25:

17:

71:. The stroke of the die must be as long as the curl. Curling is often performed as part of a high production, multiple operation progressive forming.

126:

39:

process used to form the edges into a hollow ring. Curling can be performed to eliminate sharp edges and increase the

182:

79:

The curling die is designed to curl a material of specific thickness. Dies are generally made of hardened

83:

because of the amount of wear caused by the operation. Their smooth, rounded cavities are often

116:

68:

8:

64:

36:

43:

near the curled end. Other parts are curled to perform their primary function, such as

122:

40:

67:. This will help prolong the life of the die by avoiding unnecessary damage due to

96:

176:

56:

60:

24:

162:

80:

44:

167:

16:

84:

87:and polished to help curl the material uniformly.

174:

150:Punches and Dies: Layout, Construction and Use

118:Sheet metal forming processes and die design

114:

63:, should always be turned away from the

23:

15:

175:

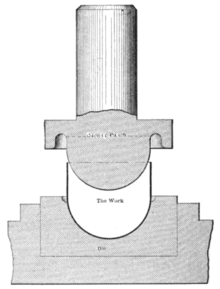

28:The four steps to create a full curl

13:

137:

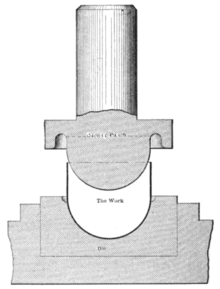

20:A schematic of the curling process

14:

194:

156:

121:, Industrial Press, p. 55,

108:

55:In the curling operation, the

1:

102:

50:

7:

115:Boljanovic, Vukota (2004),

90:

10:

199:

74:

152:. Frank Arthur Stanley

144:Handbook of Die Design

29:

21:

27:

19:

183:Fabrication (metal)

37:sheet metal forming

30:

22:

168:Metal Fabrication

128:978-0-8311-3182-1

41:moment of inertia

190:

132:

131:

112:

198:

197:

193:

192:

191:

189:

188:

187:

173:

172:

159:

140:

138:Further reading

135:

129:

113:

109:

105:

93:

77:

53:

12:

11:

5:

196:

186:

185:

171:

170:

165:

158:

157:External links

155:

154:

153:

147:

146:. Ivana Suchy.

139:

136:

134:

133:

127:

106:

104:

101:

100:

99:

97:Tailored blank

92:

89:

76:

73:

52:

49:

9:

6:

4:

3:

2:

195:

184:

181:

180:

178:

169:

166:

164:

161:

160:

151:

148:

145:

142:

141:

130:

124:

120:

119:

111:

107:

98:

95:

94:

88:

86:

82:

72:

70:

66:

62:

58:

48:

46:

42:

38:

34:

26:

18:

163:Wire Forming

149:

143:

117:

110:

78:

54:

32:

31:

45:door hinges

103:References

81:tool steel

69:scratching

51:Operation

177:Category

91:See also

75:Tooling

33:Curling

125:

85:lapped

59:, or

57:flare

35:is a

123:ISBN

61:burr

65:die

179::

47:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.