155:

146:). This technology is crucial in digital manufacturing as it not only enables mass production and flexibility, but it also provides a link between a CAD model and production. The two primary categories of CNC tooling are additive and subtractive. Major strides in additive manufacturing have come about recently and are at the forefront of digital manufacturing. These processes allow machines to address every element of a part no matter the complexity of its shape.

178:

of powder is added continually until the object is built. Another less known material drop deposition process use a build and support material to produce a 3D model. The build material is

Thermoplastic and the support material is wax. The wax is melted away after the layered model is printed. Another similar technique uses (DBM) Droplet based manufacturing to build Thermoplastic models without support with 5 axis drop positioning

225:

73:

310:

Additive manufacturing is the "process of joining materials to make objects from 3D model data, usually layer upon layer." Digital

Additive manufacturing is highly automated which means less man hours and machine utilization, and therefore reduced cost. By incorporating model data from digitized open

194:

A layer of liquid photopolymer is spread over a platform. An optical mask is generated and laid over the polymer. A UV lamp cures the resin that is not blocked by the mask. Any remaining liquid is removed and the voids are filled with wax. Liquid resin is spread over the layer that was just produced

177:

Although the most widely used ink-jet process is used for printing on paper, there are many that are applied in engineering. This process involves a printhead depositing layers of liquid material onto a filler powder in the shape of the desired object. After the powder is saturated, a fresh new layer

19:

is an integrated approach to manufacturing that is centered around a computer system. The transition to digital manufacturing has become more popular with the rise in the quantity and quality of computer systems in manufacturing plants. As more automated tools have become used in manufacturing plants

331:

Cloud-Based

Manufacturing (CBM) refers to a model that utilizes the access to open information from various resources to develop reconfigurable production lines to improve efficiency, reduce costs, and improve response to customer needs. A number of online manufacturing platforms enables users to

133:

However, other research has found evidence, not of job losses, but of a skills gap. Digital manufacturing is creating hundreds of new data-centric manufacturing jobs — roles like “collaborative robotics technician” and “predictive maintenance systems specialist" — but not enough available workers

129:

Debate continues on the impact of such systems on the manufacturing workforce. Econometric models have found that each newly installed robot displaces 1.6 manufacturing workers on average. Those models also have forecasted that by 2030 as many as 20 million additional manufacturing jobs worldwide

317:

Much like

Additive manufacturing, Rapid manufacturing uses digital models to rapidly produce a product that can be complicated in shape and heterogeneous in material composition. Rapid manufacturing utilizes not only the digital information process, but also the digital physical process. Digital

204:

A sheet material is laid on a platform and a laser cuts the desired contour. The platform is lowered by one sheet thickness and a new sheet is laid with a layer of thermal adhesive between the two sheets. A heated roller presses the sheets together and activates the adhesive. The laser cuts the

327:

Cloud-Based Design (CBD) refers to a model that incorporates social network sites, cloud computing, and other web technologies to aid in cloud design services. This type of system must be cloud computing-based, be accessible from mobile devices, and must be able to manage complex information.

122:

Digital manufacturing systems often incorporate optimization capabilities to reduce time, cost, and improve the efficiency of most processes. These systems improve optimization of floor schedules, production planning, and decision making. The system analyzes feedback from production, such as

59:

software to design the tools and machinery necessary for their intended applications. The software allows them to design the factory floor layout and the production flow. This technique lets engineers analyze the current manufacturing processes and allows them to search for ways to increase

214:

FFF is the most commonly used form of 3-D printing. Thermoplastic material is heated just beyond solidification and extruded onto a platform in the desired shape. The platform is lowered, and the next layer is extruded onto the previous layer. The process is repeated until the part is

280:

Optimization of a parts manufacturing process. This can be done by modifying and/or creating procedures within a virtual and controlled environment. By doing this the use of new robotic or automated systems can be tested in the manufacturing procedure before being physically

158:

Example of

Laminated object manufacturing process Laminated object manufacturing: principle drawing. 1 Supply roll. 2 Heated laminated roll. 3 Laser cutting beam. 4 Prism steering device. 5 Laser. 6 Laminated shape. 7 Movable table. 8 Waste roll (with cutout

284:

Digital manufacturing allows for the whole manufacturing process to be created virtually before it is implemented physically. This enables designers to see the results of their process before investing time and money into creating the physical

318:

information governs the physical process of adding material layer by layer until the product is complete. Both the information and physical processes are necessary for rapid manufacturing to be flexible in design, cheap, and efficient.

68:

Simulation can be used to model and test a system's behavior. Simulation also provides engineers with a tool for inexpensive, fast, and secure analysis to test how changes in a system can affect the performance of that system.

20:

it has become necessary to model, simulate, and analyze all of the machines, tooling, and input materials in order to optimize the manufacturing process. Overall, digital manufacturing can be seen sharing the same goals as

288:

The effects caused by changing the machines or tooling processes can be seen in real-time. This allows for analysis information to be taken for any individual part at any desired point during the manufacturing

205:

contours of this layer and the process is repeated. When the part is finished, the leftover sheet material around the perimeter of the part must be removed. The final part is coated with sealant.

266:

A Laser cutter is a CNC tool that uses a focused laser beam to cut and engrave sheet material. Cutting can be done on plastics, woods and on higher power machines, metal. Recently, affordable CO

142:

There are many different tooling processes that digital manufacturing utilizes. However, every digital manufacturing process involves the use of computerized numerical controlled machines (

170:

In this process, solid parts are formed by solidifying layers of a photopolymer with ultraviolet light. There is a wide range of acrylics and epoxies that are used in this process.

734:

239:

A water jet cutter is a CNC tool that uses a high pressure stream of water, often mixed with an abrasive material, to cut shapes or patterns out of many types of materials.

366:

248:

A CNC mill uses a rotational cutting tool to remove material from a piece of stock. Milling can be performed on most metals, many plastics, and all types of wood.

76:

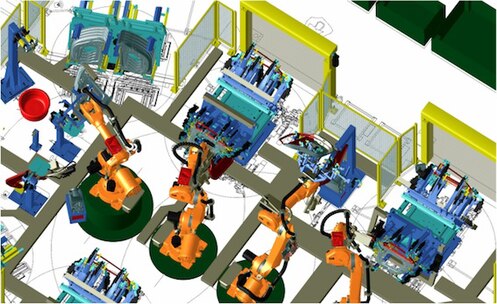

Robcad is a popular software used in digital manufacturing. Models of automated machinery and production lines can be created and simulated in real time.

523:

703:

Yan, Yongnian (June 2009). "Rapid

Prototyping and Manufacturing Technology: Principle, Representative Technics, Applications, and Development Trends".

621:

625:

126:

In addition, many technologies analyze data from simulations in order to calculate a design that is optimal before it is even built.

487:

257:

A CNC lathe removes material by rotating the work-piece while a stationary cutting tool is brought into contact with the material.

511:

228:

A CNC waterjet cutter is an example of the types of computer controlled tooling that are essential to digital manufacturing.

537:

689:

597:

21:

47:(Manufacturing x Digital), the nation's digital manufacturing institute, to speed adoption of these digital tools.

185:

This process utilizes heat produced by infrared lasers to bond a powdered material together to form a solid shape.

805:

387:

198:

25:

674:

Hon, K.K.B (July 1, 2007). "Digital additive manufacturing: From rapid prototyping to rapid manufacturing".

33:

406:

Mourtzis, Dimitris (2015). "The role of simulation in digital manufacturing: applications and outlook".

36:(DFM). The main difference is that digital manufacturing was evolved for use in the computerized world.

208:

735:"Cloud-based design and manufacturing: A new paradigm in digital manufacturing and design innovation"

444:

Bredt, James (November 17, 2000). Bains, Sunny; Irakliotis, Leo J. (eds.). "Digital manufacturing".

639:

Huang, Samuel (July 2013). "Additive manufacturing and its societal impact: a literature review".

551:

Chryssolouris, G (June 20, 2008). "Digital manufacturing: History, perspectives, and outlook".

305:

195:

and the process is repeated. When the part is finished, the wax can be melted out of the voids.

123:

deviations or problems in the manufacturing system, and generates solutions for handling them.

512:

https://cdn2.hubspot.net/hubfs/2240363/Report%20-%20How%20Robots%20Change%20the%20World.pdf

453:

72:

491:

8:

242:

188:

457:

757:

656:

615:

469:

423:

341:

29:

716:

660:

603:

593:

473:

427:

346:

164:

40:

367:"Digital Manufacturing -- The Factory of the Future is Here Today, in: IndustryWeek"

99:

Stochastic - Models where a solution is generated utilizing probabilistic parameters

761:

749:

712:

648:

461:

415:

233:

690:"Direct Digital Manufacturing: The Industrial Game-Changer You've Never Heard of"

419:

154:

753:

652:

799:

260:

96:

Deterministic - Models where a unique solution is generated per a given input

607:

587:

56:

776:"Geomiq - Online Manufacturing for CNC, Injection Moulding, Sheet Metal"

110:

Process design (e.g. assisting in the design of manufacturing processes)

224:

465:

538:"Jobs Taxonomy: Defining Manufacturing Jobs of the Future | MXD"

311:

sources, products can be produced quickly, efficiently, and cheaply.

733:

Wu, Dazhong; Rosen, David W.; Wang, Lihui; Schaefer, Dirk (2015).

87:

Dynamic - System of equations that incorporate time as a variable

219:

676:

589:

Rapid prototyping technology : selection and application

251:

149:

93:

Discrete - Dynamic model where time is separated into chunks

641:

International

Journal of Advanced Manufacturing Technology

488:"Design and Digital Manufacturing - PARC, a Xerox company"

408:

International

Journal of Computer Integrated Manufacturing

43:, Congress and the U.S. Department of Defense established

585:

143:

332:

upload their 3D files for DFM analysis and

Manufacture.

60:

efficiency in production before production even begins.

44:

322:

775:

134:

with the skills and training necessary to fill them.

90:

Continuous - Dynamic model where time passes linearly

732:

80:These models can be classified into the following:

446:Critical Technologies for the Future of Computing

270:laser cutters have become popular with hobbyists.

797:

103:Applications of simulation can be assigned to:

84:Static - System of equations at a point in time

550:

220:Examples of subtractive tooling and processes

50:

620:: CS1 maint: multiple names: authors list (

592:. New York: Marcel Dekker. pp. 27, 34.

624:) CS1 maint: numeric names: authors list (

150:Examples of additive tooling and processes

405:

223:

153:

137:

130:could be displaced due to robotization.

71:

328:Autodesk Fusion 360 is an example CBD.

798:

728:

726:

638:

566:

564:

562:

524:"The future of work in manufacturing"

443:

107:Product design (e.g. virtual reality)

439:

437:

401:

399:

397:

382:

380:

378:

376:

323:Cloud-based design and manufacturing

702:

673:

570:

13:

723:

586:Cooper, Kenneth G., 1973- (2001).

559:

553:Journal of Engineering Manufacture

388:"PLM−Product Lifecycle Management"

14:

817:

573:Principles of CAD/CAM/CAE Systems

434:

394:

373:

22:computer-integrated manufacturing

768:

705:Tsinghua Science and Technology

696:

682:

667:

632:

579:

575:. Reading, MA: Addison-Wesley.

544:

530:

516:

505:

480:

359:

199:Laminated-Object Manufacturing

1:

717:10.1016/S1007-0214(09)70059-8

352:

63:

420:10.1080/0951192X.2013.800234

298:

113:Enterprise resource planning

55:Manufacturing engineers use

34:design for manufacturability

7:

335:

274:

181:Laser sintering and fusion

117:

10:

822:

209:Fused filament fabrication

51:Three dimensional modeling

754:10.1016/j.cad.2014.07.006

653:10.1007/s00170-012-4558-5

293:

306:Additive Manufacturing

229:

160:

77:

26:flexible manufacturing

806:Digital manufacturing

742:Computer-Aided Design

315:Rapid Manufacturing -

227:

157:

138:Tooling and processes

75:

17:Digital manufacturing

571:Lee, Kunwoo (1999).

458:2000SPIE.4109..150B

189:Solid ground curing

173:Ink-Jet Processing

647:(5–8): 1191–1203.

342:Injection moulding

230:

161:

78:

30:lean manufacturing

466:10.1117/12.409215

347:Rapid prototyping

234:Water Jet Cutting

165:Stereolithography

41:Manufacturing USA

813:

790:

789:

787:

786:

772:

766:

765:

739:

730:

721:

720:

700:

694:

693:

686:

680:

679:

671:

665:

664:

636:

630:

629:

619:

611:

583:

577:

576:

568:

557:

556:

548:

542:

541:

534:

528:

527:

520:

514:

509:

503:

502:

500:

499:

490:. Archived from

484:

478:

477:

441:

432:

431:

403:

392:

391:

384:

371:

370:

363:

821:

820:

816:

815:

814:

812:

811:

810:

796:

795:

794:

793:

784:

782:

774:

773:

769:

737:

731:

724:

701:

697:

688:

687:

683:

672:

668:

637:

633:

613:

612:

600:

584:

580:

569:

560:

549:

545:

536:

535:

531:

522:

521:

517:

510:

506:

497:

495:

486:

485:

481:

442:

435:

404:

395:

386:

385:

374:

369:. Jan 10, 2017.

365:

364:

360:

355:

338:

325:

301:

296:

277:

269:

222:

152:

140:

120:

66:

53:

12:

11:

5:

819:

809:

808:

792:

791:

767:

722:

695:

681:

666:

631:

598:

578:

558:

543:

529:

515:

504:

479:

433:

393:

372:

357:

356:

354:

351:

350:

349:

344:

337:

334:

324:

321:

320:

319:

312:

300:

297:

295:

292:

291:

290:

286:

282:

276:

273:

272:

271:

267:

258:

249:

240:

221:

218:

217:

216:

206:

196:

186:

179:

171:

151:

148:

139:

136:

119:

116:

115:

114:

111:

108:

101:

100:

97:

94:

91:

88:

85:

65:

62:

52:

49:

9:

6:

4:

3:

2:

818:

807:

804:

803:

801:

781:

777:

771:

763:

759:

755:

751:

747:

743:

736:

729:

727:

718:

714:

710:

706:

699:

692:. 2001-11-30.

691:

685:

677:

670:

662:

658:

654:

650:

646:

642:

635:

627:

623:

617:

609:

605:

601:

599:0-8247-0261-1

595:

591:

590:

582:

574:

567:

565:

563:

554:

547:

539:

533:

525:

519:

513:

508:

494:on 2016-02-02

493:

489:

483:

475:

471:

467:

463:

459:

455:

451:

447:

440:

438:

429:

425:

421:

417:

413:

409:

402:

400:

398:

389:

383:

381:

379:

377:

368:

362:

358:

348:

345:

343:

340:

339:

333:

329:

316:

313:

309:

307:

303:

302:

287:

283:

279:

278:

265:

262:

261:Laser cutting

259:

256:

253:

250:

247:

244:

241:

238:

235:

232:

231:

226:

213:

210:

207:

203:

200:

197:

193:

190:

187:

184:

180:

176:

172:

169:

166:

163:

162:

156:

147:

145:

135:

131:

127:

124:

112:

109:

106:

105:

104:

98:

95:

92:

89:

86:

83:

82:

81:

74:

70:

61:

58:

48:

46:

42:

37:

35:

31:

27:

23:

18:

783:. Retrieved

779:

770:

745:

741:

708:

704:

698:

684:

675:

669:

644:

640:

634:

588:

581:

572:

552:

546:

532:

518:

507:

496:. Retrieved

492:the original

482:

449:

445:

411:

407:

361:

330:

326:

314:

304:

281:implemented.

263:

254:

245:

236:

211:

201:

191:

182:

174:

167:

141:

132:

128:

125:

121:

102:

79:

67:

54:

38:

16:

15:

57:3D modeling

39:As part of

785:2020-03-08

498:2016-02-14

353:References

64:Simulation

661:109261207

616:cite book

474:173185990

428:205630086

299:On demand

215:complete.

800:Category

748:: 1–14.

711:: 1–12.

608:45873626

414:: 3–24.

336:See also

289:process.

275:Benefits

159:shapes).

118:Analysis

762:9315605

454:Bibcode

452:: 150.

243:Milling

24:(CIM),

780:Geomiq

760:

659:

606:

596:

472:

426:

285:plant.

32:, and

758:S2CID

738:(PDF)

657:S2CID

470:S2CID

424:S2CID

294:Types

252:Lathe

626:link

622:link

604:OCLC

594:ISBN

750:doi

713:doi

649:doi

462:doi

450:150

416:doi

144:CNC

45:MxD

802::

778:.

756:.

746:59

744:.

740:.

725:^

709:14

707:.

655:.

645:67

643:.

618:}}

614:{{

602:.

561:^

468:.

460:.

448:.

436:^

422:.

412:28

410:.

396:^

375:^

28:,

788:.

764:.

752::

719:.

715::

678:.

663:.

651::

628:)

610:.

555:.

540:.

526:.

501:.

476:.

464::

456::

430:.

418::

390:.

308:-

268:2

264:-

255:-

246:-

237:-

212:-

202:-

192:-

183:-

175:-

168:-

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.