopedia

491:10.1016/j.scriptamat.2016.02.004

89:

1132:Shielded metal (Stick/MMA/SMAW)

1122:Gas tungsten (Heliarc/TIG/GTAW)

888:

860:

825:

798:

789:

776:

739:

730:

721:

410:

243:

179:carbon-fiber-reinforced polymer

175:Deutsche Forschungsgemeinschaft

27:is rotated along the weld seam.

1117:Gas metal (Microwire/MIG/GMAW)

680:

667:

614:

517:

466:

1:

832:Kord, Tyler (June 29, 2019).

455:

419:, is used to produce compact

196:

1097:Atomic hydrogen (Athydo/AHW)

924:Ahmed, Nasir (Ed.), (2005).

913:. American Welding Society.

898:. American Welding Society.

538:10.1016/j.jmapro.2018.09.020

100:appears to contradict itself

7:

1079:

998:Plastic Decorating Magazine

443:

10:

1406:

866:American Welding Society,

853:American Welding Society,

762:10.1177/073168449601500203

698:American Welding Society,

673:American Welding Society,

260:

80:

67:

52:. It is commonly used for

1309:

1274:

1233:

1155:Electric resistance (ERW)

1145:

1087:

1049:

804:Plastics Design Library,

782:Plastics Design Library,

714:Plastics Design Library,

426:

388:are common applications.

460:

236:frequency of the stack.

38:whereby high-frequency

639:10.1002/mawe.200700212

381:

276:

142:

28:

1349:Tools and terminology

485:. ELSEVIER: 135–138.

379:

270:

140:

120:for more information.

22:

1385:Packaging machinery

1185:Friction stir (FSW)

1160:Electron-beam (EBW)

567:Plastics Technology

450:Thermosonic bonding

366:transdermal patches

342:composite materials

280:signals and power.

1282:Heat-affected zone

1210:Oxyacetylene (OAW)

993:2018-05-15 at the

479:Scripta Materialia

382:

372:Packaging industry

277:

143:

141:Ultrasonic Welding

36:industrial process

32:Ultrasonic welding

29:

1362:

1361:

1305:

1304:

1165:Electroslag (ESW)

1112:Flux-cored (FCAW)

986:Crawford, Lance,

982:978-1-5699-0401-5

601:Assembly Magazine

569:. 1 December 2005

135:

134:

1397:

1195:Laser beam (LBW)

1102:Electrogas (EGW)

1074:

1067:

1060:

1051:

1050:

1036:

1029:

1022:

1013:

1012:

883:

880:

871:

864:

858:

851:

842:

841:

829:

823:

822:Grewell, p. 171.

820:

809:

802:

796:

793:

787:

780:

774:

773:

743:

737:

734:

728:

727:Grewell, p. 141.

725:

719:

712:

703:

696:

687:

686:Grewell, p. 169.

684:

678:

671:

665:

662:

651:

650:

618:

612:

611:

609:

607:

592:

579:

578:

576:

574:

559:

550:

549:

521:

515:

514:

508:

500:

498:

497:

470:

421:food ration bars

393:hermetic sealing

352:Medical industry

130:

127:

121:

93:

92:

85:

1405:

1404:

1400:

1399:

1398:

1396:

1395:

1394:

1390:Plastic welding

1365:

1364:

1363:

1358:

1301:

1292:Residual stress

1270:

1229:

1147:Other processes

1141:

1137:Submerged (SAW)

1083:

1078:

1045:

1040:

995:Wayback Machine

973:

971:Further reading

891:

886:

881:

874:

865:

861:

852:

845:

830:

826:

821:

812:

803:

799:

794:

790:

781:

777:

744:

740:

735:

731:

726:

722:

713:

706:

697:

690:

685:

681:

672:

668:

663:

654:

633:(11): 934–938.

619:

615:

605:

603:

593:

582:

572:

570:

561:

560:

553:

522:

518:

502:

501:

495:

493:

471:

467:

463:

458:

446:

429:

413:

374:

354:

325:

282:Electric motors

265:

259:

246:

199:

181:(CFRP) sheets.

167:semicrystalline

131:

125:

122:

116:Please see the

115:

94:

83:

70:

17:

16:Welding process

12:

11:

5:

1403:

1393:

1392:

1387:

1382:

1377:

1360:

1359:

1357:

1356:

1351:

1346:

1341:

1336:

1331:

1326:

1321:

1316:

1310:

1307:

1306:

1303:

1302:

1300:

1299:

1294:

1289:

1287:Photokeratitis

1284:

1278:

1276:

1272:

1271:

1269:

1268:

1263:

1258:

1253:

1248:

1243:

1237:

1235:

1231:

1230:

1228:

1227:

1222:

1217:

1212:

1207:

1205:Magnetic pulse

1202:

1197:

1192:

1187:

1182:

1177:

1172:

1167:

1162:

1157:

1151:

1149:

1143:

1142:

1140:

1139:

1134:

1129:

1124:

1119:

1114:

1109:

1104:

1099:

1093:

1091:

1085:

1084:

1077:

1076:

1069:

1062:

1054:

1047:

1046:

1039:

1038:

1031:

1024:

1016:

1010:

1009:

984:

972:

969:

968:

967:

952:

937:

922:

907:

890:

887:

885:

884:

882:Ahmed, p. 266.

872:

859:

843:

824:

810:

797:

788:

775:

756:(2): 174–182.

738:

736:Ahmed, p. 251.

729:

720:

704:

688:

679:

666:

664:Ahmed, p. 260.

652:

613:

580:

551:

516:

464:

462:

459:

457:

454:

453:

452:

445:

442:

428:

425:

412:

409:

380:Butane lighter

373:

370:

353:

350:

324:

321:

275:by ultrasound.

261:Main article:

258:

255:

251:thermoplastics

245:

242:

241:

240:

237:

230:

229:

228:

225:

222:

209:

206:

198:

195:

133:

132:

97:

95:

88:

82:

79:

69:

66:

15:

9:

6:

4:

3:

2:

1402:

1391:

1388:

1386:

1383:

1381:

1378:

1376:

1373:

1372:

1370:

1355:

1352:

1350:

1347:

1345:

1342:

1340:

1337:

1335:

1332:

1330:

1327:

1325:

1322:

1320:

1317:

1315:

1312:

1311:

1308:

1298:

1295:

1293:

1290:

1288:

1285:

1283:

1280:

1279:

1277:

1275:Related terms

1273:

1267:

1266:Shielding gas

1264:

1262:

1259:

1257:

1254:

1252:

1249:

1247:

1244:

1242:

1239:

1238:

1236:

1232:

1226:

1223:

1221:

1218:

1216:

1213:

1211:

1208:

1206:

1203:

1201:

1198:

1196:

1193:

1191:

1190:Friction stud

1188:

1186:

1183:

1181:

1178:

1176:

1173:

1171:

1168:

1166:

1163:

1161:

1158:

1156:

1153:

1152:

1150:

1148:

1144:

1138:

1135:

1133:

1130:

1128:

1125:

1123:

1120:

1118:

1115:

1113:

1110:

1108:

1105:

1103:

1100:

1098:

1095:

1094:

1092:

1090:

1086:

1082:

1075:

1070:

1068:

1063:

1061:

1056:

1055:

1052:

1048:

1044:

1037:

1032:

1030:

1025:

1023:

1018:

1017:

1014:

1007:

1003:

999:

996:

992:

989:

985:

983:

979:

975:

974:

965:

964:1-884207-17-0

961:

957:

953:

950:

949:1-56990-313-1

946:

942:

938:

935:

934:0-8493-3469-1

931:

927:

923:

920:

919:0-87171-657-7

916:

912:

908:

905:

904:0-87171-506-6

901:

897:

893:

892:

879:

877:

869:

863:

856:

850:

848:

839:

838:www.yahoo.com

835:

828:

819:

817:

815:

807:

801:

792:

785:

779:

771:

767:

763:

759:

755:

751:

750:

742:

733:

724:

717:

711:

709:

701:

695:

693:

683:

676:

670:

661:

659:

657:

648:

644:

640:

636:

632:

628:

624:

617:

602:

598:

591:

589:

587:

585:

568:

564:

558:

556:

547:

543:

539:

535:

531:

527:

520:

512:

506:

492:

488:

484:

480:

476:

469:

465:

451:

448:

447:

441:

437:

433:

424:

422:

418:

408:

406:

402:

401:polypropylene

396:

394:

389:

387:

386:blister packs

378:

369:

367:

363:

359:

349:

347:

343:

338:

333:

331:

320:

317:

311:

308:

304:

298:

295:

291:

287:

283:

274:

269:

264:

254:

252:

238:

235:

231:

226:

223:

220:

219:

217:

214:

213:piezoelectric

210:

207:

204:

203:

202:

194:

190:

188:

182:

180:

176:

171:

168:

163:

160:

156:

152:

148:

147:thermoplastic

139:

129:

126:December 2023

119:

113:

111:

107:

101:

98:This section

96:

87:

86:

78:

74:

65:

63:

59:

55:

51:

47:

44:

41:

37:

33:

26:

21:

1256:Power supply

1246:Filler metal

1219:

1200:Laser-hybrid

1127:Plasma (PAW)

1043:Metalworking

997:

955:

940:

925:

910:

895:

889:Bibliography

867:

862:

854:

837:

827:

805:

800:

791:

783:

778:

753:

747:

741:

732:

723:

715:

699:

682:

674:

669:

630:

626:

616:

604:. Retrieved

600:

571:. Retrieved

566:

529:

525:

519:

505:cite journal

494:. Retrieved

482:

478:

468:

438:

434:

430:

414:

411:Experimental

405:polyethylene

397:

390:

383:

355:

346:carbon fiber

334:

326:

312:

299:

290:transformers

278:

263:Wire bonding

247:

244:Applications

200:

191:

183:

172:

164:

144:

123:

109:

105:

103:

99:

75:

71:

31:

30:

1319:Fabrication

1297:Weldability

1089:Arc welding

606:13 November

573:13 November

532:: 104–114.

358:clean rooms

303:transistors

286:field coils

273:wire bonded

1375:Ultrasound

1369:Categories

1339:Metallurgy

1220:Ultrasonic

1215:Spot (RSW)

1170:Exothermic

496:2017-07-04

456:References

399:generally

330:automation

294:capacitors

216:transducer

197:Components

189:designs.

46:vibrations

40:ultrasonic

1334:Machining

1329:Jewellery

1241:Electrode

1234:Equipment

1006:1536-9870

870:, p. 572.

857:, p. 750.

770:137009954

702:, p. 570.

677:, p. 571.

647:136559923

546:139828540

316:fuel cell

234:resonance

155:sonotrode

118:talk page

62:materials

25:sonotrode

1344:Smithing

1180:Friction

991:Archived

808:, p. 57.

786:, p. 54.

718:, p. 56.

444:See also

362:pipettes

337:Aluminum

187:snap-fit

153:) and a

54:plastics

43:acoustic

1380:Welding

1354:Welding

1324:Forming

1314:Casting

1081:Welding

417:molding

81:Process

68:History

1251:Helmet

1004:

980:

962:

947:

932:

917:

902:

768:

645:

544:

427:Safety

307:diodes

102:

58:metals

34:is an

1261:Robot

1225:Upset

1175:Forge

1107:Flash

766:S2CID

643:S2CID

542:S2CID

461:Notes

151:anvil

1002:ISSN

978:ISBN

960:ISBN

945:ISBN

930:ISBN

915:ISBN

900:ISBN

608:2020

575:2020

511:link

305:and

292:and

110:must

56:and

50:weld

758:doi

635:doi

534:doi

487:doi

483:116

403:or

159:kHz

106:can

1371::

875:^

846:^

836:.

813:^

764:.

754:15

752:.

707:^

691:^

655:^

641:.

631:38

629:.

625:.

599:.

583:^

565:.

554:^

540:.

530:36

528:.

507:}}

503:{{

481:.

477:.

288:,

284:,

1073:e

1066:t

1059:v

1035:e

1028:t

1021:v

966:.

951:.

936:.

921:.

906:.

840:.

772:.

760::

649:.

637::

610:.

577:.

548:.

536::

513:)

499:.

489::

128:)

124:(

114:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.