1370:

101:

322:(Alkydal M 48). These have a better controlled molecular weight distribution and better durability. Alkyds for decorative use have extra oil cooked in to lengthen them and to make them more durable. Short oil resins used in stoving enamels are made from non-drying saturated oils or fatty acids. These usually have much higher hydroxyl and acid values to be able to react with the

386:(resinous oil by-product from pulp and paper manufacturing). Non-drying/plasticizer resins are made from castor, palm, coconut oils and Cardura (the proprietary name of a synthetic ester of versatic acid). Dehydrated castor oil was at one time the only oil permitted in resin manufacture in India; no edible oils were allowed.

227:

structure. To remove the water produced as a by-product and to increase the reaction rate, surplus phthalic anhydride is added. Water is thus removed with the unreacted acid by heating the bulk to a specific temperature. The reaction is not as controllable as would be desired, so a new process was introduced in which

397:

As with many resin systems and coatings, alkyds may be hybridized with other resin technologies. One example is acrylated alkyds. Although urethane alkyds are in effect a hybrid, novel technologies include manufacturing a moisture-curable polyurethane alkyd. Grafting of silicon based materials onto

416:

There has been a general trend worldwide to formulate resins and coatings that are waterborne rather than formulated with solvent as waterbased materials are perceived to be environmentally friendly. Waterborne alkyds have thus been made available too. One method is to acrylic-modify the alkyd to

217:

based alkyds are made this way. More economical alkyd resins are produced from the alcoholysis or glyceride process, in which end-product quality control is not as paramount. In this process, raw vegetable oil, high in unsaturated component, is combined with additional polyol and heated to cause

226:

into a mixture of mono- and diglyceride oils. Soybean oil is often used. Acid anhydride is added to the resulting mixture to build the molecular weight of the resin into roughly the same product as with the fatty acid process. However, the alcoholysis process produces a more randomly oriented

235:

with the water. This gives greater control at a lower temperature and also produces resins at a lower viscosity, useful in making high-solids paints. This is known as the AZO process. In both cases, the resulting product is a polyester resin to which

329:

Because the major components of an alkyd coating, i.e. fatty acids and triglyceride oils, are derived from low cost renewable resources, the cost of alkyd coatings has remained very low despite the ever-increasing cost of

177:

in air. The drying speed and the nature of the coatings depends on the amount and type of drying oil employed (more polyunsaturated oil means faster reaction in air) and presence of catalysts, the so-called

773:

307:

alkyds for decorative use such as non-drip paints. The latest alkyds are short oil resins in which the oil length is shortened by use of a polymeric chain stopper usually a monobasic acid such as

209:

process. Higher-quality, higher-performance alkyds are produced in the fatty acid process, in which the composition of the resulting resin may be more precisely controlled. In this process, an

81:. They are the dominant resin or binder in most commercial oil-based coatings. Approximately 200,000 tons of alkyd resins are produced each year. The original alkyds were compounds of

271:

and a metallic drier, which speeds up the reaction. Unlike other no-bake mould technologies, the process yields no toxic fumes, but the moulds need more air-curing time.

1265:

1183:"Synthesis of PET-based urethane-modified alkyd resins from depolymerization intermediates of post-consumer PET bottles: coating properties and thermal behaviors"

126:

Alkyd resins may be classified as drying (including semi drying) and nondrying. Both types are typically produced from dicarboxylic acids or anhydrides, such as

194:

salts are particularly effective and widely used. However, because of the carcinogenicity of cobalt, its use in alkyds is being researched to phase it out.

1290:"Synthesis of four-component acrylic-modified water-reducible alkyd resin: investigation of dilution ratio effect on film properties and thermal behaviors"

279:

Alkyd resins are usually classed as long oil, medium oil and short oil. These terms represent the oil length in the resin. Alkyds are also modified with

862:"Synthesis and performance of new modified reactive flame-retardant alkyd resin based on tetrabromophthalic anhydride as varnish for surface coatings"

417:

make it water-reducible. Synthesis techniques of acrylic-modified water-reducible alkyds to improve corrosion performance have likewise been studied.

382:(in which dehydration transforms certain of its fatty acids’ single bonds into double bonds, some of them conjugated, creating a semi-drying oil) and

516:

795:

295:

to produce a polyurethane modified alkyd. Urethane alkyds are manufactured by reacting the OH groups residual on the alkyd with NCO groups from an

213:, a polyol and an unsaturated fatty acid are combined and cooked together until the product has achieved a predetermined level of viscosity.

1160:

1110:

1060:

891:

866:

398:

alkyds has also been researched. As part of an effort to use more recycled materials, alkyds have been produced that are made from scrap

1220:

Spasojević, P. M.; Panić, V. V.; Džunuzović, J. V.; Marinković, A. D.; Woortman, A. J. J.; Loos, K.; Popović, I. G. (2015-07-16).

685:

493:

451:

1329:"Synthesis of acrylic-modified water-reducible alkyd resin: improvement of corrosion resistance in painting formulations"

590:

240:

drying oil groups are attached. At the conclusion of each process the resin is purified, diluted in solvent and sold to

533:

810:

640:

835:

697:

612:

1400:

312:

787:

399:

993:

954:

913:

326:

of the amino resins. These mixtures are usually stabilized with amines to prevent gelling on storage.

43:

1221:

721:

550:

591:"Expanded Applications and Enhanced Durability of Alkyd Coatings Using High-Performance Catalysts"

69:. The inclusion of a fatty acid confers a tendency to form flexible coatings. Alkyds are used in

1374:

162:

54:

is a modification of the original name "alcid", reflecting the fact that they are derived from

187:

97:

that were much paler in colour. From these, the alkyds that are known today were developed.

300:

8:

1390:

860:

Abd El-Wahab, H.; Abd El-Fattah, M.; Abd El-Khalik, N.; Kazlauciunas, Algy (2015-01-01).

219:

55:

433:

443:

139:

127:

109:

653:

1405:

1395:

1348:

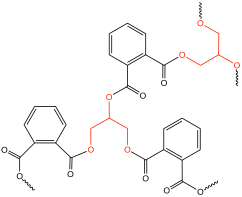

1309:

1261:

1243:

1202:

1152:

1102:

1081:

Naik, R. B.; Malvankar, N. G.; Mahato, T. K.; Ratna, D.; Hastak, R. S. (2014-07-01).

1052:

1013:

974:

935:

883:

681:

636:

529:

489:

447:

411:

39:

1340:

1301:

1233:

1194:

1144:

1094:

1044:

1009:

1005:

970:

966:

930:

925:

875:

521:

481:

439:

179:

131:

89:

sold under the name

Glyptal. These were sold as substitutes for the darker-colored

994:"Morphologies and droplet sizes of alkyd–acrylic hybrids with high solids content"

859:

769:

745:

1083:"Novel moisture-cured hyperbranched urethane alkyd resin for coating application"

912:

Chardon, Fabien; Denis, Maxinne; Negrell, Claire; Caillol, Sylvain (2021-02-01).

323:

214:

151:

147:

485:

1344:

1198:

288:

280:

210:

1327:

Aynali, Figen; Sakar, Gürcan; Kocyigit, Elif Suna; Kades, Alper (2023-11-01).

1305:

1148:

1098:

1048:

879:

473:

334:, which is the predominant raw-material source of most other coatings such as

1384:

1352:

1328:

1313:

1288:

Büyükyonga, Özge Naz; Akgün, Nagihan; Acar, Işıl; Güçlü, Gamze (2017-01-01).

1247:

1206:

1182:

1156:

1106:

1056:

1017:

978:

939:

887:

525:

359:

355:

339:

335:

237:

223:

206:

183:

166:

86:

1289:

1132:

1082:

1032:

861:

16:

Polyester resin modified by the addition of fatty acids and other components

347:

308:

62:

47:

1222:"High performance alkyd resins synthesized from postconsumer PET bottles"

367:

202:

170:

1238:

635:"Additives for Coatings" J. H. Bielman, Ed. Wiley-VCH, 2000, Weinheim.

379:

363:

304:

296:

292:

268:

198:

121:

31:

438:, Organic Chemistry, vol. 29, Elsevier, 1977, pp. 140–170,

331:

232:

143:

24:

914:"Hybrid alkyds, the glowing route to reach cutting-edge properties?"

1219:

383:

375:

371:

351:

105:

82:

1131:

Chakraborty, Ruby; Thatte, Mrunal; Soucek, Mark D. (2009-12-01).

284:

265:

257:

245:

94:

78:

74:

998:

Colloids and

Surfaces A: Physicochemical and Engineering Aspects

771:, "Polyurethane-modified alkyd resin", issued 1977-10-05

303:. By adding certain modifying resins, it is possible to produce

1369:

228:

191:

174:

135:

35:

343:

241:

155:

90:

70:

27:

261:

154:

and used in items such as paints. They are not the same as

911:

161:

For the drying resins, triglycerides are derived from poly

100:

992:

Jowkar-Deriss, Mehrnoush; Karlsson, Ola J. (2004-09-24).

1326:

1287:

1080:

478:

Surface

Coatings: Volume 1 Raw Materials and Their Usage

389:

They may be used to formulate flame-retardant coatings.

350:. Typical sources of drying oils for alkyd coatings are

1130:

291:, acrylic monomers (to make them dry more quickly) and

955:"Alkyd resins: From down and out to alive and kicking"

991:

601:(3): 45–55 – via American Coatings Association.

480:, Dordrecht: Springer Netherlands, pp. 76–109,

1180:

104:Structure of an idealized alkyd resin derived from

1031:Dziczkowski, Jamie; Soucek, Mark D. (2010-09-01).

680:(New York: McGraw-Hill Professional, 1999) p. 36.

1181:Civan Çavuşoğlu, Ferda; Acar, Işıl (2023-03-01).

1030:

1382:

197:Alkyd resins are produced in two processes: the

698:"SERKYD S63W70 | Long Oil Alkyd Resin | Serkim"

264:-based moulds. The alkyd resin is mixed with a

517:Ullmann's Encyclopedia of Industrial Chemistry

34:and other components. Alkyds are derived from

1133:"A new approach to graft siloxanes to alkyds"

811:"Novel Path to Hydroxyl-Functional Emulsions"

158:derived from natural sources such as plants.

575:The Chemistry and Processing of Alkyd Resins

1333:Journal of Coatings Technology and Research

1294:Journal of Coatings Technology and Research

1187:Journal of Coatings Technology and Research

1137:Journal of Coatings Technology and Research

1087:Journal of Coatings Technology and Research

1037:Journal of Coatings Technology and Research

867:Journal of Coatings Technology and Research

654:"Cobalt Drier for Paints | Cobalt Cem-All®"

513:

256:Alkyd or oil-urethane binders are used in

1237:

929:

588:

173:). These drying alkyds are cured by the

99:

952:

808:

471:

190:crosslinking of the unsaturated sites.

1383:

1262:"Synthesis of Waterborne alkyd resins"

507:

540:. Published online: 15 January 2003.

405:

13:

788:"Basics of Alkyd Resin Technology"

577:. Monsanto Chemical Company. 1952.

444:10.1016/b978-0-12-618502-7.50010-6

14:

1417:

1362:

1033:"A new class of acrylated alkyds"

1368:

1268:from the original on 2021-05-14.

798:from the original on 2021-05-14.

514:Frank N. Jones. "Alkyd Resins".

274:

251:

1320:

1281:

1272:

1254:

1213:

1174:

1163:from the original on 2023-03-14

1124:

1113:from the original on 2023-03-14

1074:

1063:from the original on 2023-03-14

1024:

985:

961:. Alkyds for the 21st Century.

946:

905:

894:from the original on 2023-03-14

853:

828:

802:

780:

762:

738:

714:

690:

670:

613:"Reichhold | Coatings Products"

589:Halstead, Joshua (April 2023).

1010:10.1016/j.colsurfa.2004.07.003

971:10.1016/j.porgcoat.2011.01.014

931:10.1016/j.porgcoat.2020.106025

836:"Cardura™ E10P Glycidyl Ester"

646:

629:

605:

582:

567:

543:

465:

426:

165:(often derived from plant and

115:

1:

815:Paint & Coatings Industry

420:

959:Progress in Organic Coatings

918:Progress in Organic Coatings

722:"Properties of Alkyd Resins"

551:"Properties of Alkyd Resins"

93:resins, thus creating alkyd

38:and organic acids including

30:modified by the addition of

7:

486:10.1007/978-94-011-1220-8_5

10:

1424:

1345:10.1007/s11998-023-00795-2

1199:10.1007/s11998-022-00705-y

953:Hofland, Ad (2012-04-01).

409:

392:

119:

1306:10.1007/s11998-016-9835-z

1278:US Patent 5,137,965 1992

1149:10.1007/s11998-008-9155-z

1099:10.1007/s11998-013-9561-8

1049:10.1007/s11998-009-9237-6

880:10.1007/s11998-014-9615-6

746:"Alkyd resins for paints"

44:carboxylic acid anhydride

526:10.1002/14356007.a01_409

520:. Weinheim: Wiley-VCH.

472:Elliott, W. T. (1993),

231:is added to produce an

163:unsaturated fatty acids

809:Herszenhaut, Marcelo.

182:. These catalysts are

112:

103:

1377:at Wikimedia Commons

260:for the creation of

1232:(76): 62273–62283.

726:polymerdatabase.com

702:www.serkimresin.com

555:polymerdatabase.com

220:transesterification

1401:Painting materials

1264:. September 2017.

1239:10.1039/C5RA11777A

320:-butylbenzoic acid

140:trimethylolpropane

128:phthalic anhydride

113:

110:phthalic anhydride

77:and in moulds for

40:dicarboxylic acids

1373:Media related to

792:Chemical Dynamics

686:978-0-07-134246-9

617:www.reichhold.com

495:978-94-011-1220-8

453:978-0-12-618502-7

412:Waterborne resins

406:Waterborne alkyds

180:oil drying agents

48:triglyceride oils

1413:

1372:

1357:

1356:

1339:(6): 2007–2017.

1324:

1318:

1317:

1285:

1279:

1276:

1270:

1269:

1258:

1252:

1251:

1241:

1217:

1211:

1210:

1178:

1172:

1171:

1169:

1168:

1128:

1122:

1121:

1119:

1118:

1078:

1072:

1071:

1069:

1068:

1028:

1022:

1021:

989:

983:

982:

950:

944:

943:

933:

909:

903:

902:

900:

899:

857:

851:

850:

848:

846:

832:

826:

825:

823:

821:

806:

800:

799:

784:

778:

777:

776:

772:

766:

760:

759:

757:

756:

742:

736:

735:

733:

732:

718:

712:

711:

709:

708:

694:

688:

674:

668:

667:

665:

664:

650:

644:

633:

627:

626:

624:

623:

609:

603:

602:

586:

580:

578:

571:

565:

564:

562:

561:

547:

541:

539:

511:

505:

504:

503:

502:

469:

463:

462:

461:

460:

430:

201:process and the

132:maleic anhydride

1423:

1422:

1416:

1415:

1414:

1412:

1411:

1410:

1381:

1380:

1365:

1360:

1325:

1321:

1286:

1282:

1277:

1273:

1260:

1259:

1255:

1218:

1214:

1179:

1175:

1166:

1164:

1129:

1125:

1116:

1114:

1079:

1075:

1066:

1064:

1029:

1025:

990:

986:

951:

947:

910:

906:

897:

895:

858:

854:

844:

842:

834:

833:

829:

819:

817:

807:

803:

786:

785:

781:

774:

768:

767:

763:

754:

752:

744:

743:

739:

730:

728:

720:

719:

715:

706:

704:

696:

695:

691:

675:

671:

662:

660:

652:

651:

647:

634:

630:

621:

619:

611:

610:

606:

587:

583:

579:ASIN BOOOHKKBB6

573:

572:

568:

559:

557:

549:

548:

544:

536:

512:

508:

500:

498:

496:

470:

466:

458:

456:

454:

432:

431:

427:

423:

414:

408:

395:

354:, linseed oil,

324:hydroxyl groups

277:

254:

215:Pentaerythritol

184:metal complexes

152:synthetic resin

150:. Alkyds are a

148:pentaerythritol

124:

118:

17:

12:

11:

5:

1421:

1420:

1409:

1408:

1403:

1398:

1393:

1379:

1378:

1364:

1363:External links

1361:

1359:

1358:

1319:

1300:(1): 117–128.

1280:

1271:

1253:

1212:

1193:(2): 741–761.

1173:

1143:(4): 471–481.

1123:

1093:(4): 575–586.

1073:

1043:(5): 587–602.

1023:

1004:(1): 115–125.

984:

965:(4): 274–282.

945:

904:

852:

827:

801:

794:. 2016-03-29.

779:

761:

737:

713:

689:

669:

645:

628:

604:

581:

566:

542:

535:978-3527306732

534:

506:

494:

474:"Alkyd Resins"

464:

452:

424:

422:

419:

410:Main article:

407:

404:

394:

391:

281:phenolic resin

276:

273:

253:

250:

211:acid anhydride

167:vegetable oils

120:Main article:

117:

114:

15:

9:

6:

4:

3:

2:

1419:

1418:

1407:

1404:

1402:

1399:

1397:

1394:

1392:

1389:

1388:

1386:

1376:

1371:

1367:

1366:

1354:

1350:

1346:

1342:

1338:

1334:

1330:

1323:

1315:

1311:

1307:

1303:

1299:

1295:

1291:

1284:

1275:

1267:

1263:

1257:

1249:

1245:

1240:

1235:

1231:

1227:

1223:

1216:

1208:

1204:

1200:

1196:

1192:

1188:

1184:

1177:

1162:

1158:

1154:

1150:

1146:

1142:

1138:

1134:

1127:

1112:

1108:

1104:

1100:

1096:

1092:

1088:

1084:

1077:

1062:

1058:

1054:

1050:

1046:

1042:

1038:

1034:

1027:

1019:

1015:

1011:

1007:

1003:

999:

995:

988:

980:

976:

972:

968:

964:

960:

956:

949:

941:

937:

932:

927:

923:

919:

915:

908:

893:

889:

885:

881:

877:

874:(1): 97–105.

873:

869:

868:

863:

856:

841:

837:

831:

816:

812:

805:

797:

793:

789:

783:

770:

765:

751:

747:

741:

727:

723:

717:

703:

699:

693:

687:

683:

679:

676:C. W. Ammen.

673:

659:

655:

649:

642:

641:3-527-29785-5

638:

632:

618:

614:

608:

600:

596:

592:

585:

576:

570:

556:

552:

546:

537:

531:

527:

523:

519:

518:

510:

497:

491:

487:

483:

479:

475:

468:

455:

449:

445:

441:

437:

436:

429:

425:

418:

413:

403:

401:

390:

387:

385:

381:

378:, dehydrated

377:

373:

369:

365:

361:

360:safflower oil

357:

356:sunflower oil

353:

349:

348:polyurethanes

345:

341:

337:

333:

327:

325:

321:

319:

315:

310:

306:

302:

298:

294:

290:

289:vinyl toluene

286:

282:

275:Coating types

272:

270:

267:

263:

259:

252:Metal casting

249:

247:

243:

239:

234:

230:

225:

224:triglycerides

221:

216:

212:

208:

207:monoglyceride

204:

200:

195:

193:

189:

185:

181:

176:

172:

168:

164:

159:

157:

153:

149:

145:

141:

137:

133:

129:

123:

111:

107:

102:

98:

96:

92:

88:

87:phthalic acid

84:

80:

76:

72:

68:

66:

60:

58:

53:

49:

45:

41:

37:

33:

29:

26:

22:

1336:

1332:

1322:

1297:

1293:

1283:

1274:

1256:

1229:

1226:RSC Advances

1225:

1215:

1190:

1186:

1176:

1165:. Retrieved

1140:

1136:

1126:

1115:. Retrieved

1090:

1086:

1076:

1065:. Retrieved

1040:

1036:

1026:

1001:

997:

987:

962:

958:

948:

921:

917:

907:

896:. Retrieved

871:

865:

855:

843:. Retrieved

839:

830:

818:. Retrieved

814:

804:

791:

782:

764:

753:. Retrieved

749:

740:

729:. Retrieved

725:

716:

705:. Retrieved

701:

692:

678:Metalcasting

677:

672:

661:. Retrieved

657:

648:

631:

620:. Retrieved

616:

607:

598:

595:CoatingsTech

594:

584:

574:

569:

558:. Retrieved

554:

545:

515:

509:

499:, retrieved

477:

467:

457:, retrieved

435:Alkyd Resins

434:

428:

415:

396:

388:

328:

317:

313:

309:benzoic acid

278:

255:

196:

160:

125:

64:

56:

51:

20:

18:

845:26 February

840:SpecialChem

820:26 February

368:soybean oil

305:thixotropic

293:isocyanates

203:alcoholysis

171:linseed oil

116:Manufacture

50:. The term

32:fatty acids

1391:Polyesters

1385:Categories

1167:2023-03-14

1117:2023-03-08

1067:2023-03-09

924:: 106025.

898:2023-03-08

755:2021-05-14

731:2021-05-14

707:2021-05-14

663:2021-05-15

622:2021-05-14

560:2021-05-14

501:2021-05-14

459:2021-05-14

421:References

380:castor oil

364:walnut oil

297:isocyanate

269:isocyanate

199:fatty acid

138:, such as

122:Drying oil

63:organic ac

1353:1935-3804

1314:1935-3804

1248:2046-2069

1207:1935-3804

1157:1935-3804

1107:1935-3804

1057:1935-3804

1018:0927-7757

979:0300-9440

940:0300-9440

888:1935-3804

402:bottles.

332:petroleum

266:polymeric

233:azeotrope

144:glycerine

95:varnishes

75:varnishes

25:polyester

1406:Polymers

1396:Coatings

1266:Archived

1161:Archived

1111:Archived

1061:Archived

892:Archived

796:Archived

658:Borchers

384:tall oil

376:corn oil

372:fish oil

352:tung oil

340:acrylics

248:makers.

188:catalyze

106:glycerol

83:glycerol

393:Hybrids

344:epoxies

285:styrene

258:casting

246:varnish

238:pendant

222:of the

169:, e.g.

136:polyols

79:casting

36:polyols

1351:

1312:

1246:

1205:

1155:

1105:

1055:

1016:

977:

938:

886:

775:

750:Polynt

684:

639:

532:

492:

450:

336:vinyls

299:often

229:xylene

192:Cobalt

175:oxygen

134:, and

71:paints

1375:Alkyd

242:paint

186:that

156:resin

146:, or

91:copal

52:alkyd

28:resin

23:is a

21:alkyd

1349:ISSN

1310:ISSN

1244:ISSN

1203:ISSN

1153:ISSN

1103:ISSN

1053:ISSN

1014:ISSN

975:ISSN

936:ISSN

884:ISSN

847:2024

822:2024

682:ISBN

637:ISBN

530:ISBN

490:ISBN

448:ISBN

346:and

318:tert

314:para

262:sand

244:and

108:and

85:and

61:and

59:ohol

46:and

1341:doi

1302:doi

1234:doi

1195:doi

1145:doi

1095:doi

1045:doi

1006:doi

1002:245

967:doi

926:doi

922:151

876:doi

522:doi

482:doi

440:doi

400:PET

311:or

301:TDI

205:or

130:or

57:alc

42:or

19:An

1387::

1347:.

1337:20

1335:.

1331:.

1308:.

1298:14

1296:.

1292:.

1242:.

1228:.

1224:.

1201:.

1191:20

1189:.

1185:.

1159:.

1151:.

1139:.

1135:.

1109:.

1101:.

1091:11

1089:.

1085:.

1059:.

1051:.

1039:.

1035:.

1012:.

1000:.

996:.

973:.

963:73

957:.

934:.

920:.

916:.

890:.

882:.

872:12

870:.

864:.

838:.

813:.

790:.

748:.

724:.

700:.

656:.

615:.

599:20

597:.

593:.

553:.

528:.

488:,

476:,

446:,

374:,

370:,

366:,

362:,

358:,

342:,

338:,

287:,

283:,

142:,

73:,

65:id

1355:.

1343::

1316:.

1304::

1250:.

1236::

1230:5

1209:.

1197::

1170:.

1147::

1141:6

1120:.

1097::

1070:.

1047::

1041:7

1020:.

1008::

981:.

969::

942:.

928::

901:.

878::

849:.

824:.

758:.

734:.

710:.

666:.

643:.

625:.

563:.

538:.

524::

484::

442::

316:-

67:s

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.