193:, of a casting is defined as the weight of the casting divided by the weight of the total amount of metal poured. Risers can add a lot to the total weight being poured, so it is important to optimize their size and shape. Risers exist only to ensure the integrity of the casting, they are removed after the part has cooled, and their metal is remelted to be used again; as a result, riser size, number, and placement should be carefully planned to reduce waste while filling all the shrinkage in the casting.

58:. Most metals are less dense as a liquid than as a solid so castings shrink upon cooling, which can leave a void at the last point to solidify. Risers prevent this by providing molten metal to the casting as it solidifies, so that the cavity forms in the riser and not the casting. Risers are not effective on materials that have a large freezing range, because directional solidification is not possible. They are also not needed for casting processes that utilized pressure to fill the mold cavity.

24:

99:

338:

Because all of the mold and material factors are the same for n. If a cylinder is chosen for the geometry of the riser and the height to diameter ratio is locked, then the equation can be solved for a diameter, which makes this method a simple way to calculate the minimum size for a riser. Note that

141:

The connection of the riser to the molding cavity can be an issue for side risers. On one hand the connection should be as small as possible to make separation as easy as possible, but, on the other, the connection must be big enough for it to not solidify before the riser. The connection is usually

77:

briefly states that the slowest cooling time is achieved with the greatest volume and the least surface area; geometrically speaking, this is a sphere. So, ideally, a riser should be a sphere, but this isn't a very practical shape to insert into a mold, so a cylinder is used instead. The height to

85:

The casting must be designed to produce directional solidification, which sweeps from the extremities of the mold cavity toward the riser(s). Thus, the riser can feed molten metal continuously to part of the casting that is solidifying. One method to achieve this is by placing the riser near the

170:

when casting ingots. It is essentially a live open riser, with a hot ceramic liner instead of just the mold materials. It is inserted into the top of the ingot mould near the end of the pour, and the rest of the metal is then poured. Its purpose is to maintain a reservoir of molten metal, which

333:

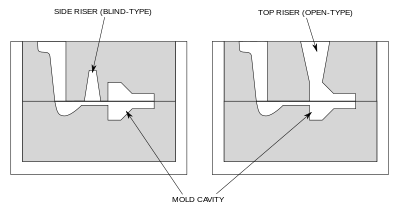

122:. An open riser is usually bigger than a blind because the open riser loses more heat to mold through the top of the riser. Finally, if the riser receives material from the gating system and fills before the mold cavity it is known as a

81:

The shrinkage must be calculated for the casting to confirm that there is enough material in the riser to compensate for the shrinkage. If it appears there is not enough material then the size of the riser must be increased.

145:

There are risering aids that can be implemented to slow the cooling of a riser or decrease its size. One is using an insulating sleeve and top around the riser. Another is placing a heater around only the riser.

86:

thickest and largest part of the casting, as that part of the casting will cool and solidify last. If this type of solidification is not possible, multiple risers that feed various sections of the casting or

244:

114:. Top risers are advantageous because they take up less space in the flask than a side riser, plus they have a shorter feeding distance. If the riser is open to the atmosphere it is known as an

106:

A riser is categorized based on three criteria: where it is located, whether it is open to the atmosphere, and how it is filled. If the riser is located on the casting then it is known as a

255:

200:

by setting the solidification time for the riser to be longer than that of the casting. Any time can be chosen but 25% longer is usually a safe choice, which is written as follows:

66:

Risers are only effective if three conditions are met: the riser cools after the casting, the riser has enough material to compensate for the casting shrinkage, and the casting

138:. Live risers are usually smaller than dead risers. Top risers are almost always dead risers and risers in the gating system are almost always live risers.

339:

if a top riser is used the surface area that is shared between the riser and the casting should be subtracted from the area on the casting and the riser.

613:

575:

142:

made short to take advantage of the heat of both the riser and the molding cavity, which will keep it hot throughout the process.

606:

544:

476:

206:

599:

568:

516:

878:

636:

328:{\displaystyle \left({\frac {V}{A}}\right)_{\text{riser}}^{n}=1.25\left({\frac {V}{A}}\right)_{\text{casting}}^{n}}

78:

diameter ratio of the cylinder varies depending on the material, location of the riser, size of the flask, etc.

795:

181:. With a hot top only 1 to 2% of the ingot goes to waste, prior to its use, up to 25% of the ingot was wasted.

561:

651:

693:

177:

67:

130:. If the riser fills with material that has already flowed through the mold cavity it is known as a

688:

852:

424:

673:

466:

172:

449:

754:

734:

729:

678:

73:

For the riser to cool after the casting, the riser must cool more slowly than the casting.

8:

775:

197:

74:

55:

668:

641:

827:

822:

744:

661:

656:

540:

512:

472:

429:

47:

40:

719:

534:

87:

770:

171:

drains down to fill the pipe as the casting cools. The hot top was invented by

167:

872:

724:

698:

622:

44:

51:

23:

739:

703:

683:

584:

17:

646:

118:, but if the riser is completely contained in the mold it is known as a

847:

842:

98:

837:

832:

166:, is a specialized riser, used to help counteract the formation of

857:

817:

785:

553:

790:

780:

110:, but if it is located next to the casting it is known as a

800:

196:

One way to calculate the minimum size of a riser is to use

507:

Degarmo, E. Paul; Black, J. T.; Kohser, Ronald A. (2003).

16:"Underfeeder" redirects here. For the health problem, see

239:{\displaystyle t_{\text{riser}}=1.25t_{\text{casting}}}

258:

209:

506:

490:

410:

389:

370:

327:

238:

870:

536:Metal Casting Computer-Aided Design And Analysis

422:

471:, Johns Hopkins University Press, p. 178,

607:

569:

27:A bronze casting showing the sprue and risers

406:

404:

402:

400:

398:

385:

383:

381:

379:

366:

364:

614:

600:

576:

562:

447:

448:Oberg, Erik; Jones, Franklin Day (1920),

395:

376:

361:

527:Manufacturing Engineering and Technology

509:Materials and Processes in Manufacturing

97:

22:

871:

464:

425:"Riser filled by electro-slag welding"

595:

557:

532:

525:Kalpakjian, Serope, et al. (2001).

355:

13:

529:. Published by Pearson Education.

14:

890:

583:

491:Degarmo, Black & Kohser 2003

454:, Industrial Press, p. 129.

411:Degarmo, Black & Kohser 2003

390:Degarmo, Black & Kohser 2003

371:Degarmo, Black & Kohser 2003

500:

423:Cmj Network, Inc (1959-06-25),

796:Semi-finished casting products

484:

458:

441:

416:

349:

1:

342:

7:

621:

149:

10:

895:

539:, PHI Learning Pvt. Ltd.,

15:

813:

763:

712:

629:

591:

102:Different types of risers

61:

468:American Iron, 1607-1900

184:

93:

68:directionally solidifies

879:Casting (manufacturing)

511:(9th ed.). Wiley.

465:Gordon, Robert (1996),

329:

240:

173:Robert Forester Mushet

103:

28:

853:Tools and terminology

669:Investment (Lost wax)

330:

241:

101:

26:

256:

207:

652:Evaporative-pattern

324:

288:

189:The efficiency, or

70:towards the riser.

493:, pp. 287–288

325:

295:

259:

236:

158:, also known as a

104:

90:may be necessary.

35:, also known as a

29:

866:

865:

809:

808:

546:978-81-203-2726-9

533:Ravi, B. (2005),

478:978-0-8018-6816-0

430:The New Scientist

317:

308:

281:

272:

233:

217:

886:

689:Semi-solid metal

616:

609:

602:

593:

592:

578:

571:

564:

555:

554:

549:

522:

494:

488:

482:

481:

462:

456:

455:

445:

439:

438:

420:

414:

408:

393:

387:

374:

368:

359:

353:

334:

332:

331:

326:

323:

318:

315:

313:

309:

301:

287:

282:

279:

277:

273:

265:

245:

243:

242:

237:

235:

234:

231:

219:

218:

215:

198:Chvorinov's rule

164:

163:

75:Chvorinov's rule

894:

893:

889:

888:

887:

885:

884:

883:

869:

868:

867:

862:

805:

771:Casting defects

759:

708:

625:

620:

587:

582:

547:

519:

503:

498:

497:

489:

485:

479:

463:

459:

446:

442:

421:

417:

409:

396:

388:

377:

369:

362:

354:

350:

345:

319:

314:

300:

296:

283:

278:

264:

260:

257:

254:

253:

230:

226:

214:

210:

208:

205:

204:

187:

175:who named it a

161:

160:

152:

96:

64:

21:

12:

11:

5:

892:

882:

881:

864:

863:

861:

860:

855:

850:

845:

840:

835:

830:

825:

820:

814:

811:

810:

807:

806:

804:

803:

798:

793:

788:

783:

778:

773:

767:

765:

761:

760:

758:

757:

752:

747:

742:

737:

732:

727:

722:

716:

714:

710:

709:

707:

706:

701:

696:

691:

686:

681:

676:

674:Permanent mold

671:

666:

665:

664:

659:

649:

644:

639:

633:

631:

627:

626:

619:

618:

611:

604:

596:

589:

588:

581:

580:

573:

566:

558:

552:

551:

545:

530:

523:

517:

502:

499:

496:

495:

483:

477:

457:

451:Iron and steel

440:

415:

413:, p. 287.

394:

392:, p. 288.

375:

373:, p. 286.

360:

347:

346:

344:

341:

336:

335:

322:

312:

307:

304:

299:

294:

291:

286:

276:

271:

268:

263:

247:

246:

229:

225:

222:

213:

186:

183:

151:

148:

95:

92:

63:

60:

9:

6:

4:

3:

2:

891:

880:

877:

876:

874:

859:

856:

854:

851:

849:

846:

844:

841:

839:

836:

834:

831:

829:

826:

824:

821:

819:

816:

815:

812:

802:

799:

797:

794:

792:

789:

787:

784:

782:

779:

777:

774:

772:

769:

768:

766:

762:

756:

753:

751:

748:

746:

743:

741:

738:

736:

733:

731:

728:

726:

725:Cope and drag

723:

721:

718:

717:

715:

711:

705:

702:

700:

699:Shell molding

697:

695:

692:

690:

687:

685:

682:

680:

677:

675:

672:

670:

667:

663:

660:

658:

655:

654:

653:

650:

648:

645:

643:

640:

638:

635:

634:

632:

628:

624:

617:

612:

610:

605:

603:

598:

597:

594:

590:

586:

579:

574:

572:

567:

565:

560:

559:

556:

548:

542:

538:

537:

531:

528:

524:

520:

518:0-471-65653-4

514:

510:

505:

504:

492:

487:

480:

474:

470:

469:

461:

453:

452:

444:

436:

432:

431:

426:

419:

412:

407:

405:

403:

401:

399:

391:

386:

384:

382:

380:

372:

367:

365:

358:, p. 63.

357:

352:

348:

340:

320:

310:

305:

302:

297:

292:

289:

284:

274:

269:

266:

261:

252:

251:

250:

227:

223:

220:

211:

203:

202:

201:

199:

194:

192:

182:

180:

179:

174:

169:

165:

157:

147:

143:

139:

137:

133:

129:

125:

121:

117:

113:

109:

100:

91:

89:

83:

79:

76:

71:

69:

59:

57:

53:

49:

46:

45:metal casting

43:built into a

42:

38:

34:

25:

19:

749:

740:Molding sand

694:Shaw process

679:Plaster mold

585:Metalworking

535:

526:

508:

501:Bibliography

486:

467:

460:

450:

443:

434:

428:

418:

351:

337:

248:

195:

190:

188:

176:

159:

155:

153:

144:

140:

135:

131:

127:

123:

119:

115:

111:

107:

105:

84:

80:

72:

65:

36:

32:

30:

18:Underfeeding

823:Fabrication

764:Terminology

637:Centrifugal

437:(136): 1383

162:feeder head

120:blind riser

50:to prevent

843:Metallurgy

713:Components

642:Continuous

343:References

136:cold riser

132:dead riser

124:live riser

116:open riser

112:side riser

838:Machining

833:Jewellery

662:Lost foam

657:Full mold

630:Processes

356:Ravi 2005

128:hot riser

108:top riser

56:shrinkage

41:reservoir

873:Category

848:Smithing

150:Hot tops

52:cavities

858:Welding

828:Forming

818:Casting

786:Foundry

745:Pattern

623:Casting

316:casting

232:casting

156:hot top

54:due to

39:, is a

543:

515:

475:

178:Dozzle

88:chills

62:Theory

37:feeder

791:Ingot

781:Dross

776:Draft

755:Sprue

750:Riser

735:Flask

720:Chill

280:riser

216:riser

191:yield

185:Yield

168:pipes

94:Types

33:riser

801:Slag

730:Core

704:Spin

684:Sand

541:ISBN

513:ISBN

473:ISBN

293:1.25

224:1.25

48:mold

647:Die

249:or

134:or

126:or

875::

433:,

427:,

397:^

378:^

363:^

154:A

31:A

615:e

608:t

601:v

577:e

570:t

563:v

550:.

521:.

435:5

321:n

311:)

306:A

303:V

298:(

290:=

285:n

275:)

270:A

267:V

262:(

228:t

221:=

212:t

20:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.